Magnetic detecting device and material identifying device

a magnetic detection and material technology, applied in the direction of magnetic property measurement, material magnetic variables, instruments, etc., can solve the problems of inability to apply methods, objects that are not being conveyed, and inability to obtain measurements instantaneously, so as to prevent a magnetic field induced, reduce the effect of noise components, and improve repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

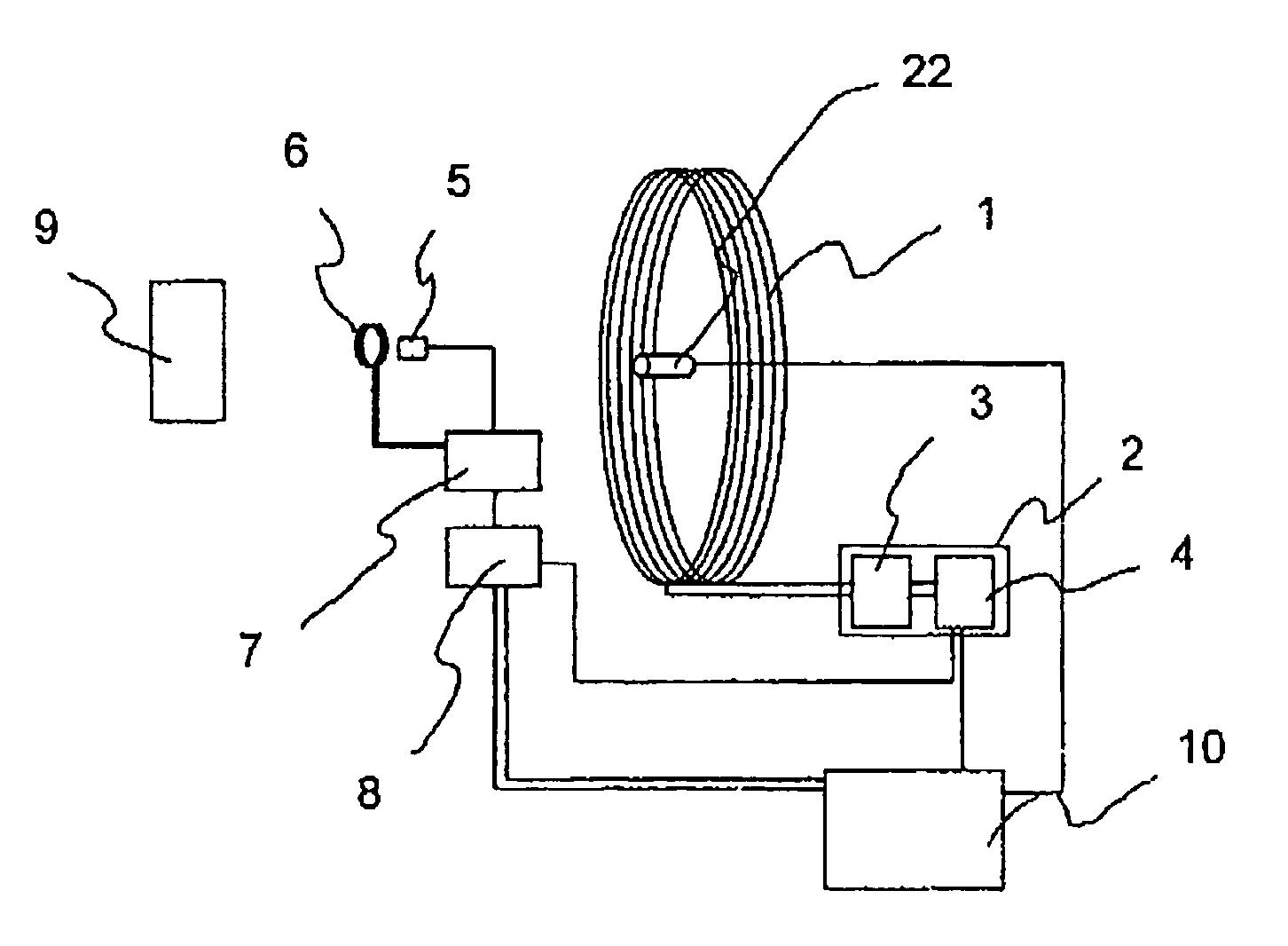

[0084]FIG. 1 is a schematic diagram showing a basic configuration of a magnetic detecting device according to the present invention. A magnetic field is applied by an apply coil 1 in order to measure a magnetic response of a test object 9. The frequency of the applied magnetic field can be changed by a power source 2 for the apply coil with the use of a signal sender 4. The generated signal drives a current source 3 to apply an alternate current to the apply coil 1. A change in the magnetic field induced by the test object 9 is detected by means of a magnetic sensor 5 comprising a magnetoresistance element. As a matter of course, any one of a magnetic impedance effect sensor, a flux gate, a superconducting quantum interference device can also be used instead. Environmental magnetic noises including the terrestrial magnetism is also input to the magnetic sensor 5, as well as the magnetic field from the test object 9. Not only that, the applied magnetic field is also applied to the ma...

embodiment 2

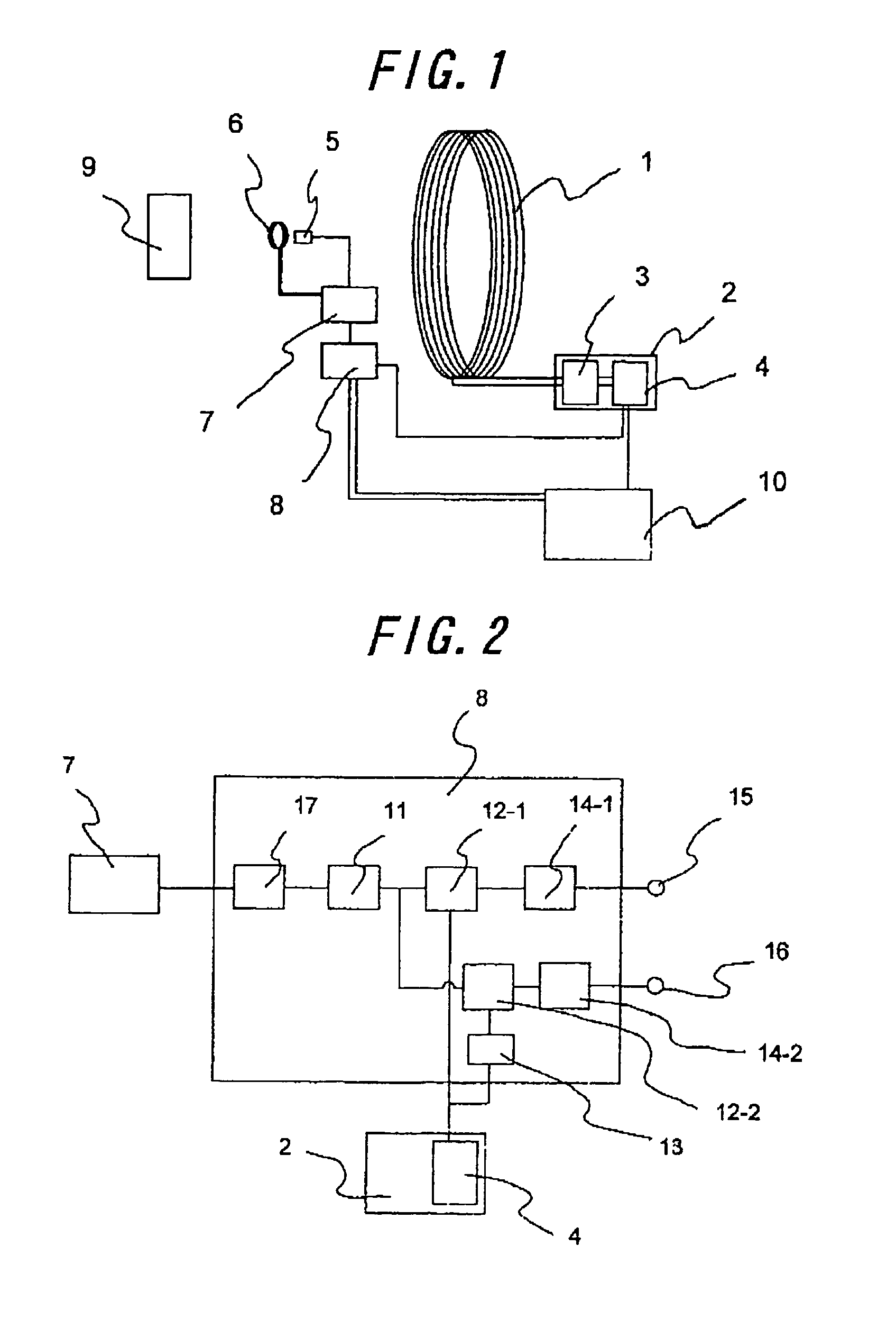

[0087]FIG. 3 is a schematic diagram showing a configuration of a coil of a magnetic detecting device according to a second embodiment of the present invention. The second embodiment relates to the magnetic detecting device according to the first embodiment, wherein the cancel coil 6 is separated into an apply coil magnetic field cancel coil 20 and a direct magnetic field cancel coil 21, and the apply coil magnetic field cancel coil 20 is connected to the power source 2 for the apply coil with the serially connected apply coil 1. Because the apply coil magnetic field cancel coil 20 and the apply coil 1 are connected in series, magnetic fields generated by the two coils have the same frequency. Consequently, adjustment is not required for the purpose of cancellation.

embodiment 3

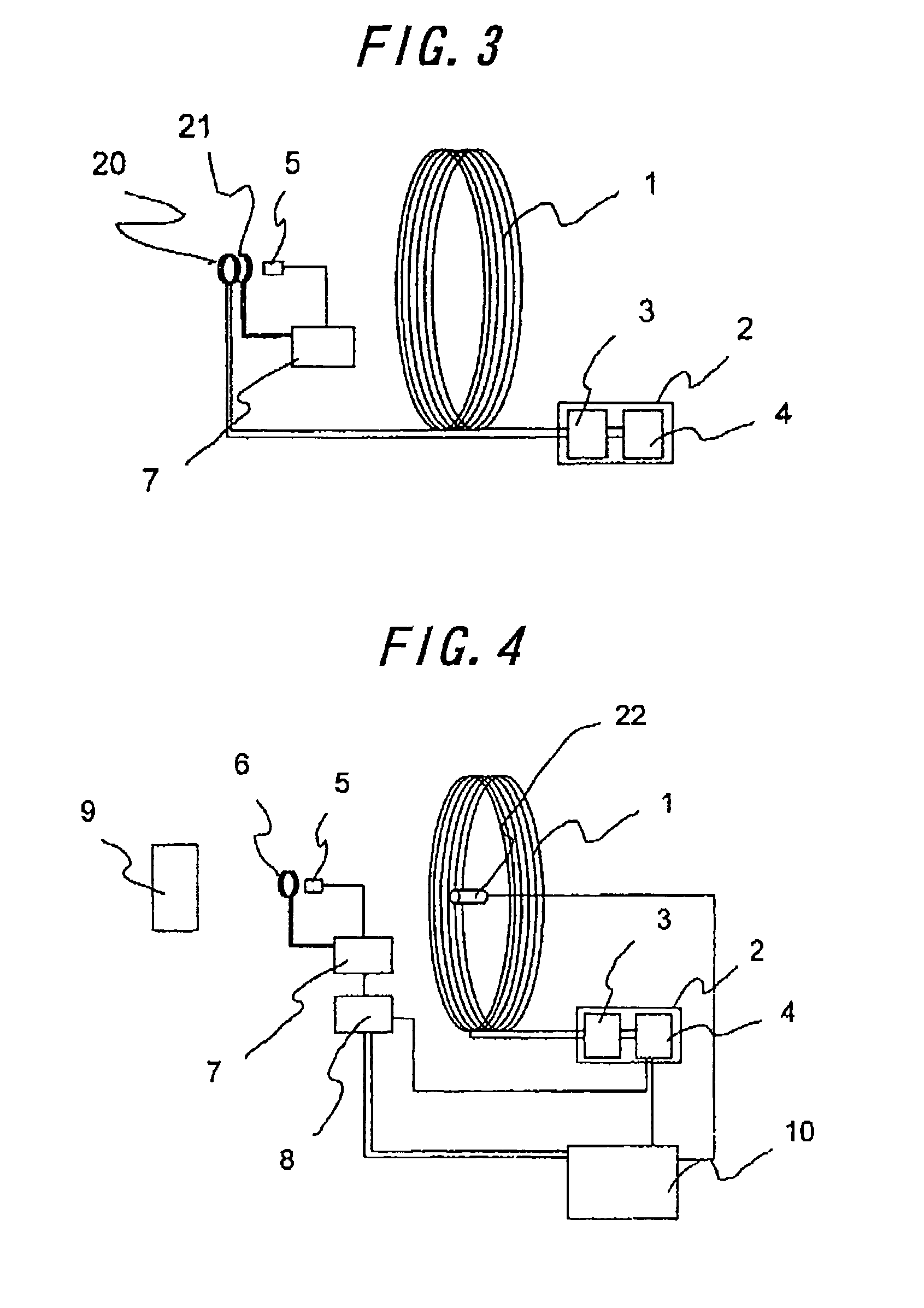

[0088]FIG. 4 is a schematic diagram showing a basic configuration of a magnetic detecting device according to a third embodiment of the present invention. In the third embodiment there is provided a distance measurement means 22 for determining positions of the test object 9 and the apply coil 1. The distance measurement means 22 may be placed anywhere, either near the apply coil 1 or the magnetic sensor 5, provided that relative distances between the distance measurement means 22 and both the apply coil 1 and the magnetic sensor 5 are known. A magnetic response from the test object 9 for the applied magnetic field varies according to the distance from the apply coil 1, and the intensity of the signal differs greatly according to the distance from the magnetic sensor 5 for detecting the magnetic response. Thus, measurement can be carried out with higher repeatability by providing the distance measurement means 22.

[0089]FIG. 5 is a diagram showing a correspondence between the applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com