Preparation technology for super-hydrophobic surface of 7075 aluminum alloy

A technology of super-hydrophobic surface and preparation process, which is applied in the field of preparation technology of 7075 aluminum alloy super-hydrophobic surface, can solve the problems of not achieving super-hydrophobic effect, etc., and achieve the effect of improving controllability and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

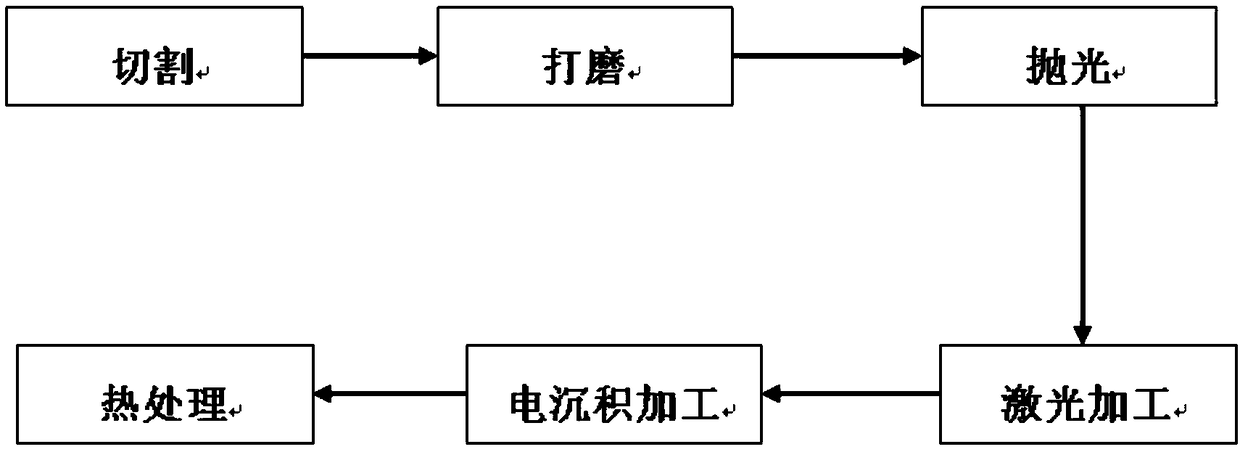

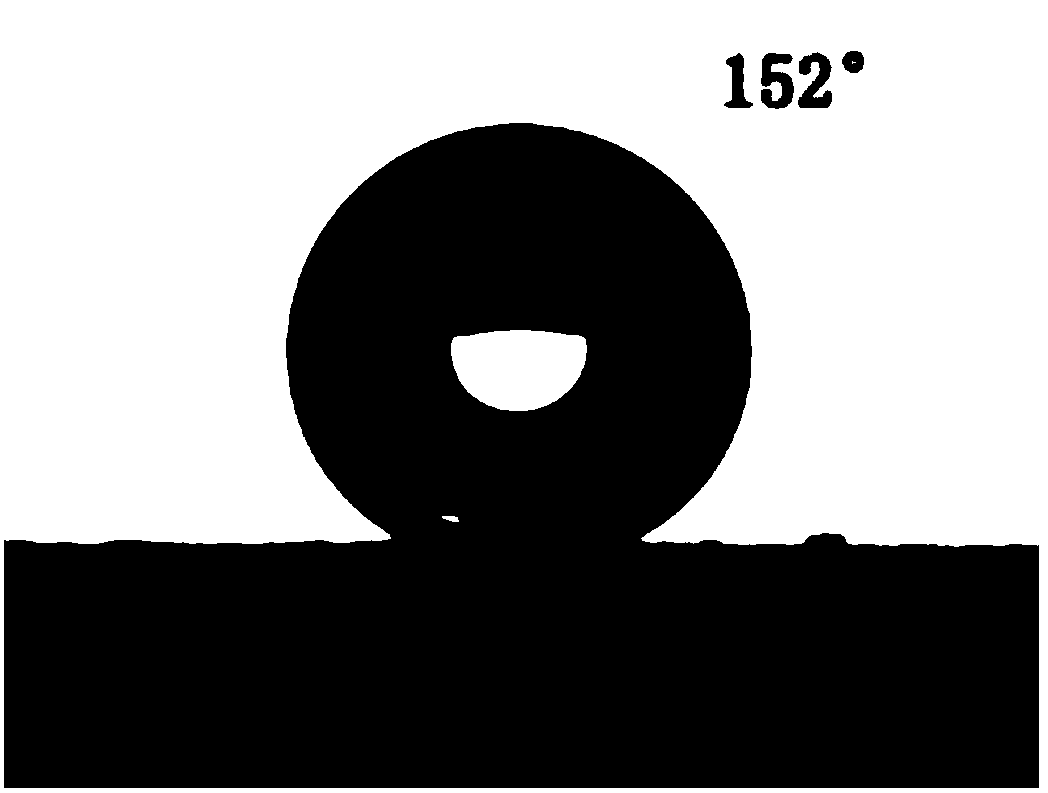

[0021] The applicant adopts the method of combining laser micromachining technology and electrodeposition technology to realize the superhydrophobic performance of the aluminum alloy surface. Utilizing the special structure on the surface of some plants with super-hydrophobic surfaces in nature, such as rose petals, the present invention adopts a combination of laser processing and electrodeposition to manufacture such structures to reduce surface wetting and achieve surface super-hydrophobicity. The difference between the present invention and the existing electric brush plating laser composite processing method is that the contact angle obtained is as shown in Table 1 through different processing procedures:

[0022] Table 1

[0023] craft

power supply

Contact angle (°)

Laser Electrodeposition Composite Processing

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com