Method for eliminating selective laser melting molding cracks of 7075 aluminum alloy

A technology of laser melting and aluminum alloy, which is applied in the field of 3D printing, can solve the problems of reduced density of parts and not particularly firm combination, and achieve the effect of suppressing thermal cracks and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

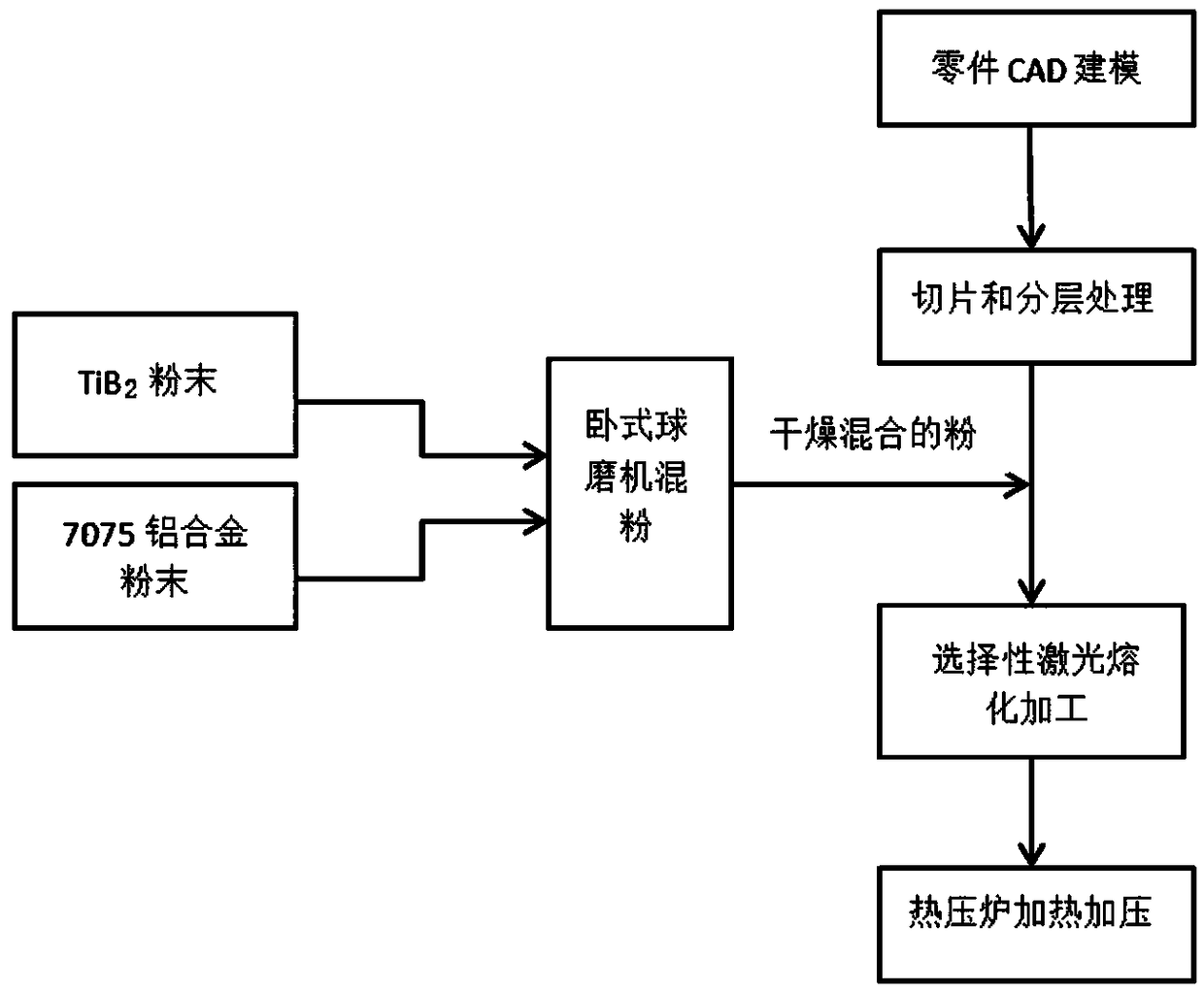

[0027] A method for eliminating cracks formed by selective laser melting of 7075 aluminum alloy, comprising the following steps:

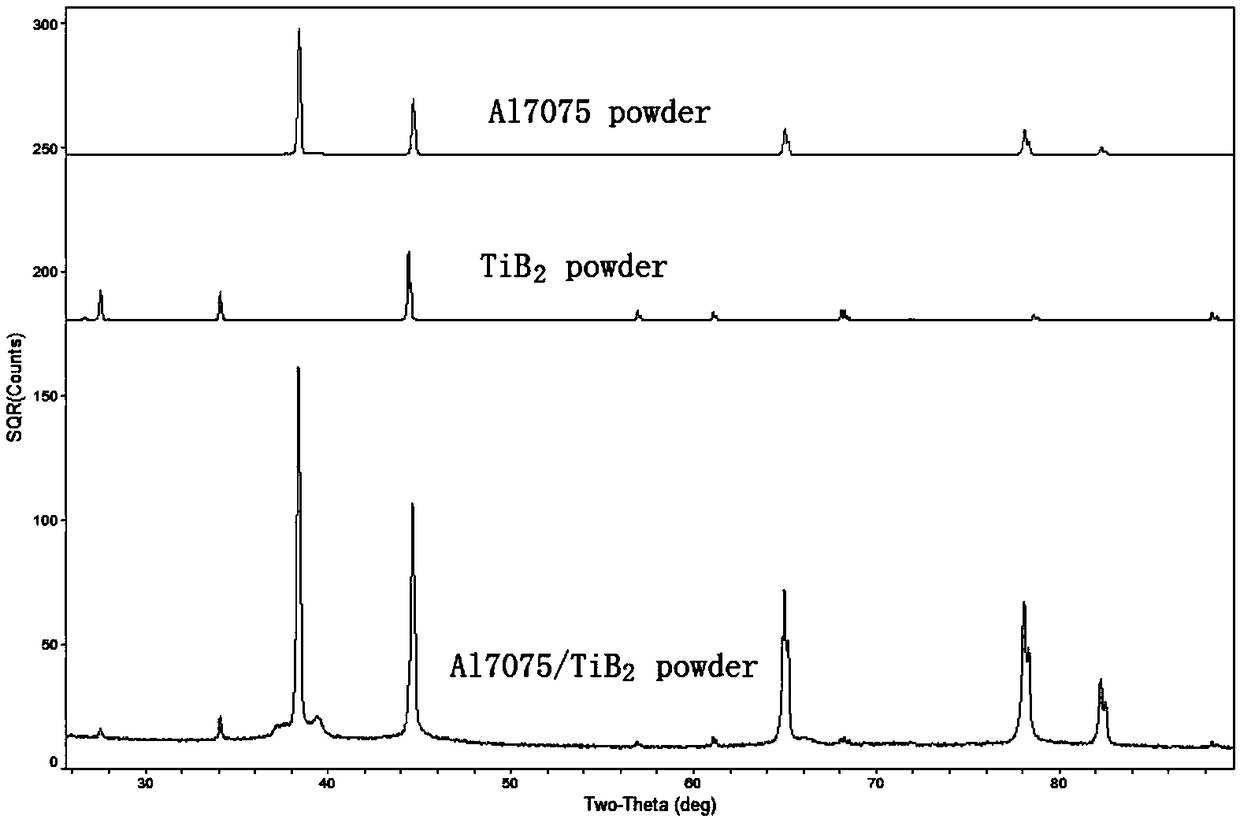

[0028] (1) In an argon-protected glove box, weigh 7075 aluminum alloy raw powder and TiB 2 Submicron powder (purity is 99%) for use, 7075 aluminum alloy powder and TiB 2 The mass ratio of submicron powder is 98.5:1.5;

[0029] (2) The weighed 7075 aluminum alloy powder and TiB 2 The submicron powder is placed in the ball mill tank in the argon protective glove box, and then the ball mill tank is locked, and high-purity argon gas is introduced after the ball mill tank is taken out;

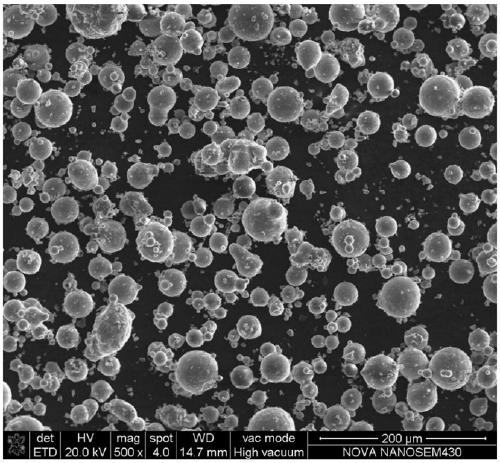

[0030] (3) Put the ball mill jar into a horizontal ball mill for powder mixing. The ball mill speed is 200r / min, and the powder mixing time is 3h. Take out the ball mill jar, put it in a vacuum glove box, take out the mixed powder, and put the powder in a dry place. Dry in the oven at 80°C for 8 hours;

[0031] (4) Control the computer in the selective laser melting...

Embodiment 2

[0034] A method for eliminating cracks formed by selective laser melting of 7075 aluminum alloy, comprising the following steps:

[0035] (1) In an argon-protected glove box, weigh 7075 aluminum alloy raw powder and TiB 2 Submicron powder (purity is 99%) for use, 7075 aluminum alloy powder and TiB 2 The mass ratio of submicron powder is 97.0:3.0;

[0036] (2) The weighed 7075 aluminum alloy powder and TiB 2 The submicron powder is placed in the ball mill tank in the argon protective glove box, and then the ball mill tank is locked, and high-purity argon gas is introduced after the ball mill tank is taken out;

[0037] (3) Put the ball mill jar into a horizontal ball mill for powder mixing, the ball mill speed is 200r / min, and the powder mixing time is 5h, take out the ball mill jar, put it in a vacuum glove box, take out the mixed powder, put the powder in a dry place Dry in the oven at 80°C for 8 hours;

[0038] (4) Control the computer in the selective laser melting mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com