Isothermal forging forming die and method for 7075 aluminum alloy tapered casing

A technology for isothermal die forging and forming dies, which is used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can solve the problems of surface coarse grain defects, forming difficulties, flow line disorder, etc., and achieve high production efficiency. Reduce cutting workload and improve the effect of mold design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

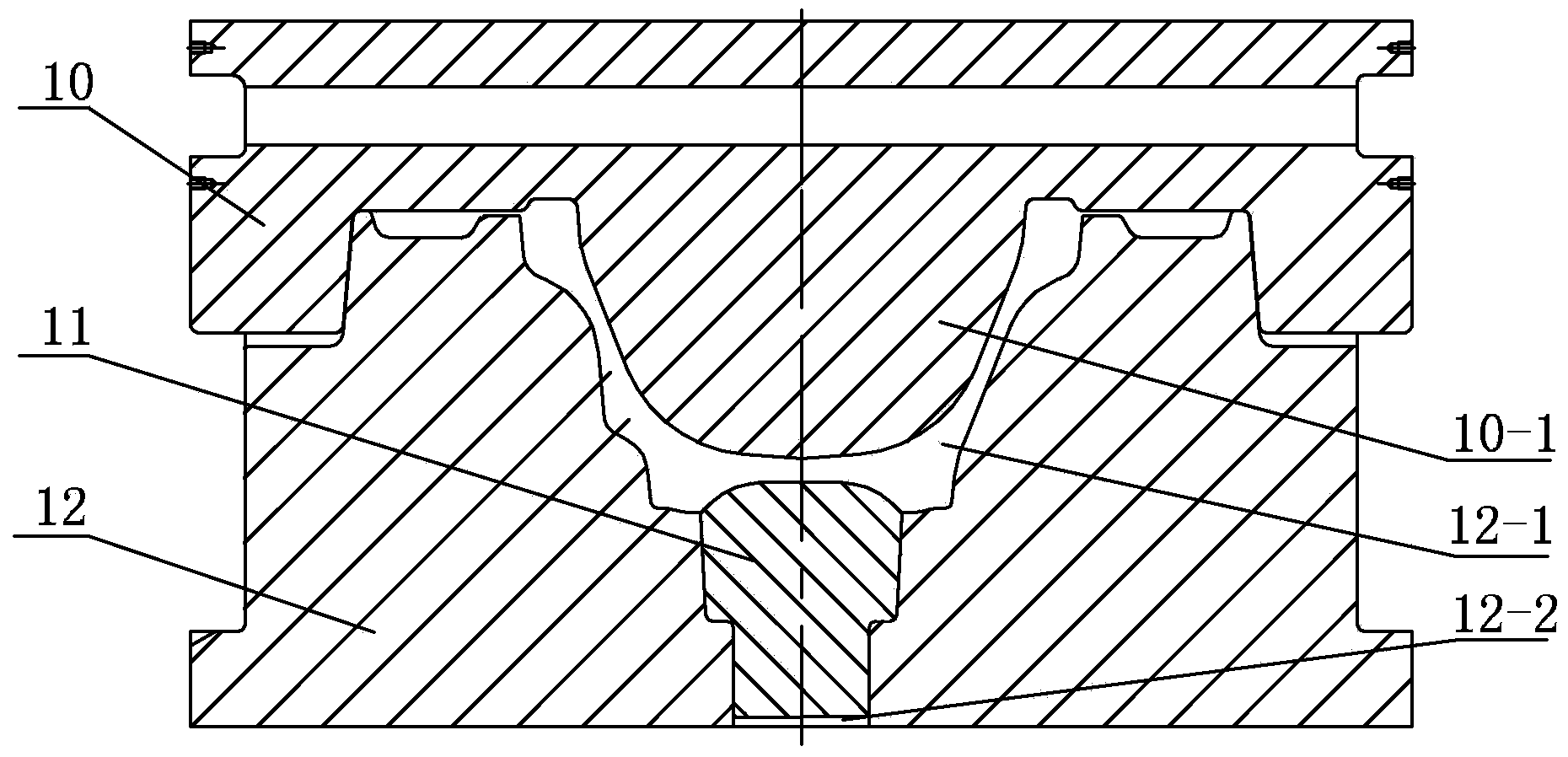

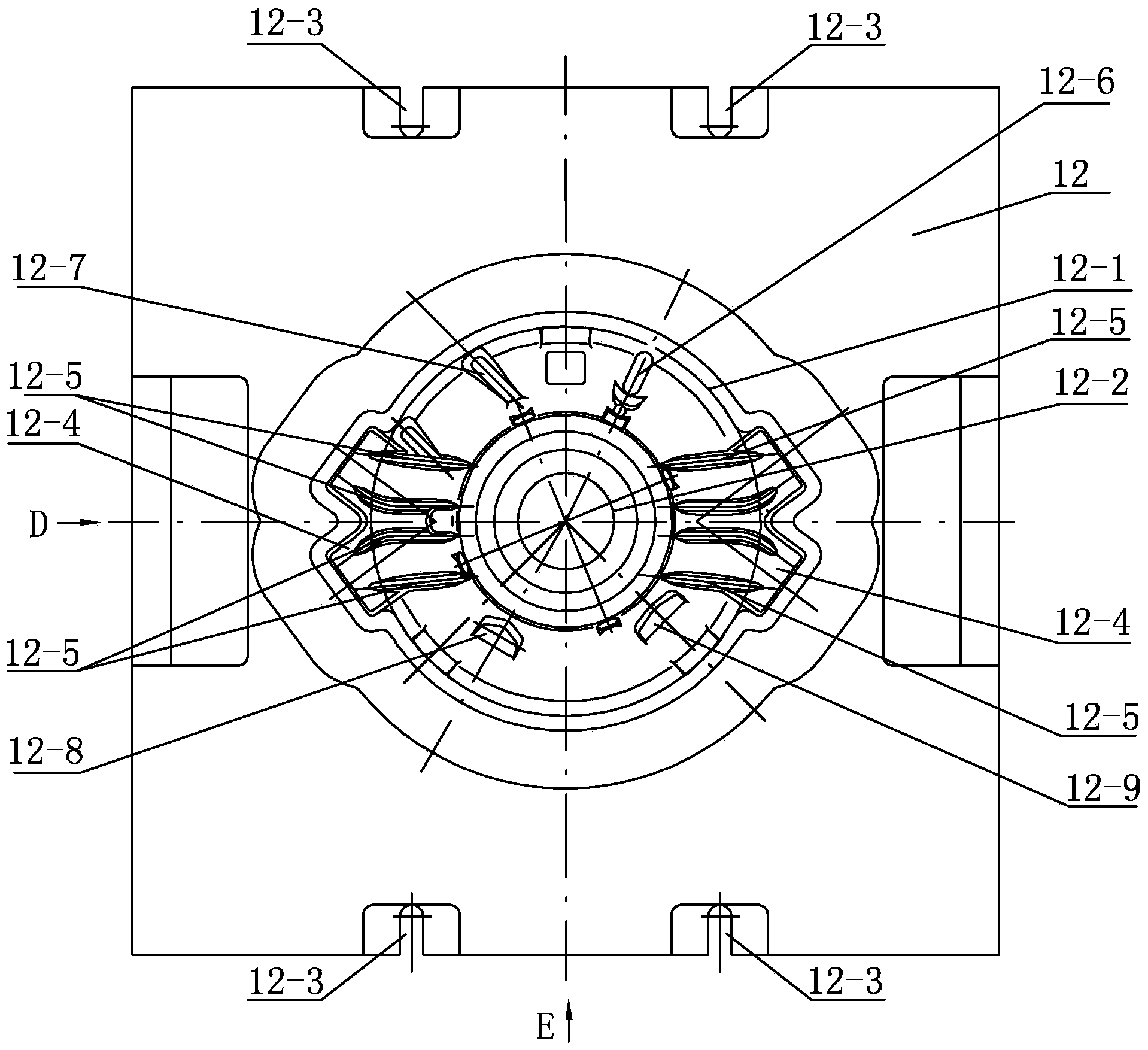

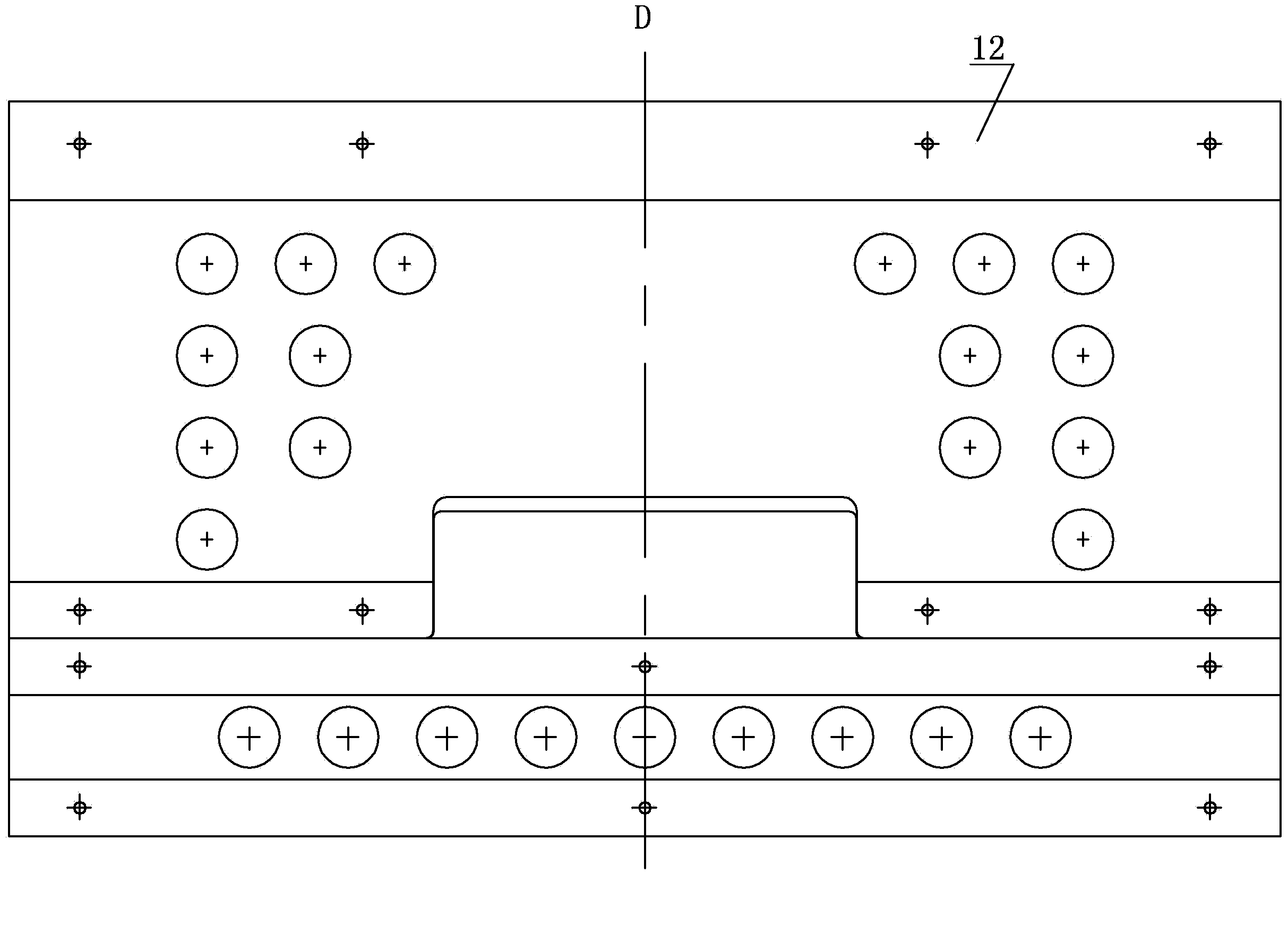

[0023] Specific implementation mode one: combine Figure 1-Figure 4 To illustrate this embodiment, a 7075 aluminum alloy conical casing isothermal die forging forming die of this embodiment includes an upper die 10, a push rod 11 and a lower die 12, and the middle part of the upper surface of the lower die 12 is sequentially processed from top to bottom Die cavity 12-1 and ejection hole 12-2 are arranged, and die cavity 12-1 and ejection hole 12-2 run through, and the shape of die cavity 12-1 is conical, and the middle part of the lower surface of upper mold 10 is processed with The punch 10-1 matched with the mold cavity 12-1 is provided with four lug grooves 12-4 on the edge of the upper surface of the lower die 12, wherein two lug grooves 12-4 are placed against each other, and the other two The lug grooves 12-4 are placed against each other, and the two lug grooves 12-4 and the other two lug grooves 12-4 are arranged oppositely, and eight lug grooves are arranged on the inne...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 2 To describe this embodiment, the side of the upper mold 10 of this embodiment is provided with an upper clamping groove, and the side of the lower mold 12 is provided with a lower clamping groove 12-3. Such setting facilitates die clamping and fixing of the upper die 10 and the lower die 12, and facilitates the final forging of the conical casing forging.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 1-Figure 17 This embodiment is described. In this embodiment, the isothermal die forging forming method of 7075 aluminum alloy conical casing is realized by using the isothermal forging forming die of embodiment one or two. The 7075 aluminum alloy conical casing is isothermal forging forming The method is realized according to the following steps: 1. Blank making: put the cylindrical 7075 aluminum alloy blank into a box-type heating furnace and heat it to 100-150°C, then take it out and spray graphite emulsion solution evenly on its surface, and then The billet sprayed with the graphite emulsion aqueous solution is put into a box-type heating furnace and heated to 420°C-440°C, and kept warm for 2.5-3.5 hours. The surface of the cavity of the anvil upsetting mold is uniformly sprayed with graphite emulsion solution, and then the flat anvil upsetting mold sprayed with graphite emulsion solution is heated to 420-430°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com