Regular bed modular high temperature gas cooled reactor and its fuel sphere disposal method

A high-temperature gas-cooled reactor and modular technology, applied in the field of nuclear reactors, can solve the problems of not being able to obtain the best power and temperature distribution, large uneven coefficient of axial and radial power, and large flow resistance of coolant, so as to improve energy efficiency. Effects of conversion efficiency, high adaptability and stability, uniform deep burnup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

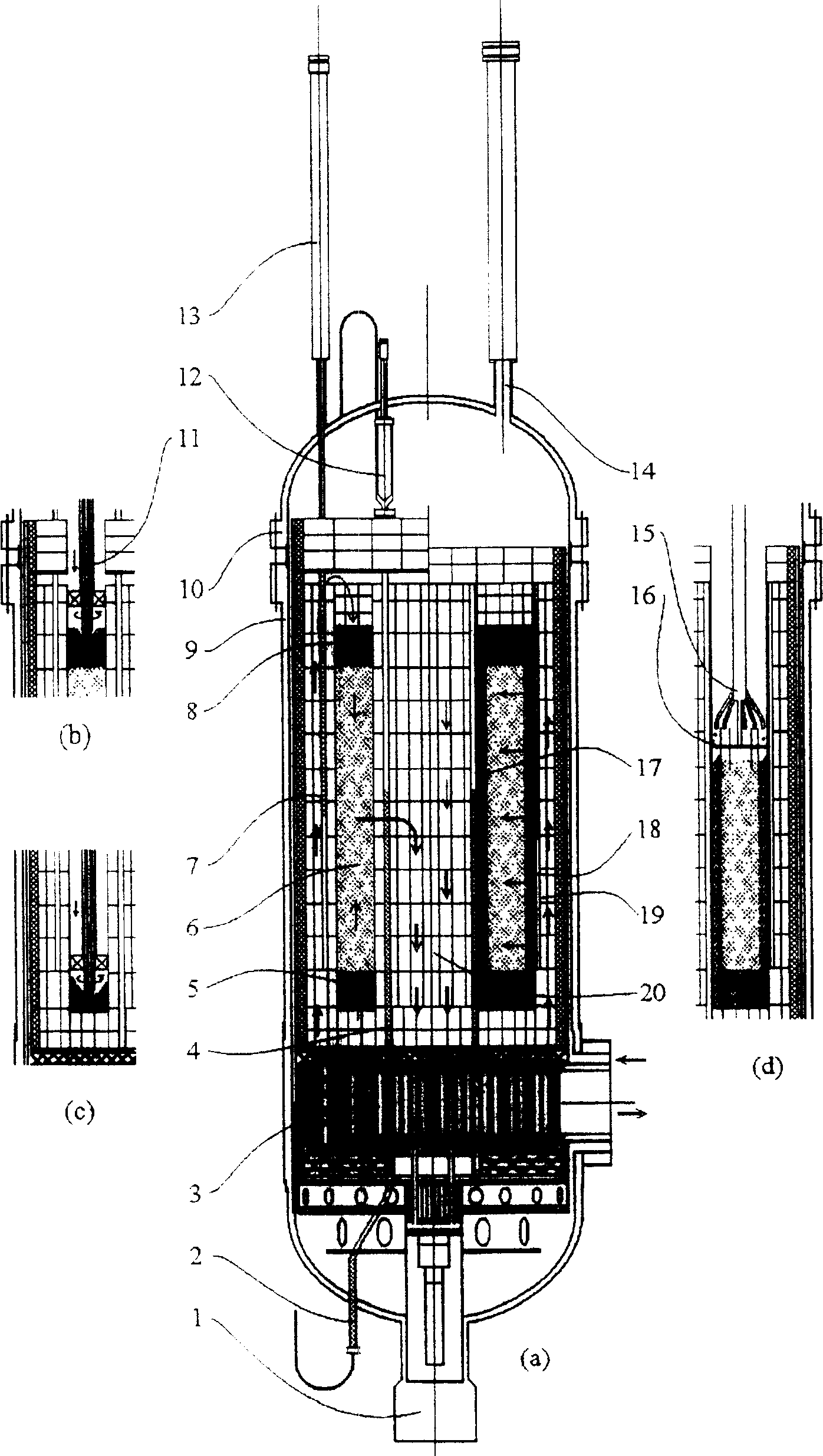

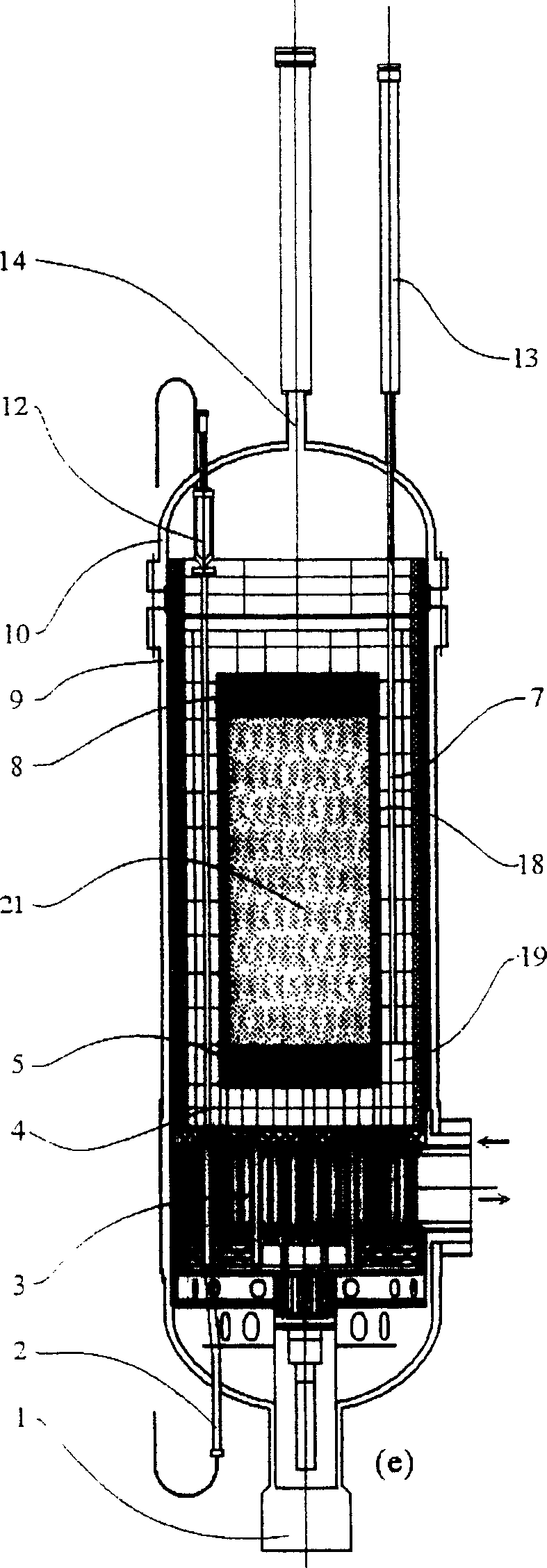

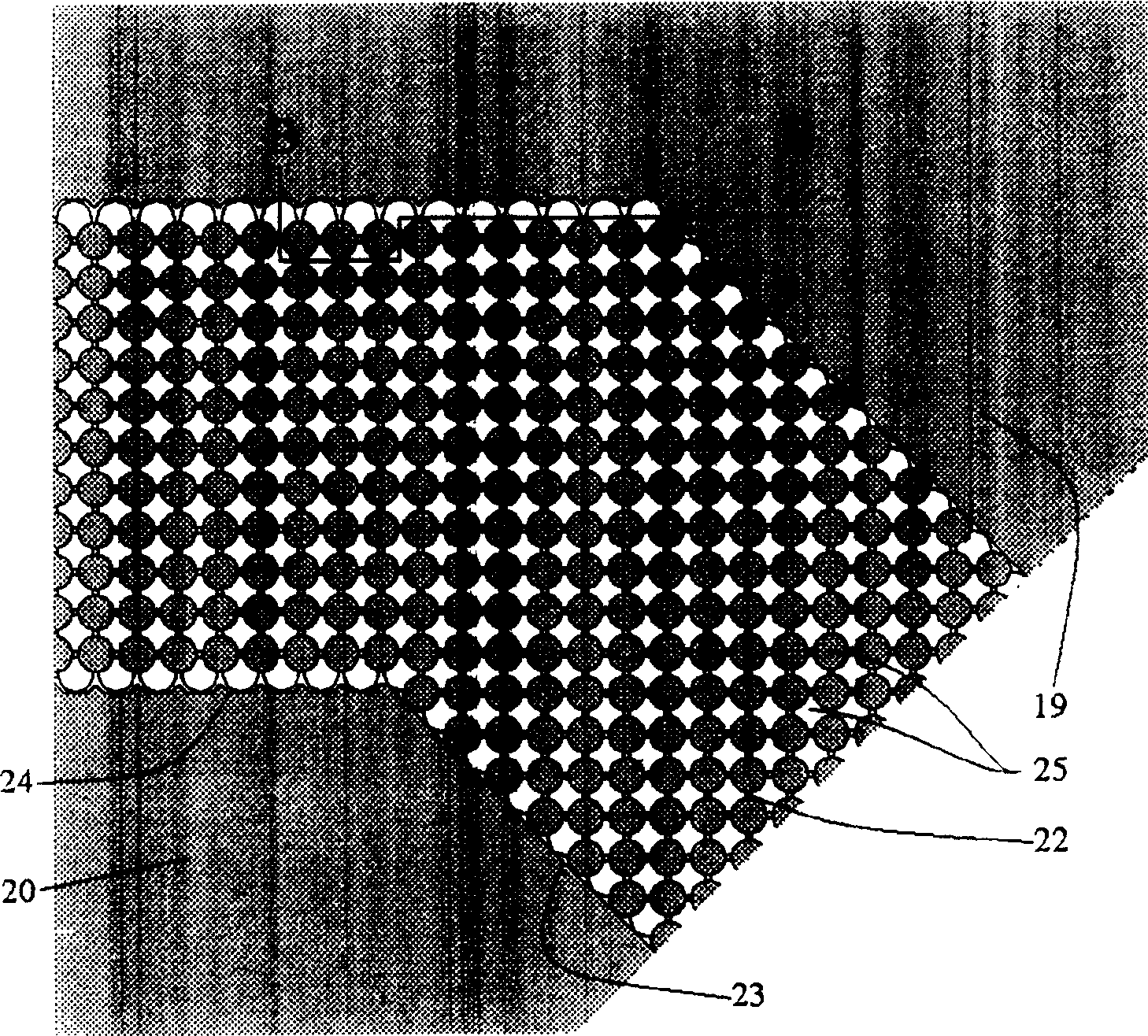

[0042] The regular bed modular high-temperature gas-cooled reactor proposed by the present invention has a structure such as figure 1 As shown, it includes fuel ball cores 6 and 21, graphite block reflection layers 19 and 20, control rods 7, absorbing pellets 4, and a steel pressure vessel 9. The graphite block reflectors 19 and 20 are placed in the steel pressure vessel 9; the described cores 6 and 21 are placed in the cavities formed by the graphite block reflectors 19 and 20, and the core is a solid column 21, such as figure 1 e shown, or hollow columnar 6, such as figure 1 As shown in a, helium is placed in the core and the reflective layer of the graphite block. The control rods 7 or the absorbing balls 4 are placed in the graphite reflective layers 19 and 20; it is characterized in that the fuel balls 25 are arranged in a square on the horizontal plane in the cavity of the graphite reflective layer, and the depression formed at the center of every 4 balls becomes the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com