Manufacturing method and equipment for continuous fiber reinforced thermoplastic resin prepreg tape

A technology of reinforced thermoplastic and continuous fiber, applied in the direction of coating, etc., can solve the problems of high requirements, poor impregnation effect, low production cost, etc., achieve good technical effect, improve impregnation effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

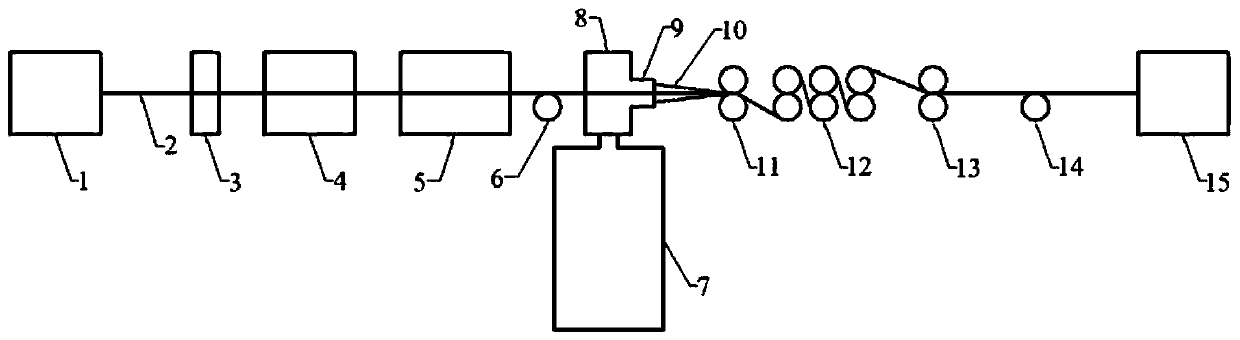

[0033] In this embodiment, the schematic diagram of the equipment used to prepare continuous fiber reinforced thermoplastic resin prepreg tape is as follows figure 1 As shown, it includes a creel (1) with tension control, a splitting comb (3), a preheating device (4), a spreading device (5), a guide roller (6), an extruder (7), an extruder Mold (8), hot pressing roller (11), S type hot pressing roller group (12), hot pressing roller (13), guide roller (14) and winding device (15). The main feature of the invention is that multiple processes such as resin film preparation, resin film and continuous fiber compounding, and resin film impregnation of continuous fiber are completed in one step on the same equipment, and S-type hot pressing roller group is used to improve the impregnation effect of resin on carbon fiber .

[0034] Utilize the method for manufacturing continuous fiber-reinforced thermoplastic resin prepreg with equipment of the present invention, comprise the steps:...

Embodiment 2

[0048] Continuous fiberglass reinforced polypropylene prepreg tape.

[0049] According to the steps in Example 1, the continuous glass fiber bundles (Jushi Group, 362C, 2400dtex) are unwound from the creel (1), and the continuous fiber bundles are arranged in parallel by the splitting comb (3), and the tension on the creel is adjusted. Damping device to control the tension on the continuous fiber bundle during the unwinding process.

[0050] The continuous fiber bundle is passed through a preheating device (4). The preheating method is resistance wire heating, and the heating temperature is set at 230°C.

[0051] The preheated continuous fiber bundle is widened by the spreading device (5), and the spreading method is roller spreading.

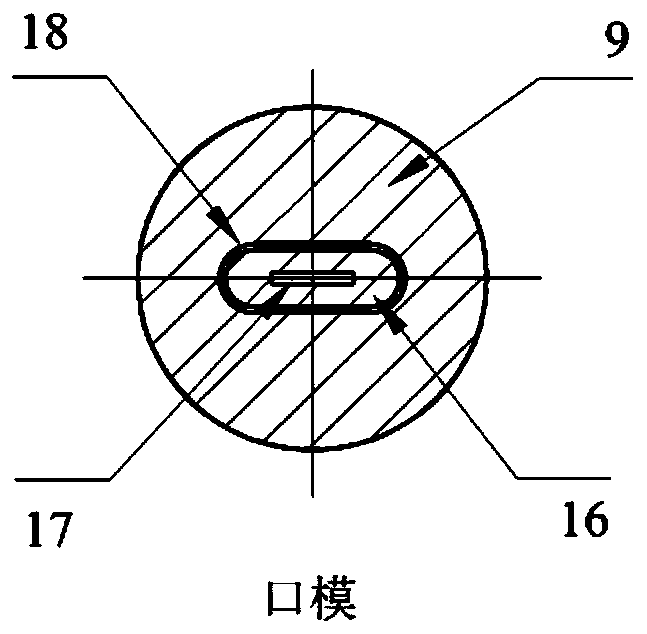

[0052] The continuous fiber bundles after spreading go out from the through hole (17) of the mandrel (16), and pass through the hot pressing roller (11), S-shaped hot pressing roller group (12), hot pressing roller (13), Guide roller (14), i...

Embodiment 3

[0057] Continuous carbon fiber reinforced nylon 6 prepreg tape.

[0058] According to the step in the embodiment 1, the continuous carbon fiber bundle (Toray, Japan, T700sc × 12k) is unwound from the creel (1), and the continuous fiber bundle is arranged in parallel by the splitting comb (3), and the tension on the creel is adjusted. Damping device to control the tension on the continuous fiber bundle during the unwinding process.

[0059] The continuous fiber bundle is passed through a preheating device (4). The preheating method is infrared heating, and the heating temperature is set at 280°C.

[0060] The preheated continuous fiber bundle is widened by the spreading device (5), and the spreading method is roller spreading.

[0061] The continuous fiber bundles after spreading go out from the through hole (17) of the mandrel (16), and pass through the hot pressing roller (11), S-shaped hot pressing roller group (12), hot pressing roller (13), Guide roller (14), is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com