Low temperature ultrasonic aging treatment method for 7075 aluminium alloy

A technology of ultrasonic aging and treatment method, which is applied in the field of aluminum alloy heat treatment, can solve the problems of complex aging process, long aging time and low efficiency, and achieve the effects of improving overall performance, reducing the time required for aging, and dispersing the distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

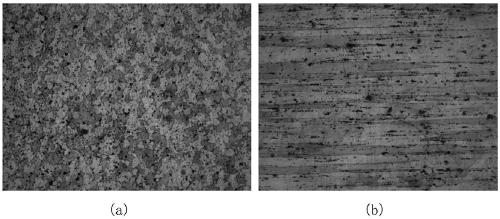

Image

Examples

Embodiment 1

[0037] A kind of 7075 aluminum alloy low-temperature ultrasonic aging treatment method, it comprises the steps:

[0038] (1) Raise the temperature of the oil bath in the constant temperature oil bath to 120°C and keep it warm. The oil bath medium is methyl silicone oil.

[0039] (2) Put the 7075 aluminum alloy workpiece after solid solution treatment into the oil bath for heat preservation.

[0040] (3) After the temperature of the workpiece rises to the temperature of the oil bath, the power ultrasonic field is then introduced into the oil bath. The power ultrasonic field introduction process adopts continuous input, the ultrasonic tool head is closely fixed with the surface of the workpiece, the ultrasonic is turned on, and the ultrasonic vibration is directly transmitted to the workpiece substrate. The ultrasonic frequency range is 40KHZ; the ultrasonic intensity is 15W / cm 2 . The aging process time is 1h.

[0041] (4) Turn off the ultrasonic and take out the ultrasoni...

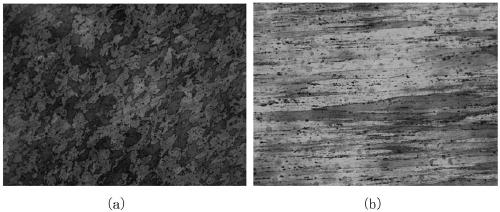

Embodiment 2

[0043] A kind of 7075 aluminum alloy low-temperature ultrasonic aging treatment method, it comprises the steps:

[0044] (1) Raise the temperature of the oil bath in the constant temperature oil bath to 80°C and keep it warm. The oil bath medium is methyl silicone oil.

[0045] (2) Put the 7075 aluminum alloy workpiece after solid solution treatment into the oil bath for heat preservation.

[0046] (3) After the temperature of the workpiece rises to the temperature of the oil bath, the power ultrasonic field is then introduced into the oil bath. The power ultrasonic field introduction process adopts continuous input, insert the ultrasonic tool head into the 1-2cm below the oil surface above the workpiece, and turn on the ultrasonic. The ultrasonic frequency range is 30KHZ; the ultrasonic intensity is 10W / cm 2 . The aging process time is 1.5h.

[0047] (4) Turn off the ultrasonic and take out the ultrasonic tool head. Take the workpiece out of the oil bath and air cool to r...

Embodiment 3

[0049] A kind of 7075 aluminum alloy low-temperature ultrasonic aging treatment method, it comprises the steps:

[0050] (1) Keep the temperature of the oil bath in the constant temperature oil bath at room temperature of 25°C and keep it warm. The oil bath medium is methyl silicone oil.

[0051] (2) Put the 7075 aluminum alloy workpiece after solid solution treatment into the oil bath for heat preservation.

[0052] (3) After the temperature of the workpiece rises to the temperature of the oil bath, the power ultrasonic field is then introduced into the oil bath. The power ultrasonic field is introduced by connecting the ultrasonic tool head with the oil bath container, turning on the ultrasonic, and indirectly inputting the ultrasonic vibration into the oil bath. The power ultrasonic field introduction process adopts the pulse method, that is, ultrasonic treatment with a duration of 30 minutes is performed every 10 minutes during the aging process. Ultrasonic frequency ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com