7075 aluminum alloy ultrasonic solution treatment method

A solution treatment and aluminum alloy technology, applied in the field of ultrasonic solution treatment of 7075 aluminum alloy, can solve the problems of harsh process requirements, difficult thermal processing, narrow thermal processing temperature range, etc., to increase the interval range and reduce the solution time , the effect of reducing the degree of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

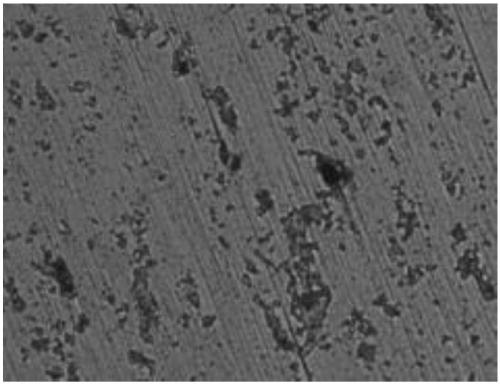

Embodiment 1

[0034] A 7075 aluminum alloy ultrasonic solution treatment method, it comprises the steps:

[0035] (1) Raise the temperature of the salt bath in the salt bath furnace to 430°C and keep it warm. The salt bath liquid medium is a nitrate salt bath, the composition is 50% KNO3+50% NaNO3, and the use temperature is between 230-550°C.

[0036] (2) Put the 7075 aluminum alloy workpiece into the salt bath to keep warm.

[0037] (3) After the temperature of the workpiece rises to 430°C, insert the ultrasonic tool head 1-2cm below the surface of the saline solution above the workpiece, and turn on the ultrasound. The ultrasonic frequency is 40KHZ; the ultrasonic intensity is 15W / cm 2 , heat preservation ultrasonic treatment time is 20min;

[0038] (4) Turn off the ultrasonic and take out the ultrasonic tool head. The workpiece is quickly taken out of the salt bath furnace, and quickly quenched into flowing water at room temperature to cool, and the transfer time is less than 8S.

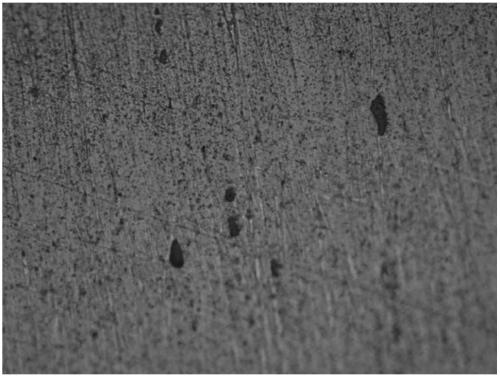

Embodiment 2

[0040] A 7075 aluminum alloy ultrasonic solution treatment method, it comprises the steps:

[0041] (1) Raise the temperature of the salt bath in the salt bath furnace to 445°C and keep it warm. The medium of the salt bath liquid is a nitrate salt bath, the composition is 100% NaNO3, and the operating temperature is between 350-600°C.

[0042] (2) Put the 7075 aluminum alloy workpiece into the salt bath to keep warm.

[0043] (3) After the temperature of the workpiece rises to 445°C, insert the ultrasonic tool head 1-2cm below the surface of the saline solution above the workpiece, and turn on the ultrasound. The ultrasonic frequency is 30KHZ; the ultrasonic intensity is 10W / cm 2 , heat preservation ultrasonic treatment time is 30min;

[0044](4) Turn off the ultrasonic and take out the ultrasonic tool head. The workpiece is quickly taken out of the salt bath furnace, and quickly quenched into flowing water at room temperature to cool, and the transfer time is less than 8S...

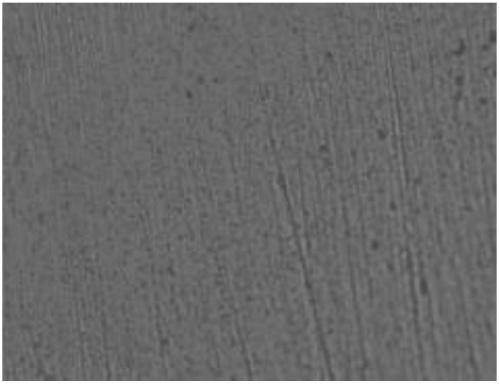

Embodiment 3

[0046] A 7075 aluminum alloy ultrasonic solution treatment method, it comprises the steps:

[0047] (1) Raise the temperature of the salt bath in the salt bath furnace to 460°C and keep it warm. The medium of the salt bath liquid is a nitrate salt bath, the composition is 100% KNO3, and the operating temperature is between 350-600°C.

[0048] (2) Put the 7075 aluminum alloy workpiece into the salt bath to keep warm.

[0049] (3) After the temperature of the workpiece rises to 460°C, connect the ultrasonic tool head to the salt bath container, turn on the ultrasonic, and directly input the ultrasonic vibration into the salt solution. The ultrasonic frequency is 20KHZ; the ultrasonic intensity is 5W / cm 2 , heat preservation ultrasonic treatment time is 50min;

[0050] (4) Turn off the ultrasonic and take out the ultrasonic tool head. The workpiece is quickly taken out of the salt bath furnace, and quickly quenched into flowing water at room temperature to cool, and the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com