Dissimilar metal welding joint and welding method thereof

A technology for welding joints and dissimilar metals, used in welding/welding/cutting items, welding equipment, metal processing equipment, etc., and can solve problems such as low joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

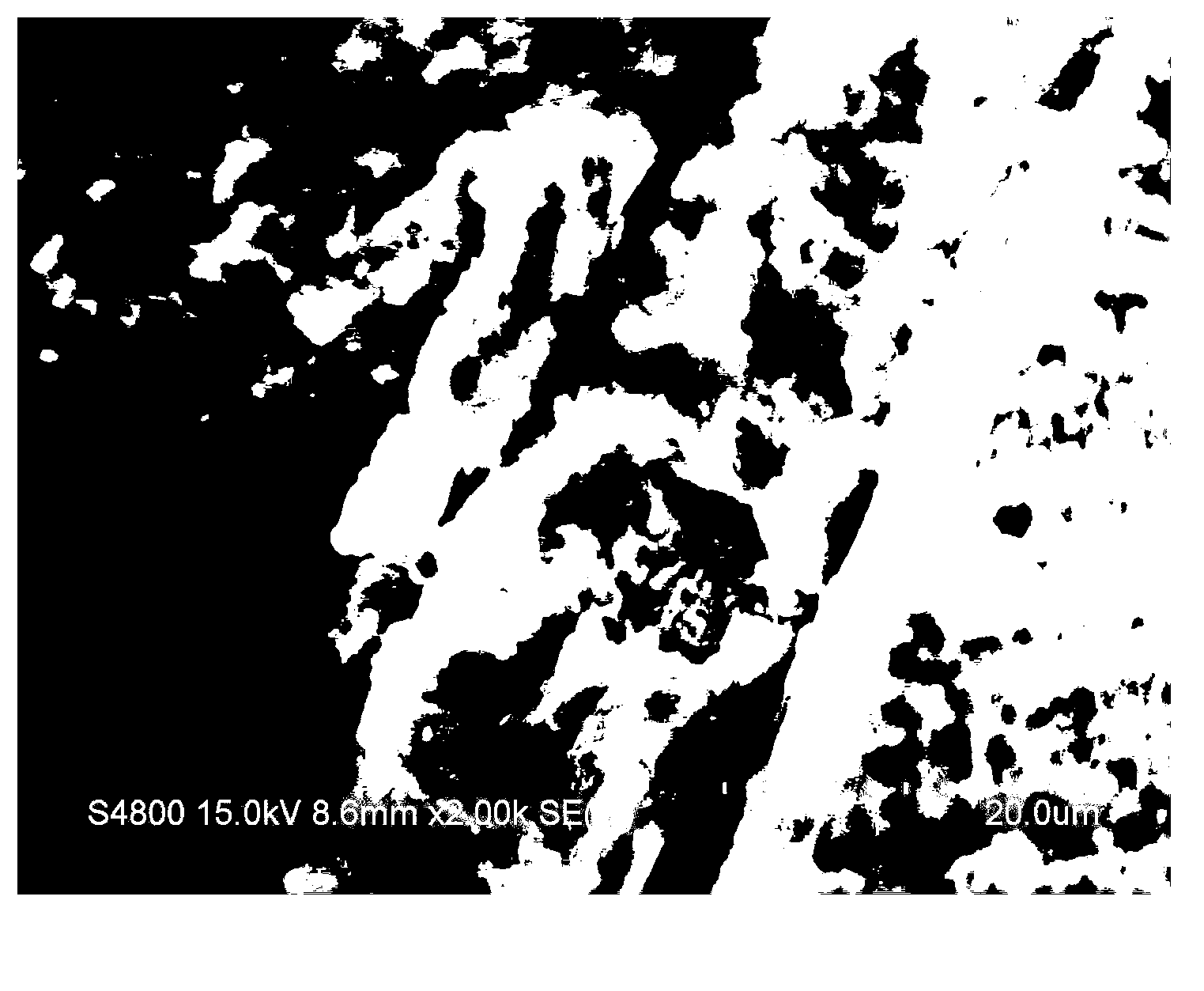

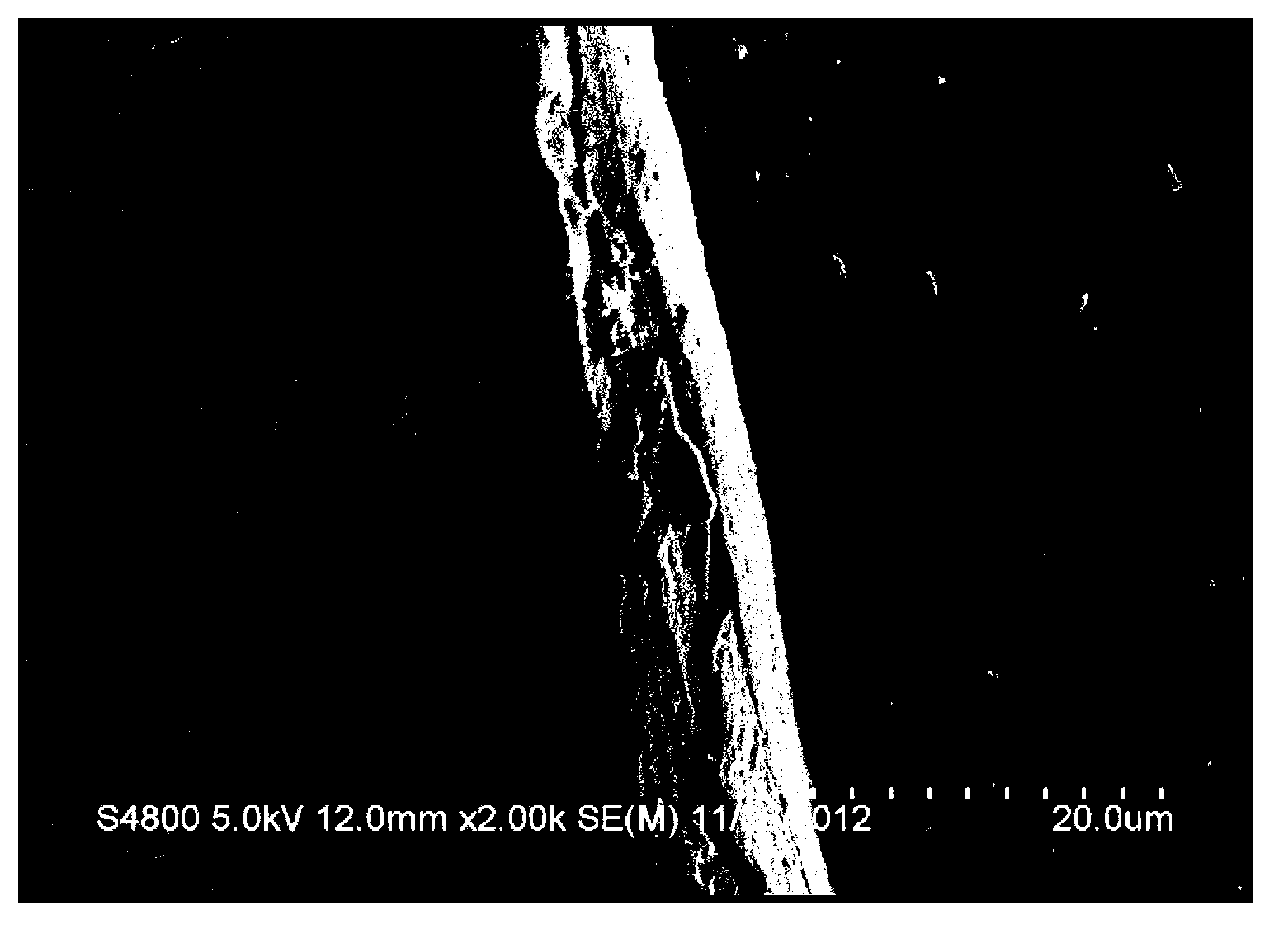

Image

Examples

Embodiment 1

[0029] (1) Place the 6mm thick AZ31 magnesium alloy welding plate and the 6mm thick 7075 aluminum alloy welding plate, and fix them on the backing plate. The 7075 aluminum alloy welding plate is placed on the forward surface, and the AZ31 magnesium alloy welding plate is placed on the retreating surface ; The shoulder of the stirring head is in the shape of a double concave ring, the stirring needle is a tapered right-handed thread with three planes, the diameter of the stirring needle is 5mm to 7mm, and the shoulder of the stirring head is 20mm; the length of the stirring needle is longer than the welding The thickness of the board is less than 0.4mm;

[0030] (2) The stirring needle is centered with the welding interface, and the stirring head rotates counterclockwise; when welding starts, the insertion speed of the stirring head is 20mm / min, the insertion depth is 5.9mm, and stays for 3s; when starting to move, the rotating speed of the stirring head is 400r / min, the weldin...

Embodiment 2

[0033] The 6mm thick AZ31 magnesium alloy and the 6mm thick 7075 aluminum alloy are docked and placed, fixed on the backing plate, the 7075 aluminum alloy welding plate is placed on the retreating surface, and the AZ31 magnesium alloy welding plate is placed on the forward surface, and the rest of the preparation method steps are implemented in the same way Example 1, a dissimilar metal welded joint was obtained.

[0034] It can be seen that grooves appear on the surface of the welded joint through visual inspection.

Embodiment 3

[0036] (1) Same as step (1) of Example 1;

[0037] (2) Offset the axis of the stirring needle by 1mm toward the direction of the AZ31 magnesium alloy; the inclination angle of the stirring head is 2.5°; the rest of the steps are the same as step (2) of Example 1 to obtain a welded joint of dissimilar metals.

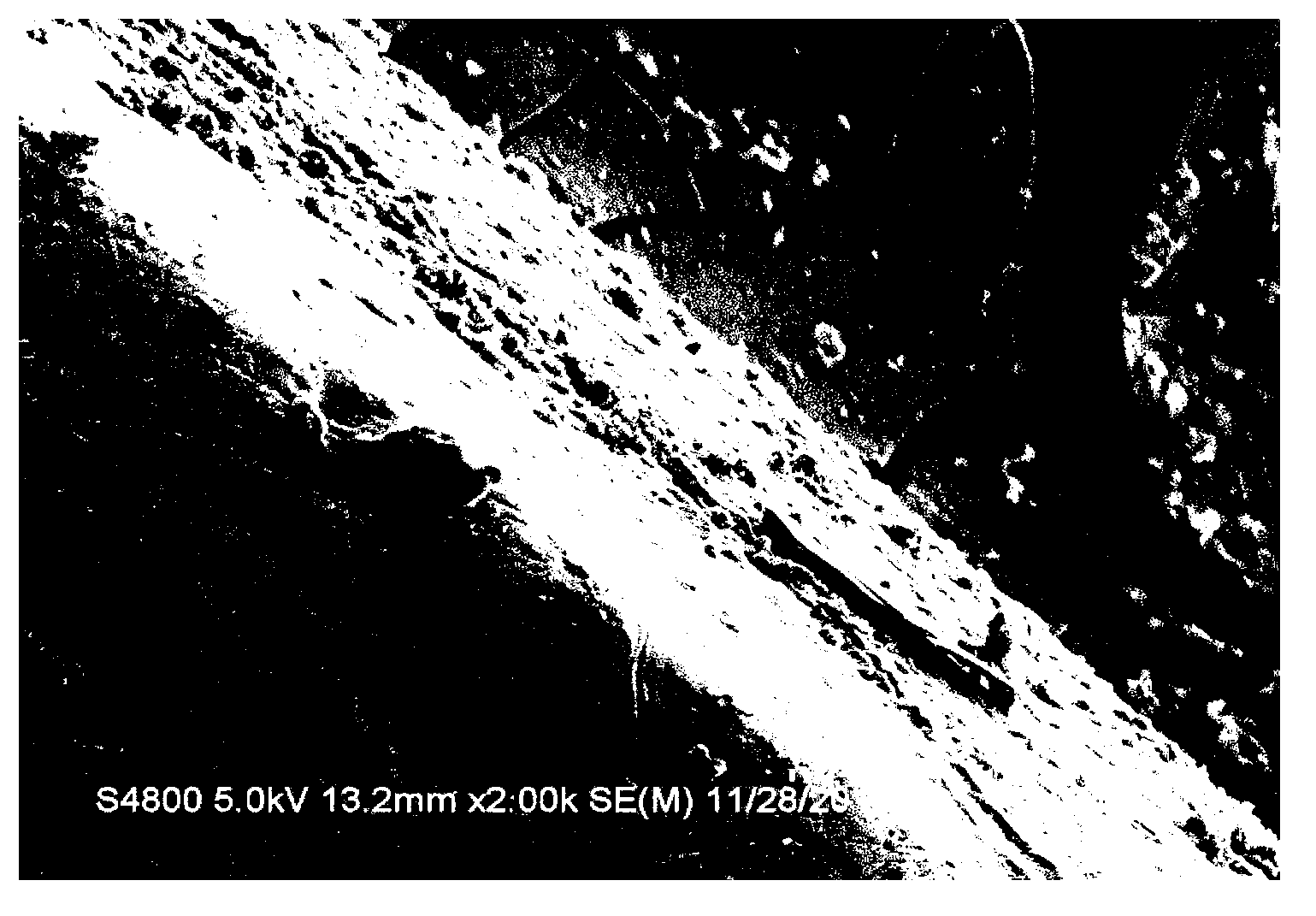

[0038] According to the mechanical performance test and microstructure analysis: if figure 2 As shown, the cracks and intermetallic thickness in the intermetallic compound at the interface of the welded joint are significantly less than those of the welded joint prepared in Example 1, and the tensile strength of the joint is 31.2 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com