Two-stage aging treatment technology for 7075 aluminum alloy

A dual-stage aging and treatment process technology, applied in the field of 7075 aluminum alloy treatment process, can solve problems such as unsatisfactory properties of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

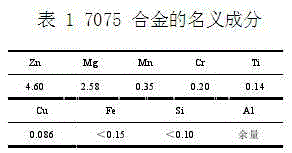

[0021] The semi-continuous ingot of 7075 alloy used in the experiment was provided by Northeast Light Alloy Co., Ltd., and the nominal composition of the alloy is shown in Table 1. The alloy is homogenized at 450°C / 24h, hot rolled into a 5mm thin plate at 420°C, and then subjected to two-stage solution treatment at 460°C / 2h+480°C / 1h.

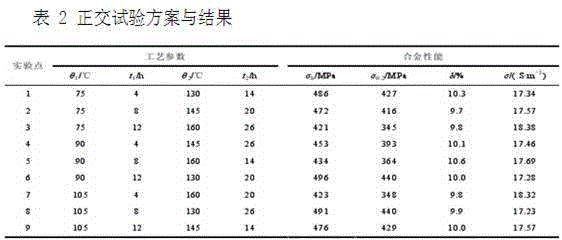

[0022] The L9(34) orthogonal test scheme was designed for the four process parameters of the dual-stage aging process (pre-aging temperature θ1 and time t1, final aging temperature θ2 and time t2). Then, the range analysis is carried out on the experimental results to determine the best treatment process.

[0023]

[0024] The mechanical performance test at room temperature was completed on the Instron8301 multifunctional mechanical performance testing machine, and the relative conductivity test was carried out on the 7501 eddy current conductivity meter according to the regulations of GB / T12966. TEM was performed on a TecnaiG2 analytical el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com