Method of aluminum alloys of scrap aircraft reused to produce 2024 or 7075 aluminum alloy

A waste aluminum alloy and aluminum alloy technology, which is applied in the field of circular economy, can solve the problems of incomplete composition adjustment, many types of alloy elements, and increased production costs, and achieve the effects of avoiding solid inclusions, reducing gas content, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

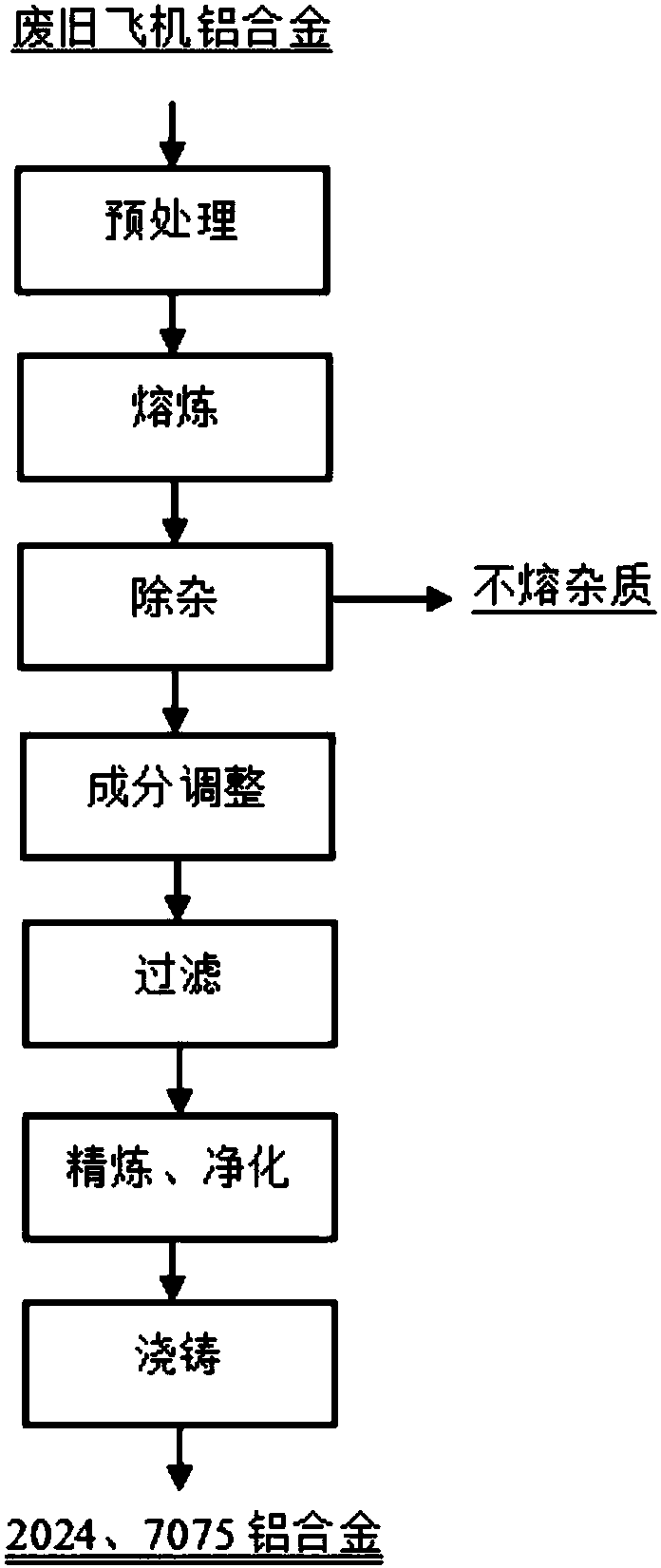

[0030] A method for producing 7075 aluminum alloy by recycling waste aircraft aluminum alloy

[0031] (1) Pretreatment: Crushing waste aircraft aluminum alloys, magnetic separation to remove iron, flotation to remove heavy metals, air elutriation to remove non-aluminum polymers and non-aluminum composite materials, and eddy current separation to remove glass;

[0032] (2) Melting: smelting the pretreated waste aircraft aluminum alloy until it is completely melted to obtain an aluminum alloy melt at a melting temperature of 700°C;

[0033] (3) Impurity removal: Purifying the aluminum alloy melt with a ceramic foam filter plate with a pore size of 10ppi, separating unmelted impurities in the aluminum alloy melt, and obtaining the aluminum alloy melt after impurity removal;

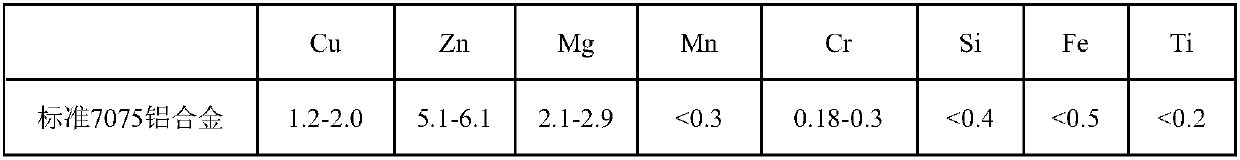

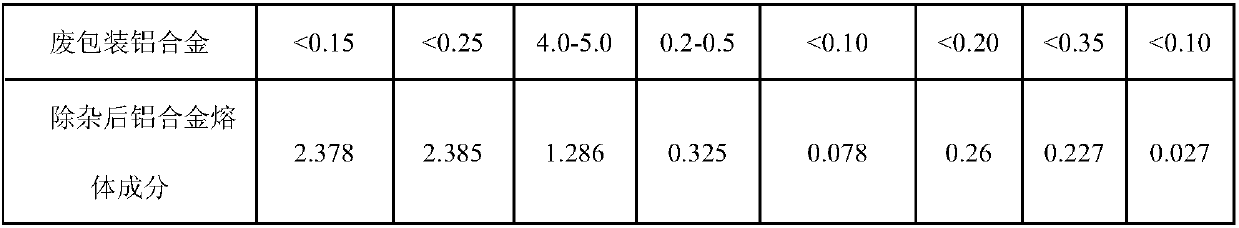

[0034] (4) Composition adjustment: two samples were taken from different parts of the aluminum melt after removal of impurities for composition detection. Table 1 shows the composition of the standard 7075 ...

Embodiment 2

[0045] A method for producing 2024 aluminum alloy by recycling waste aircraft aluminum alloy.

[0046] (1) Pretreatment: Crushing waste aircraft aluminum alloys, magnetic separation to remove iron, flotation to remove heavy metals, air elutriation to remove non-aluminum polymers and non-aluminum composite materials, and eddy current separation to remove glass;

[0047] (2) Melting: smelting the pretreated waste aircraft aluminum alloy until it is completely melted, and the melting temperature is 800°C;

[0048](3) Impurity removal: Purify the aluminum alloy melt with a ceramic foam filter plate with a pore size of 10ppi, separate the unmelted impurities in the aluminum alloy melt, and obtain the aluminum alloy melt after the impurity removal;

[0049] (4) Composition adjustment: 2 samples were taken from different parts of the aluminum alloy melt after removal of impurities for composition detection. Table 3 shows the composition of the standard 2024 aluminum alloy in "GB / T31...

Embodiment 3

[0059] A method for producing 7075 aluminum alloy by recycling waste aircraft aluminum alloy.

[0060] (1) Pretreatment: Crushing waste aircraft aluminum alloys, magnetic separation to remove iron, flotation to remove heavy metals, air elutriation to remove non-aluminum polymers and non-aluminum composite materials, and eddy current separation to remove glass;

[0061] (2) Melting: smelting the pretreated waste aircraft aluminum alloy until it is completely melted, and the melting temperature is 750°C;

[0062] (3) Impurity removal: Purify the aluminum alloy melt with a foam ceramic filter plate with a pore size of 10ppi, separate the unmelted impurities, and obtain the aluminum alloy melt after the impurity removal;

[0063] (4) Composition adjustment: two samples were taken from different parts of the aluminum alloy melt after impurity removal for composition detection. Table 5 shows the composition of the standard 7075 aluminum alloy in "GB / T3190-2008 Wrought Aluminum and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com