Forming device and method for semi-solid slurry of nanometer SiC-particle-reinforced 7075-aluminum-based composite material

A technology of aluminum-based composite materials and semi-solid slurry, which is applied in the forming device and field of forming semi-solid slurry of nano-SiC particles reinforced 7075 aluminum-based composite materials, which can solve poor interface wettability, high cost, and long process flow, etc. problem, to achieve the effect of uniform spheroidization and fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

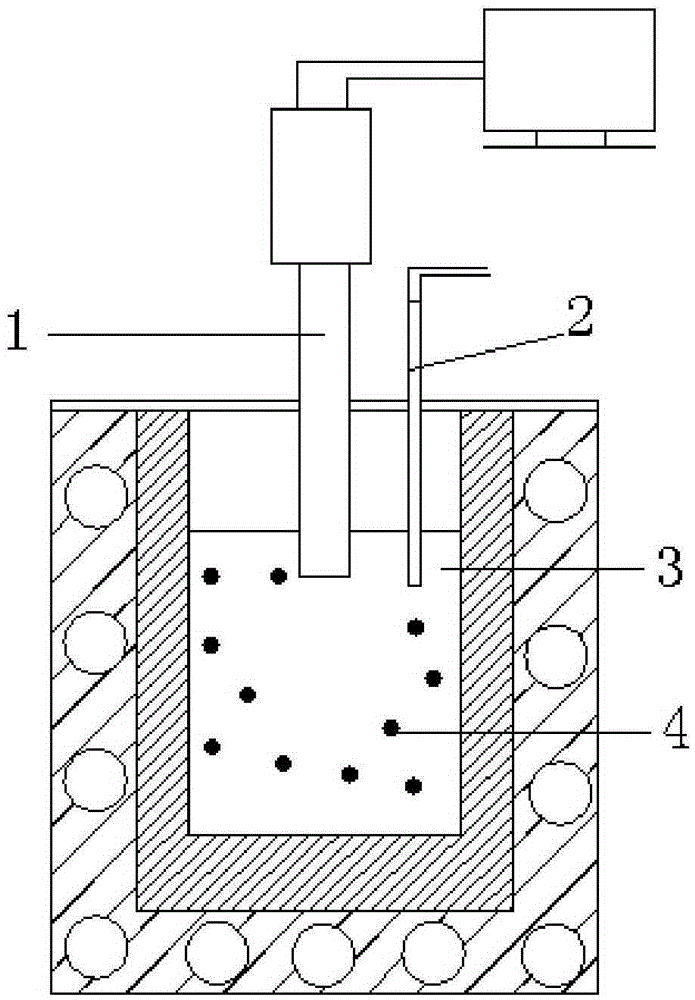

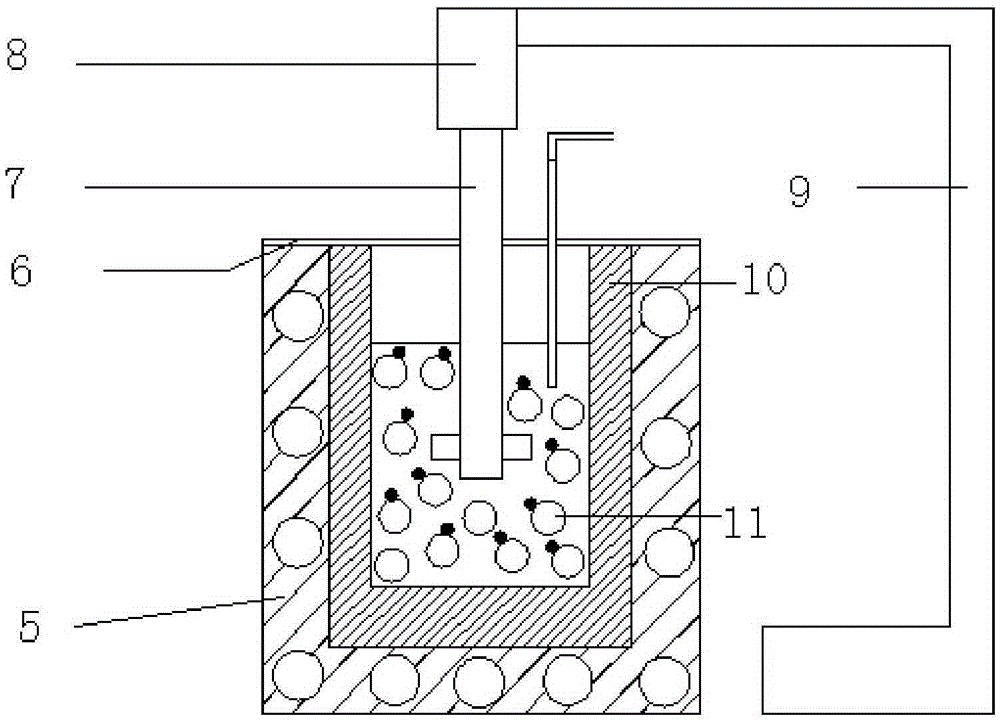

[0043] Specific embodiment 1: This embodiment is a preparation device for semi-solid slurry of nano-SiC particles reinforced 7075 aluminum-based composite materials, including an ultrasonic vibration device 1, a thermocouple 2, a resistance furnace 5, a cover plate 6, a stirrer 7, a motor 8, frame 9 and crucible 10;

[0044] The crucible 10 is placed in the resistance furnace 5; the cover plate 6 is covered on the upper end surface of the resistance furnace 5, and the middle position of the cover plate 6 is provided with a punching hole, and the ultrasonic vibration device 1 or the stirrer 7 passes through the cover plate 6 The punching hole extends into the inside of the crucible 10; the upper end of the agitator 7 is connected with the motor 8, and the motor 8 and the frame 9 are fixedly connected by bolts.

specific Embodiment approach 2

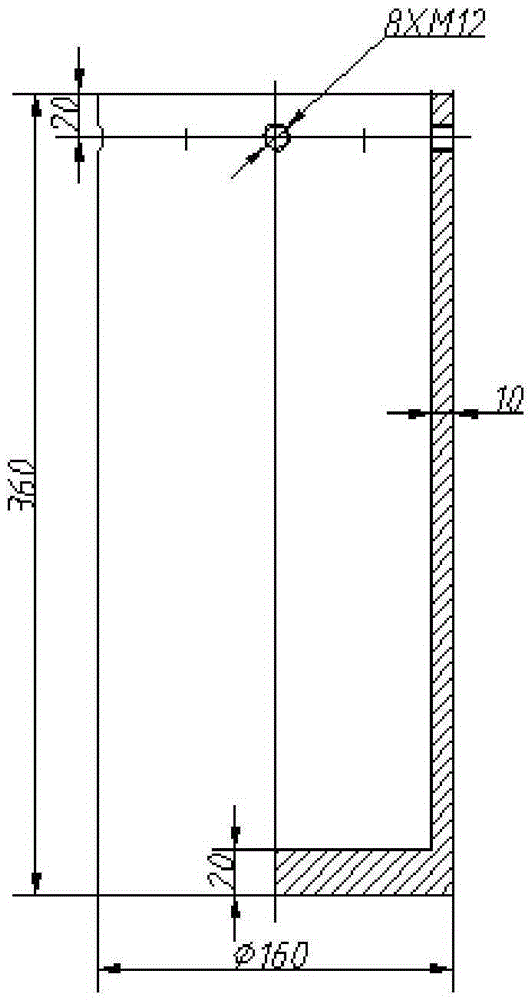

[0045] Specific embodiment two: the difference between this embodiment and specific embodiment one is: described crucible 10 is made by molybdenum alloy material, and the method for making is to adopt powder metallurgy method; The external diameter of crucible 10 is 160mm, and internal diameter is 140mm, a height of 360mm, and a bottom wall thickness of 20mm; the inner tank material of the resistance furnace 5 is SiC ceramic material. Others are the same as the first embodiment.

specific Embodiment approach 3

[0046] Specific implementation mode three: This implementation mode is a method for preparing semi-solid slurry of nano-SiC particle reinforced 7075 aluminum-based composite material, which is specifically prepared according to the following method:

[0047] 1. Preparation of liquid 7075 aluminum alloy: heating the resistance furnace 5 to 650°C, then putting the extruded 7075 aluminum alloy billet into the crucible 10, and then keeping it at 650°C for 10-16 minutes to obtain liquid 7075 aluminum alloy;

[0048] 2. Ultrasonic cleaning: using ethanol as a cleaning agent, ultrasonically clean the nano-SiC particles at a power of 100W for 2 minutes to 3 minutes, and then dry them to obtain nano-SiC particles after ultrasonic cleaning;

[0049] 3. Mixing and ultrasonication: Add the nano-SiC particles after ultrasonic cleaning to the liquid 7075 aluminum alloy at a temperature of 650°C to obtain a mixed melt of nano-SiC particles and 7075 aluminum alloy; then place the ultrasonic vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com