Nano silicon carbide reinforced aluminum matrix composite and preparing method thereof

A technology of nano-silicon carbide and composite materials, applied in the field of materials, can solve the problems of high cost, complex preparation process, and inability to distribute nano-silicon carbide particles uniformly, and achieve the effects of improving tensile strength and hardness and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

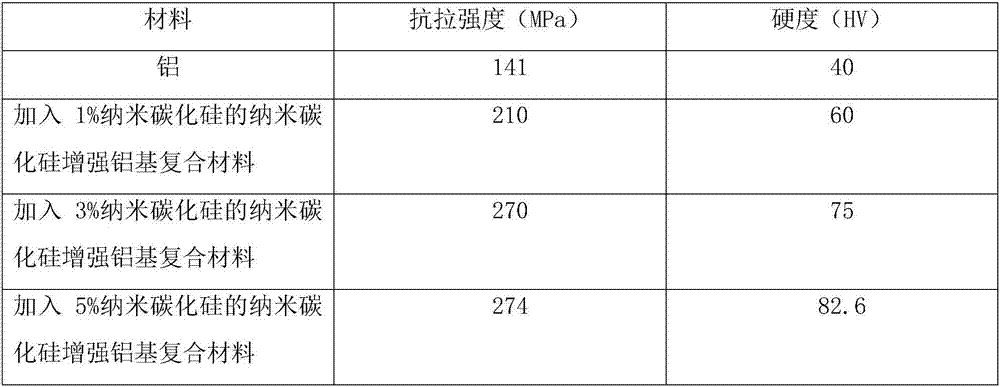

Embodiment 1

[0023] (1) 3% nano silicon carbide powder (particle size is 30nm) is put into the beaker that fills 250ml dehydrated alcohol, carry out ultrasonic vibration dispersion 60min, wherein the frequency of ultrasonic vibration is 60KHZ, simultaneously 97% 7075 aluminum alloy powder ( The particle size is 65μm) into a beaker filled with 250ml of absolute ethanol for electromagnetic stirring, and then under magnetic stirring, the solution containing nano-silicon carbide is added dropwise to the 7075 aluminum alloy powder solution, and then continue to stir for 35min, and let it settle After the composite powder has completely settled, pour out part of the clear liquid and place it in an oven at 90°C overnight to obtain a mixed powder. Put the composite material powder in a ball mill for 5 hours, and set the speed at 200rpm, and add about 2.0wt% of Stearic acid; (2) the resulting mixture is pressed into shape at 60MPa pressure and room temperature, and kept at 60MPa pressure for 8min; (...

Embodiment 2

[0025] (1) 5% nano silicon carbide powder (particle size is 40nm) is put into the beaker that fills 250ml dehydrated alcohol, carry out ultrasonic vibration dispersion 65min, wherein the frequency of ultrasonic vibration is 60KHZ, simultaneously 95% 7075 aluminum alloy powder ( The particle size is 30μm) into a beaker filled with 250ml of absolute ethanol for electromagnetic stirring, and then under magnetic stirring, the solution containing nano-silicon carbide is added dropwise to the 7075 aluminum alloy powder solution, and then continue to stir for 40min, and let it settle After the composite powder has completely settled, pour out part of the clear liquid and place it in a 95°C oven overnight to obtain a mixed powder. Put the composite material powder in a ball mill for 5 hours, and set the speed to 200rpm. During the process, add about 2.0wt% of Stearic acid; (2) the resulting mixture is pressed into shape at 65MPa pressure and room temperature, and kept at 65MPa pressure...

Embodiment 3

[0027] (1) 1% nano silicon carbide powder (particle size is 20nm) is put into the beaker that fills 250ml dehydrated alcohol, carry out ultrasonic vibration dispersion 55min, wherein the frequency of ultrasonic vibration is 60KHZ, simultaneously 99% 7075 aluminum alloy powder ( The particle size is 100μm) into a beaker filled with 250ml of absolute ethanol for electromagnetic stirring, then under magnetic stirring, the solution containing nano-silicon carbide is added dropwise to the 7075 aluminum alloy powder solution, and then continue to stir for 30min, and let it settle After the composite powder has completely settled, pour out part of the clear liquid and place it in an oven at 80°C overnight to obtain a mixed powder. Put the composite material powder in a ball mill for 5 hours, and set the speed to 200rpm. During the process, add about 2.0wt% of Stearic acid; (2) the resulting mixture is pressed into shape at 55MPa pressure and room temperature, and kept at 55MPa pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com