High-intensity aluminum alloy material for automobile hub and production technology thereof

A technology of aluminum alloy material and automobile wheel hub, which is applied in the field of high-strength aluminum alloy material for automobile wheel hub and its production process, can solve the problems of brittleness of aluminum alloy, difficult to find, unstable casting quality, etc., and achieves high mechanical strength and excellent processing. performance, high loads and lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

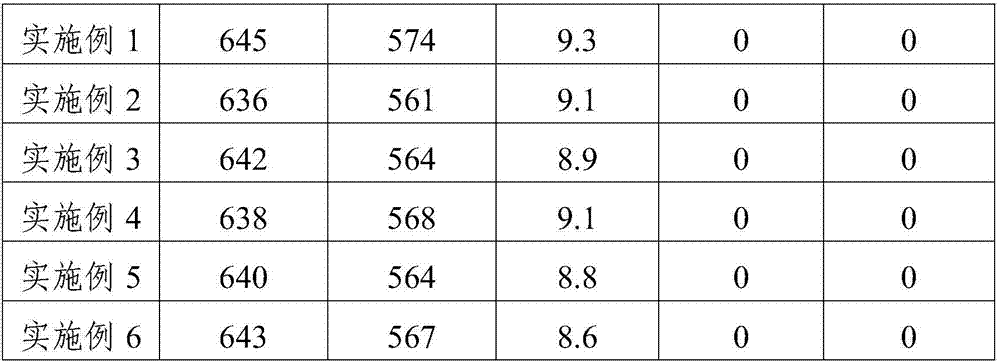

Embodiment 1

[0019] A high-strength aluminum alloy material for automobile wheels, the mass percentages of the components in the aluminum alloy material are: Si: 3%, Mg: 0.6%, Mn: 0.08%, Ti: 0.28%, W: 0.03%, Sr : 0.016%, Y: 0.08%, Cu: 0.05%, Ni: 0.2%, Zr: 0.1%, and the balance is Al and unavoidable impurities.

[0020] The production process of the high-strength aluminum alloy material for the above-mentioned automobile wheel hub comprises the following steps:

[0021] (1) Heat and melt aluminum, silicon, magnesium, and copper in an electric furnace at 900°C, then add other alloy components except aluminum, silicon, magnesium, and copper, and continue to heat up to 1160°C until all alloy elements are melted Obtain aluminum alloy melt;

[0022] (2) Adjust the temperature of the aluminum alloy melt to 820°C, add a refining agent (the amount of the refining agent is 0.3% of the weight of the aluminum alloy melt), remove impurities and refine and degas, the refining and degassing time is 25mi...

Embodiment 2

[0025] A high-strength aluminum alloy material for automobile wheels, the mass percentage of each component in the aluminum alloy material is: Si: 3.2%, Mg: 0.6%, Mn: 0.1%, Ti: 0.3%, W: 0.025%, Sr : 0.02%, Y: 0.06%, Cu: 0.06%, Ni: 0.18%, Zr: 0.07%, and the balance is Al and unavoidable impurities.

[0026] The production process of the high-strength aluminum alloy material for the above-mentioned automobile wheel hub comprises the following steps:

[0027] (1) Heat and melt aluminum, silicon, magnesium, and copper in an electric furnace at 880°C, then add other alloy components except aluminum, silicon, magnesium, and copper, and continue to heat up to 1180°C until all alloy elements are melted Obtain aluminum alloy melt;

[0028] (2) Adjust the temperature of the aluminum alloy melt to 800°C, add a refining agent (the amount of the refining agent is 0.28% of the weight of the aluminum alloy melt), remove impurities and refine and degas, the refining and degassing time is 20m...

Embodiment 3

[0031] A high-strength aluminum alloy material for automobile wheels, the mass percentage of each component in the aluminum alloy material is: Si: 2.2%, Mg: 0.4%, Mn: 0.12%, Ti: 0.2%, W: 0.04%, Sr : 0.01%, Y: 0.05%, Cu: 0.07%, Ni: 0.12%, Zr: 0.12%, and the balance is Al and unavoidable impurities.

[0032] The production process of the high-strength aluminum alloy material for the above-mentioned automobile wheel hub comprises the following steps:

[0033] (1) Heat and melt aluminum, silicon, magnesium, and copper in an electric furnace at 920°C, then add other alloy components except aluminum, silicon, magnesium, and copper, and continue to heat up to 1120°C until all alloy elements are melted Obtain aluminum alloy melt;

[0034] (2) Adjust the temperature of the aluminum alloy melt to 780°C, add a refining agent (the amount of the refining agent is 0.32% of the weight of the aluminum alloy melt), remove impurities and refine and degas, the refining and degassing time is 30m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com