Additional coating for transparent polyimide film, application method of additional coating and cover plate film

A technology of transparent polyimide and polyimide substrates, applied in coatings, polyurea/polyurethane coatings, instruments, etc., can solve problems such as difficult wetting, improve surface energy and better environmental adaptability , the effect of reducing the poor wetting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

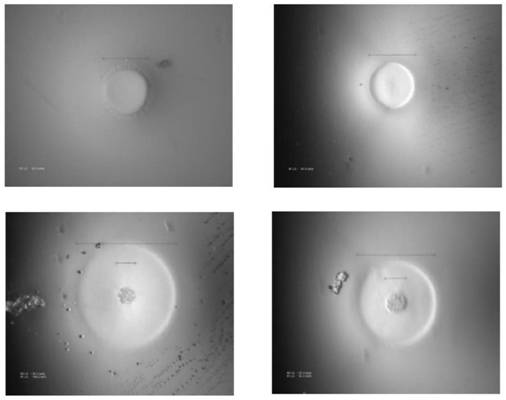

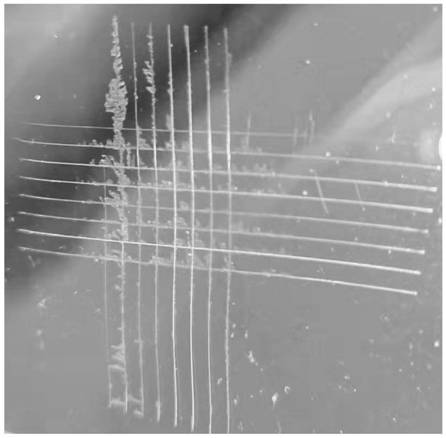

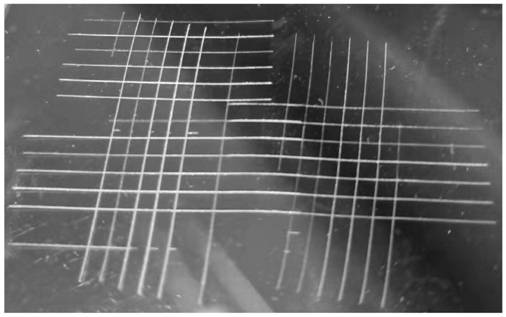

Image

Examples

Embodiment 5

[0059] The formula of the upper hardening solution HC022 in Example 5 is 24 parts by weight of hemisiloxane resin R0550, 2 parts of hexafunctional urethane acrylic resin R0310, 12 parts of monomeric resin R0243, 2 parts of photoinitiator PI184, 30 parts by weight of MEK, 30 parts by weight Parts by weight of MIBK, 0.4 parts by weight of perfluoropolyether leveling agent A088.

[0060]

[0061]

[0062] Table 1 Embodiment 1-8 corresponding selection parameters

[0063]

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com