125 DEG C irradiation crosslinking type low-smoke halogen-free polyolefin as well as preparation method and application thereof

A cross-linked, polyolefin technology, used in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve problems such as low tensile properties, low volume resistivity, and improved material conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

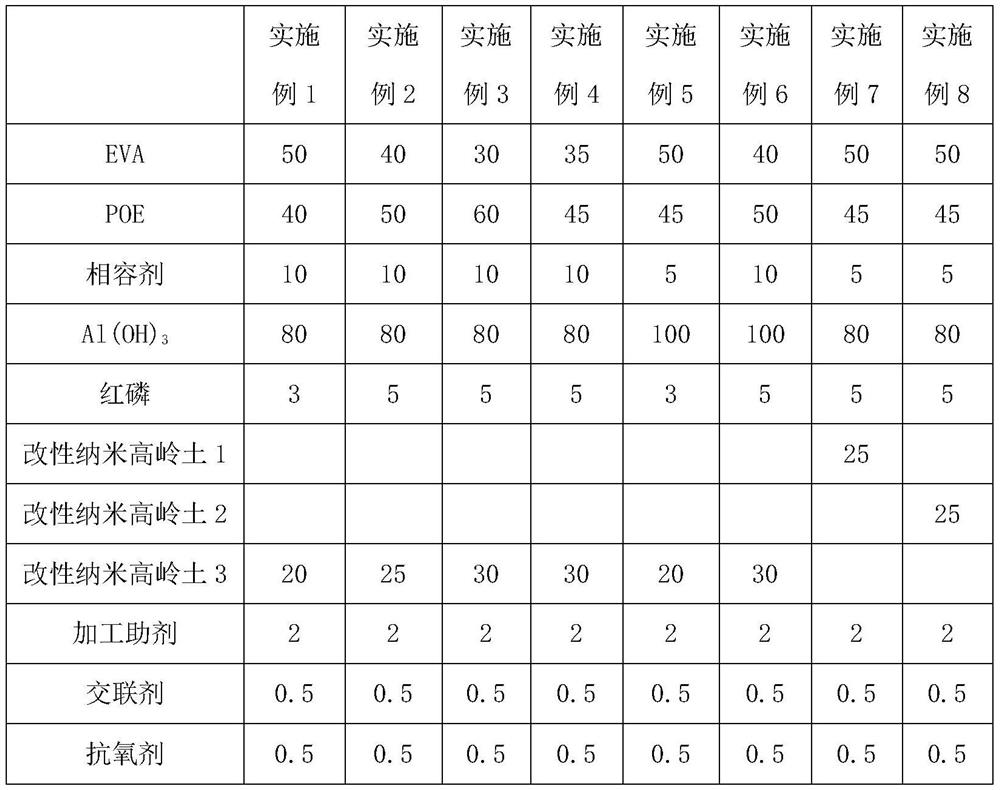

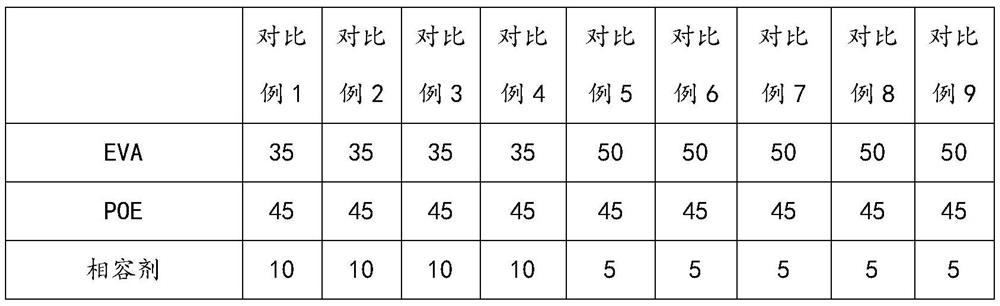

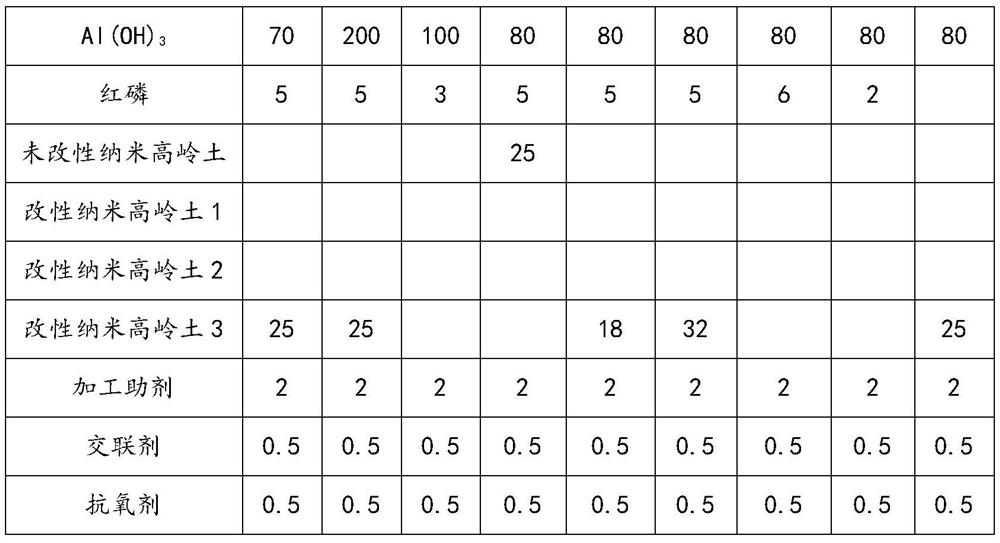

Examples

preparation example Construction

[0056] The preparation method of modified nano kaolin is as follows:

[0057] Put the kaolin into a drying oven at 90°C, dry it in vacuum for 4 hours, and fully dry the water in the kaolin;

[0058] Add the dried nano-kaolin and dimethyl sulfoxide into a constant temperature oil bath according to the weight ratio of 1:2, react at 120°C for 4 hours, filter, wash the excess dimethyl sulfoxide with acetone, and dry in vacuum to obtain di Methyl sulfoxide modified kaolin compound;

[0059] Continue to mix the compound and stearic acid according to the weight ratio of 100:1 through a high-speed mixer and stir rapidly for 5 minutes to obtain the final dimethyl sulfoxide and stearic acid modified kaolin.

[0060] The concrete detection method of each performance of the present invention is as follows:

[0061] (1). Tensile properties: according to GB / T 1040.3-2006, type 5 spline, thickness 1±0.1mm, tensile rate 250mm / min;

[0062] (2) Volume resistivity: test according to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com