Flange with neck and its preparing method

A high-neck flange and flange technology, which is used in the field of neck flanges and their preparation, can solve the problems of unguaranteed air tightness, low reliability requirements, and unguaranteed quality, and achieves high productivity. , The effect of high material utilization rate and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

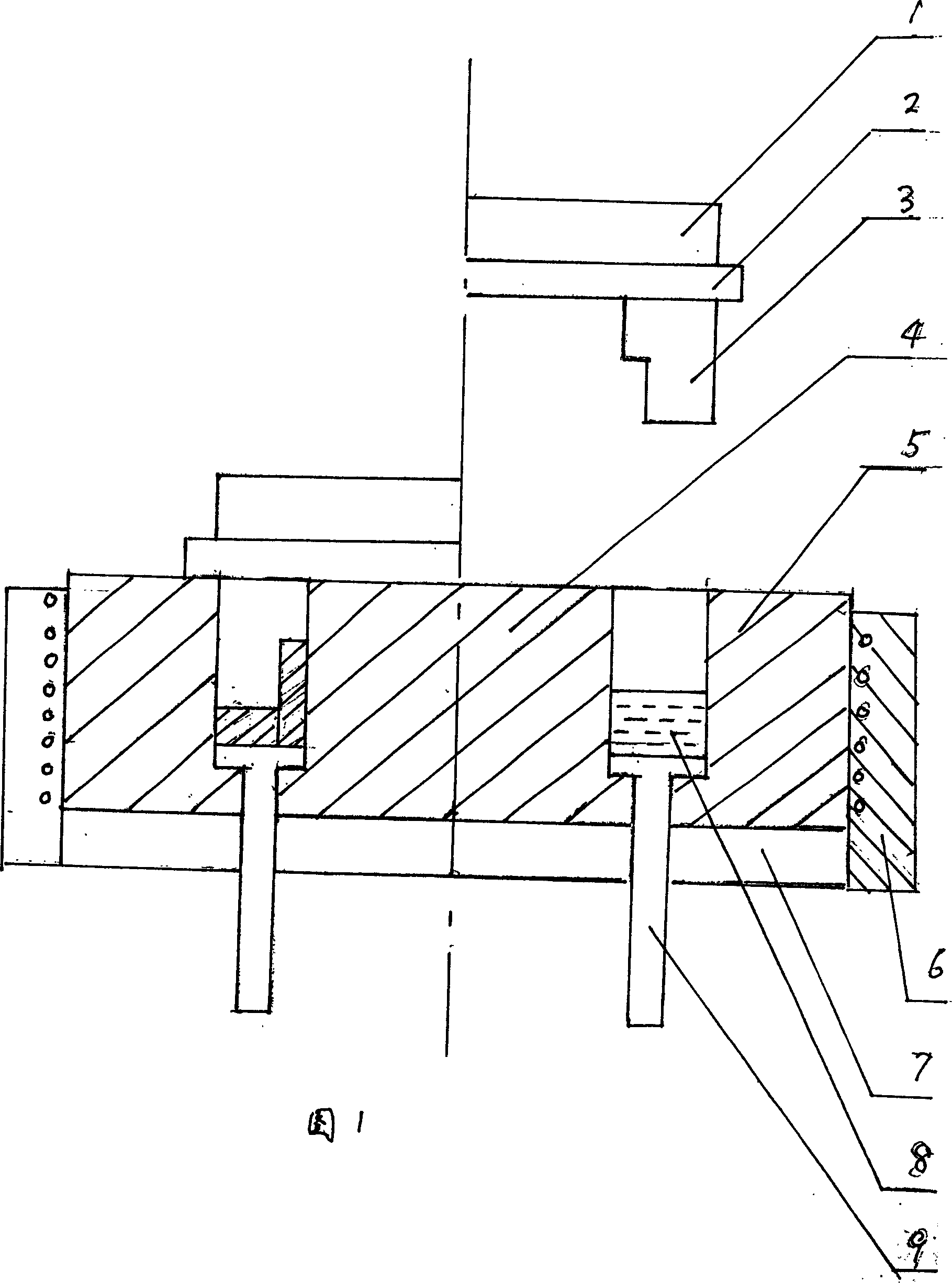

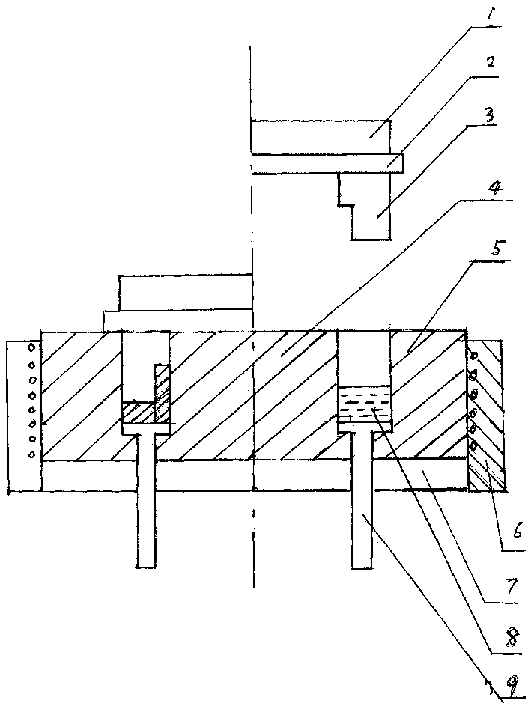

Image

Examples

Embodiment

[0021] LF 2R High neck flange, smelting alloy according to GB3193-82 standard, pouring at 700±15°C, mold temperature 250±50°C, mold closing time, pressure gradually rising time is not more than 5 seconds, when reaching 25MPa, hold pressure for 1 minute and 30 seconds Up to 2 minutes, open the touch, and eject the workpiece. In order to make the workpiece easy to come out, the lubricant can be sprayed in the inner cavity of the mold. The material of the flange is a deformed alloy, which is not suitable for casting. The performance of the flange prepared by the method of this embodiment reaches σ D ≥187Mpa, δ≥24%, good welding performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com