A high-strength high-magnesium aluminum alloy and its casting process

A high-magnesium-aluminum alloy, high-strength technology, applied in the field of high-strength, high-magnesium aluminum alloy and its casting process, can solve problems such as low strength, and achieve the effects of overcoming casting cracks, improving the appearance of castings, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

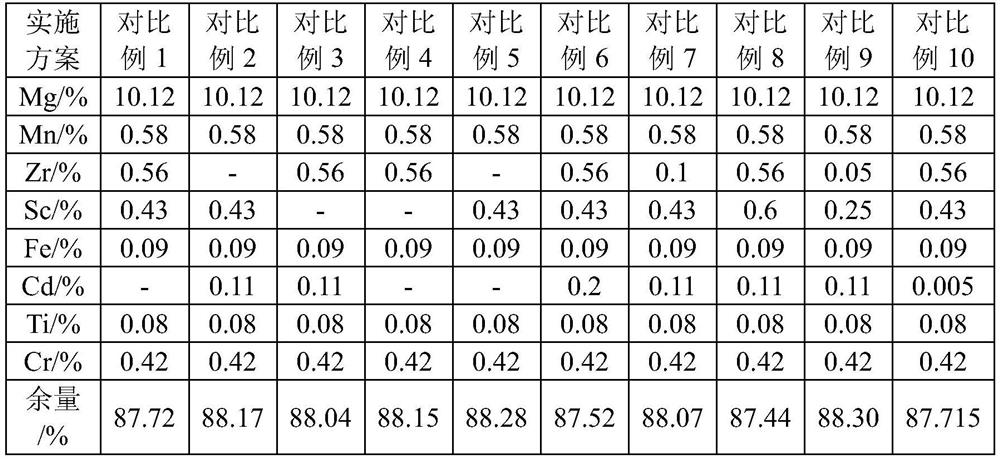

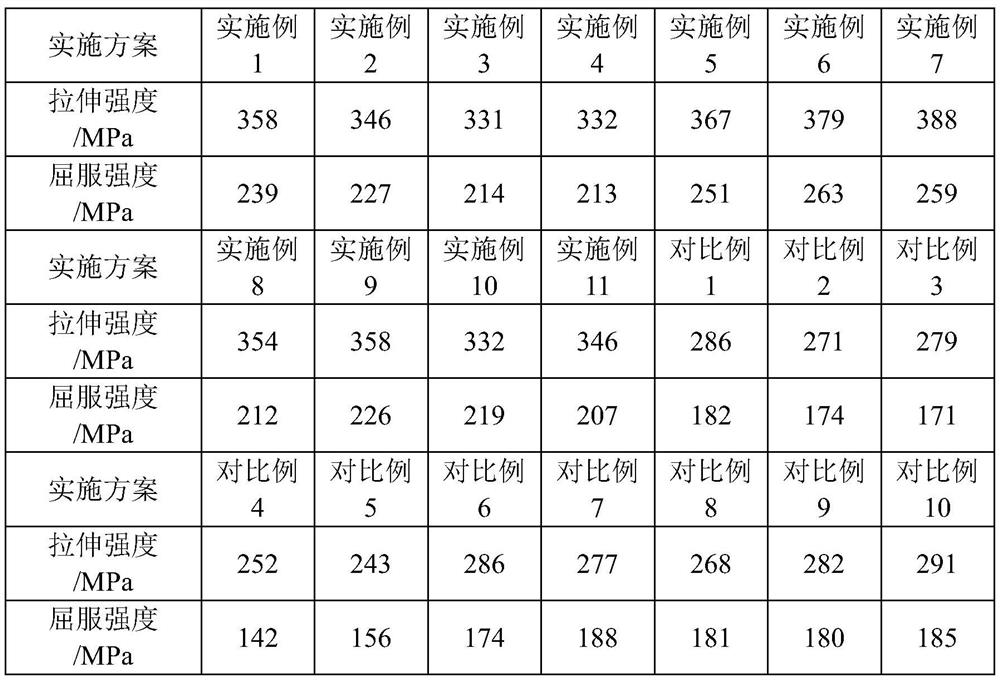

Examples

Embodiment 1

[0038] A high-strength high-magnesium aluminum alloy, the raw materials for preparing high-magnesium aluminum alloy include the following raw materials in mass percentage: Mg8.03%, Mn0.58%, Zr0.56%, Sc0.43%, Fe0.09%, Cd0.11%, Ti0.08 %, Cr 0.42%, the balance is Al and other unavoidable impurities.

[0039] The smelting process specifically includes the following steps:

[0040] S1. Prepare raw materials for preparing high-magnesium aluminum alloys according to the above proportions.

[0041] S2. Melting aluminum ingots: Melt aluminum ingots at a temperature of 750°C. After the aluminum ingots are smelted, heat preservation and smelting at a temperature of 750°C for 15 minutes, then add other alloy raw materials (Mg, Mn, Zr, Sc, Fe, Cd, Ti, Cr ), and smelt other alloy raw materials at a temperature of 750°C to obtain the initial smelting alloy liquid.

[0042] S3. After adding 0.07wt% refining agent to the initial smelting alloy liquid, carry out standing treatment at a temper...

Embodiment 2

[0047] A high-strength high-magnesium aluminum alloy, the raw materials for preparing high-magnesium aluminum alloy include the following raw materials in mass percentage: Mg7.96%, Mn 0.5%, Zr 0.1%, Sc 0.3%, Fe 0.01%, Cd 0.02%, Ti 0.03 %, Cr 0.3%, the balance is Al and other unavoidable impurities.

[0048] The smelting process specifically includes the following steps:

[0049] S1. Prepare raw materials for preparing high-magnesium aluminum alloys according to the above proportions.

[0050] S2. Melting aluminum ingots: Melt aluminum ingots at a temperature of 720°C. After the aluminum ingots are smelted, heat preservation and smelting at a temperature of 720°C for 18 minutes, then add other alloy raw materials (Mg, Mn, Zr, Sc, Fe, Cd, Ti, Cr ), and smelt other alloy raw materials at a temperature of 720°C to obtain the initial smelting alloy liquid.

[0051] S3. After adding 0.07wt% refining agent to the initial smelting alloy liquid, carry out standing treatment at a temp...

Embodiment 3

[0056] A high-strength high-magnesium aluminum alloy, the raw materials for preparing high-magnesium aluminum alloy include the following raw materials in mass percentage: Mg11.2%, Mn0.8%, Zr0.9%, Sc0.56%, Fe0.15%, Cd0.16%, Ti0.12 %, Cr 0.52%, the balance is Al and other unavoidable impurities.

[0057] The smelting process specifically includes the following steps:

[0058] S1. Prepare raw materials for preparing high-magnesium aluminum alloys according to the above proportions.

[0059] S2. Melting aluminum ingots: Melt aluminum ingots at a temperature of 780°C. After the aluminum ingots are smelted, heat preservation and smelting at a temperature of 780°C for 20 minutes, then add other alloy raw materials (Mg, Mn, Zr, Sc, Fe, Cd, Ti, Cr ), and smelt other alloy raw materials at a temperature of 780°C to obtain the initial smelting alloy liquid.

[0060] S3. After adding 0.07wt% refining agent to the initial smelting alloy liquid, carry out standing treatment at a temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com