An insulated lifting platform

A technology of lifting platforms and lifting frames, which is applied in the direction of lifting devices, etc., can solve problems such as live maintenance difficulties, large differences in structural specifications, and high electrical performance requirements, and achieve the effects of facilitating manual handling, improving power supply capacity, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

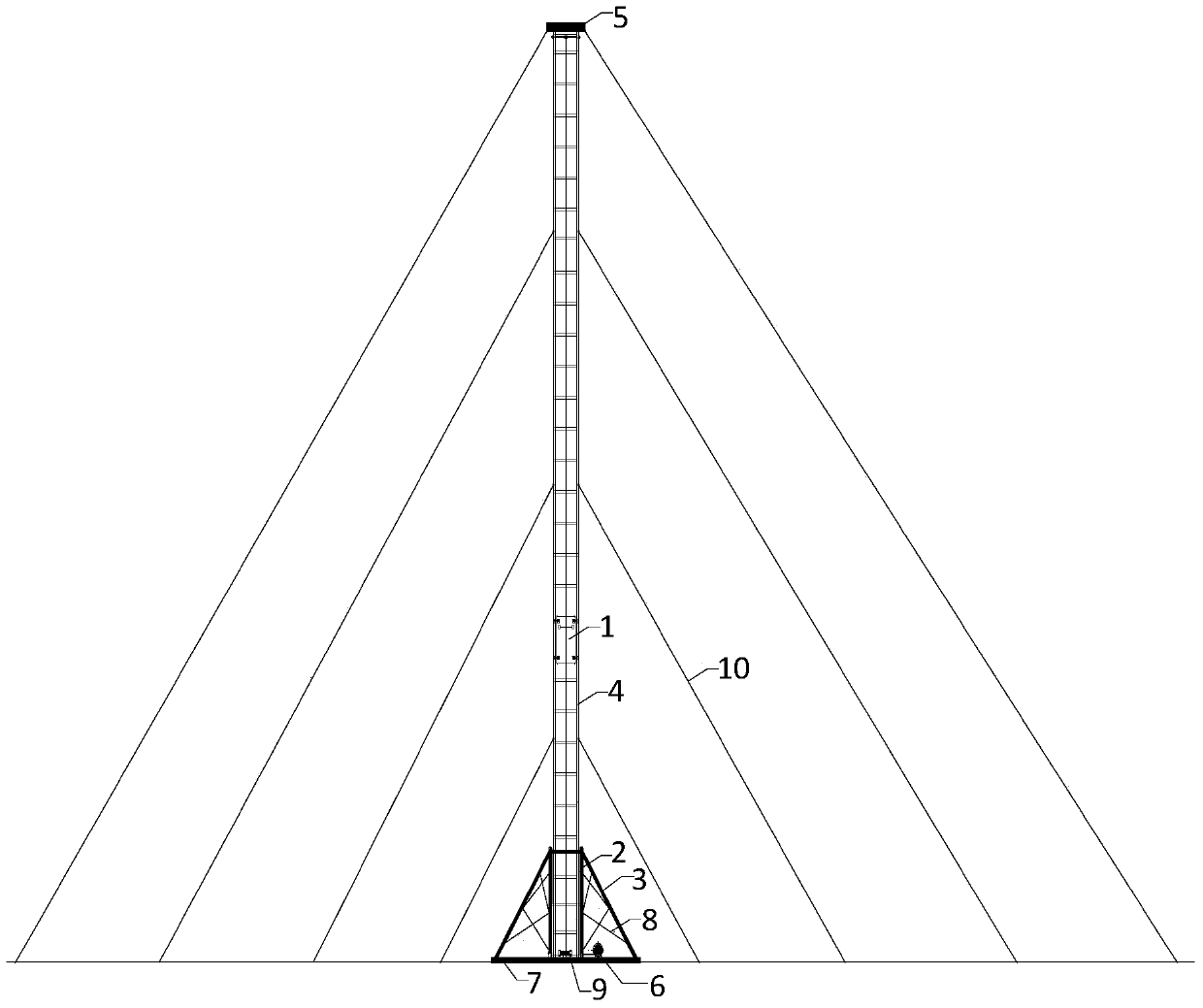

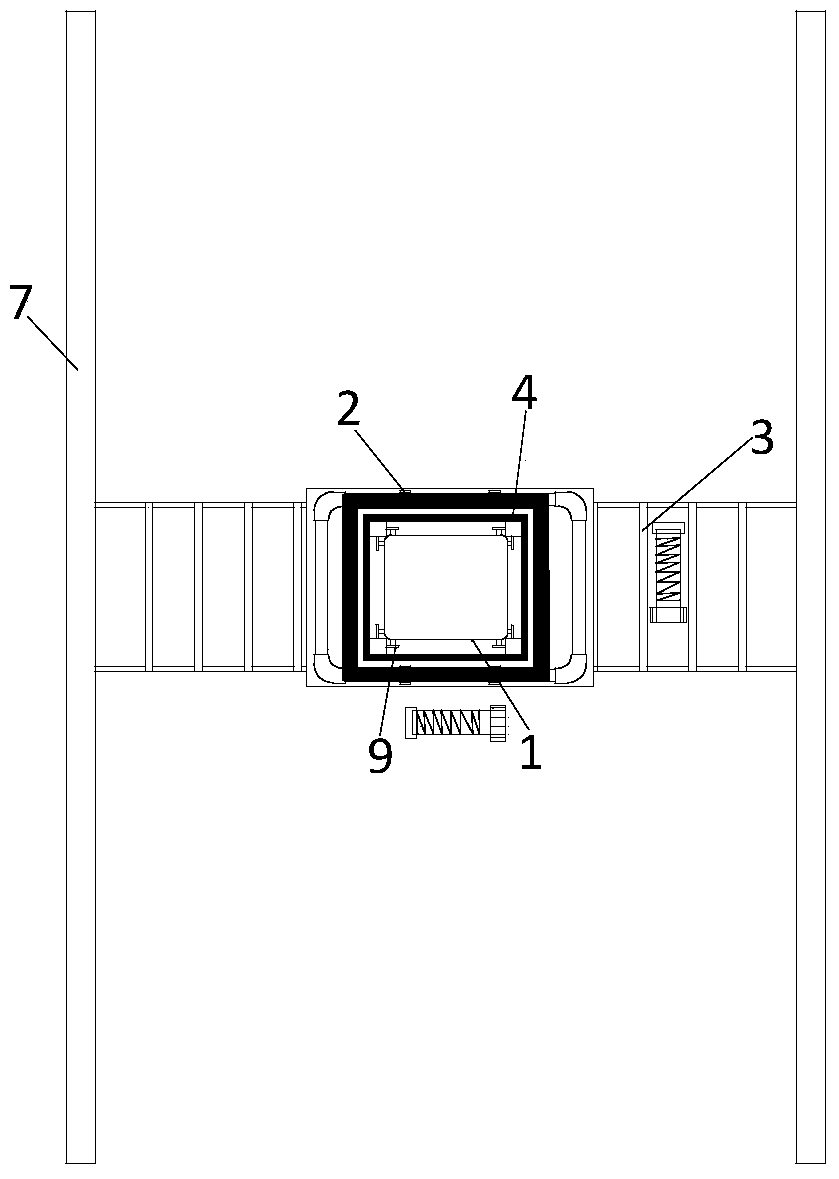

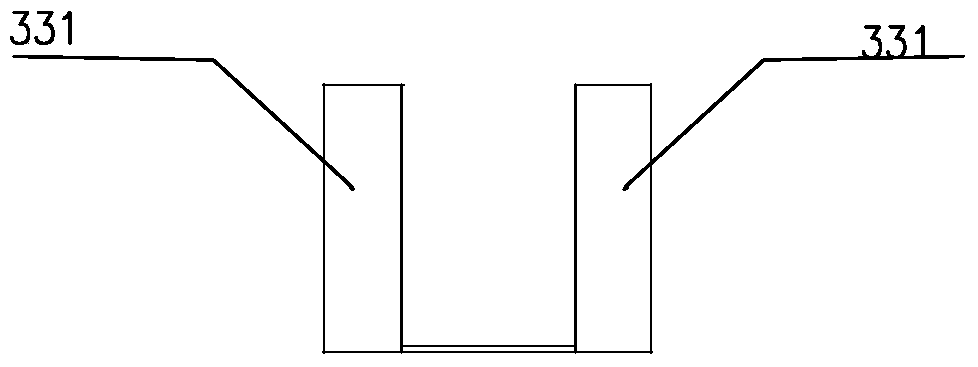

[0042] An insulated lifting platform for live work in a UHV substation, including a lifting basket, a pole frame, an aluminum alloy ladder, a lifting frame, a working platform, a winch for the lift, a base, a diagonal brace, a winch for lifting the hanging basket, and a wind rope; Two aluminum alloy ladders are arranged on the base of the insulating lifting platform. One side of the aluminum alloy ladder is vertical and the other side is inclined. A support rod is provided between the vertical surface and the inclined surface; The vertical surfaces are connected to each other by frame beams to form the frame of the insulating lifting platform. The door side of the lifting basket has frame beams on the upper part, and the lower part has no frame beams for the access of the lifting frame. Frame beam; lifting frame is provided in the middle of the frame of the lifting platform, and two adjacent lifting frames are connected through a connecting kit, and a lifting frame fixing kit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com