Production process of aluminum alloy shell for electronic product

A technology of electronic products and production process, which is applied in the field of aluminum alloys, can solve the problems that cannot meet the development requirements of large-screen and thinner consumer electronic products, and cannot meet consumers' high decorative requirements for the appearance of electronic products. The texture is not fine enough, etc., to achieve the effect of reducing hair crystals and columnar crystals, improving mechanical properties, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

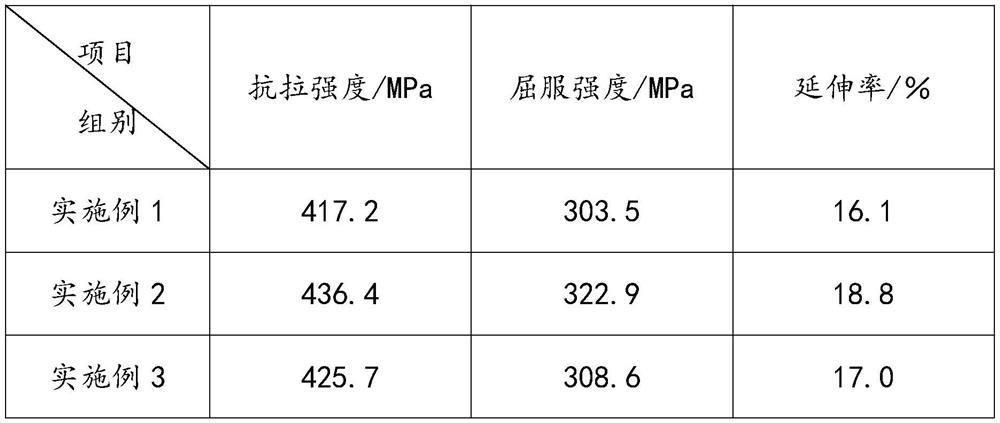

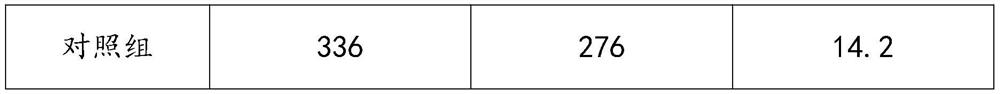

Examples

Embodiment 1

[0035] A production process for an aluminum alloy casing for an electronic product, comprising the steps of:

[0036] Step 1: Raise the temperature of the melting furnace to 770°C, and put 102 aluminum alloy into the furnace to melt;

[0037] Step 2: Keep the temperature of the furnace constant, stir for 6 minutes, let stand for 8 minutes, remove the scum on the surface of the molten aluminum, and cycle stirring-stand-removing slag 3 times;

[0038] Step 3: Raise the temperature of the melting furnace to 830°C, then add zinc ingots, aluminum-copper master alloys, aluminum-manganese master alloys, aluminum-zirconium master alloys, and aluminum-yttrium master alloys into the melting furnace, stir and melt to form aluminum alloy liquid A;

[0039] Step 4: Magnetically stir the aluminum alloy liquid A in step 3 for 3 minutes, then let it stand for 4 minutes, then stir again, stir in a cycle-stand until the temperature of the aluminum alloy liquid drops to 725°C, keep the temperatu...

Embodiment 2

[0057] A production process for an aluminum alloy casing for an electronic product, comprising the steps of:

[0058] Step 1: Raise the temperature of the melting furnace to 800°C, and put 102 aluminum alloy into the furnace to melt;

[0059] Step 2: Keep the temperature of the furnace constant, stir for 8 minutes, let stand for 12 minutes, remove the scum on the surface of the aluminum liquid, and cycle stirring-stand-slagging-removing 4 times;

[0060] Step 3: Raise the temperature of the melting furnace to 860°C, then add zinc ingots, aluminum-copper master alloys, aluminum-manganese master alloys, aluminum-zirconium master alloys, and aluminum-yttrium master alloys into the melting furnace, stirring and melting to form aluminum alloy liquid A;

[0061] Step 4: Magnetically stir the aluminum alloy liquid A in step 3 for 5 minutes, then let it stand for 6 minutes, then stir again, stir in a cycle-stand still until the temperature of the aluminum alloy liquid drops to 750°C, ...

Embodiment 3

[0079] A production process for an aluminum alloy casing for an electronic product, comprising the steps of:

[0080] Step 1: Raise the temperature of the melting furnace to 785°C, and put 102 aluminum alloy into the furnace to melt;

[0081] Step 2: Keep the temperature of the furnace constant, stir for 7 minutes, let stand for 10 minutes, remove the scum on the surface of the aluminum liquid, and cycle stirring-stand-slagging-removing 4 times;

[0082] Step 3: Raise the temperature of the melting furnace to 845°C, then add zinc ingots, aluminum-copper master alloys, aluminum-manganese master alloys, aluminum-zirconium master alloys, and aluminum-yttrium master alloys into the melting furnace, stir and melt to form aluminum alloy liquid A;

[0083] Step 4: Magnetically stir the aluminum alloy liquid A in step 3 for 4 minutes, then let it stand for 5 minutes and then stir again, stir in a cycle-stand until the temperature of the aluminum alloy liquid drops to 740°C, keep the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com