Preparation method of wear-resistant metal-multi-component ceramic composite modified coating on titanium alloy surface

A wear-resistant metal and ceramic composite technology, which is applied in the coating process and coating of metal materials, can solve the problems of material waste, deviation, coating hardness cracks, etc., achieve good toughness, obvious grain refinement, and improve durability The effect of grinding performance

Active Publication Date: 2022-06-03

YANSHAN UNIV

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In recent years, research on wear-resistant coatings on the surface of laser cladding titanium alloys has been widely carried out, but there are still many problems to be solved urgently, such as the balance between the hardness and toughness of the coating, the problem that cracks are easy to occur when the hardness of the coating is too high, etc.

In addition, because laser processing is different from traditional processing such as casting, it is open processing. At the moment of laser irradiation, the metal-ceramic elements added to the powder material are melting and decomposing, and even evaporation or ablation occurs, which is very complicated. The physical and chemical changes caused by the waste of materials also deviate from the original intention of the design

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

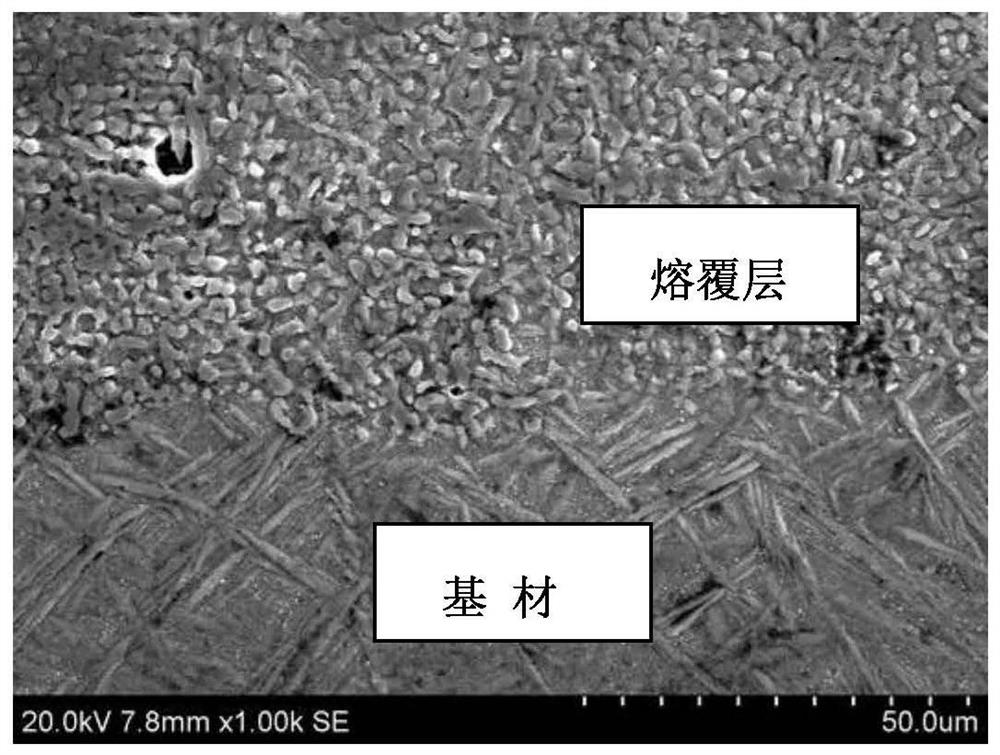

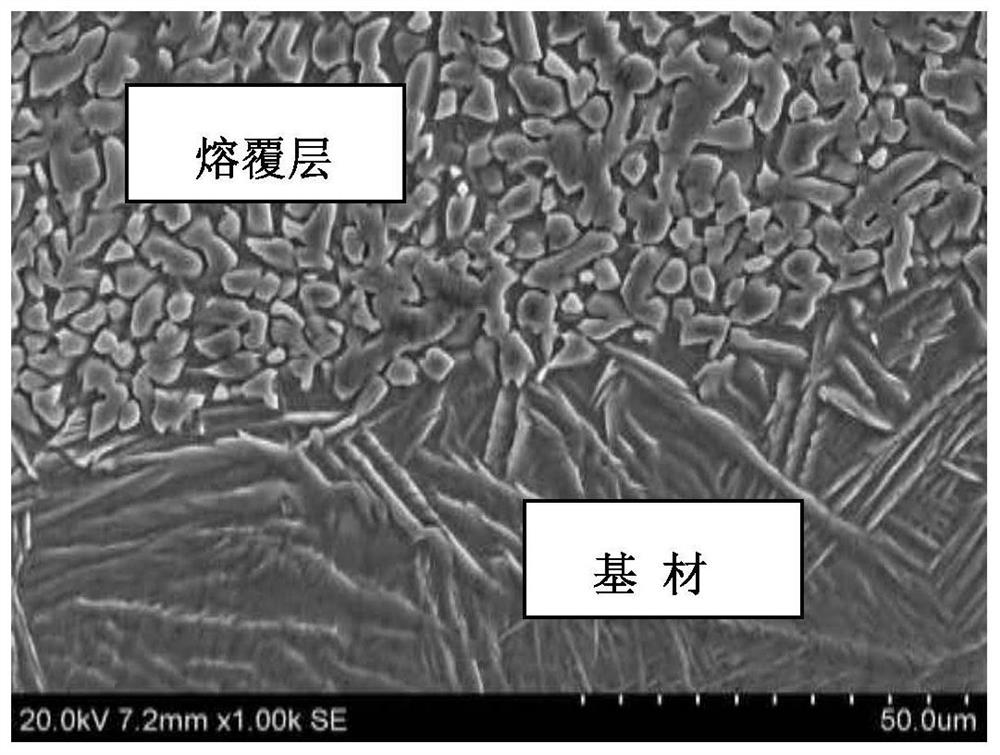

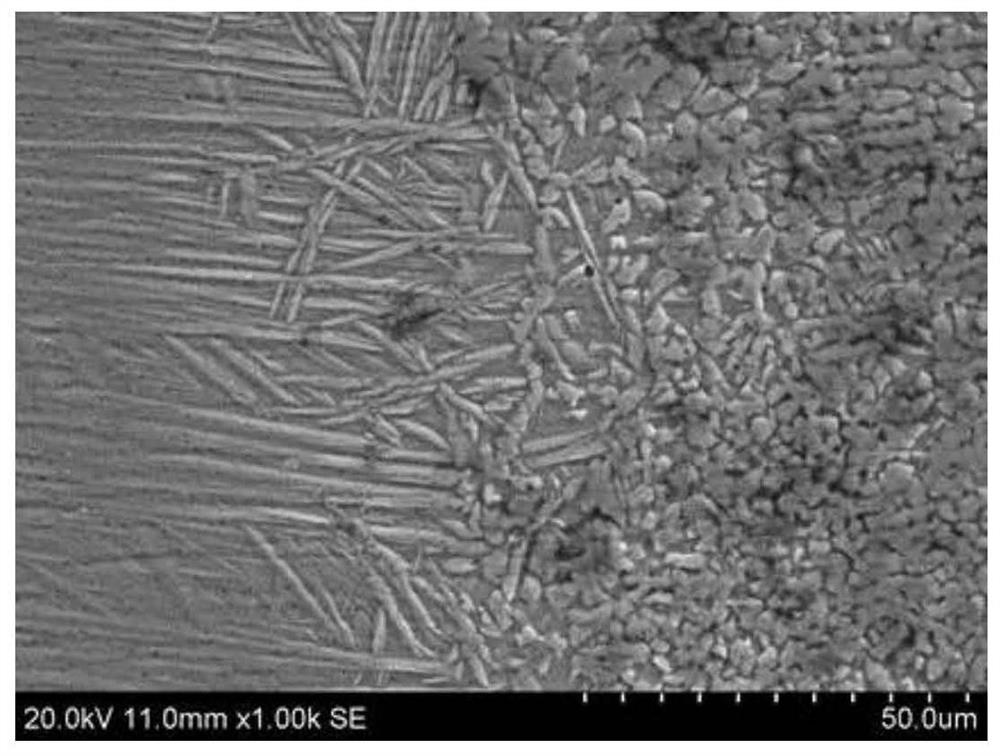

The invention relates to a method for preparing a wear-resistant metal-multi-element ceramic composite modified coating on the surface of titanium alloy, which belongs to the technical field of surface engineering and comprises the following steps: (1) preparing pre-alloyed powder for use; (2) using industrial alcohol Clean the surface of the substrate to be clad, and then blacken the surface of the substrate; (3) Convey the pre-alloyed powder prepared in step (1) to the substrate to be clad in step (2) through coaxial powder feeding Laser cladding was carried out on the surface of the material to prepare a wear-resistant metal-multi-element ceramic composite modified coating on the titanium alloy surface. The composite modified coating prepared by the present invention has obvious grain refinement, which achieves the purpose of fine-grain strengthening, ensures that the coating has high toughness while having high hardness, thereby greatly improving the wear resistance of titanium alloys, and further improving the performance of titanium alloys. The service life of the alloy under complex working conditions.

Description

Preparation method of wear-resistant metal-multi-component ceramic composite modified coating on titanium alloy surface technical field The present invention relates to a kind of preparation method of titanium alloy surface wear-resistant metal-multicomponent ceramic composite modified coating, belonging to surface engineering technology. Background technique [0002] Titanium alloys are widely used in aerospace and Petrochemical and other engineering fields. However, due to the high friction coefficient, poor wear resistance, and low high temperature oxidation resistance of titanium alloys There are shortcomings, which will seriously affect the service life of its service parts, and also limit its wider application in the aerospace industry. Studies have shown that surface modification techniques such as laser cladding are effective means to improve the surface properties of titanium alloys. Laser cladding technology is a kind of using high-energy laser and metal p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C24/10C22C14/00C22C32/00B22F9/04

CPCC23C24/103B22F9/04C22C32/0052C22C14/00B22F2009/043B22F2009/041

Inventor 郑立娟闫茂荣田宁刘绍峰张阔付宇明

Owner YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com