Patents

Literature

37results about How to "Poor toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

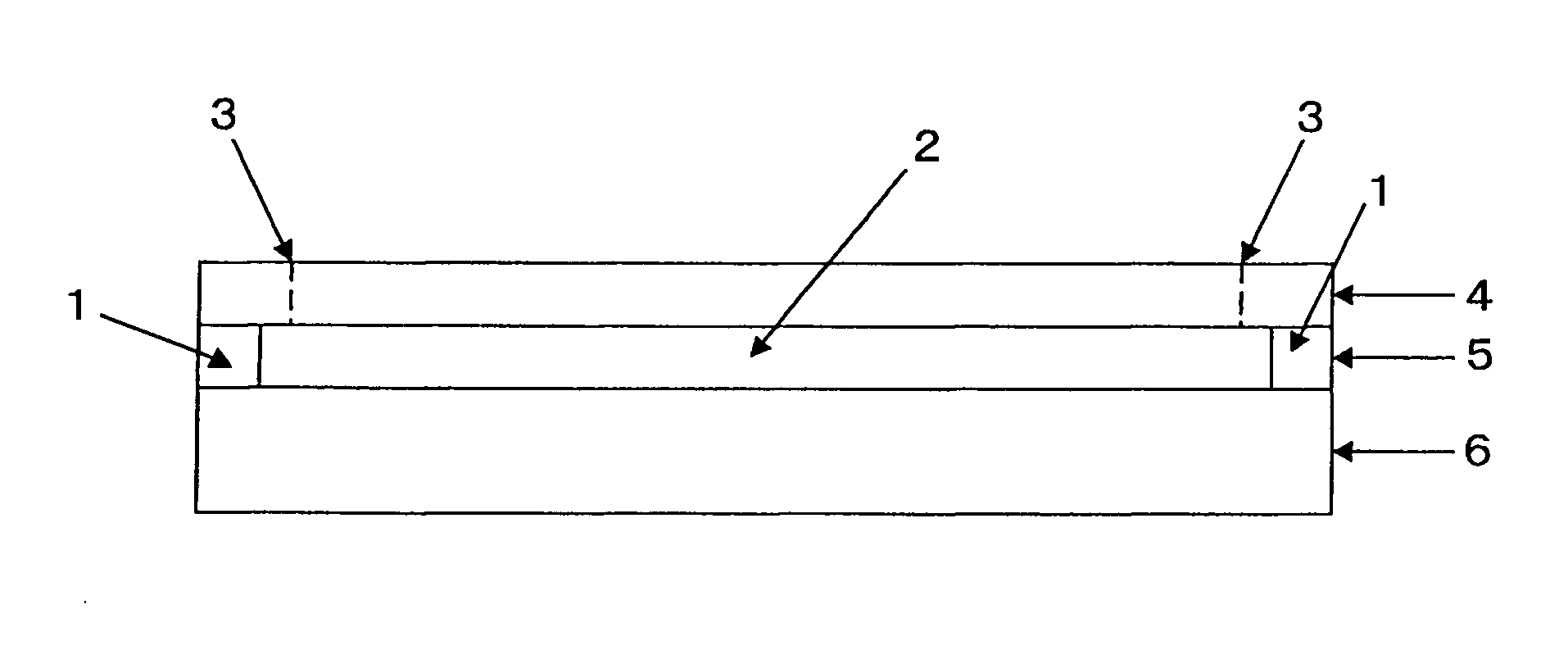

Method for fixing plastic substrate, circuit substrate and method for producing same

InactiveUS20080099134A1Strength and toughness be poorSmoothly cut outLamination ancillary operationsSolid-state devicesControl treatmentAdhesive materials

A method for fixing a plastic substrate, comprising (1) applying or sticking an adhesive material onto a supporting substrate to form an adhesive material layer on the supporting substrate, (2) applying selective adhesive strength controlling treatment to the adhesive material layer to form at least two regions of a low adhesive strength region and a high adhesive strength region, and (3) applying under pressure a plastic substrate to the adhesive material layer at most 300 Torr.

Owner:FUJIFILM CORP

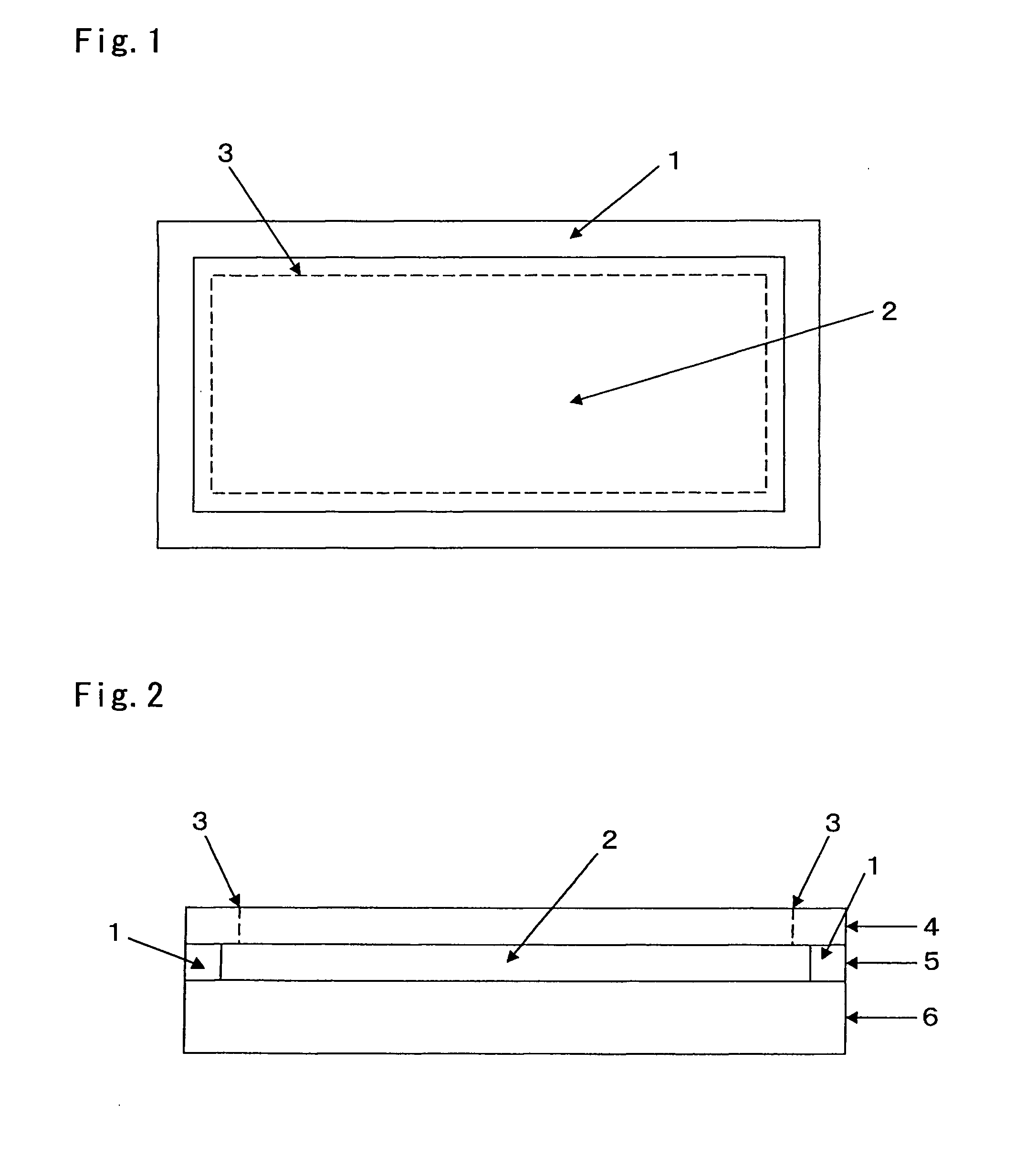

Preform for composite material and composite material

InactiveUS20040137208A1Excellent interlaminar debonding propertyPoor toughnessSynthetic resin layered productsNon-woven fabricsTransfer moldingFiber-reinforced composite

A preform can be molded by resin transfer molding and yields a composite material having excellent strength and excellent interlaminar debonding resistance. The preform, which is for producing a fiber-reinforced composite, comprises layers of laminated structure of a reinforcing material comprising reinforcement fibers and has, between these layers, a layer comprising a thermoplastic resin and having space so as not to inhibit a liquid resin from flowing therethrough. The preform is molded to yield a fiber-reinforced composite material.

Owner:MITSUBISHI CHEM CORP

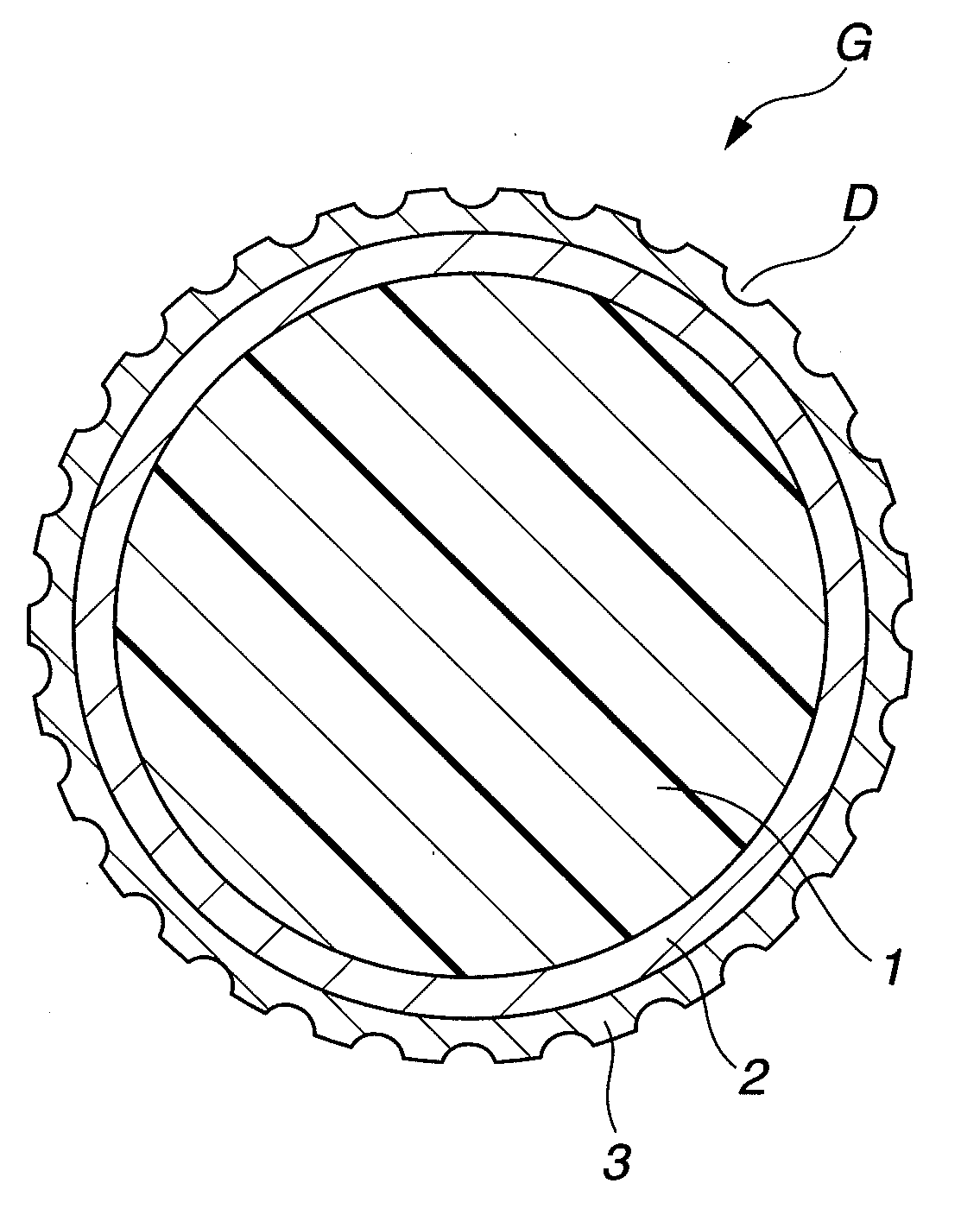

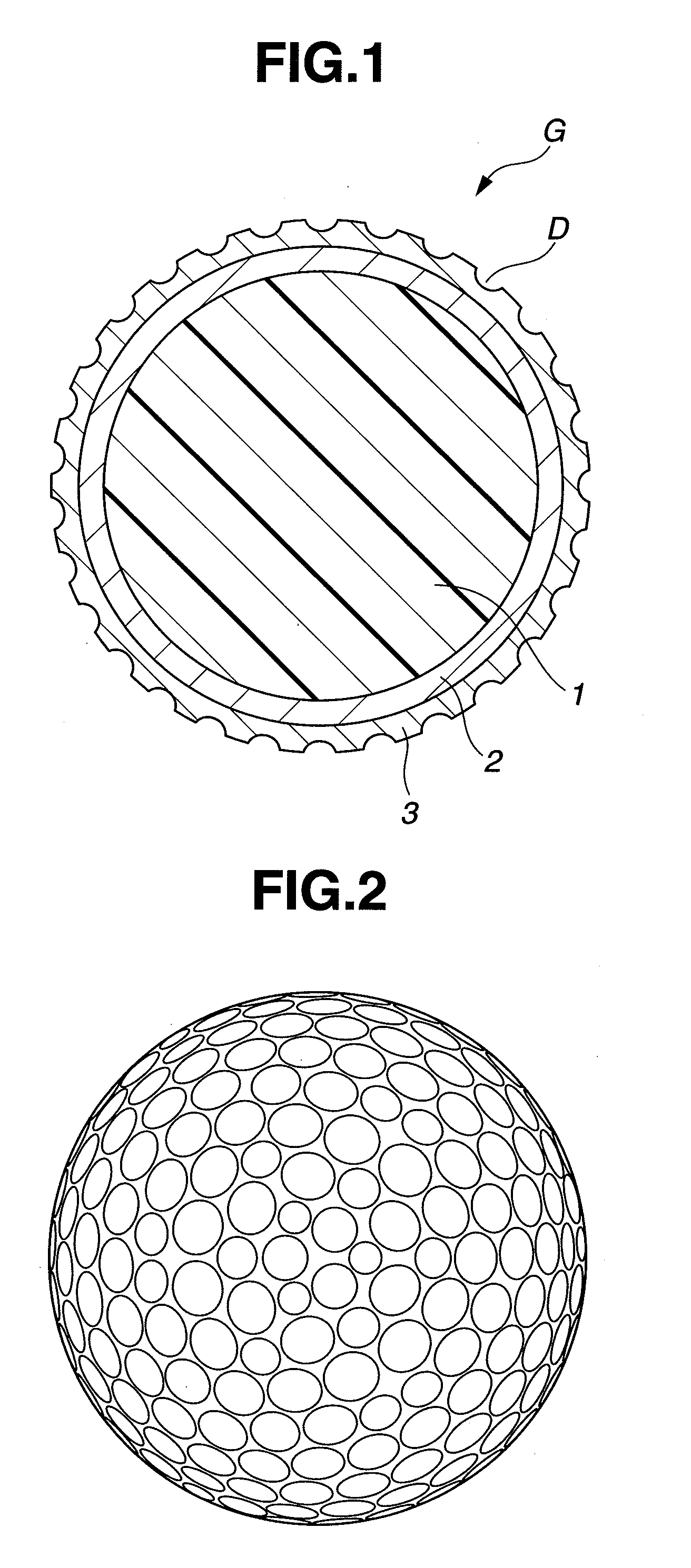

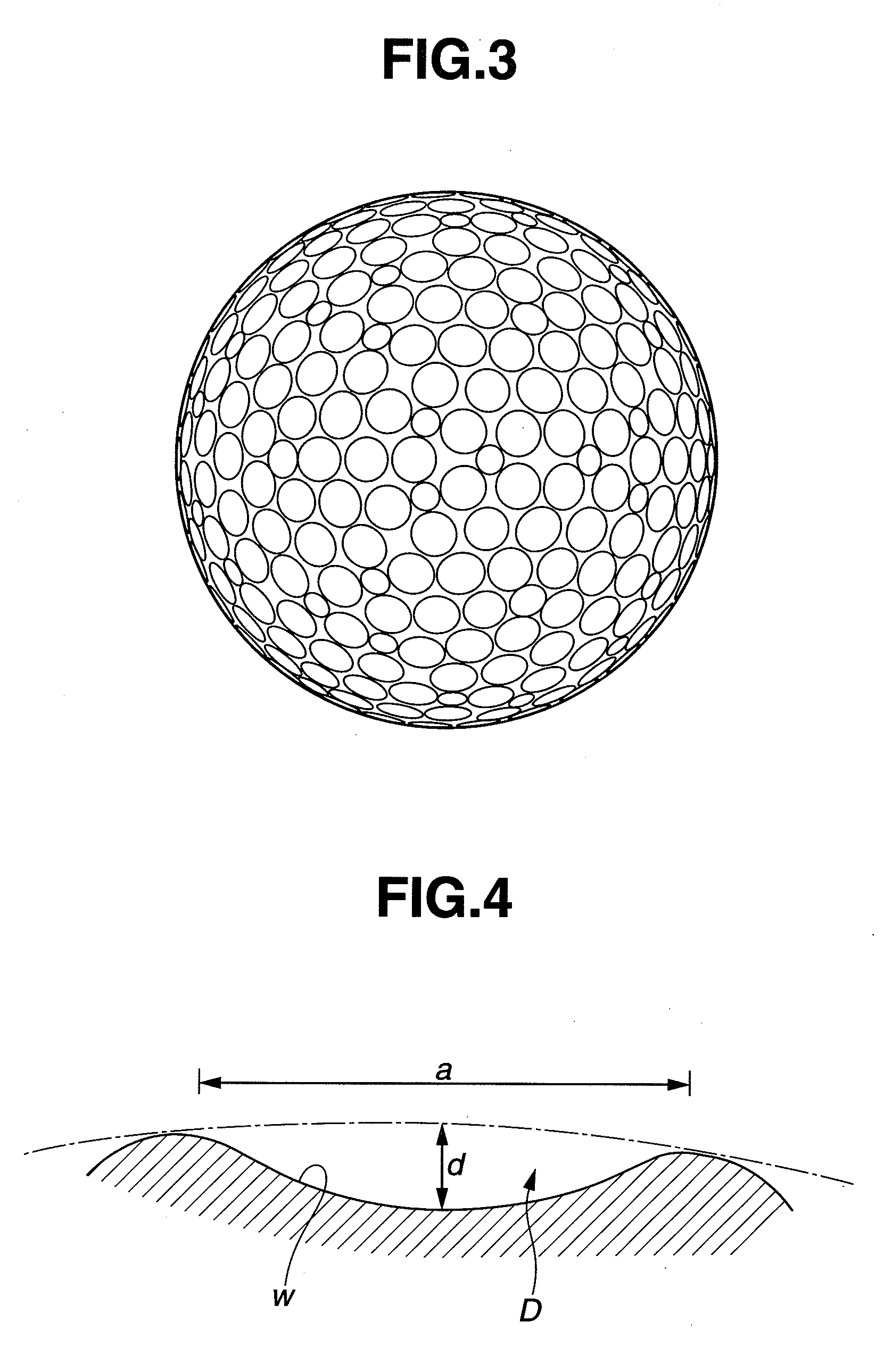

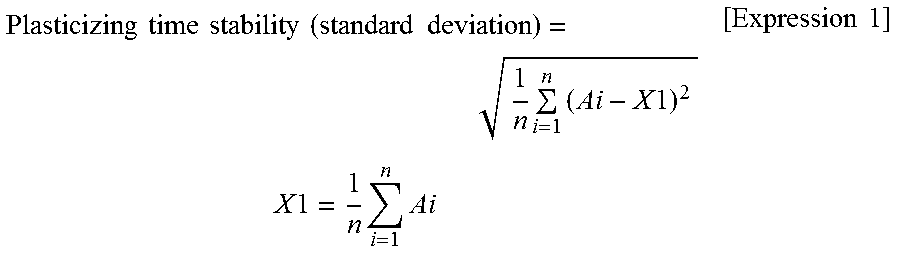

Golf ball

InactiveUS20090209366A1Slow down the spin rateImprove wear resistanceGolf ballsSolid ballsEngineeringHardness

The invention provides a golf ball composed of a core, a cover having a plurality of dimples on an outside surface thereof, and an intermediate layer disposed between the core and the cover. The core has a deflection, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of at least 3.0 mm but not more than 5.0 mm. The intermediate layer is formed of a highly neutralized resin material, and has a Shore D hardness of at least 40 but not more than 60 and a thickness of at least 1.7 mm but not more than 4.0 mm. The number of dimples is at least 272 but not more than 348. The golf ball, through a combination of dimples which do not cause a loss of lift in the low-velocity, low-spin rate region of the ball trajectory and a low-spin construction, travels farther and is therefore beneficial for competitive use by both skilled and amateur golfers.

Owner:BRIDGESTONE SPORTS

Tool made of cubic boron nitride sintered body

InactiveUS20130291446A1Prevent rapid cooling of a workpieceLow thermal conductivityPigmenting treatmentOther chemical processesMetallurgyBoron nitride

A tool includes a cubic boron nitride sintered body at least at a tool working point. The cubic boron nitride sintered body contains cubic boron nitride, a heat insulating phase, and a binder phase. Cubic boron nitride is contained in the cubic boron nitride sintered body by not less than 60 volume % and not more than 99 volume %, and the heat insulating phase includes one or more types of first compound composed of one or more types of element selected from the group consisting of Al, Si, Ti, and Zr and one or more types of element selected from the group consisting of N, C, O, and B. The first compound is contained in the cubic boron nitride sintered body by not less than 1 mass % and not more than 20 mass % and it has an average particle size smaller than 100 nm.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Layered polyamide film

InactiveUS20070160806A1Prevent peelingExcellent in resistanceSynthetic resin layered productsBoxesPHENOL LIQUIDLayered structure

A polyamide-based laminated film with a multi-layered structure including 5 or more layers, having (a) an aromatic polyamide layer, (b) an aliphatic polyamide layer and (c) a layer made of a mixture containing an aromatic polyamide and an aliphatic polyamide at a weight ratio of 5:95 to 20:80. Layer (c) disposed adjacent to layer (a) and / or (b), and said film having 5 or less pinholes per 497 cm2. The polyamide-based laminated film in which at least one layer of the film is a polyamide-based resin layer containing a hindered phenol-based antioxidant in an amount of 0.01 to 0.5% by weight, and a thickness of the polyamide-based resin layer is 10% or more but less than 80% of a whole thickness of the film, the resultant laminated film is further excellent in hydrothermal resistance and adhesion to other plastic films and, therefore, can be suitably used as a packaging material for foods, medical products and drugs or chemicals which tend to be deteriorated in quality upon exposure to oxygen.

Owner:MITSUBISHI PLASTICS INC

Polyvinyl chloride modifier and composite, and preparation method therefor

ActiveUS20160115308A1Increase stirring intensityLow viscosityLiquid surface applicatorsSynthetic resin layered productsPolyvinyl chlorideToughening

The present invention discloses a polyvinyl chloride modifier, composition and a preparation method thereof. The composition comprises the following components by parts by weight: (a) polyvinyl chloride resin of 100 parts, and (b) a toughening modifier of 2-16 parts, the toughening modifier being rubber powder whose an elongation at break is greater than 2201% and which contains weight percentage of chlorine of 5-45 wt %. The elongation at break of the polyvinyl chloride composition of the present invention is greatly improved, and the defect of low elongations at break of polyvinyl chloride product is substantially solved accordingly, therefore, the application scope of polyvinyl chloride surely will be greatly widened.

Owner:SHANDONG RIKE CHEM

Polyamide, polyamide composition, and molded article

ActiveUS20150175744A1Excellent high temperature strengthGood fatigue resistanceSpecial tyresDiaminePolyamide

A polyamide comprising a unit containing at least one (a) alicyclic dicarboxylic acid and a unit containing a (b) diamine having 8 or more carbon atoms, wherein the polyamide satisfies the following conditions (1) and (2): (1) a sulfuric acid relative viscosity ηr at 25° C. is 2.3 or more; and (2) Mw (weight average molecular weight) / Mn (number average molecular weight) is 4.0 or less.

Owner:ASAHI KASEI CHEM CORP

High-elasticity skin-softening type polyurethane condom and preparation method thereof

The invention relates to a high-elasticity skin-softening type polyurethane condom and a preparation method thereof. The condom is prepared from the following raw materials in parts by weight: 80-100parts of an emulsion containing 25-30% of an unsaturated group, namely polyester polyol, in percentage by mass, 20-25 parts of an emulsion containing 15-20% of an unsaturated group, namely polyester polyol, in percentage by mass, 0.5-1 part of a closed isocyanate cross-linking agent, 0.2-0.5 part of a defoaming agent, 0.2-0.5 part of an aqueous adhesion promoter, 2-3 parts of a fulvic acid sealant, 3-5 parts of graphite, 50-80 parts of a sodium sulfate solution which is 1% in mass percentage, an adequate amount of absolute ethyl alcohol and an adequate amount of pure water; and the preparationmethod comprises three steps, namely preparing an inner layer stock solution, preparing an outer layer stock solution and shaping the condom. The condom provided by the invention is high in strength,high in elasticity and strong in skin affinity.

Owner:海氏海诺乳胶(青岛)有限公司

Cubic boron nitride sintered body tool

ActiveUS8993132B2Improve performanceProlong lifePigmenting treatmentMaterial nanotechnologyMetallurgyBoron nitride

A cubic boron nitride sintered body tool has, at least at a cutting edge, a cubic boron nitride sintered body composed of a cubic boron nitride particle and a binder phase. The binder phase contains at least Al2O3 and a Zr compound. On any straight line in the sintered body, the mean value of a continuous distance occupied by Al2O3 is 0.1-1.0 μm, and the standard deviation of the continuous distance occupied by Al2O3 is not more than 0.8. On the straight line, X / Y is 0.1-1 where X represents the number of points of contact between Al2O3 and the Zr compound, and Y represents the sum of the number of points of contact between Al2O3 and cBN and the number of points of contact between Al2O3 and binder phase component(s) other than Al2O3 and the Zr compound.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

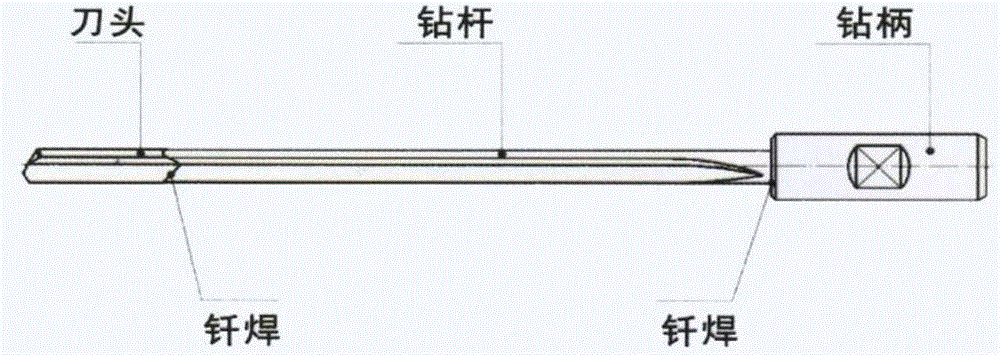

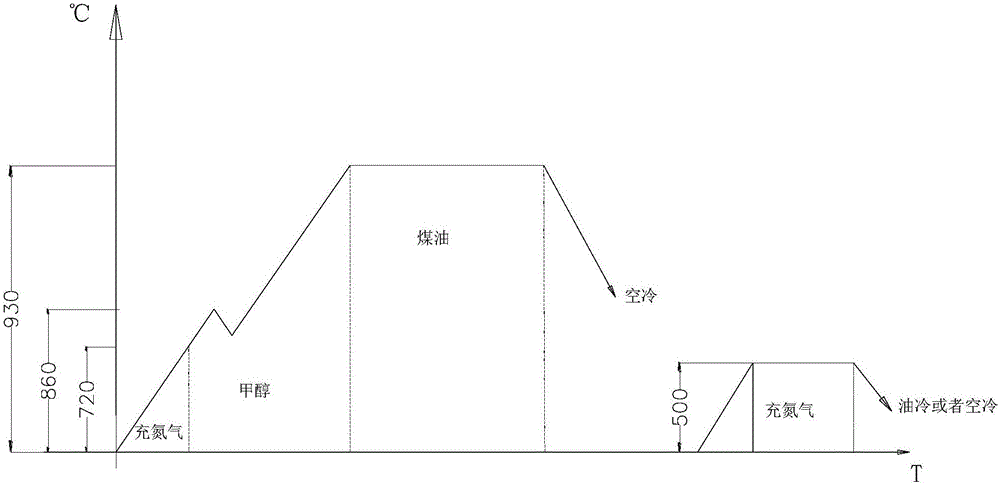

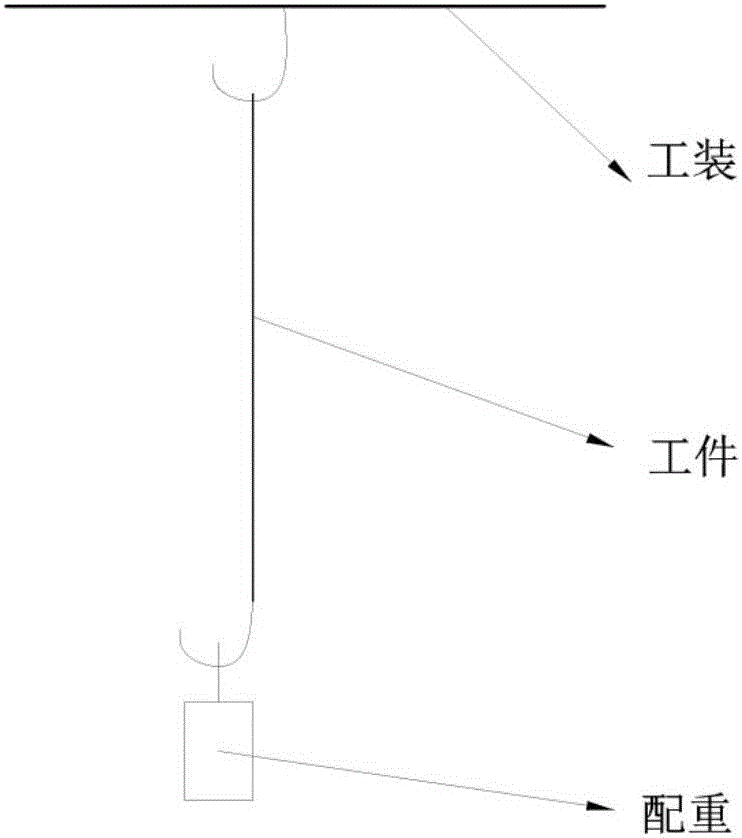

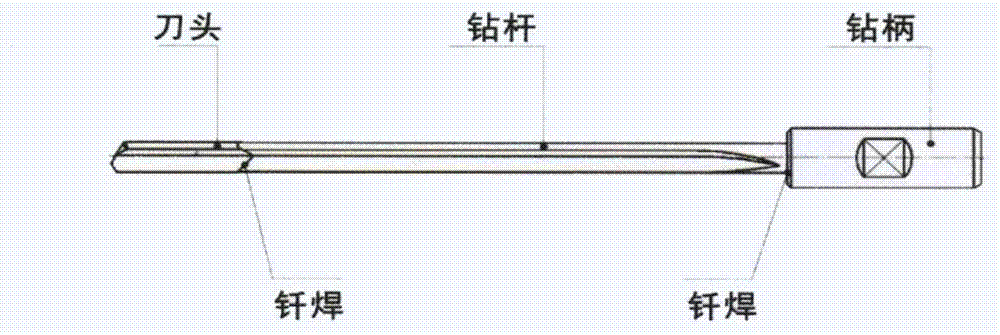

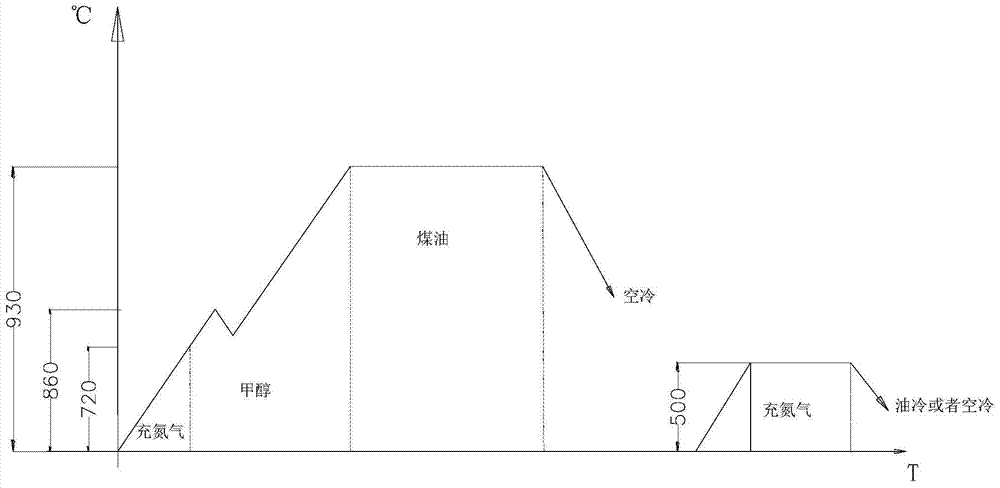

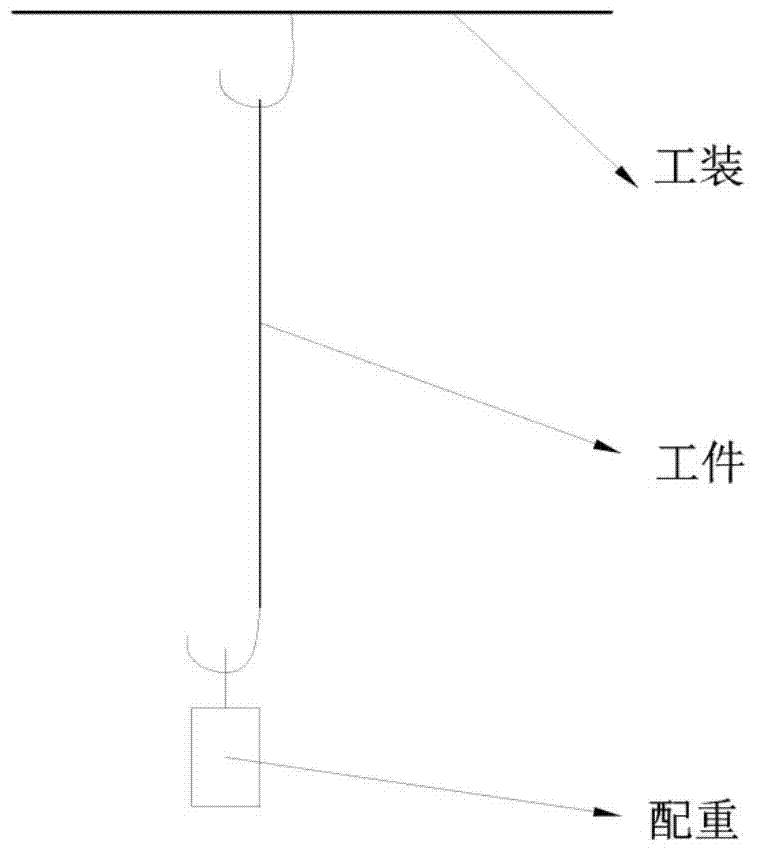

Strengthening, toughening and straightening process for deep hole machining gun-drill drill rod

ActiveCN105063323AHigh alloy contentHigh strengthSolid state diffusion coatingFurnace typesShielding gasQuenching

The invention relates to the technical field of machining methods of deep hole machining equipment, in particular to a strengthening, toughening and straightening process for a deep hole machining gun-drill drill rod. The process includes the following steps that 1) material selection, pipe manufacturing and forming are conducted, and superior alloy steel or tool steel or carburizing steel is selected and machined to form the deep hole machining gun-drill drill rod before heat treatment; 2) heat treatment strengthening, toughening and straightening are integrated, the deep hole machining gun-drill drill rod before heat treatment is vertically hung on a tool, a balance weight is hung at the bottom end of the deep hole machining gun-drill drill rod, and carburizing, quenching, balance weight automatic straightening or quenching and automatic straightening are conducted; and 3) tempering, straightening and cooling are conducted. Compared with the prior art, the superior alloy steel or tool steel or carburizing steel is selected as raw materials, through heat treatment of a controlled atmosphere furnace, a vacuum furnace and a high-frequency furnace and under the gravity effect of the balance weight, automatic straightening or carburizing steel carburizing and quenching are conducted, the carbon content is increased, and toughness is enhanced; heat treatment strengthening, toughening and straightening are integrated, and automatic straightening is achieved in the tempering process.

Owner:佛山市云昇金属科技有限公司

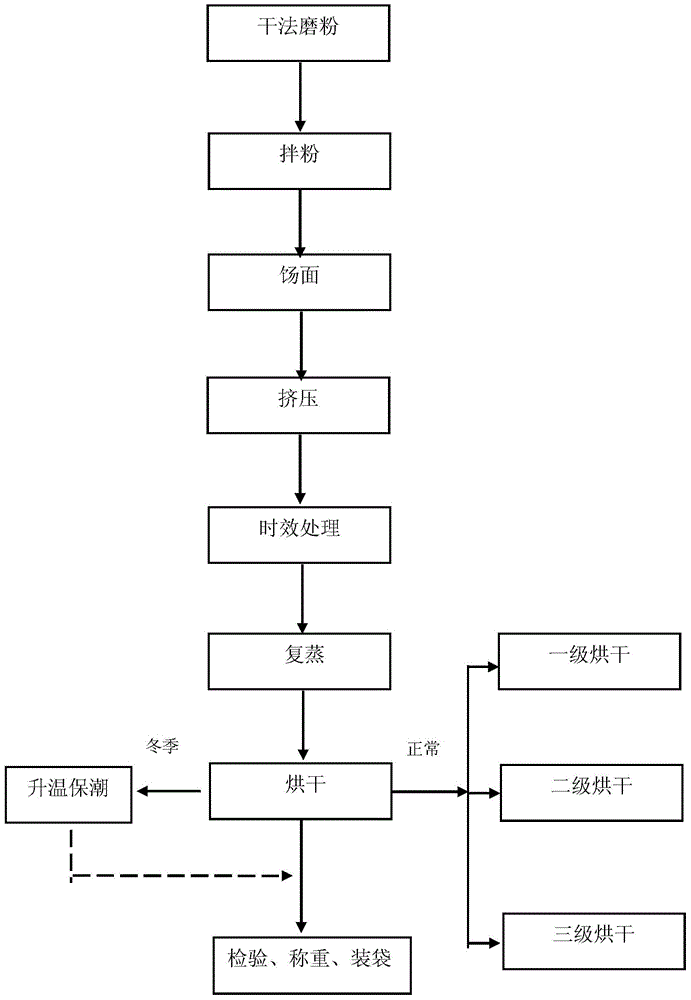

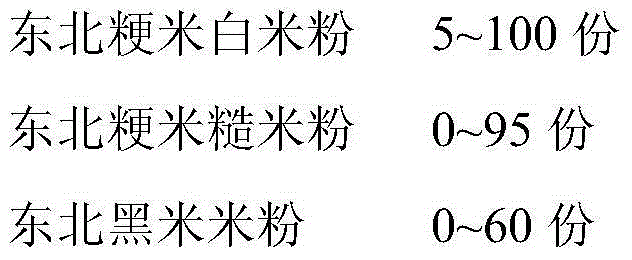

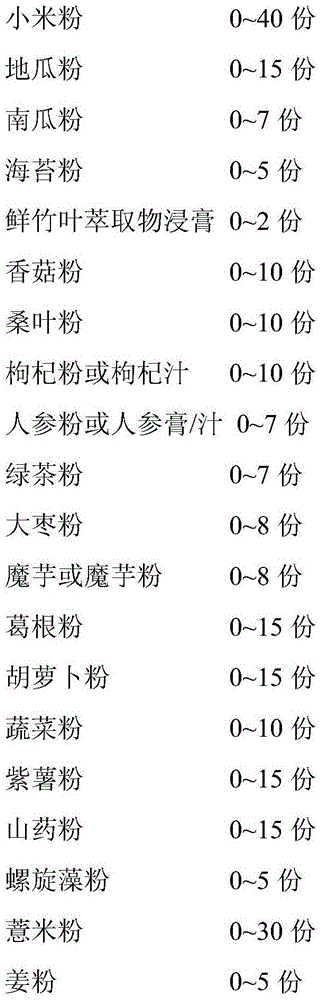

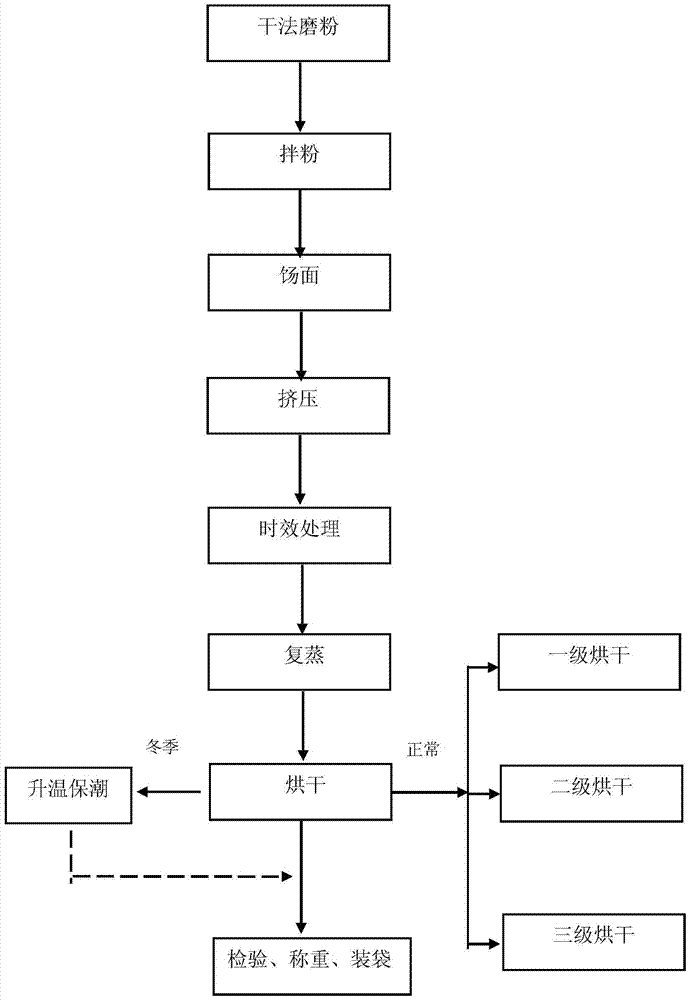

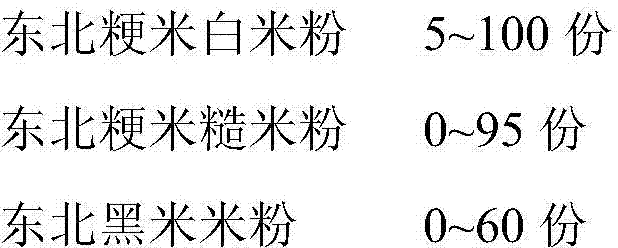

Gluten-free instant hand-pulled noodles and preparation method and formula thereof

ActiveCN104366277AReduce amylose contentBad tasteFood thermal treatmentFood dryingSafety indexAdditive ingredient

The invention provides gluten-free instant hand-pulled noodles and a preparation method and a formula thereof and relates to the field of food deep processing. The gluten-free instant hand-pulled noodles are mainly prepared from cereals such as Chinese Northeast non-glutinous polished rice, Chinese Northeast non-glutinous unpolished rice, Chinese Northeast black rice and millet with manufactured goods which are rich in nutrition and have health care effect serving as minor ingredients by means of technologies of flour milling, flour mixing, standing for a while, primary extrusion, secondary extrusion, aging treatment, variable-temperature drying, ventilative cooling, bagging, inspection, sealing packing, boxing and the like. The obtained hand-pulled noodles are chewy, refreshing and slippery, avoid being mixed with soup, breakage and adhesion during cooking and are good in taste and sweet after taste. What is more important is that the noodles are smooth and pleasing in appearance and oily before being cooked and can completely reach the international highest safety index of gluten content not exceeding 5-10PPM, thereby being more nutritional and safer. Moreover, production efficiency is improved greatly, energy consumption and pollution discharge are reduced, and more environment friendliness and lower carbon are achieved.

Owner:大连弘润莲花食品有限公司

Epoxy resin blend dispersion and a process for preparing the dispersion

InactiveUS20150105492A1Enhancing final propertyImprove toughnessEpoxy resin coatingsEpoxySolvent free

The present invention relates to an aqueous epoxy resin blend dispersion of a high mw epoxy resin and a liquid epoxy resin with a dispersant having an interfacial tension such that a drop of the mixture of the dispersant in a melt of the epoxy resin blend against water is less than 2 dynes / cm, preferably less than 1 dyne / cm, and a process for preparing this epoxy resin blend dispersion. Specifically, the process is a solvent free melt kneading or shearing dispersion process wherein the dispersion is processed at from 50 to 150° C., and the resulting dispersion is stable.

Owner:DOW GLOBAL TECH LLC

Polyvinyl chloride mixture and preparation method therefor

ActiveUS20160115307A1Low elongationPoor toughnessLiquid surface applicatorsCoatingsPolyvinyl chloridePolymer chemistry

The present invention discloses a polyvinyl chloride mixture and a preparation method thereof. The mixture comprises the following components in parts be weight: (a) polyvinyl chloride resin of 100 parts and (b) a toughening modifier of 2-20 parts, the toughening modifier being rubber powder whose elongation at break is 1601%-2200% and which contains the percentage of chlorine of 5-45 wt %. The elongation at break of the polyvinyl chloride mixture of the present inventions is greatly improved, and the defect of low elongation at break of the polyvinyl chloride product is substantially solved accordingly; therefore, the application scope of polyvinyl chloride surely will be greatly widened.

Owner:SHANDONG RIKE CHEM

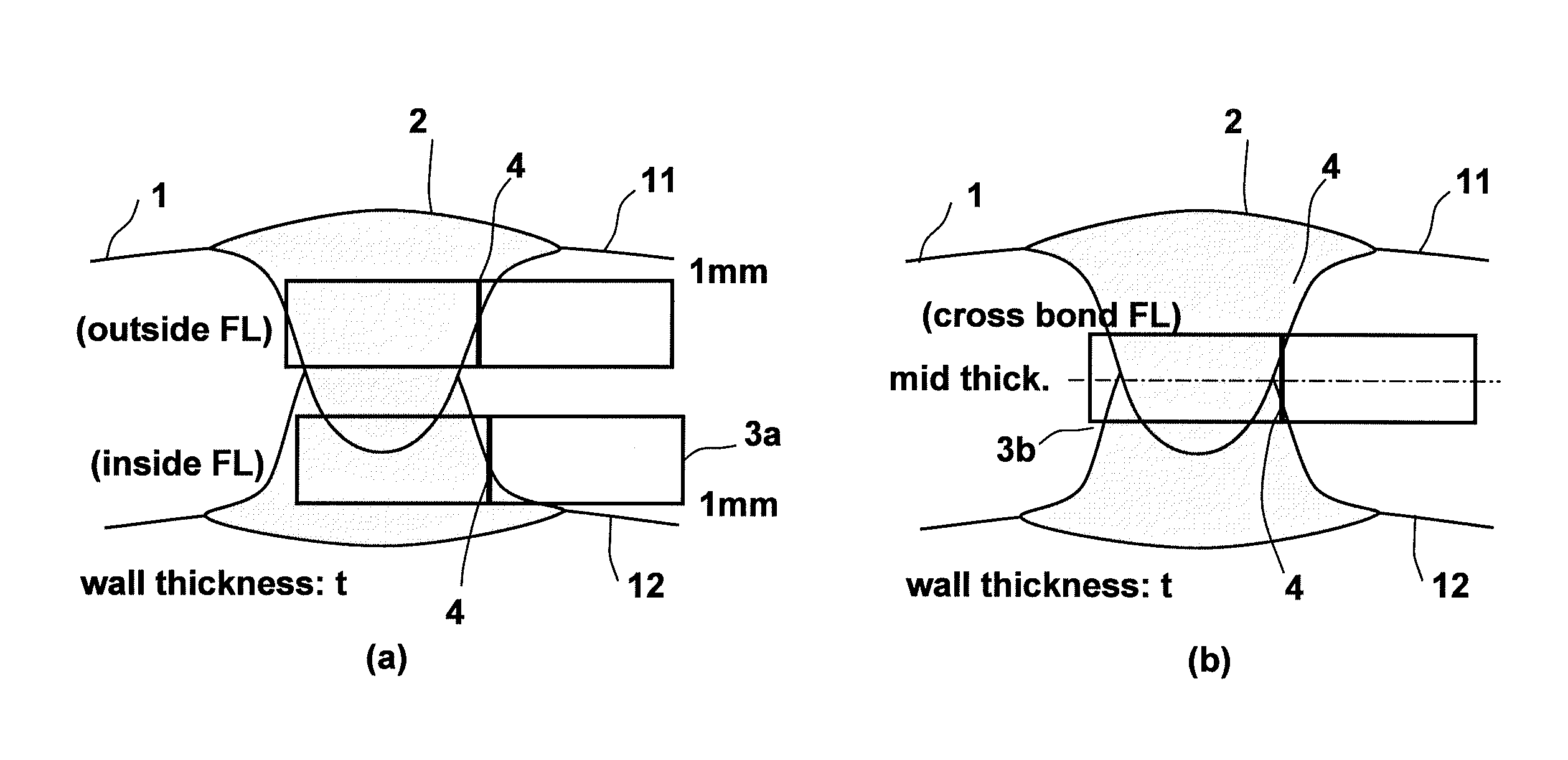

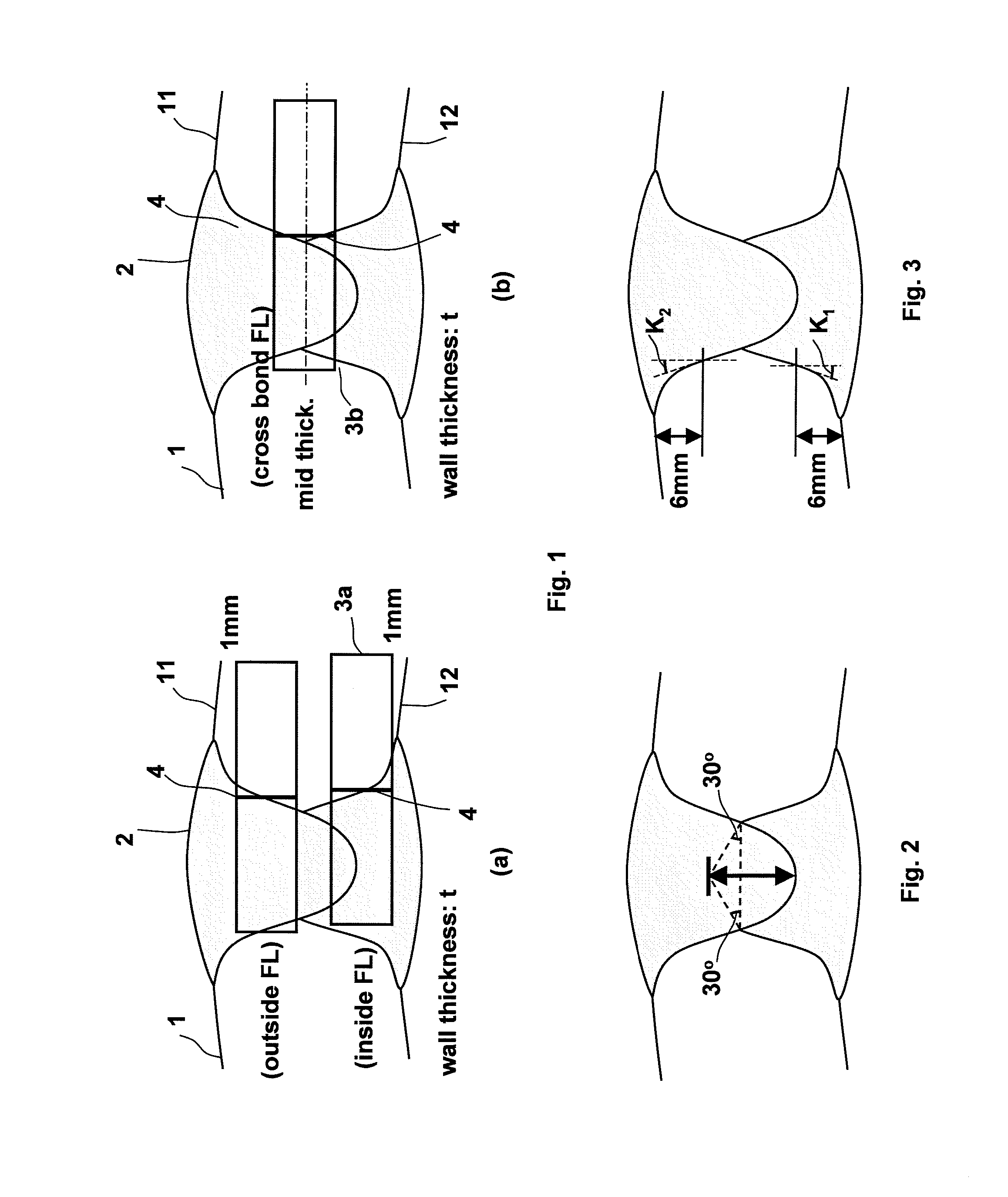

Welded steel pipe with excellent welded heat-affected zone toughness and process for producing same

InactiveUS20140227549A1Improve productivityLow costArc welding apparatusFurnace typesButt weldingAustenite grain

A welded steel pipe with excellent welded heat-affected zone toughness includes a butt weld formed by prior welding either an inner surface or an outer surface with a single layer for each of the inner and outer surfaces, wherein in the metallographic structure of a welded heat-affected zone, the martensite-austenite constituent (MA) area fraction is 4% or less, the average prior-austenite grain size is 400 μm or less, and the following items are taken into account: the average prior-austenite grain size of a welded heat-affected zone formed by prior welding, the average prior-austenite grain size of a welded heat-affected zone formed by subsequent welding, the bead width determined at a position 5 mm apart from the tip of a weld bead formed by subsequent welding, the fusion line tilt angle of a weld bead of prior welding, and the fusion line tilt angle of a weld bead of subsequent welding.

Owner:JFE STEEL CORP

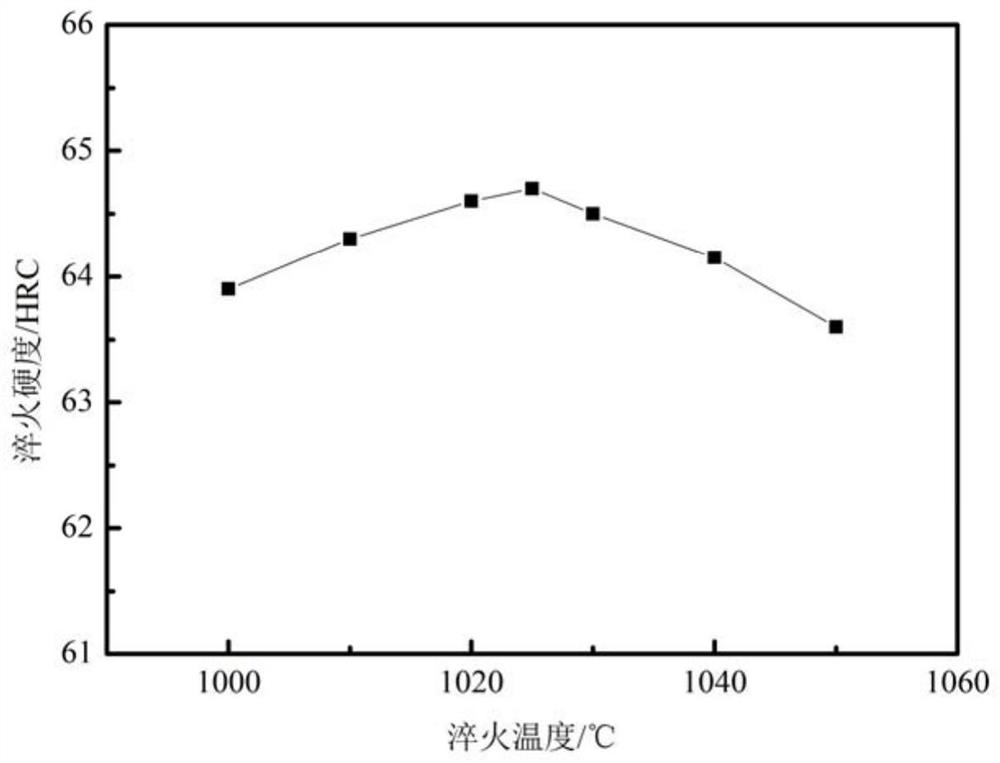

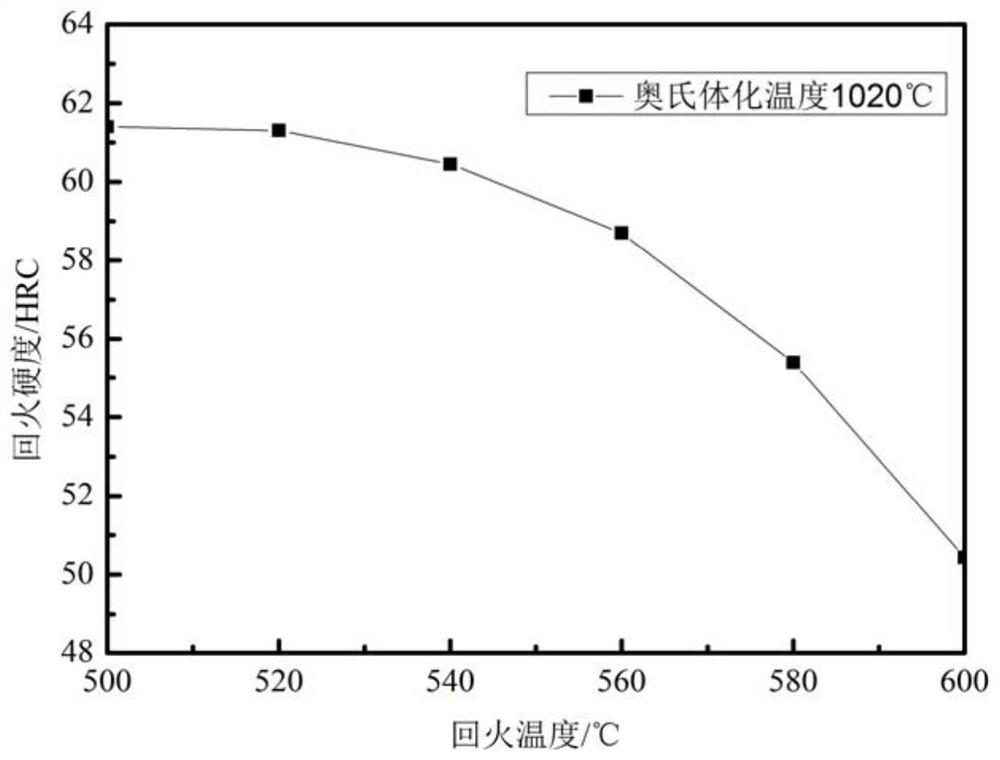

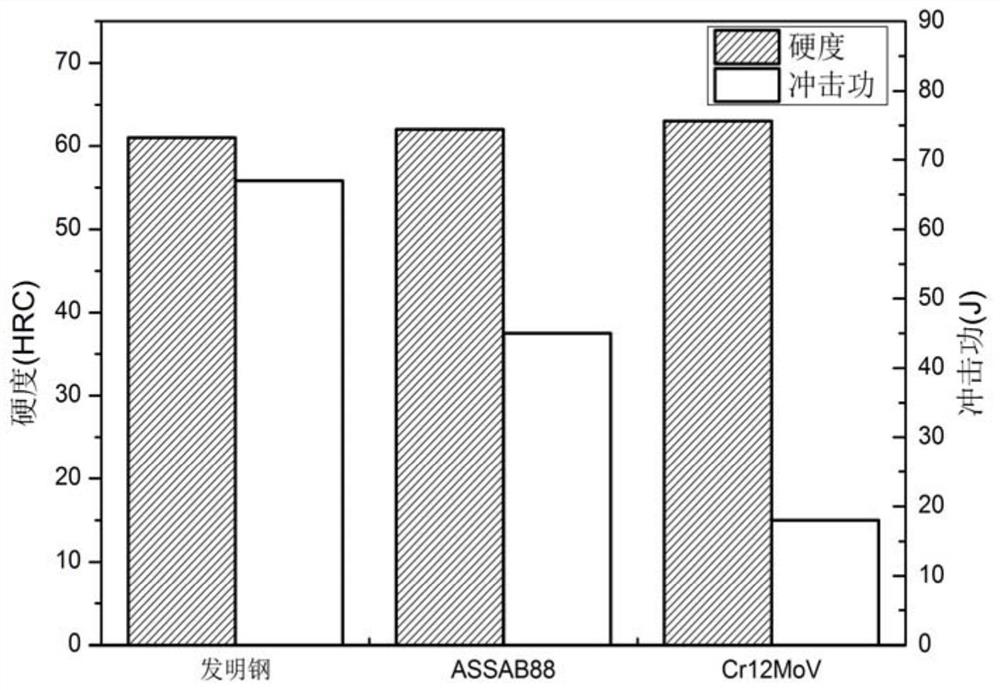

1500MPa hot stamping part cold trimming and punching tool die steel and preparation method thereof

ActiveCN113737106APoor toughnessPoor chipping resistanceIncreasing energy efficiencyHot stampingTempering

The invention discloses 1500MPa hot stamping part cold trimming and punching tool die steel and a preparation method thereof. The die steel comprises chemical components including, by weight percent, 0.65%-0.75% of C, 0.40%-0.60% of Si, 0.20%-0.40% of Mn, 4.50%-5.80% of Cr, 1.70%-1.90% of Mo, 0.55%-0.65% of V, less than or equal to 0.015% of P, less than or equal to 0.010% of S and the balance Fe and inevitable impurity elements. After being subjected to induction melting, electroslag remelting, forging, annealing and quenching and tempering heat treatment, the die steel has excellent anti-tipping and anti-cracking performance, and due to high hardness and high wear resistance, it is guaranteed that materials are not prone to abrasion or galling in the blanking process; and after a reasonable heat treatment process, good dimensional stability is achieved, and the size out-of-tolerance of a tool due to heat treatment is avoided.

Owner:BAOSHAN IRON & STEEL CO LTD +1

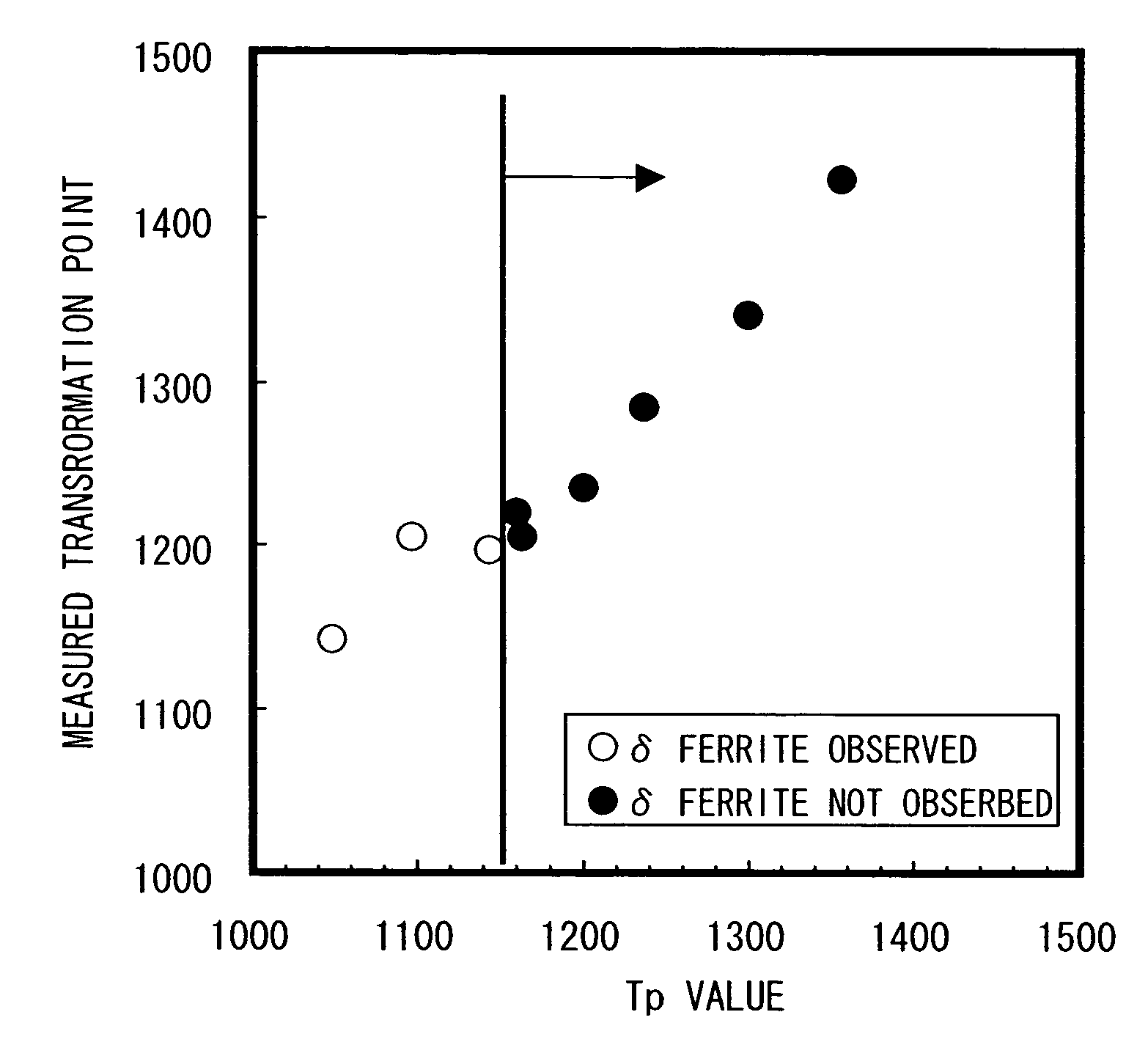

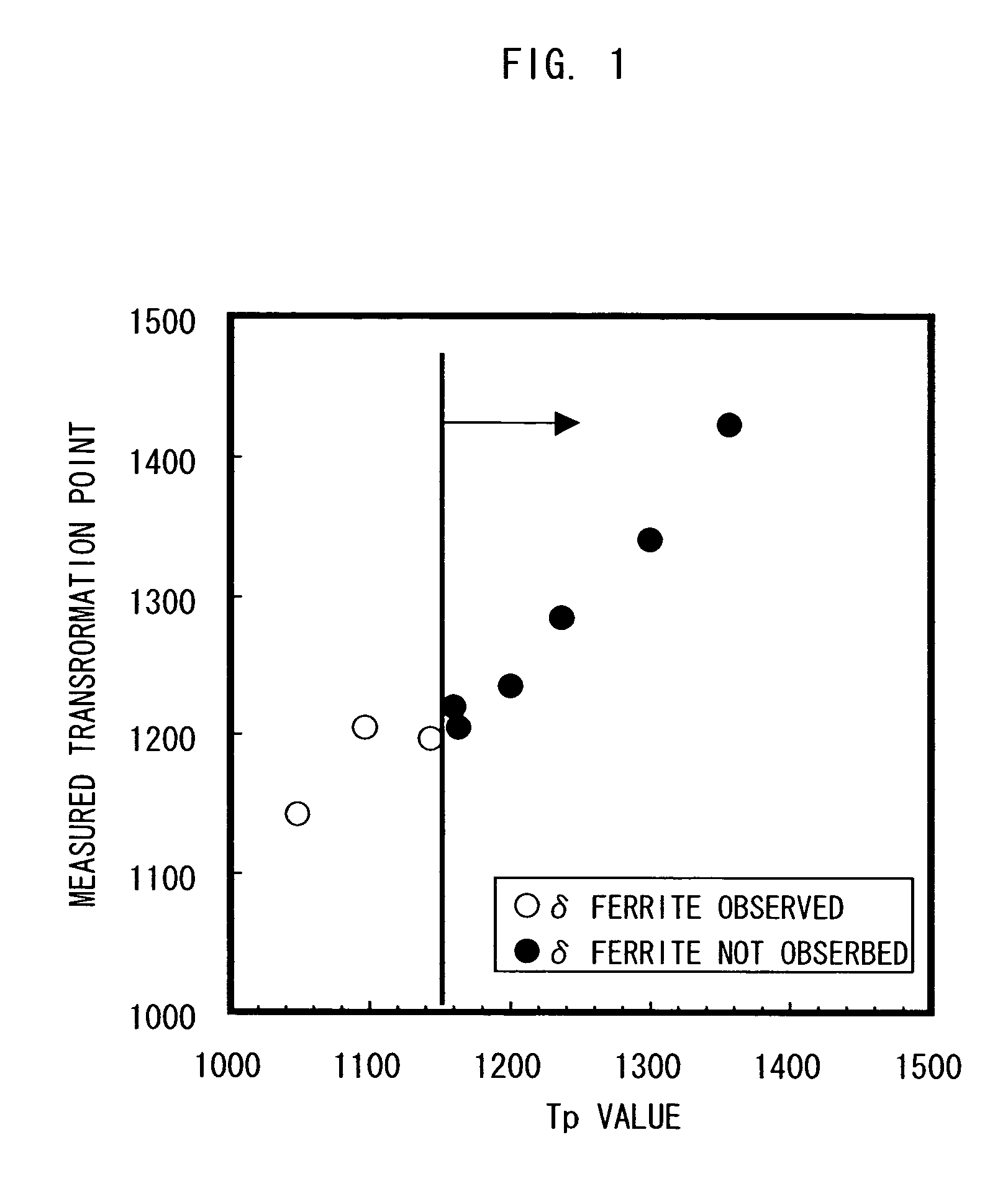

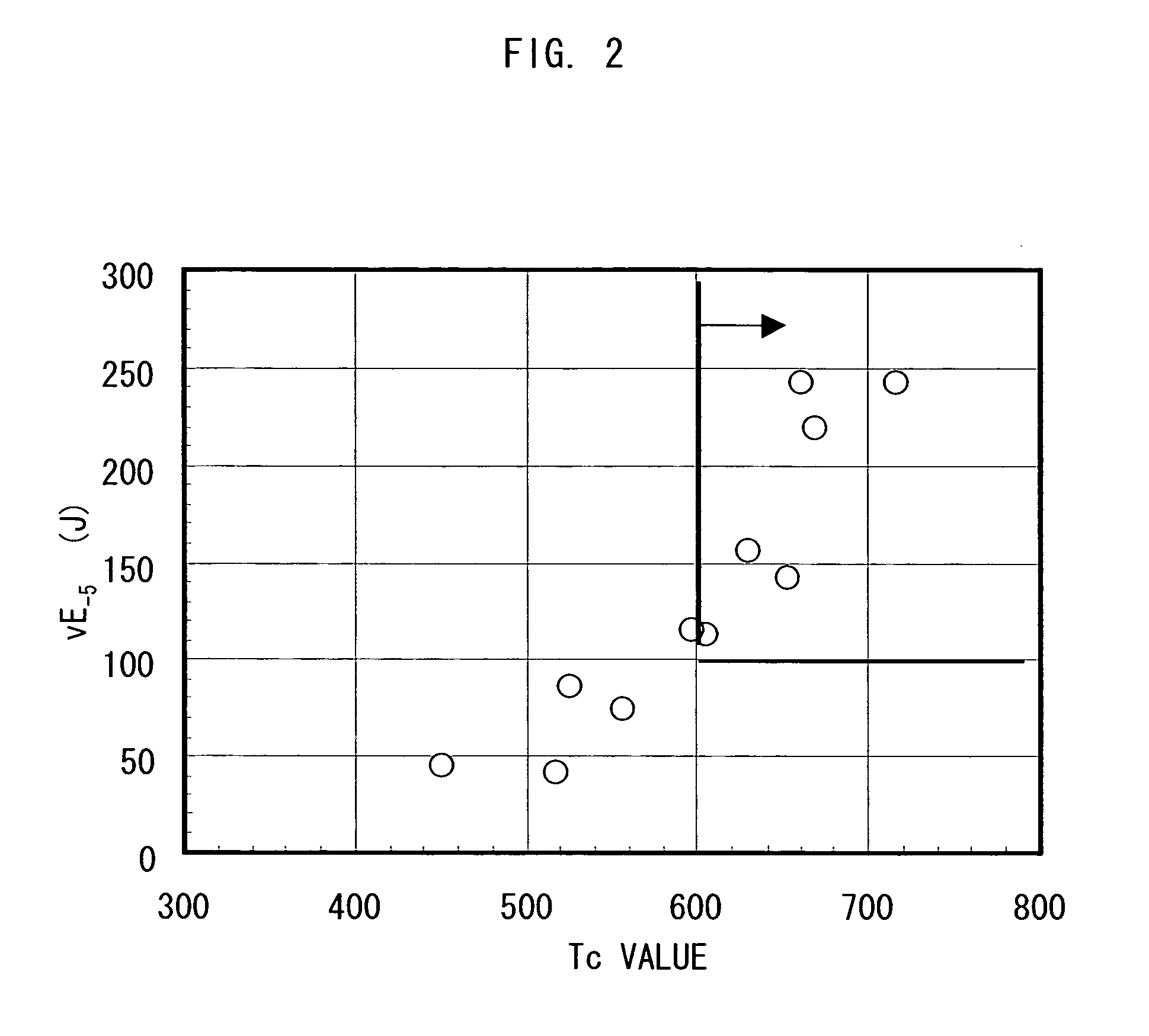

Corrosion-Resistant Steel Excellent in Toughness of Base Metal and Weld Portion, and Method of Manufacturing the Same

A corrosion-resistant steel excellent in toughness of a base metal and a weld portion said steel slab contains, in % by weight, C: 0.2% or less; Si: 0.01 to 2.0%; Mn: 0.1 to 4% or less; P: 0.03% or less; S: 0.01% or less; Cr: 3 to 11%; Al: 0.1 to 2%; and N: 0.02%, and has values of 1150 or above, and 600 or above respectively for Tp and Tc expressed by the equations below using concentrations of Cr, Al, C, Mn, Cu and Ni respectively given as % Cr, % Al, % C, % Mn, % Cu and % Ni. Tp=1601−(34% Cr+287% Al)+(500% C+33% Mn+60% Cu+107% Ni); and Tc=910+80% Al−(300% C+80% Mn+15% Cr+55% Ni).

Owner:NIPPON STEEL CORP

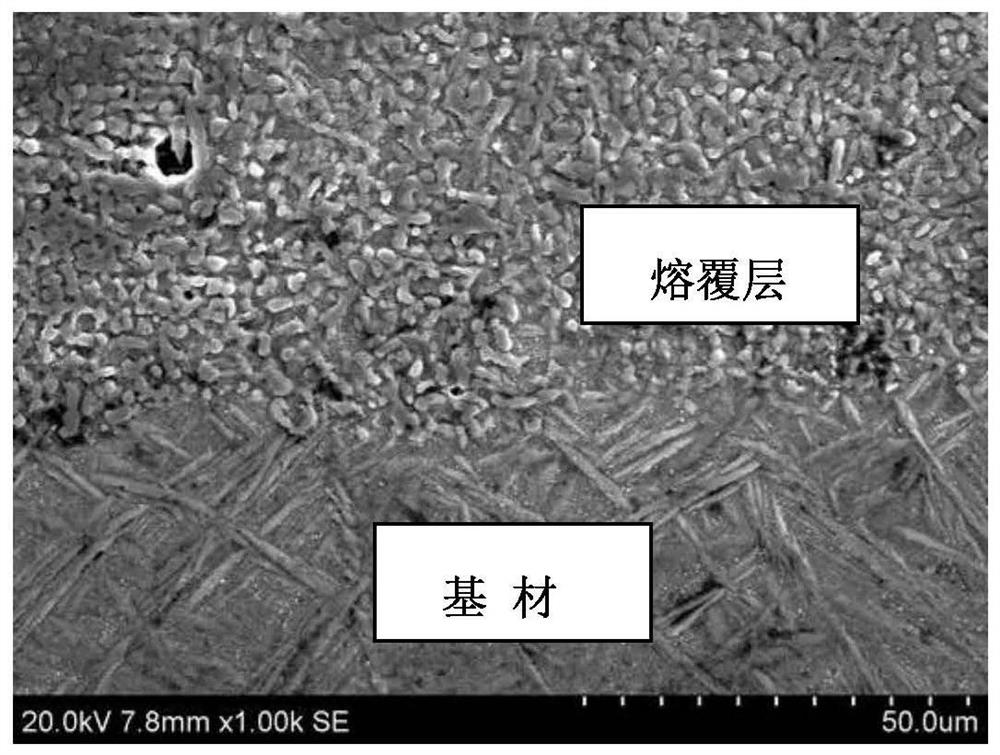

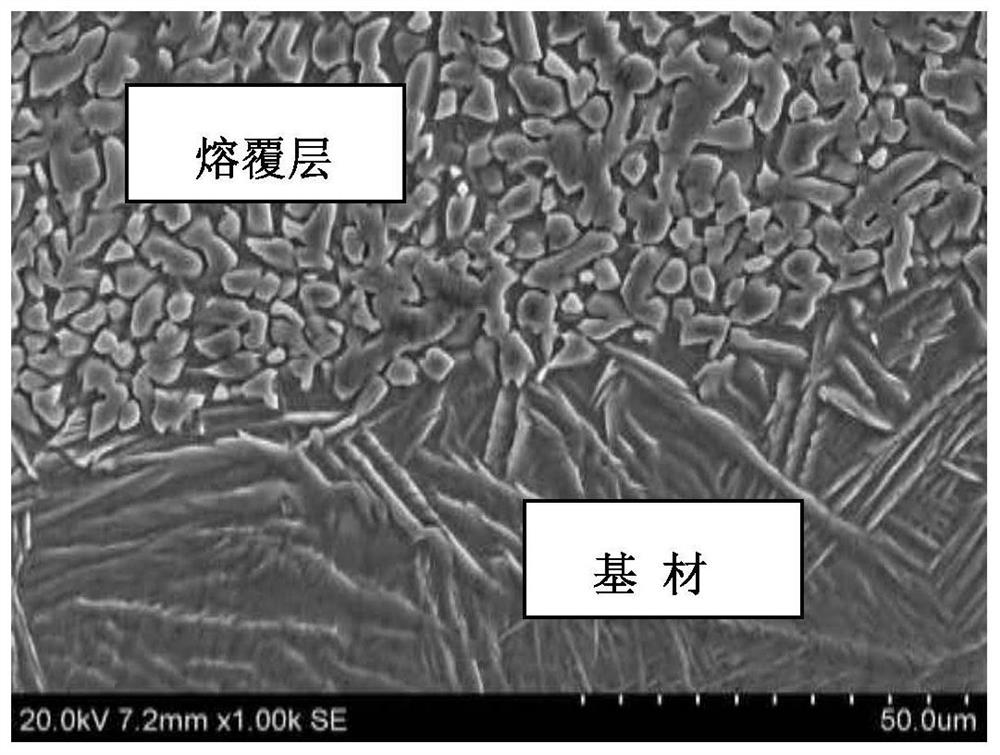

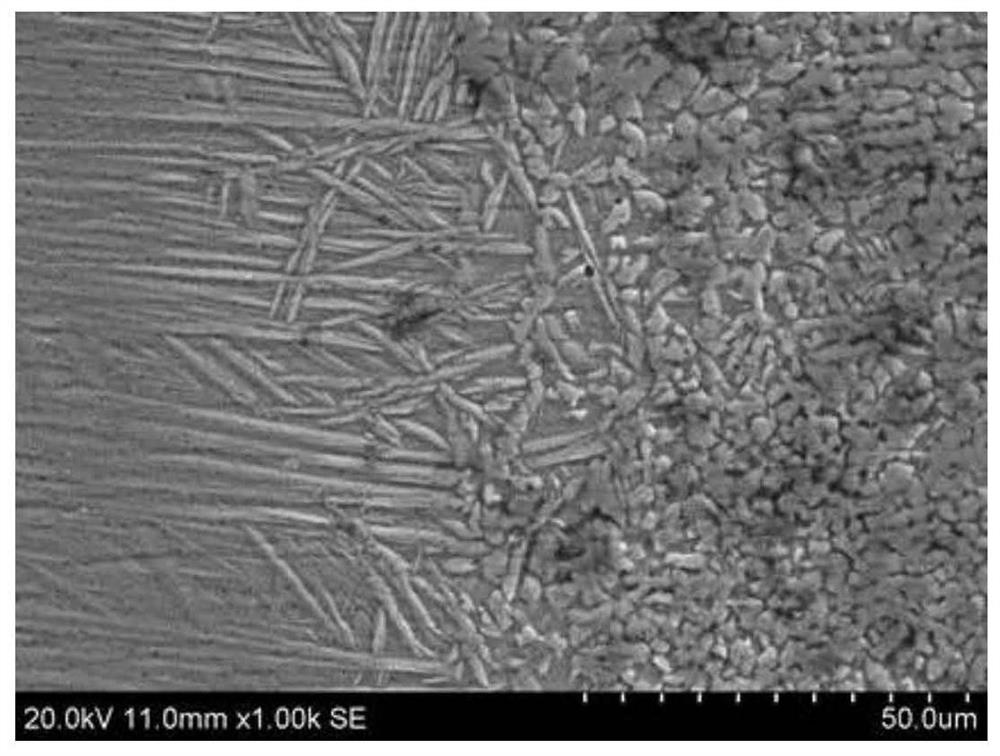

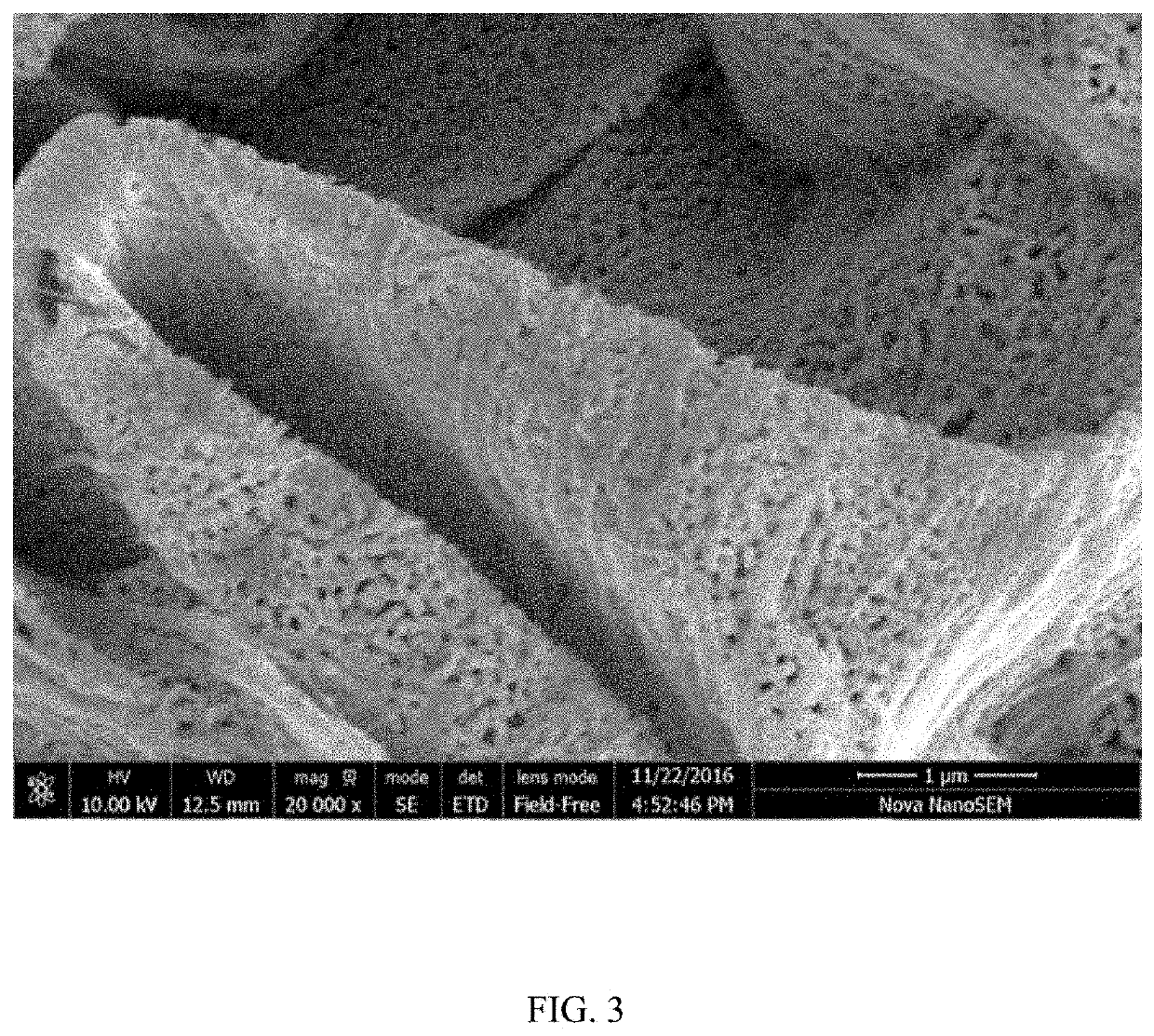

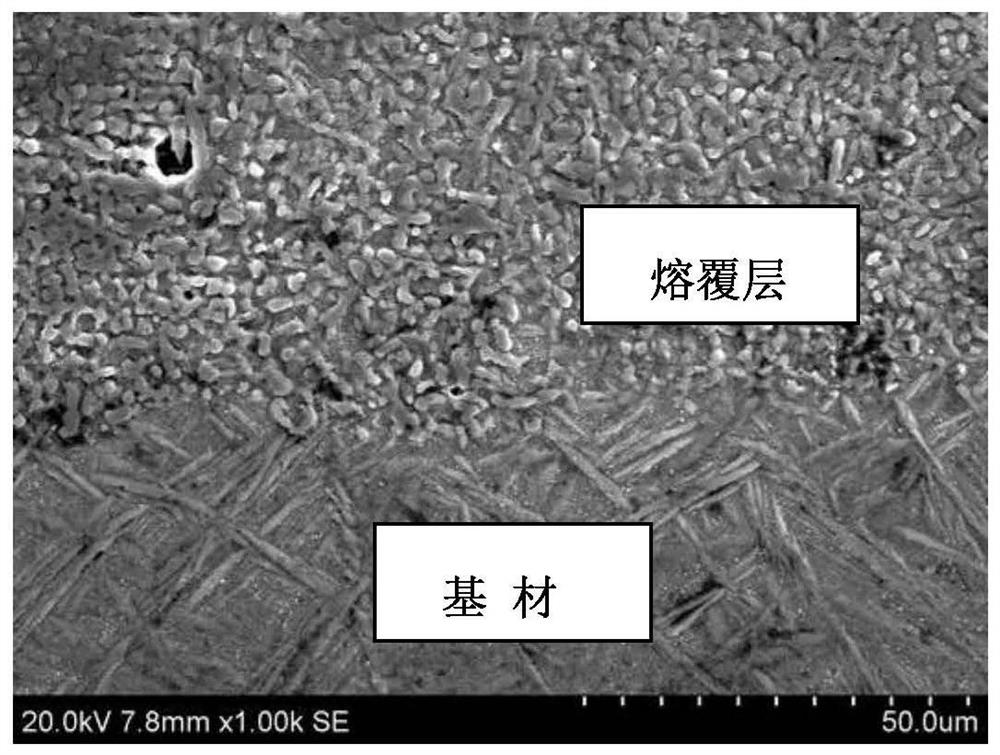

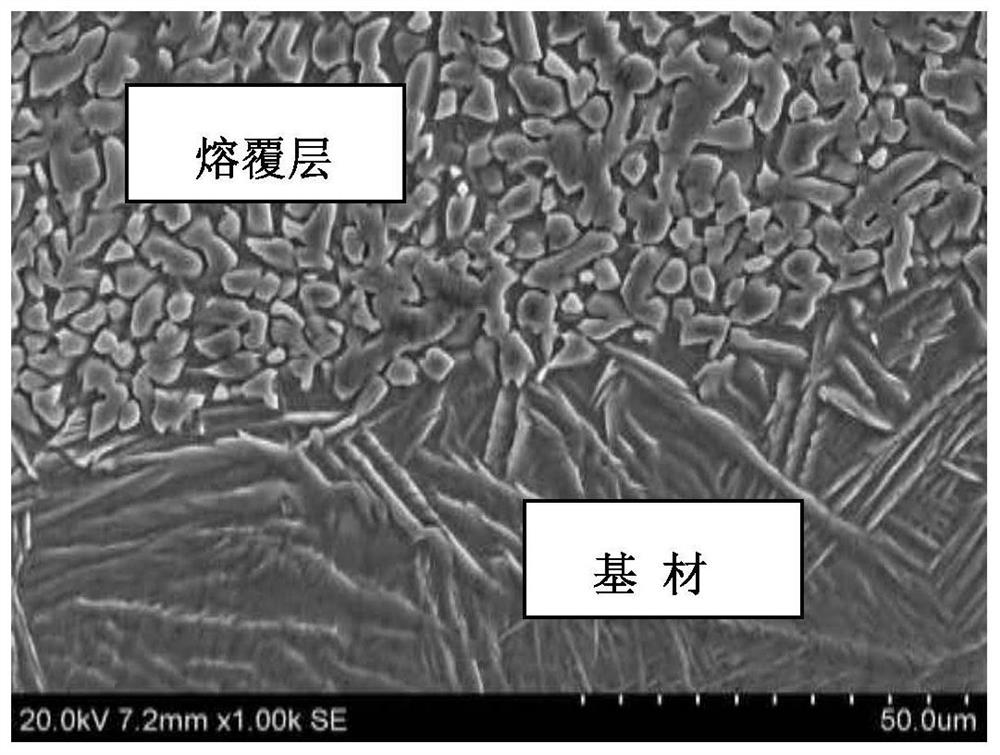

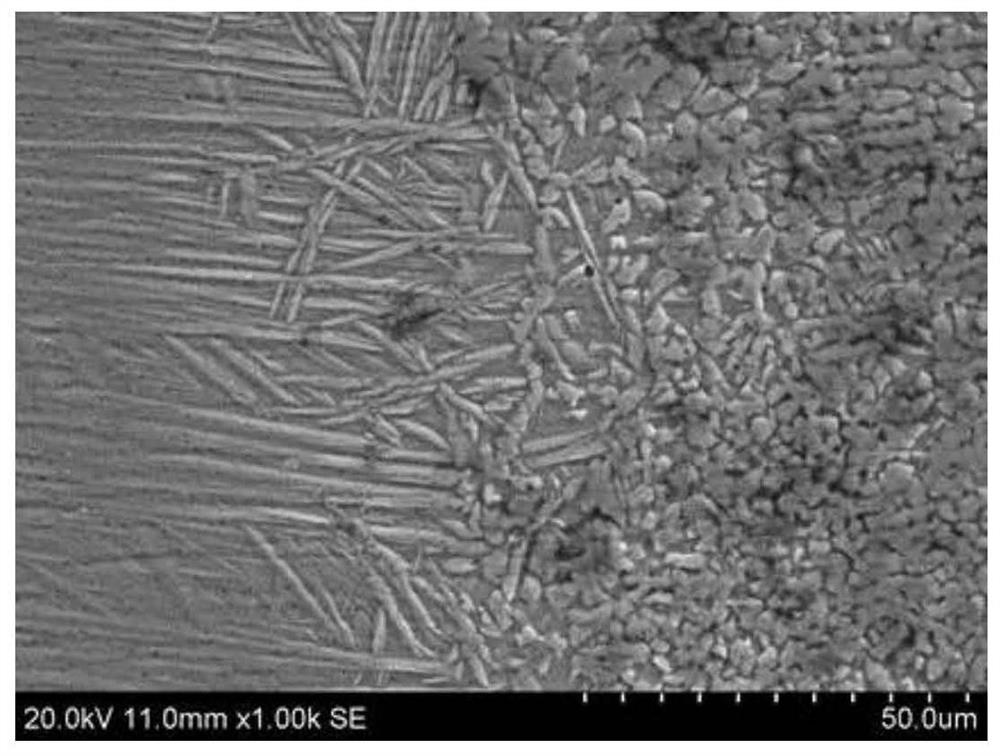

Preparation method of wear-resistant metal-multi-element ceramic composite modified coating on surface of titanium alloy

ActiveCN113667974AHigh hardnessImprove toughnessMetallic material coating processesSurface engineeringCeramic composite

The invention relates to a preparation method of a wear-resistant metal-multi-element ceramic composite modified coating on the surface of a titanium alloy, and belongs to the technical field of surface engineering. The preparation method of the wear-resistant metal-multi-element ceramic composite modified coating on the surface of the titanium alloy comprises the following steps: (1) preparing pre-alloyed powder for later use; (2) cleaning the to-be-clad surface of a base material by adopting industrial alcohol, and then carrying out blackening treatment on the surface of the base material; and (3) coaxially conveying the pre-alloyed powder prepared in the step (1) to the to-be-clad surface of a base material, which is treated in the step (2), carrying out laser cladding, and preparing to obtain the wear-resistant metal-multi-element ceramic composite modified coating on the surface of the titanium alloy. The composite modified coating prepared through the preparation method is obvious in grain refinement, the purpose of grain refinement strengthening is achieved, the coating is guaranteed to have high hardness and high toughness at the same time, and therefore the wear resistance of the titanium alloy can be greatly improved, and then the service life of the titanium alloy under a complex working condition is prolonged.

Owner:YANSHAN UNIV

Epoxy resin blend dispersion and a process for preparing the dispersion

InactiveUS9346925B2Enhancing final propertyImprove toughnessSynthetic resin layered productsEmulsion paintsEpoxySolvent free

The present invention relates to an aqueous epoxy resin blend dispersion of a high mw epoxy resin and a liquid epoxy resin with a dispersant having an interfacial tension such that a drop of the mixture of the dispersant in a melt of the epoxy resin blend against water is less than 2 dynes / cm, preferably less than 1 dyne / cm, and a process for preparing this epoxy resin blend dispersion. Specifically, the process is a solvent free melt kneading or shearing dispersion process wherein the dispersion is processed at from 50 to 150° C., and the resulting dispersion is stable.

Owner:DOW GLOBAL TECH LLC

Steam barrier resin, steam barrier coating agent, steam barrier film, and steam barrier laminate

InactiveUS20140370314A1Improve barrier propertiesPoor toughnessSynthetic resin layered productsLaminationUnsaturated hydrocarbonSolvent

The present invention provides as steam barrier resin, a steam barrier coating agent, a steam barrier film, and a steam barrier laminate that exhibit an improved steam barrier property. The steam barrier resin of the present invention is obtained by reacting a carboxylic acid group and / or an acid anhydride group of a copolymer (C) with an organometallic complex (D). The copolymer (C) is obtained by polymerizing an unsaturated hydrocarbon monomer (A) and an unsaturated carboxylic acid and / or an unsaturated dicarboxylic anhydride (B). Further, the steam barrier resin includes metal bridging between the copolymers (C). The steam barrier coating agent of the present invention contains the steam barrier resin and a solvent (B). The steam barrier film of the present invention is a film containing the steam barrier resin of the present invention. The steam barrier laminate is obtained by laminating the steam barrier film of the present invention on at least one surface of a substrate film.

Owner:TOYO INK SC HOLD CO LTD

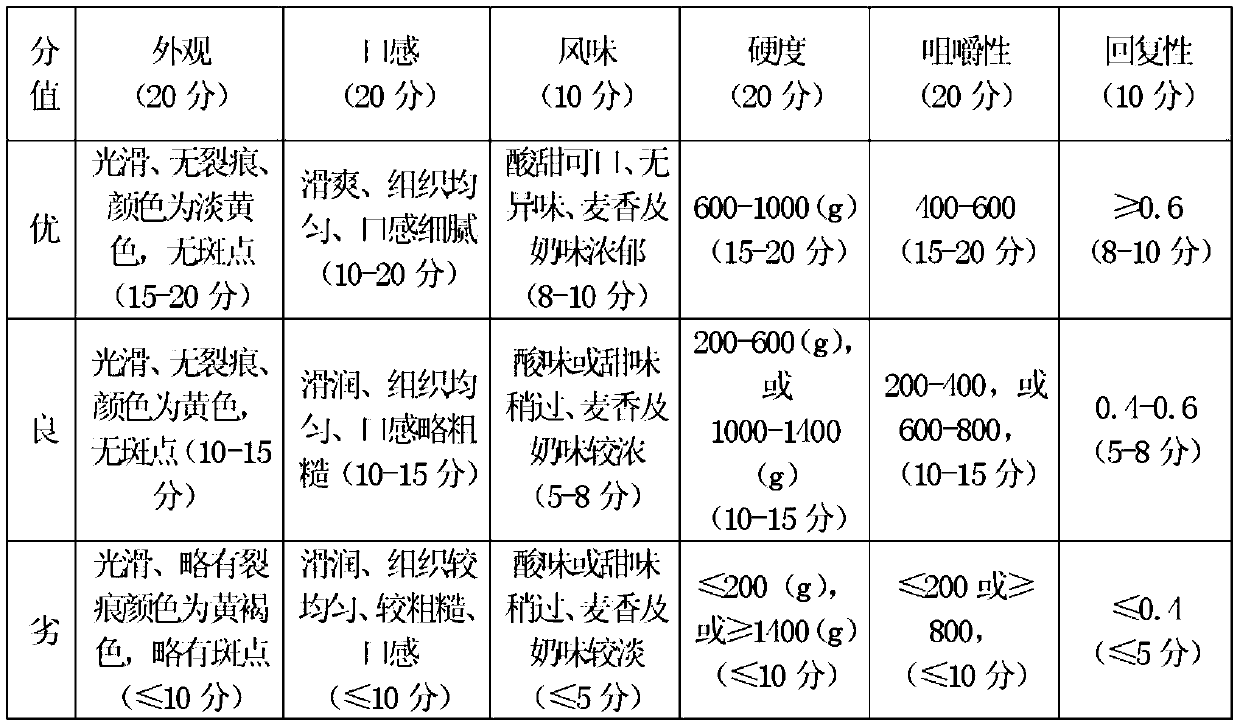

Wheat germ blancmange and preparation method thereof

The invention relates to a preparation method of wheat germ blancmange. The preparation method comprises the following steps of taking 10 parts by weight of wheat germs, soaking the taken wheat germsin 90-100 parts by weight of water for 2 hours, and then performing superfine crushing to obtain micronized liquid of which the granularity D50 is smaller than or equal to 5[mu]m; adding 0.18-0.3 partby weight of a composite emulsifying agent and milk powder, performing placing in a homogenizing machine, and performing homogenizing twice so as to obtain homogenizing liquid; taking 0.72-1.0 part by weight of blancmange powder and 13.5-20 parts by weight of white granulated sugar, and performing mixing so as to obtain a mixture; adding the mixture to the homogenizing liquid, performing heatingto a boiling state, and maintaining the micro boiling state for 5-10min so as to obtain wheat germ blancmange liquid; and performing cooling to 50-60 DEG C, and adding 0.1-0.11 part by weight of a sour agent and 0.001-0.0011 part by weight of wheat-fragrance essence. The wheat germ blancmange prepared by the method has nutrient components of the wheat germs, and is fine and smooth in mouth feel, tender, smooth and plump in shape. Besides, the method is simple in steps, and the wheat germ blancmange is convenient to prepare.

Owner:BENGBU COLLEGE

Modified epoxy polyurethane sealant and preparation method thereof

InactiveCN113278396AImprove wear resistanceImprove insulation performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDibutyl tin dilaurateVinyl ester

The invention relates to the technical field of sealants, in particular to a modified epoxy polyurethane sealant and a preparation method thereof. The modified epoxy polyurethane sealant comprisses the following raw materials in parts by weight: 10 to 20 parts of bisphenol A epoxy resin, 10 to 20 parts of vinyl ester resin, 0.1 to 0.5 part of silicon dioxide, 0.1 to 0.5 part of aluminum trioxide, 0.1 to 0.5 part of graphene oxide, 0.01 to 0.2 part of octadecylamine, 5 to 10 parts of a silane coupling agent, 10 to 30 parts of propylene oxide, 30 to 50 parts of dicyclohexylmethane diisocyanate, 30 to 60 parts of polyether triol, 1 to 3 parts of dibutyltin dilaurate, 1 to 5 parts of a polyaziridine cross-linking agent,1 to 5 parts of diethyl toluenediamine, 2 to 8 parts of a curing agent and 20 to 30 parts of a solvent. The prepared modified epoxy polyurethane sealant has the advantages of excellent mechanical property, good adhesion property, good weather resistance, high temperature resistance, good electrical insulating property and the like.

Owner:邹微丽

Polyamide, polyamide composition, and molded article

A polyamide comprising a unit containing at least one (a) alicyclic dicarboxylic acid and a unit containing a (b) diamine having 8 or more carbon atoms, wherein the polyamide satisfies the following conditions (1) and (2): (1) a sulfuric acid relative viscosity ηr at 25° C. is 2.3 or more; and (2) Mw (weight average molecular weight) / Mn (number average molecular weight) is 4.0 or less.

Owner:ASAHI KASEI CHEM CORP

Polyether composition, low VOC polyurethane foam and preparation method therefor

A polyether composition for a polyurethane foam is provided, comprising a polyether polyol and a polyether carbonate polyol that has a primary hydroxyl group molar content of not less than 40 mol %. A method for preparing a polyurethane foam is further provided, comprising the following steps: preparing a mixture by preheating and melting the polyether composition for a polyurethane foam, a foaming agent, a chain extender, a catalyst, a pore-forming agent and a foam stabilizer, and mixing well; cooling the mixture; and performing a polymerization reaction by adding an isocyanate to the cooled mixture and mixing, thus obtaining a polyurethane foam product. The use of the polyether carbonate polyol with the primary hydroxyl group molar content of not less than 40 mol % overcomes the defects of unstable performance of polyurethane and poor mechanical properties of products when the VOC content of the polyurethane foam is reduced by adding additives in the prior art.

Owner:JUYUAN CHEM IND CO LTD

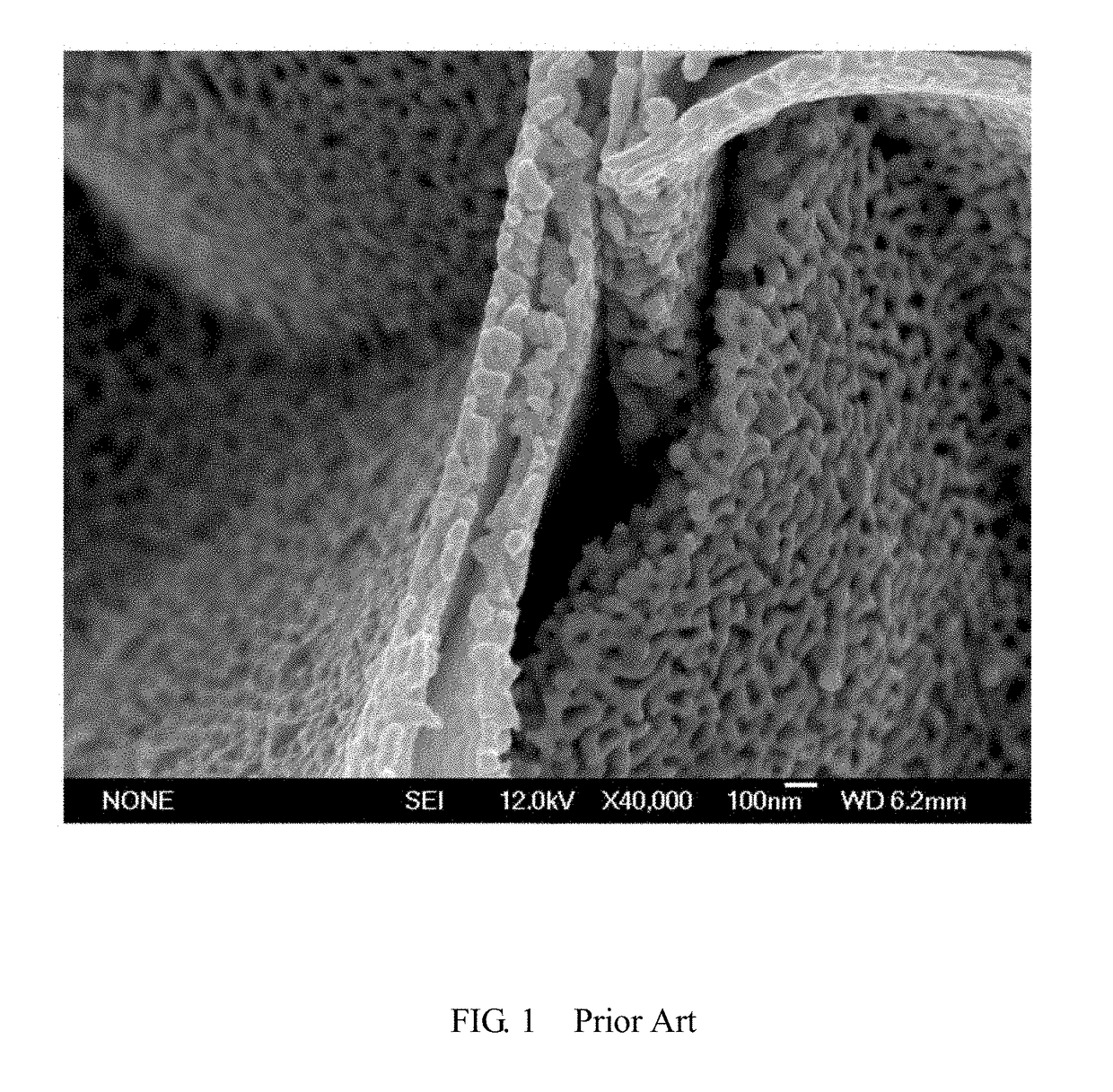

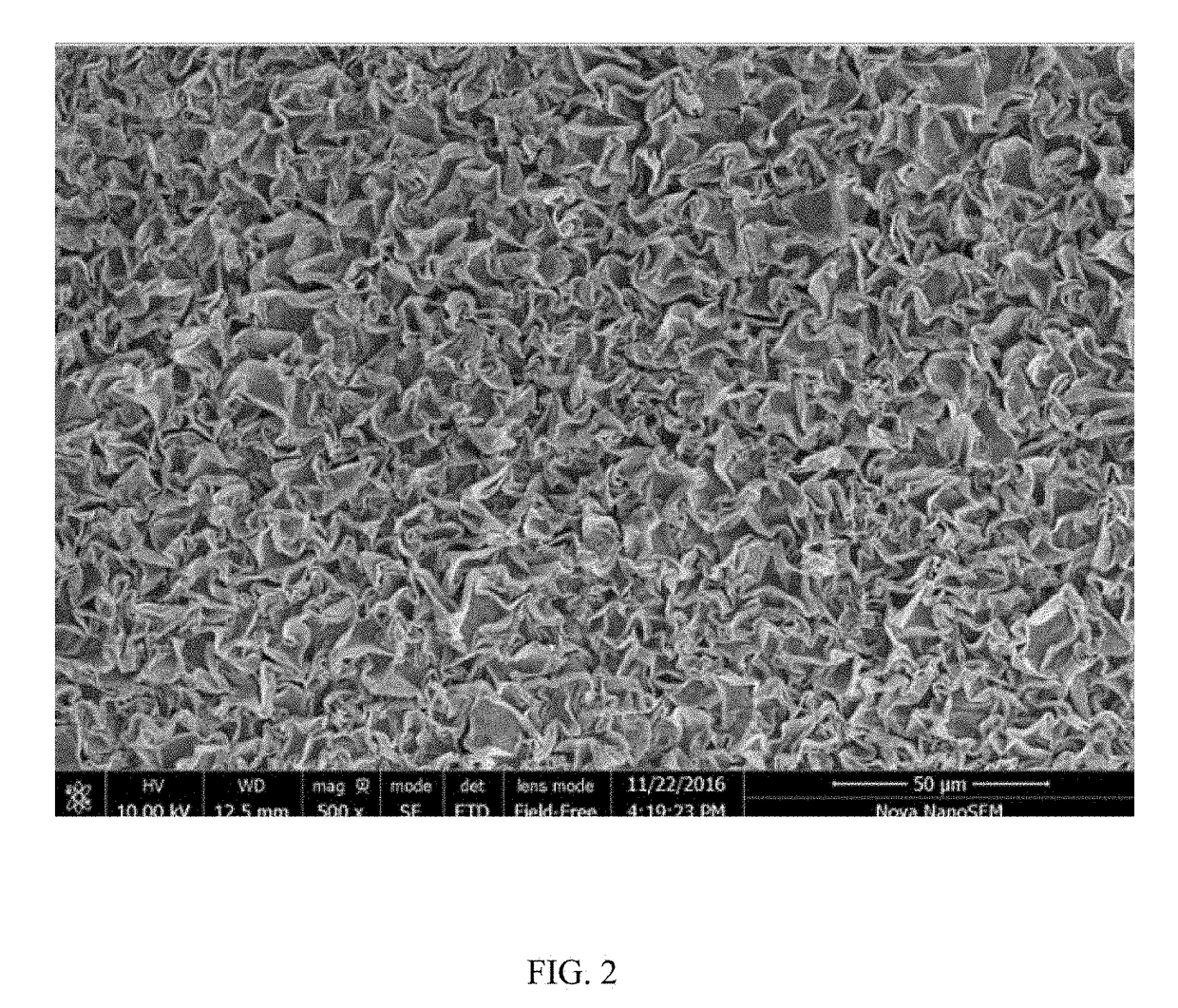

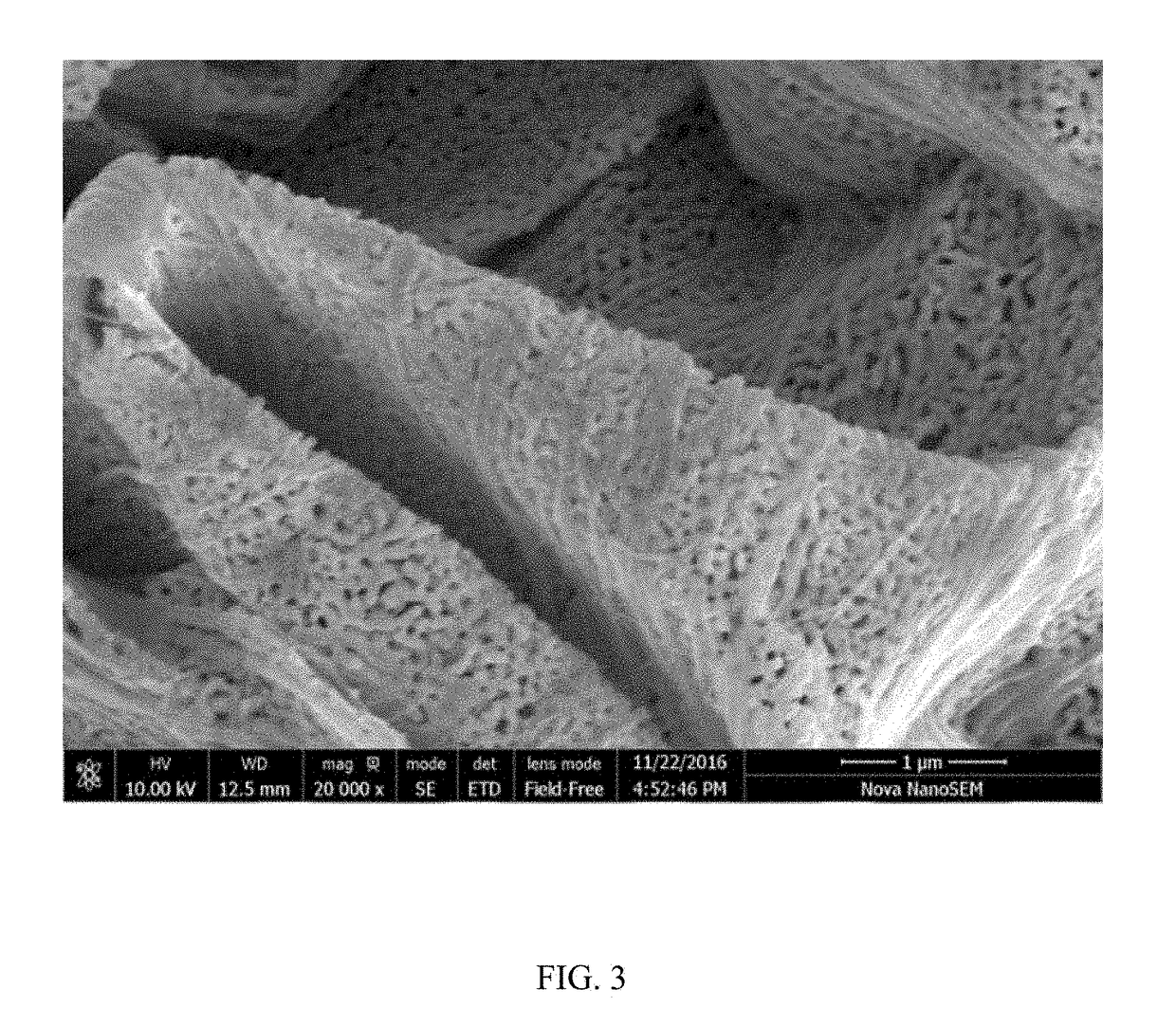

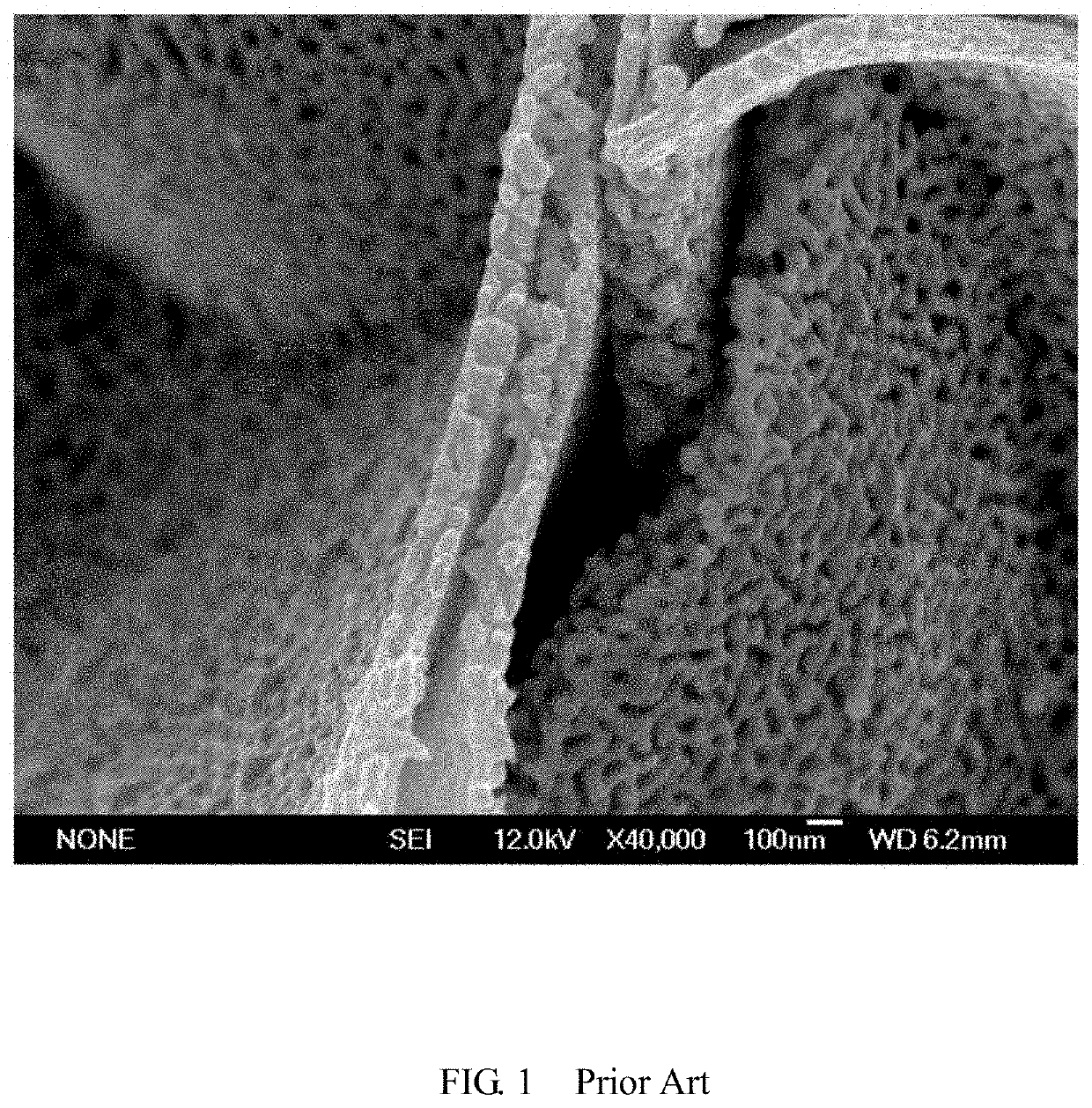

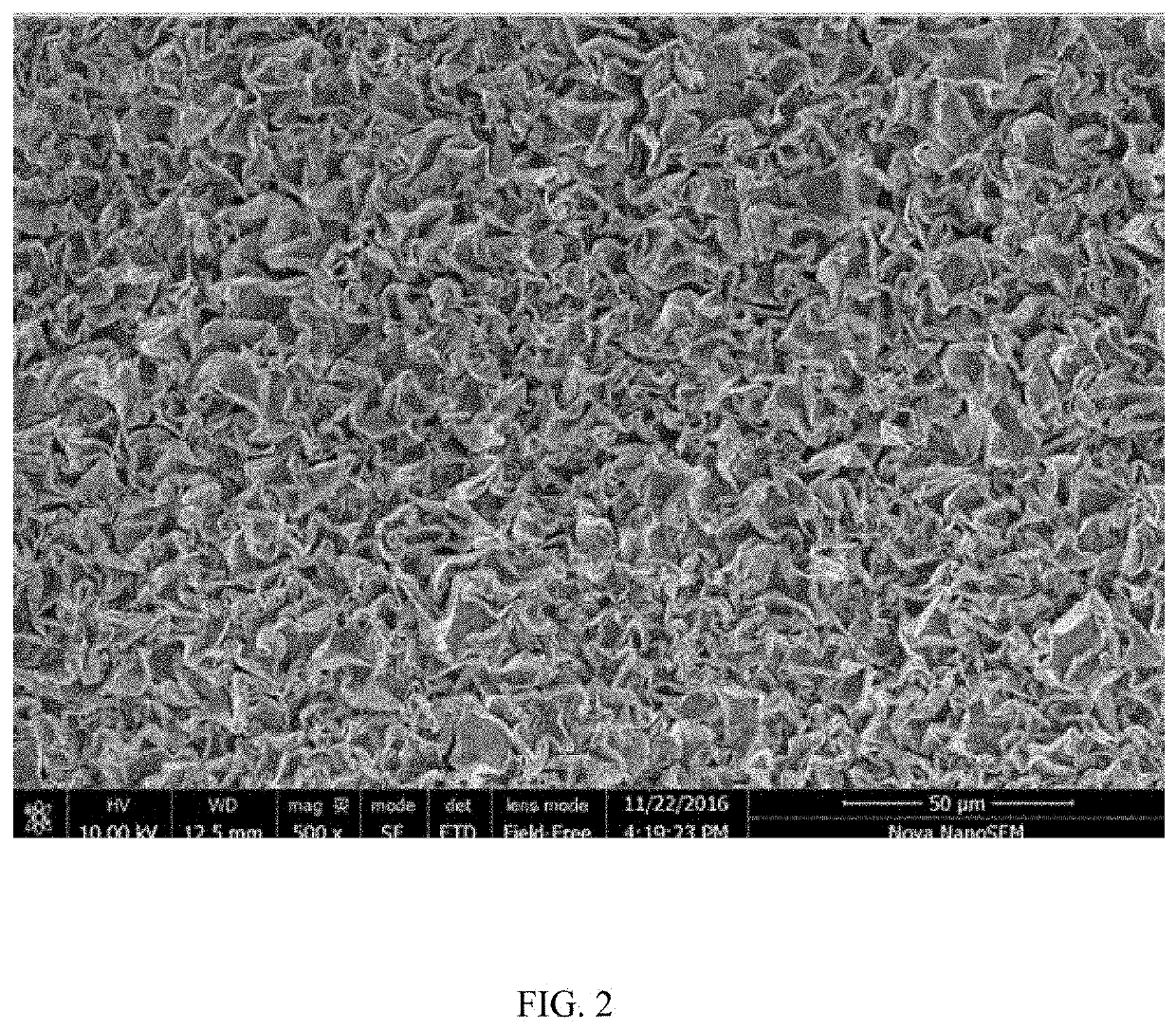

Composite structure with porous metal

ActiveUS20180354228A1Poor toughnessLimited applicationMaterial nanotechnologyLaminationCarbon nanotubeComposite structure

A composite structure with porous metal comprises a porous metal structure and a carbon nanotube structure comprising a plurality of carbon nanotubes, the carbon nanotube structure is fixed on surface of the porous metal structure, and the porous metal structure and the carbon nanotube structure are shrunk together to form a plurality of wrinkled parts.

Owner:TSINGHUA UNIV +1

Toughening and Straightening Technology of Gun Drilling Drill Rod for Deep Hole Processing

ActiveCN105063323BHigh alloy contentHigh strengthSolid state diffusion coatingFurnace typesShielding gasCarburizing

The present invention relates to the technical field of processing methods for deep hole processing equipment, in particular to the process of toughening and straightening gun drill rods for deep hole processing, comprising the following steps: 1) material selection, pipe making and forming, selecting high-quality alloy steel, tool steel or Carburized steel, processed into a deep hole processing gun drill pipe before heat treatment; 2) heat treatment strengthening and toughening and straightening integration, the deep hole processing gun drill pipe before heat treatment is hung vertically on the tooling, deep The counterweight is mounted on the bottom end of the hole processing gun drill drill pipe for carburizing, quenching, self-alignment of the counterweight or quenching and self-straightening; 3) tempering, straightening, and cooling. Compared with the prior art, this The invention uses high-quality alloy steel, tool steel or carburizing steel as raw materials, and through heat treatment in a protective gas furnace, vacuum furnace, and high-frequency furnace, under the gravity of the counterweight, self-alignment or carburizing and quenching of carburizing steel improves The carbon content is lowered, the toughness is strengthened; the heat treatment is strengthened and toughened and straightened, and the tempering process is self-aligned.

Owner:佛山市云昇金属科技有限公司

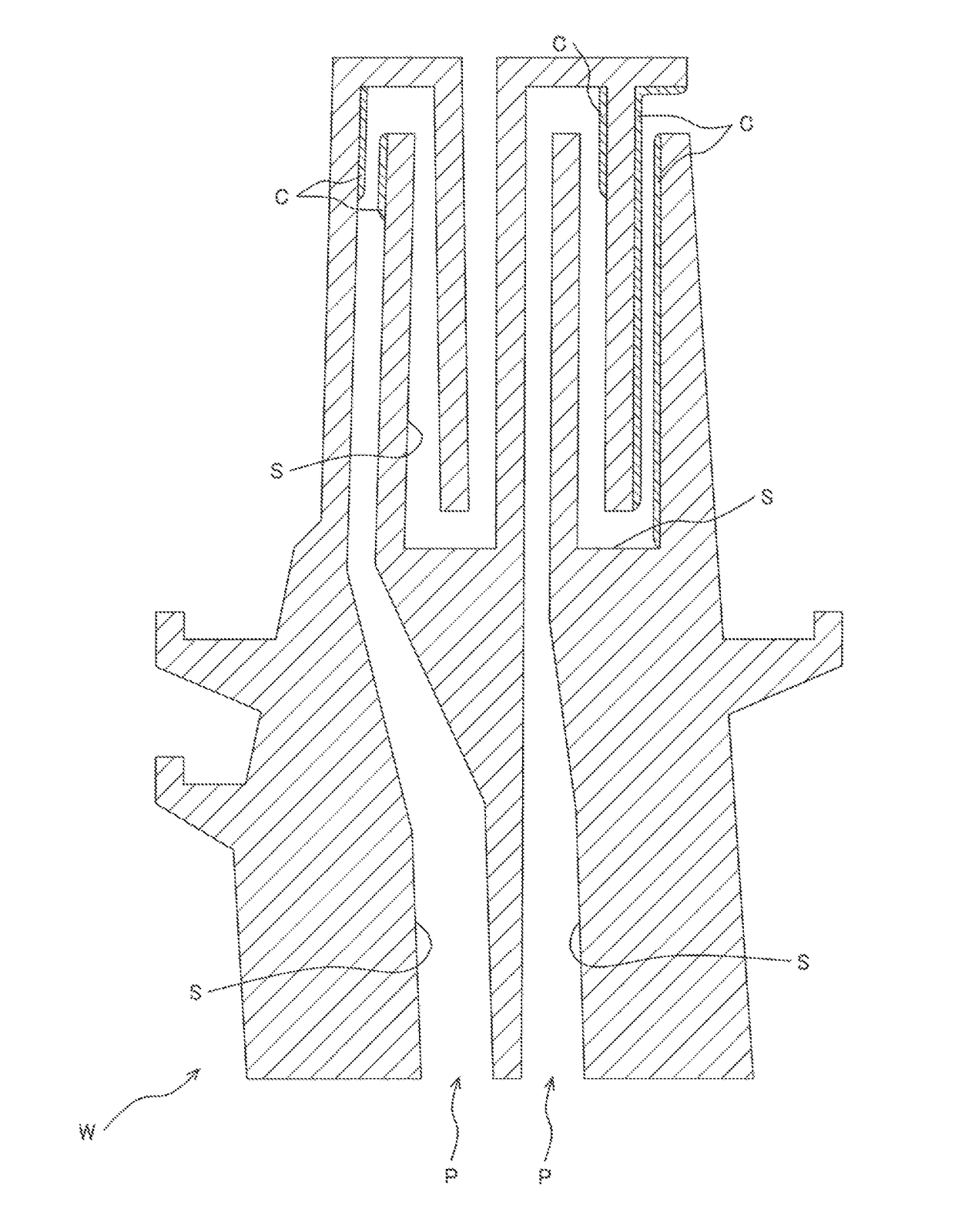

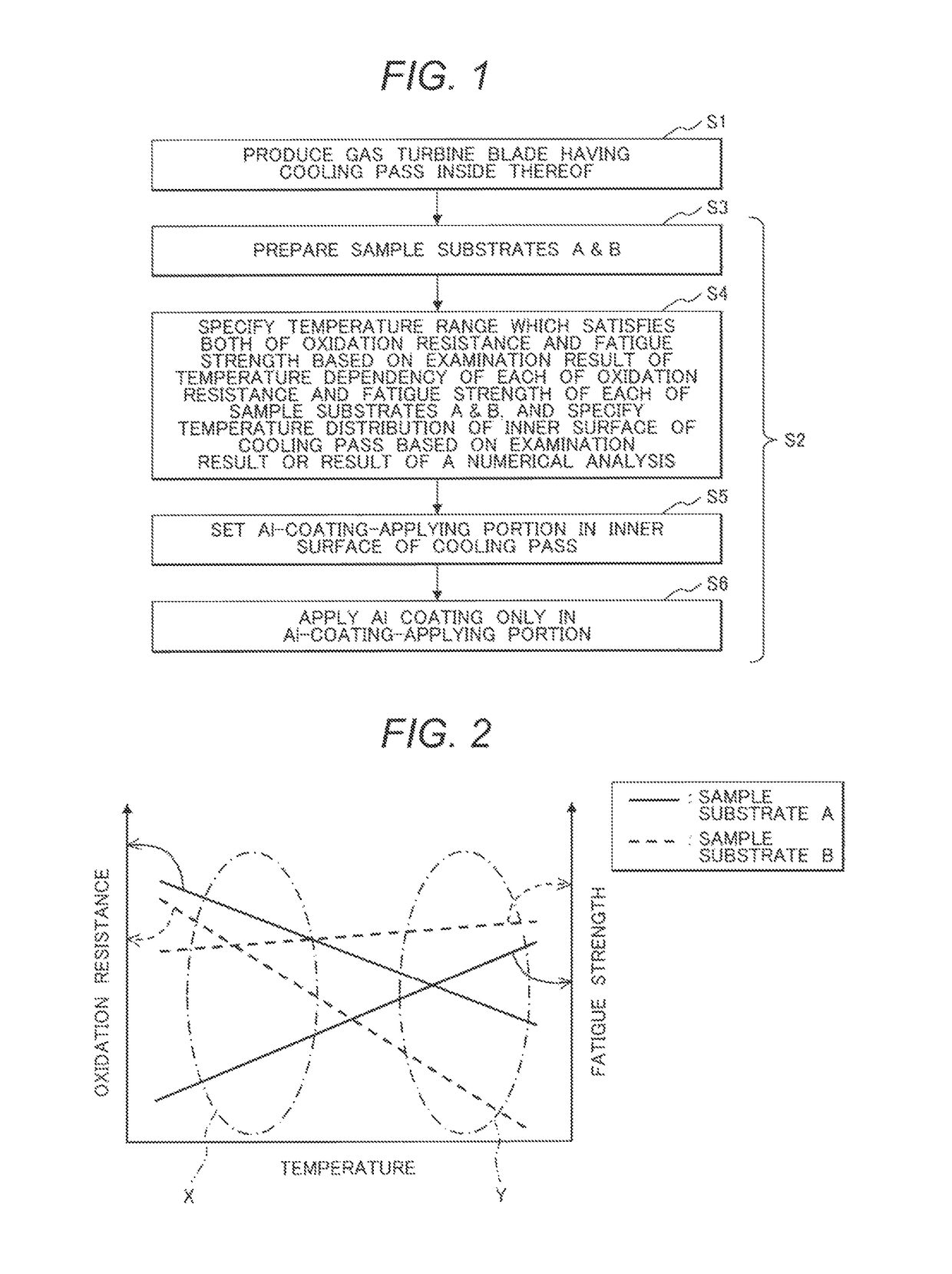

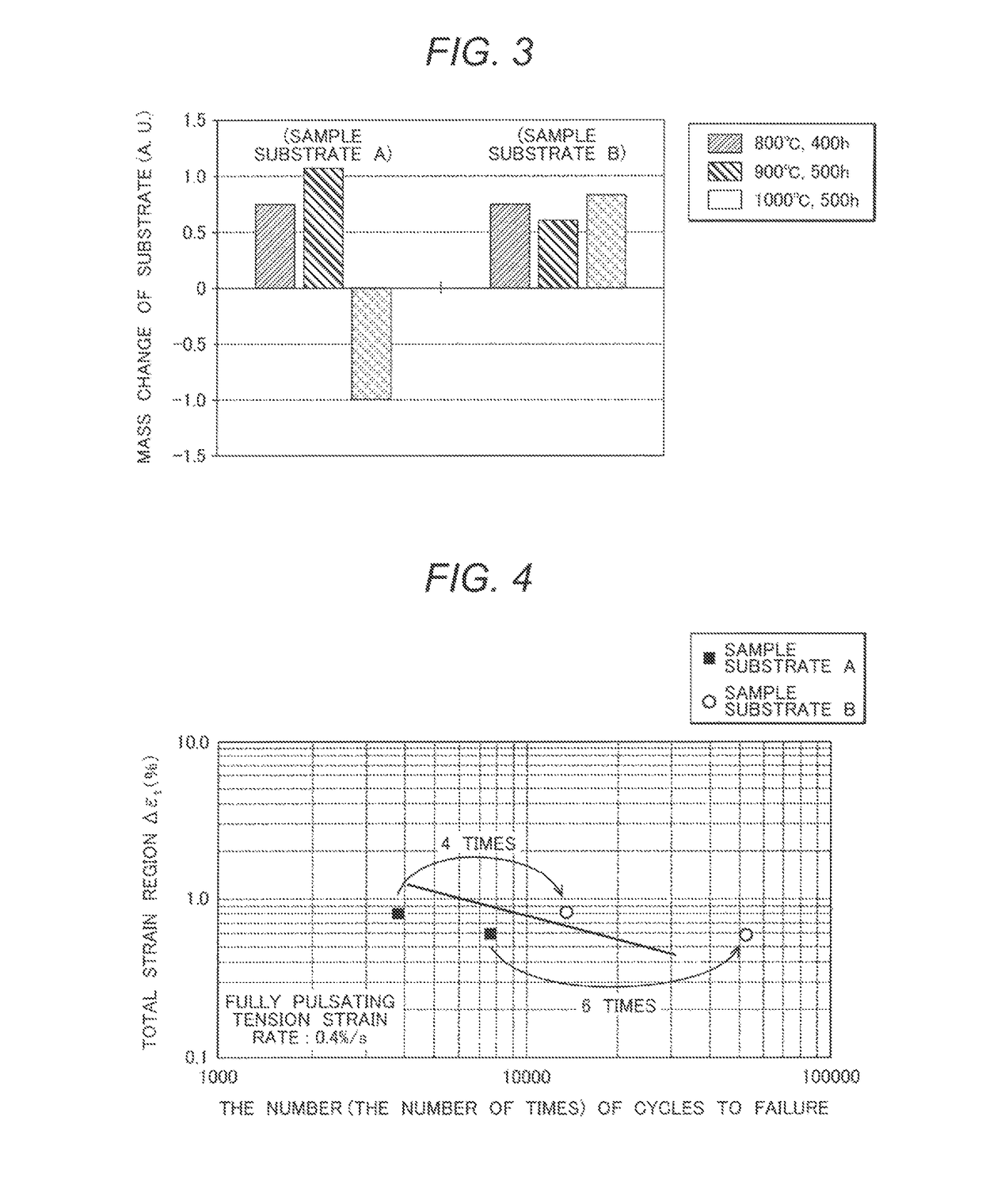

Method for manufacturing gas turbine blade, and gas turbine blade

ActiveUS9732411B2Oxidization can be acceleratedFatigue strength is very importantBlade accessoriesSolid state diffusion coatingTurbine bladeEngineering

Owner:MITSUBISHI POWER LTD

Gluten-free instant ramen and its preparation method and recipe

ActiveCN104366277BReduce amylose contentBad tasteFood thermal treatmentFood dryingSafety indexAdditive ingredient

The invention provides gluten-free instant hand-pulled noodles and a preparation method and a formula thereof and relates to the field of food deep processing. The gluten-free instant hand-pulled noodles are mainly prepared from cereals such as Chinese Northeast non-glutinous polished rice, Chinese Northeast non-glutinous unpolished rice, Chinese Northeast black rice and millet with manufactured goods which are rich in nutrition and have health care effect serving as minor ingredients by means of technologies of flour milling, flour mixing, standing for a while, primary extrusion, secondary extrusion, aging treatment, variable-temperature drying, ventilative cooling, bagging, inspection, sealing packing, boxing and the like. The obtained hand-pulled noodles are chewy, refreshing and slippery, avoid being mixed with soup, breakage and adhesion during cooking and are good in taste and sweet after taste. What is more important is that the noodles are smooth and pleasing in appearance and oily before being cooked and can completely reach the international highest safety index of gluten content not exceeding 5-10PPM, thereby being more nutritional and safer. Moreover, production efficiency is improved greatly, energy consumption and pollution discharge are reduced, and more environment friendliness and lower carbon are achieved.

Owner:大连弘润莲花食品有限公司

Composite structure with porous metal

ActiveUS10919261B2Poor toughnessLimited applicationMaterial nanotechnologyLaminationNanotubeComposite structure

A composite structure with porous metal comprises a porous metal structure and a carbon nanotube structure comprising a plurality of carbon nanotubes, the carbon nanotube structure is fixed on surface of the porous metal structure, and the porous metal structure and the carbon nanotube structure are shrunk together to form a plurality of wrinkled parts.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com