Preparation method of wear-resistant metal-multi-element ceramic composite modified coating on surface of titanium alloy

A wear-resistant metal and ceramic composite technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of coating hardness cracks, material waste, deviation, etc., to improve wear resistance, good toughness, fine grain obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

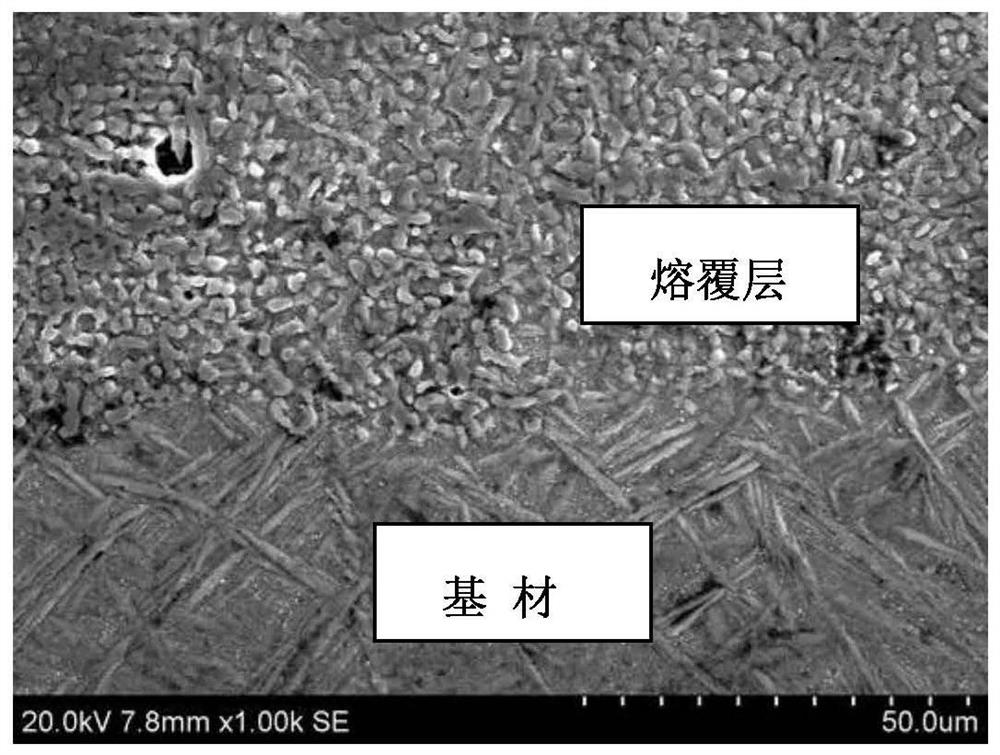

[0030] A method for preparing a wear-resistant metal-multielement ceramic composite modified coating on the surface of a titanium alloy, comprising the following steps:

[0031] (1) Preparation of pre-alloyed powder, specifically including the following steps:

[0032] S1. Take four powders of HfC, TaC, ZrC and NbC with a particle size of 100-270 mesh, and mix them in a ratio of 1:1:1:1 by mass;

[0033] S2, put the mixed powder of S1 into a high-energy ball mill, and perform ball milling to obtain a ground ceramic phase powder;

[0034] S3. Take the spherical titanium alloy powder with a particle size of 400-500 mesh, put the titanium alloy powder and the ceramic phase powder obtained by grinding in S2 into a ball mill for ball milling to obtain a ground pre-alloyed powder, and the ceramic phase powder in the pre-alloyed powder The mass percentage is 5% to 15%.

[0035] Wherein, the grinding balls used in the S2 and S3 ball milling are corundum balls with a diameter of 1mm ...

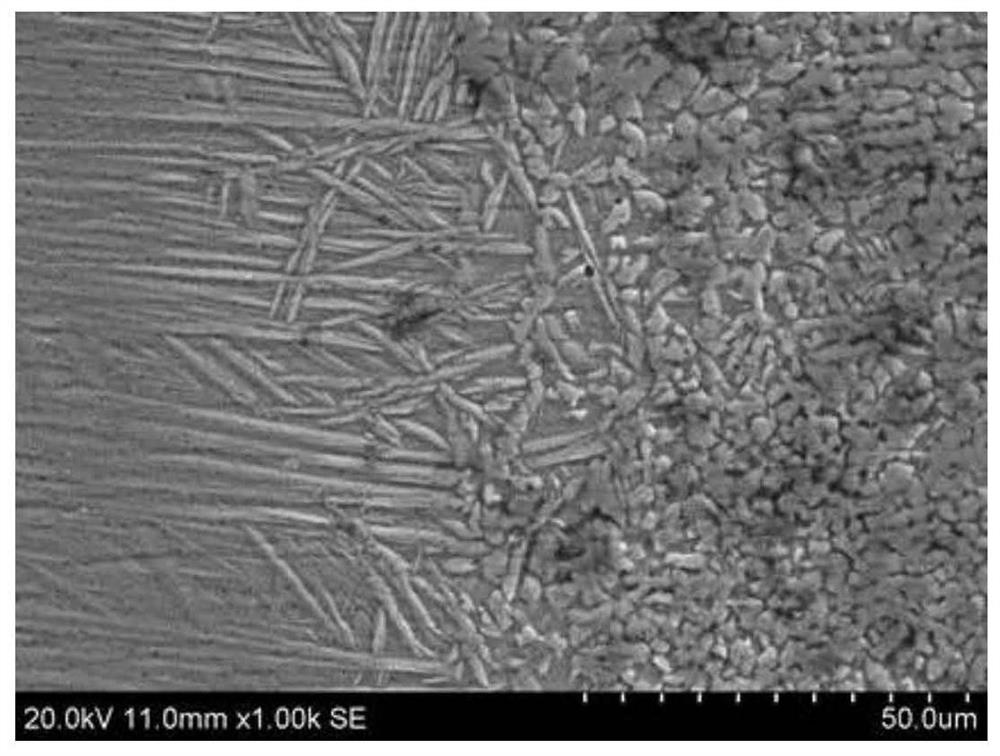

Embodiment 1

[0040] A method for preparing a wear-resistant metal-multielement ceramic composite modified coating on the surface of a titanium alloy, comprising the following steps:

[0041] (1) Preparation of pre-alloyed powder, including the following steps:

[0042] S1. The particle size is HfC, TaC, ZrC and NbC four kinds of powders with a particle size of 100-270 mesh, mixed in a ratio of 1:1:1:1 by mass;

[0043] S2. Put the mixed powder into a high-energy ball mill for ball milling. During ball milling, the grinding balls are mixed corundum balls with a diameter of 1mm and 3mm and a quantity ratio of 1:4. The volume ratio of the ball to material is about 3:1. The ball milling time For 12 hours, the ground ceramic phase powder was obtained;

[0044] S3. Take the spherical TC4 powder with a particle size of 400 to 500 meshes, grind the TC4 powder and the ceramic phase powder obtained by S2, and put them into a ball mill for ball milling, wherein the ceramic phase powder accounts for ...

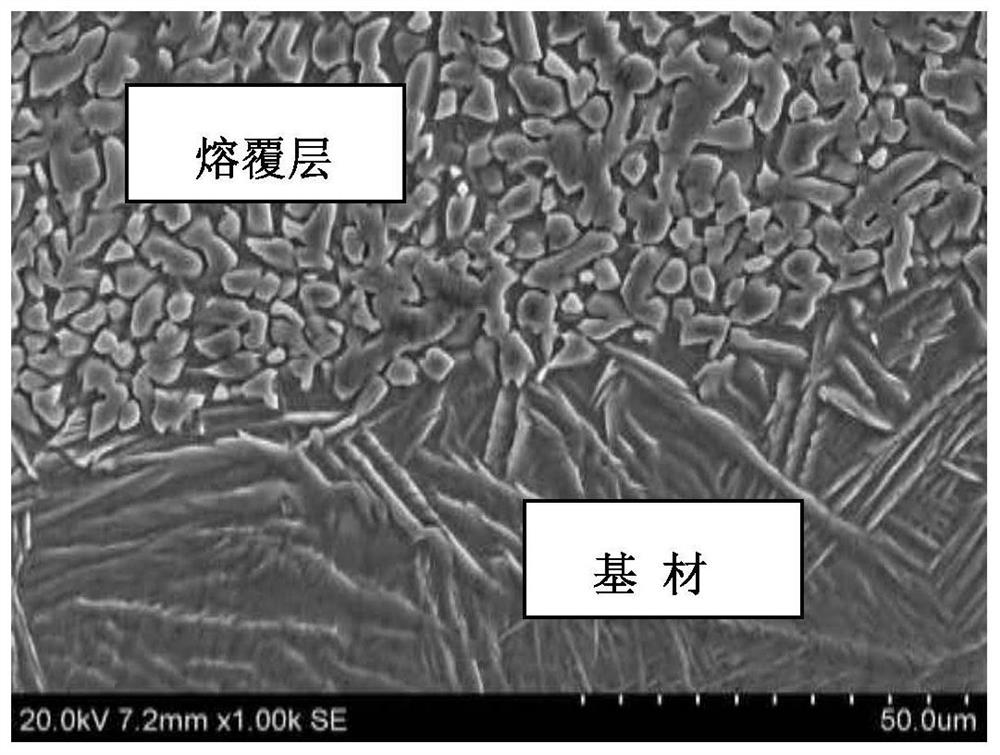

Embodiment 2

[0049]A method for preparing a wear-resistant metal-multielement ceramic composite modified coating on the surface of a titanium alloy, comprising the following steps:

[0050] (1) Preparation of pre-alloyed powder, including the following steps:

[0051] S1. Take four powders of HfC, TaC, ZrC and NbC with a particle size of 100-270 mesh, and mix them in a ratio of 1:1:1:1 by mass;

[0052] S2. Put the mixed powder into a high-energy ball mill for ball milling. During ball milling, the grinding balls are mixed corundum balls with a diameter of 1mm and 3mm and a quantity ratio of 1:4. The volume ratio of the ball to material is about 3:1. The ball milling time For 10 hours, the ground ceramic phase powder was obtained;

[0053] S3. Take the spherical TC4 powder with a particle size of 400-500 meshes, grind the TC4 powder and the ceramic phase powder obtained by S2, and put them into a ball mill for ball milling, wherein the ceramic phase powder accounts for 10% of the total ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com