Patents

Literature

33results about How to "Poor mechanical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

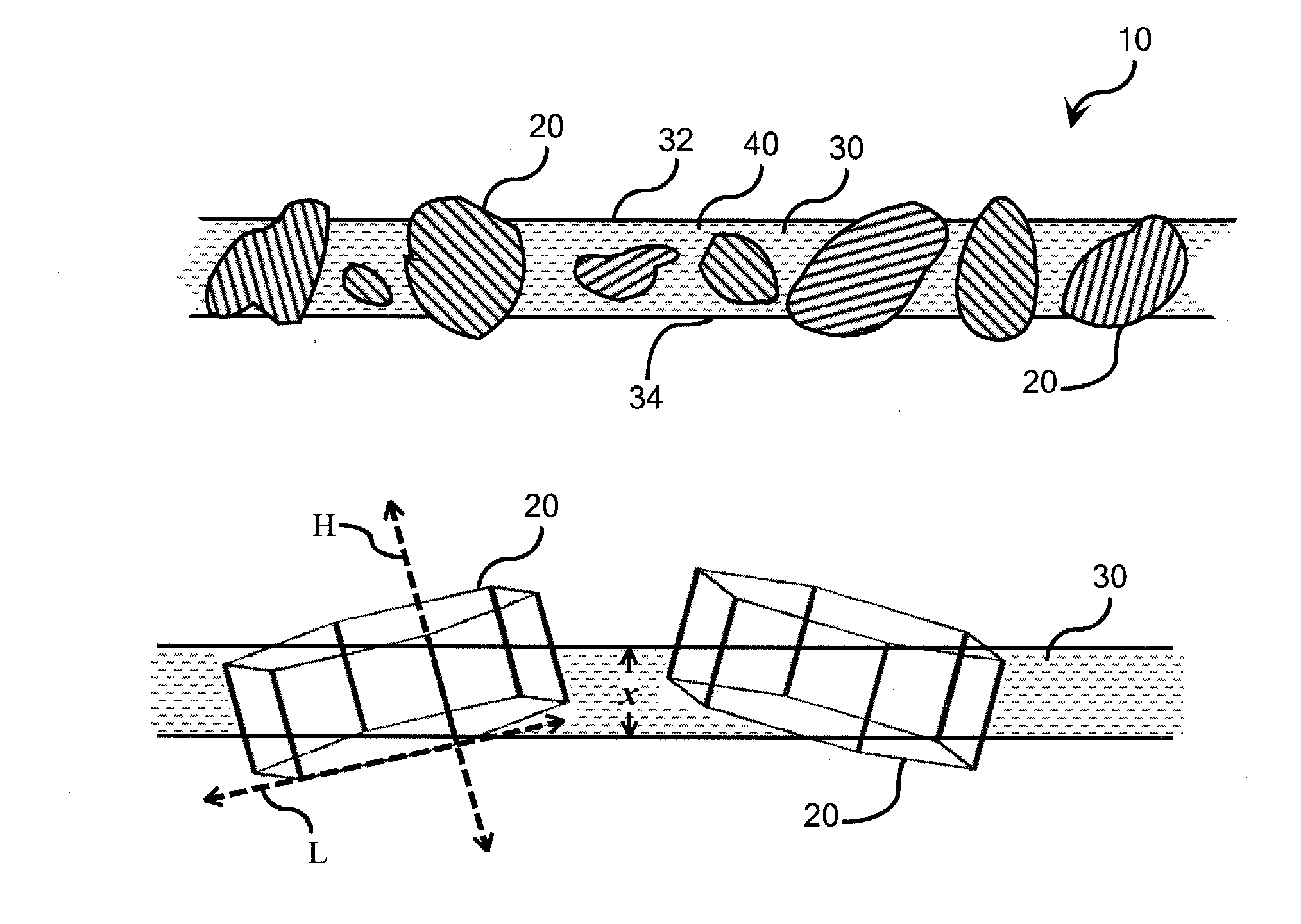

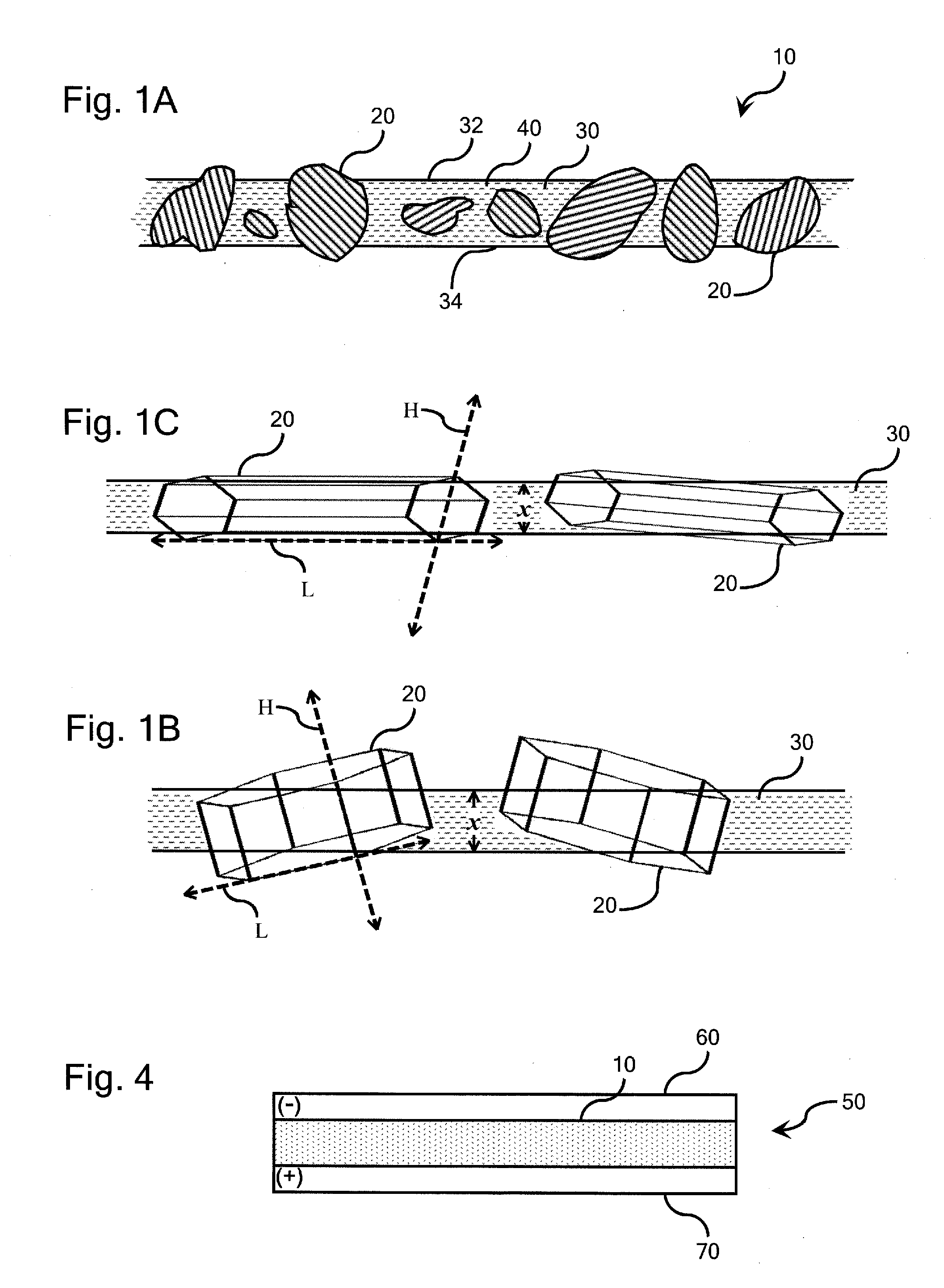

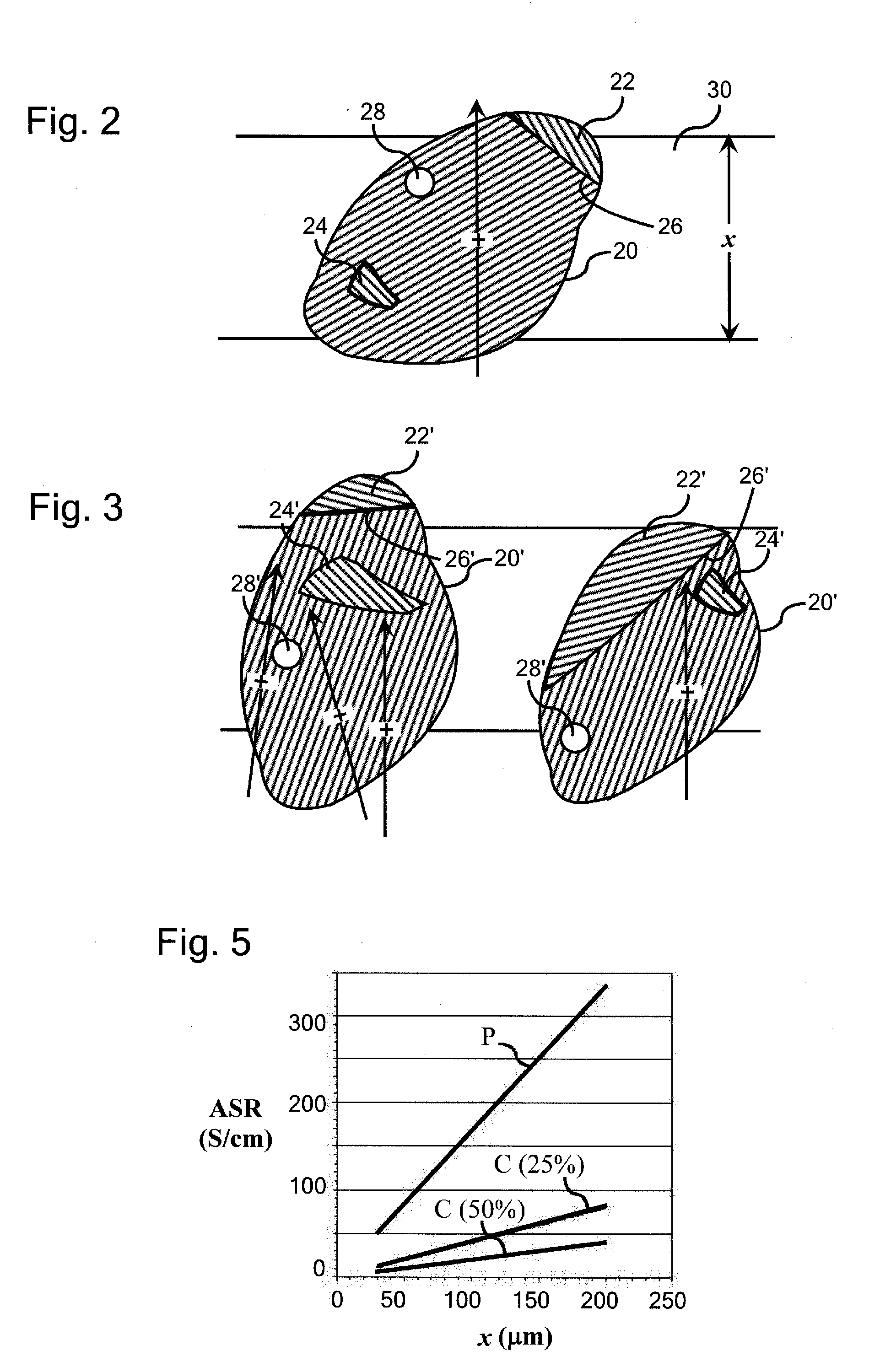

Ion-conducting composite electrolyte comprising path-engineered particles

ActiveUS20140065513A1Made practicalLimit ionic conductivityFrom normal temperature solutionsLiquid separation by electricityPath lengthComposite electrolyte

An ion-conducting composite electrolyte is provided comprising path-engineered ion-conducting ceramic electrolyte particles and a solid polymeric matrix. The path-engineered particles are characterized by an anisotropic crystalline structure and the ionic conductivity of the crystalline structure in a preferred conductivity direction H associated with one of the crystal planes of the path-engineered particle is larger than the ionic conductivity of the crystalline structure in a reduced conductivity direction L associated with another of the crystal planes of the path-engineered particle. The path-engineered particles are sized and positioned in the polymeric matrix such that a majority of the path-engineered particles breach both of the opposite major faces of the matrix body and are oriented in the polymeric matrix such that the preferred conductivity direction H is more closely aligned with a minimum path length spanning a thickness of the matrix body than is the reduced conductivity direction L.

Owner:CORNING INC

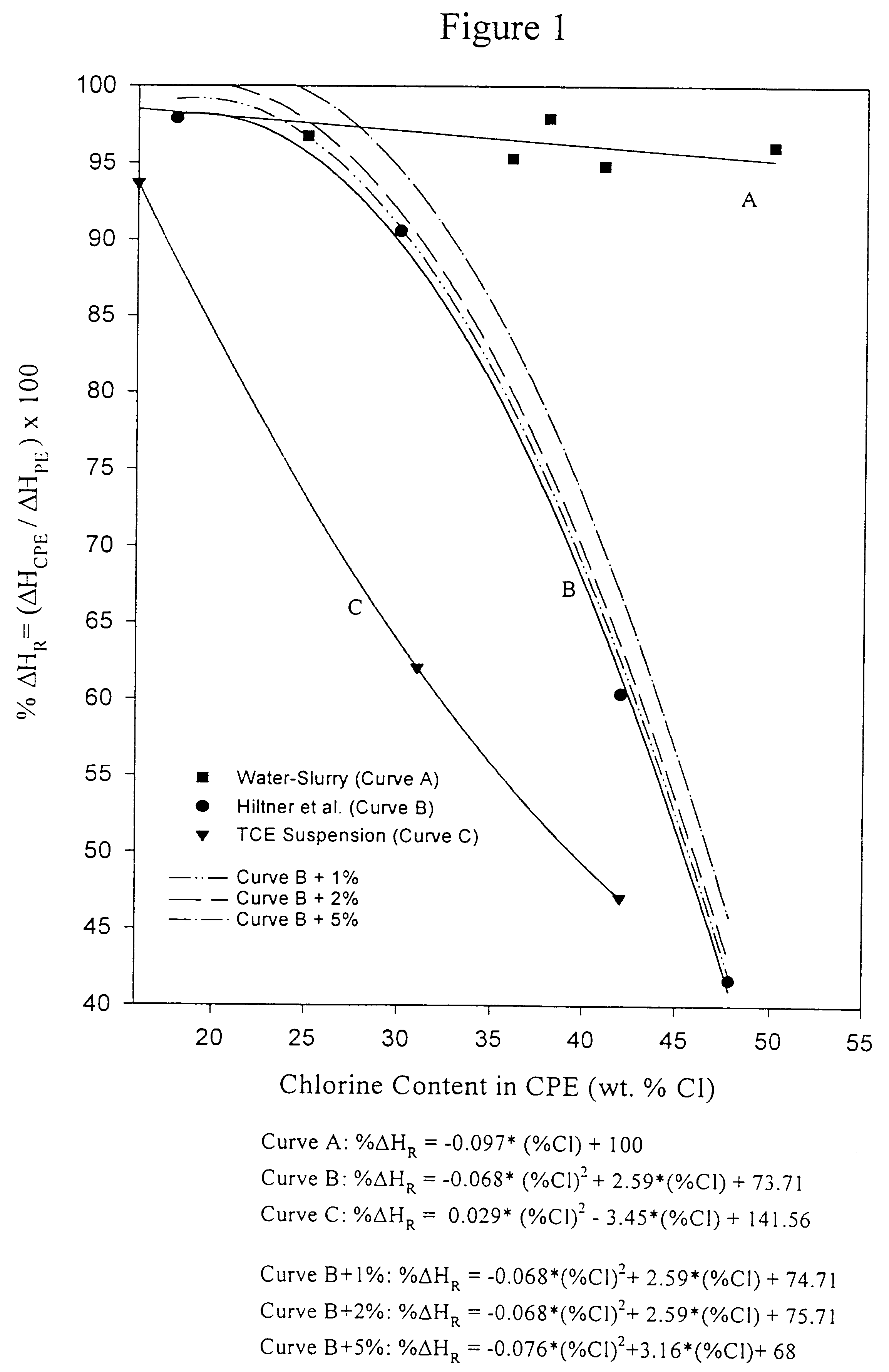

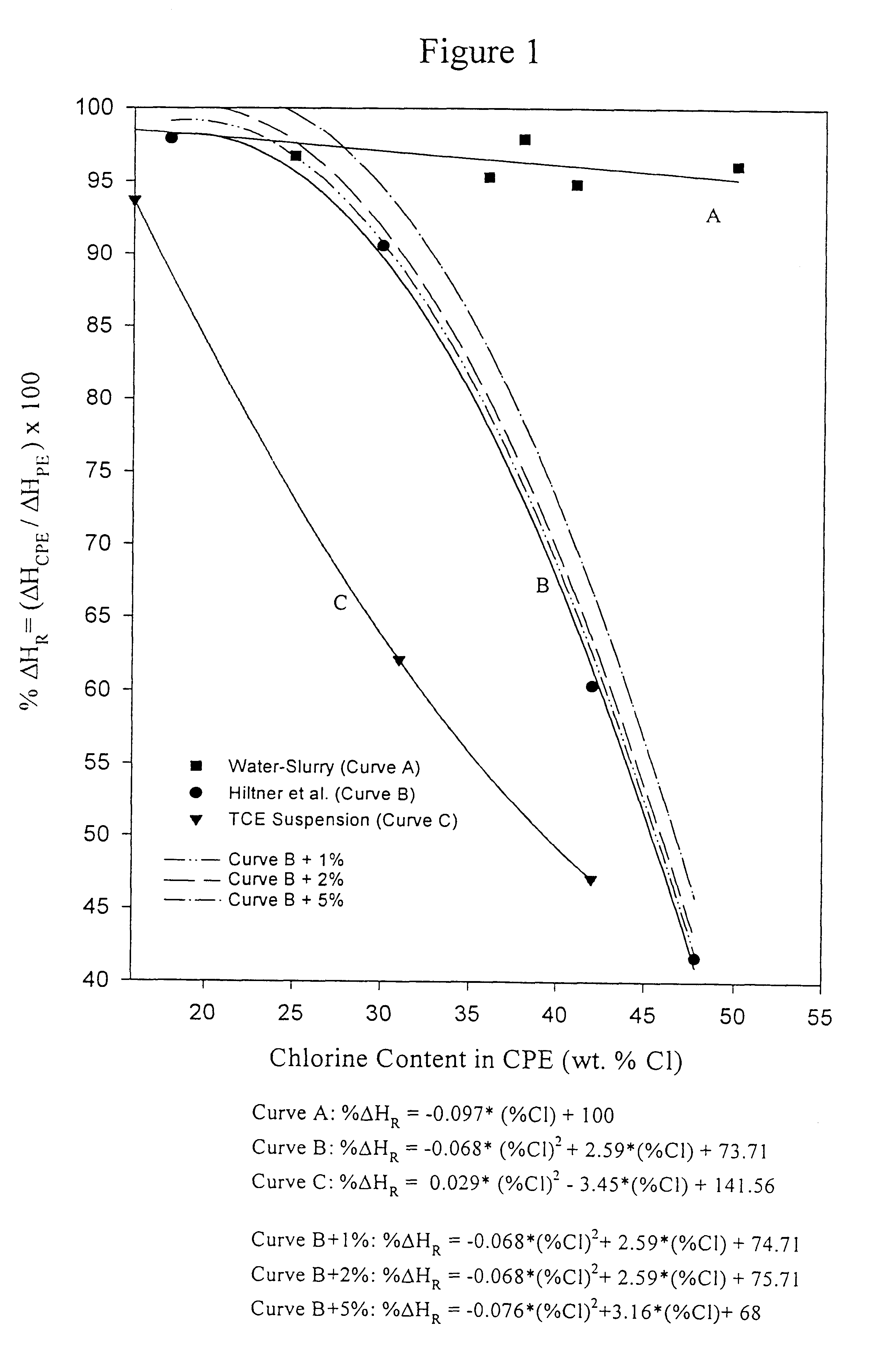

Blocky chlorinated polyolefins, process for making and use as impact modifier compatibilizer for PVC or CPVC

Blocky chlorinated polyolefins are disclosed as compatibilizers of PVC and / or CPVC resins with polyolefin elastomers. The blocky chlorinated polyolefins facilitate the dispersion of the elastomers as a dispersed phase with the proper size for impact modification of the PVC and / or CPVC. The blocky chlorinated polyolefin provides better adhesion between the elastomer and the PVC and / or CPVC providing better physical properties such as impact strength as measured by Notched Izod and variable height impact testing (VHIT) than did the randomly chlorinated polyolefins, often used as processing aids and as impact modifiers in PVC or CPVC. The differences in properties achieved with blocky chlorinated polyolefins versus randomly chlorinated polyolefins are attributed to the individual blocks of the blocky polyolefin being compatible (and / or co-crystalizable) with either the polyolefin elastomer or the PVC / CPVC resulting in better adhesion between phases. Also disclosed is a process for making optimal blocky chlorinated polyolefins.

Owner:NOVEON INC

Polyethylene fiber and a non-woven fabric using the same

InactiveUS6303220B1Superior crimp retainabilityImprove radiation resistanceFilament/thread formingWoven fabricsPolymer scienceYoung's modulus

A polyethylene fiber having a high apparent Young's modulus, high breaking tensile strength and low breaking elongation. The fiber also exhibits residual percentage crimp suitable enough for carding, so that the cardability, which has been conventionally difficult to improve, can be remarkably increased. Further, the fiber can be formed into a non-woven fabric having a soft touch feeling such that the fabric is suitable for medical use as well as hygienic use. In addition, the polyethylene fiber of this invention can be mixed with other fibers such as cellulose fiber to obtain a high absorbent fiber network material.

Owner:JNC CORP

Tablet, process for producing the same, and molded article obtained therefrom

InactiveUS20050098916A1Stabilize metering timeEvenly dispersedSynthetic resin layered productsCellulosic plastic layered productsCompression moldingChemistry

Tablets of thermoplastic resin and filler, in which the compositional ratio of the two is so controlled that the thermoplastic resin accounts for from 1 to 40% by volume and the filler for from 60 to 99% by volume based on the sum of the two, 100% by volume, are obtained by compression-molding thermoplastic resin powder and filler into the tablets, or melt-kneading thermoplastic resin and filler followed by compression-molding the powder of the resulting composition into the tablets. The filler content thereof is high, heretofore unknown in the art, and the tablets efficiently exhibit the properties of the filler therein.

Owner:TORAY IND INC

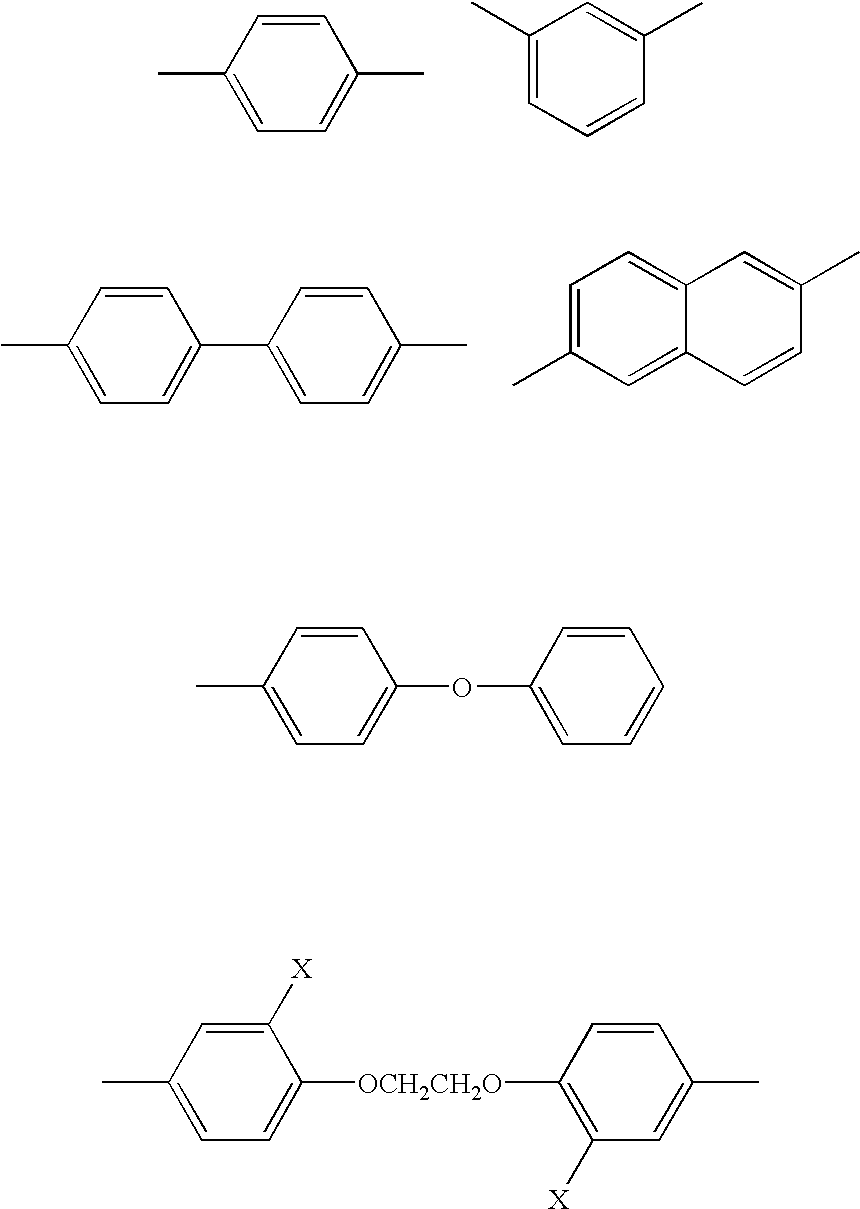

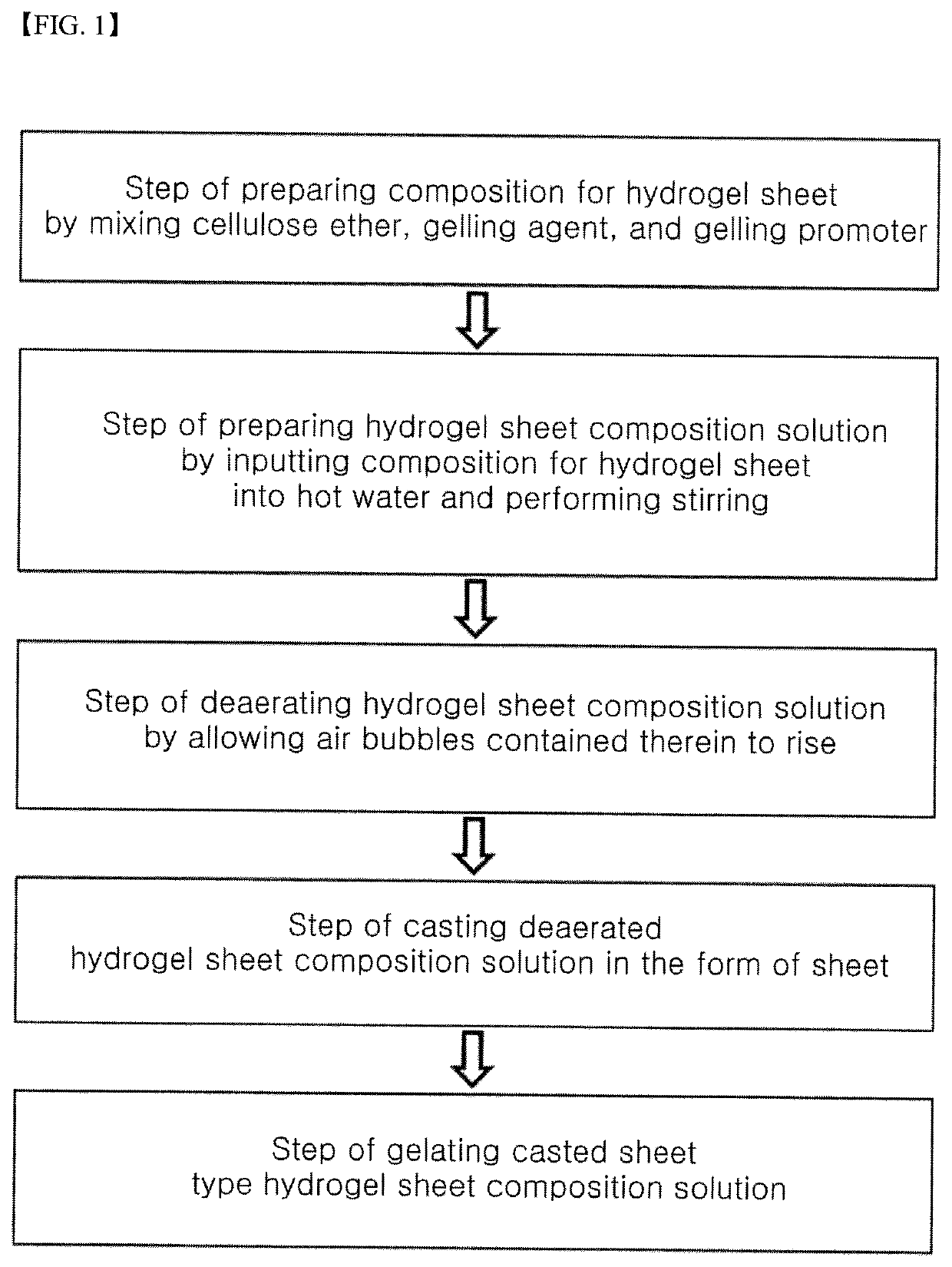

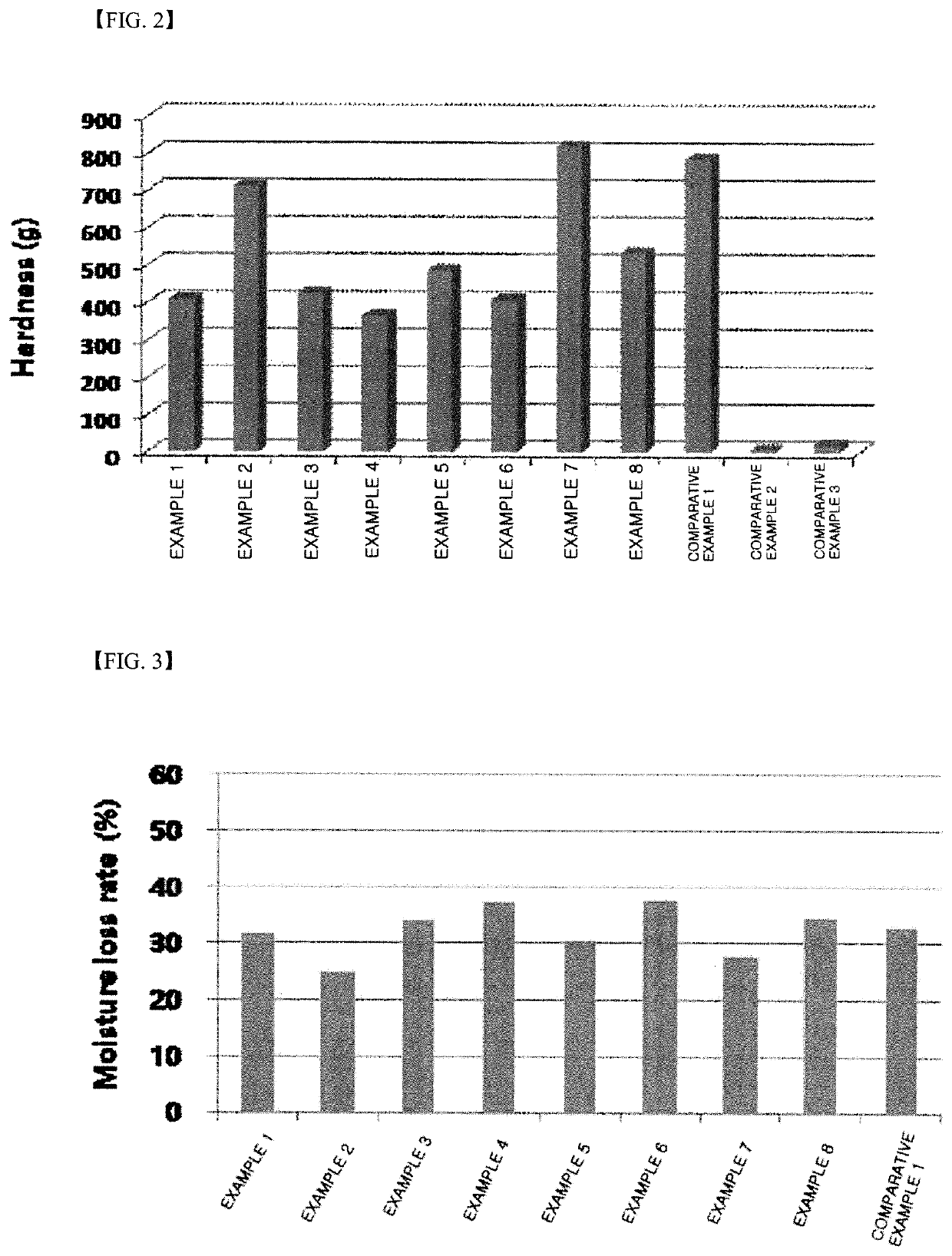

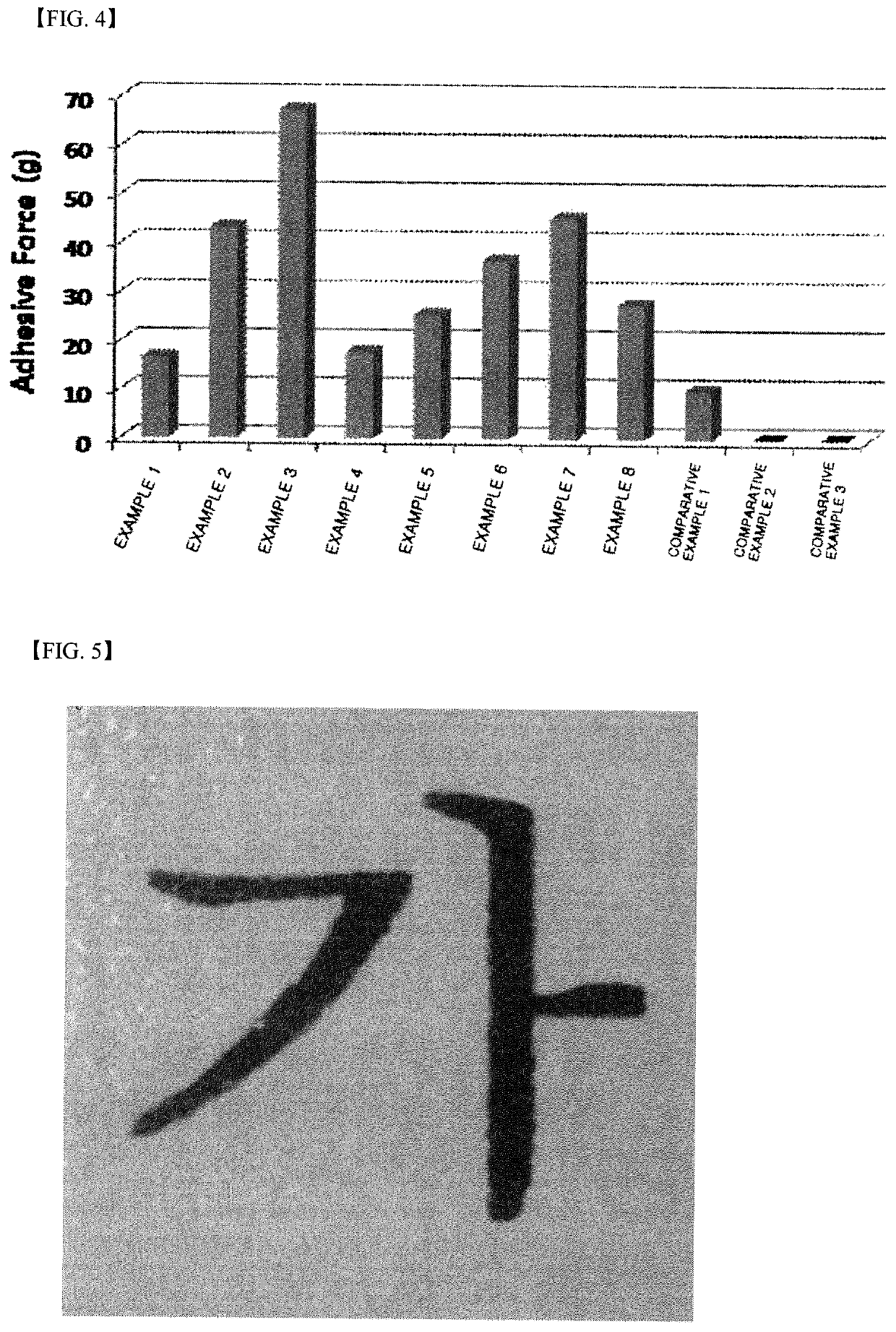

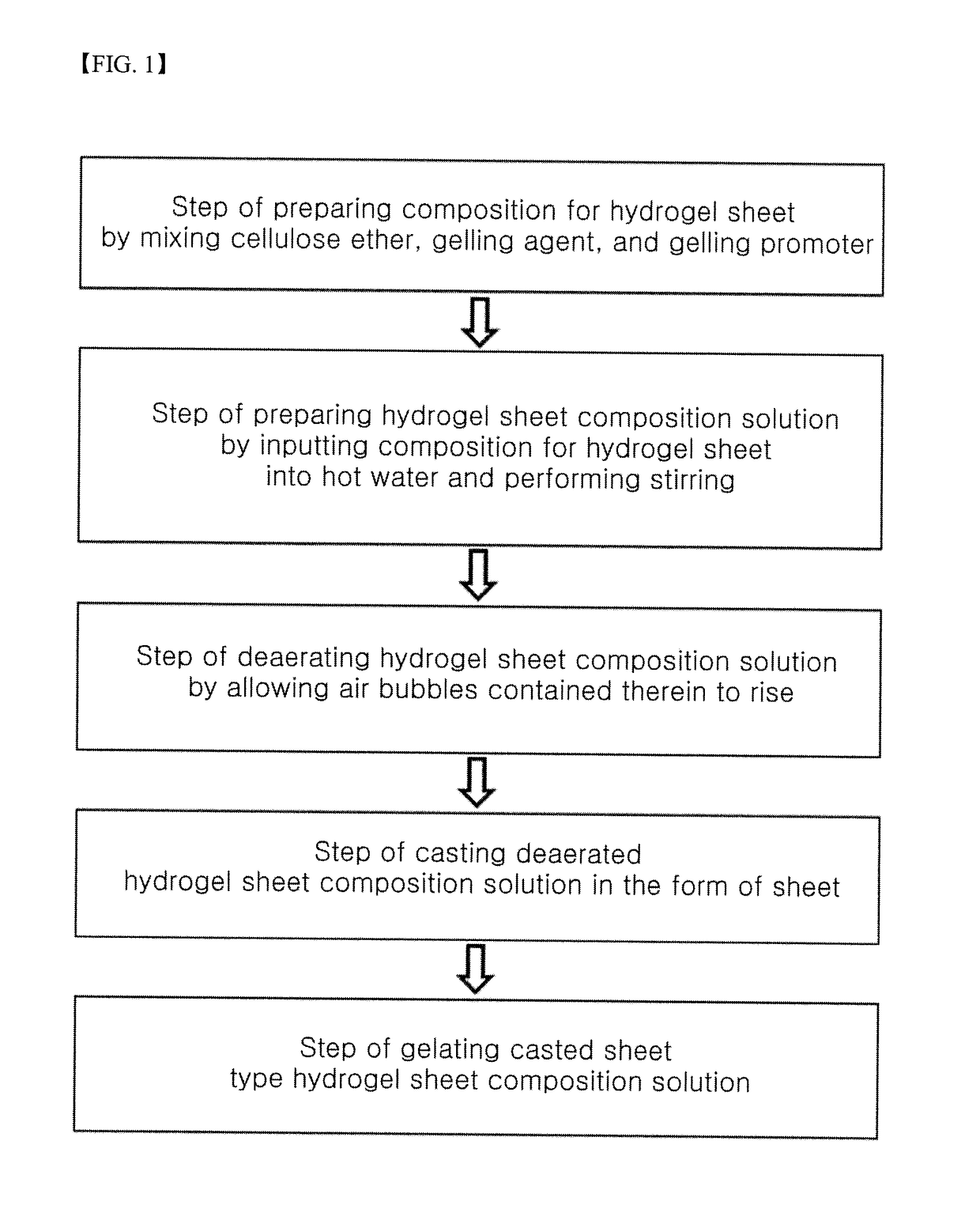

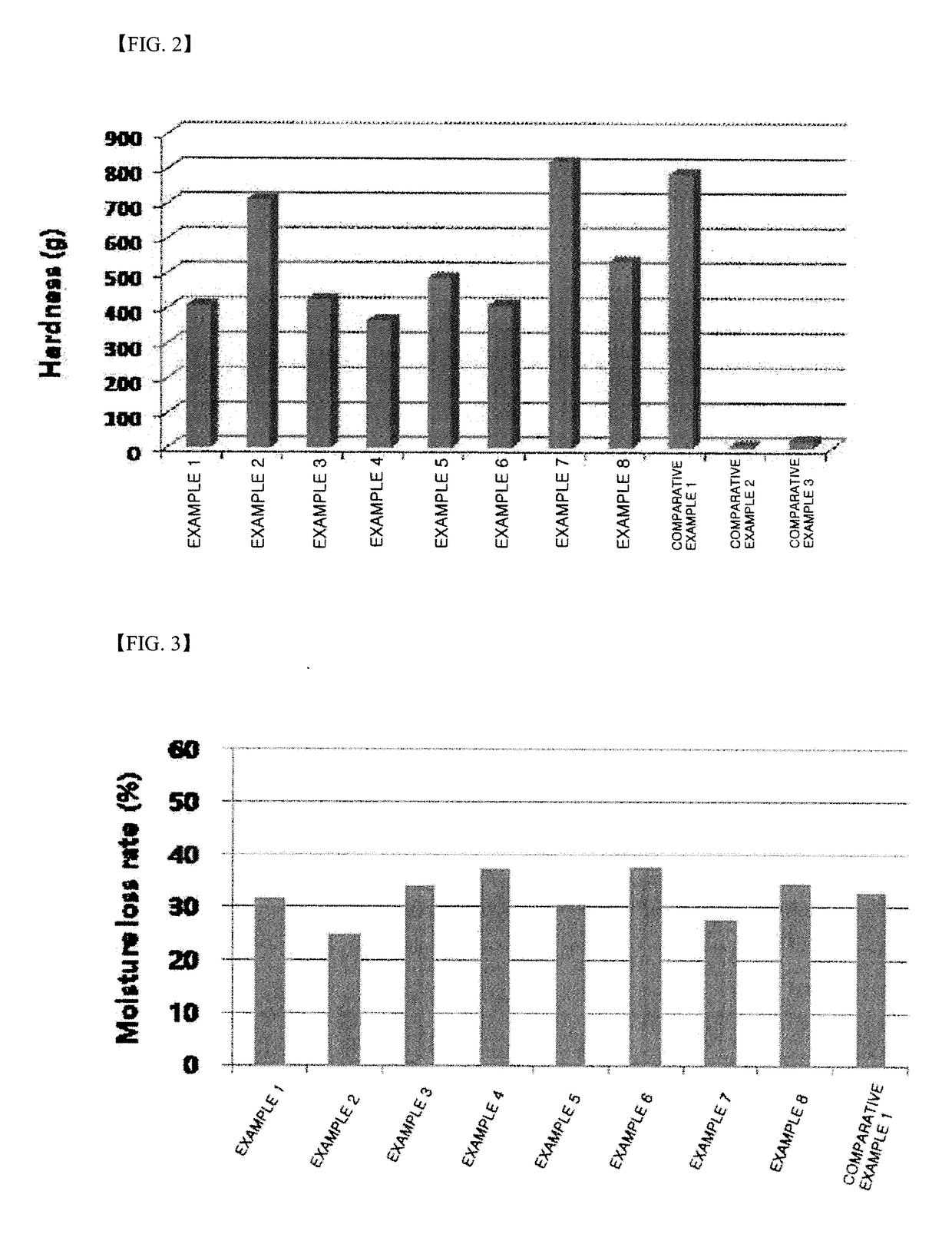

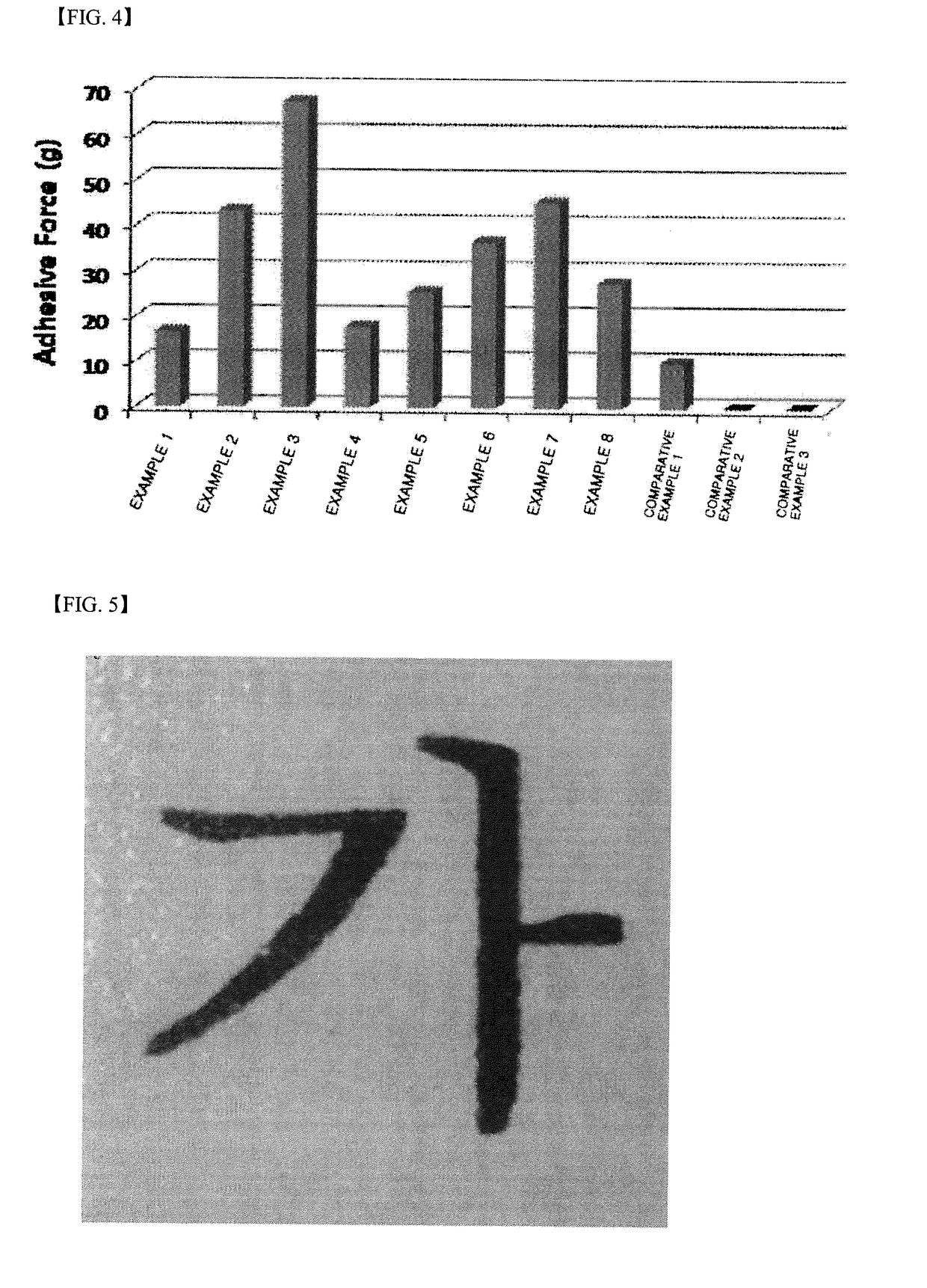

Composition for hydrogel sheet, hydrogel sheet manufactured therefrom, and method for manufacturing same

ActiveUS10617608B2Unique hydrophilicityUnique flexibilityCosmetic preparationsToilet preparationsCellulosePolymer science

The present invention relates to a composition for a hydrogel sheet including a cellulose ether, a gelling agent, and a gelling promoter, a hydrogel sheet prepared therefrom, and a method of preparing the hydrogel sheet. According to the present invention, the composition for a hydrogel sheet can be used to prepare a hydrogel sheet capable of maintaining the shape thereof without a support by limiting a type of the gelling agent and / or a viscosity of the cellulose ether included in the composition.

Owner:LOTTE FINE CHEM CO LTD

Process For Producing Flexible Polyurethane Foam Using Natural Oil Polyols

ActiveUS20130197114A1Low usage levelLess corrosive mixtureOther chemical processesSulfolaneMechanical crushing

A composition and process useful to make flexible polyurethane foams and in particular flexible molded polyurethane foams is disclosed. The usage of dipolar aprotic liquids such as DMSO, DMI, sulfolane, N-methyl-acetoacetamide, N,N-dimethylacetoacetamide as well as glycols containing hydroxyl numbers OH#≦1100 as cell opening aides for 2-cyanoacetamide or other similar molecules containing active methylene or methine groups to make a polyurethane foam is also disclosed. The advantage of using cell opener aids results in a) no foam shrinkage; b) lower use levels of cell opener; c) foam performance reproducibility d) optimum physical properties. In addition, combining the acid blocked amine catalyst together with the cell opener and the cell opener aid results in a less corrosive mixture as well as provides a method that does not require mechanical crushing for cell opening.

Owner:EVONIK OPERATIONS GMBH

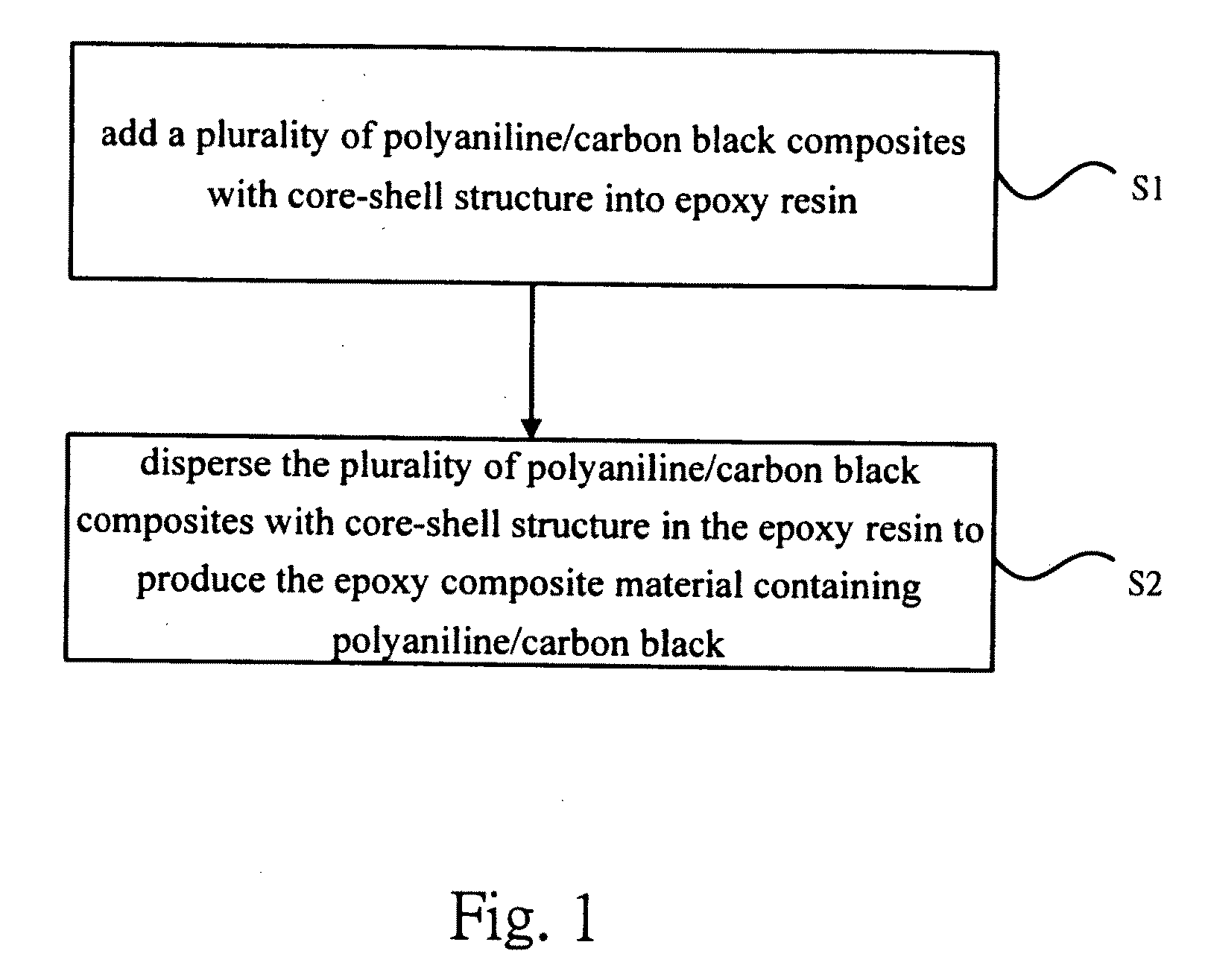

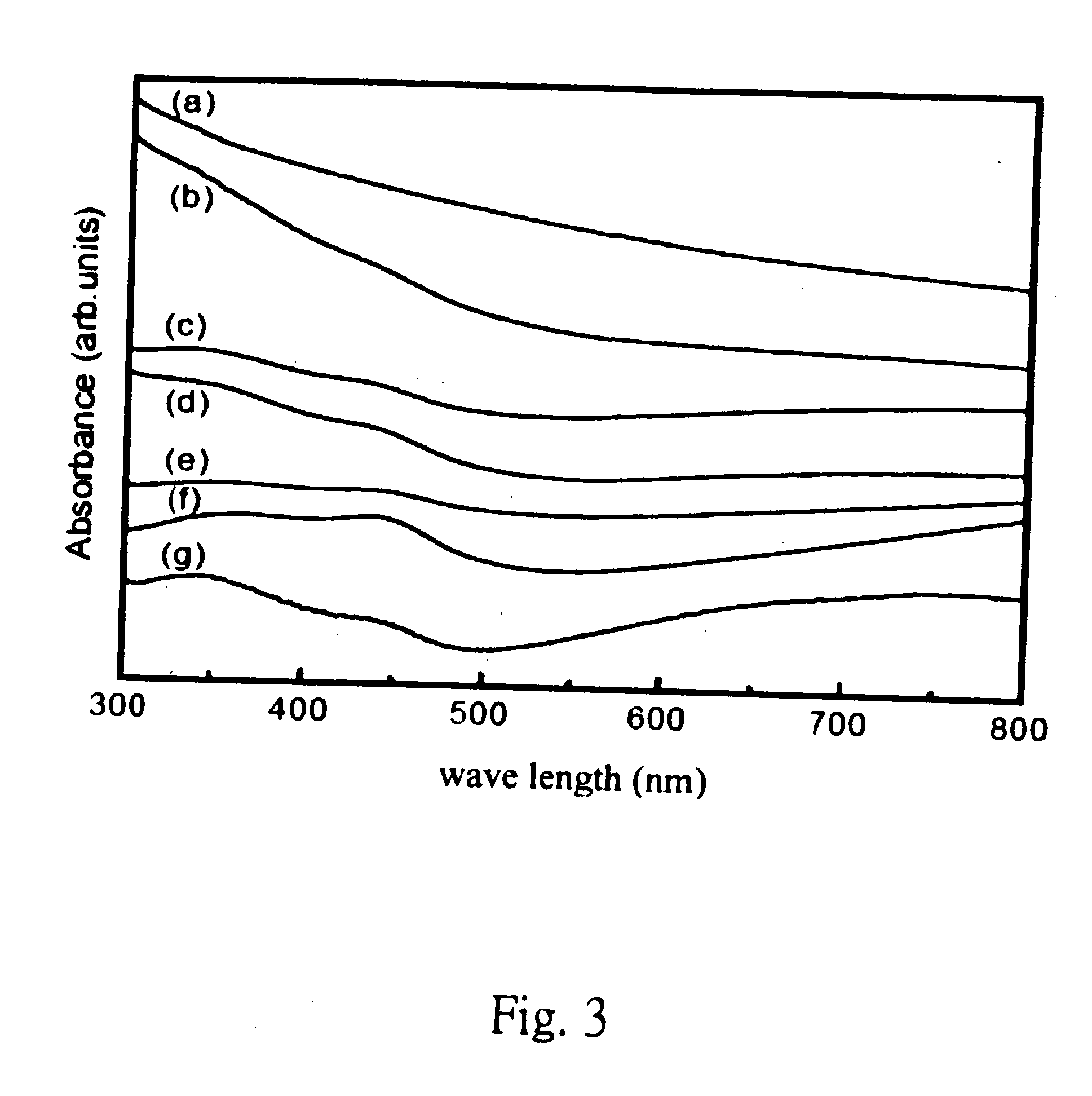

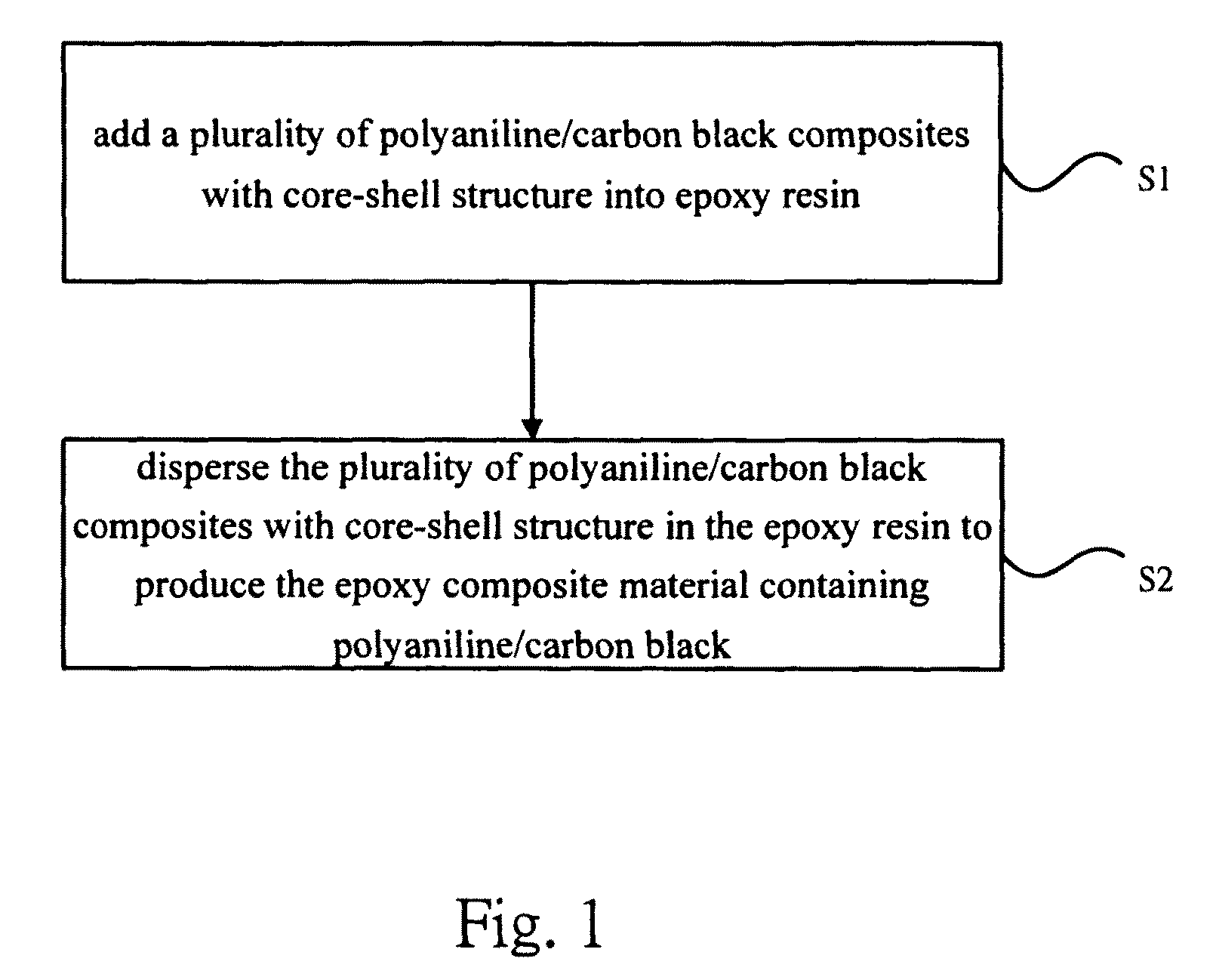

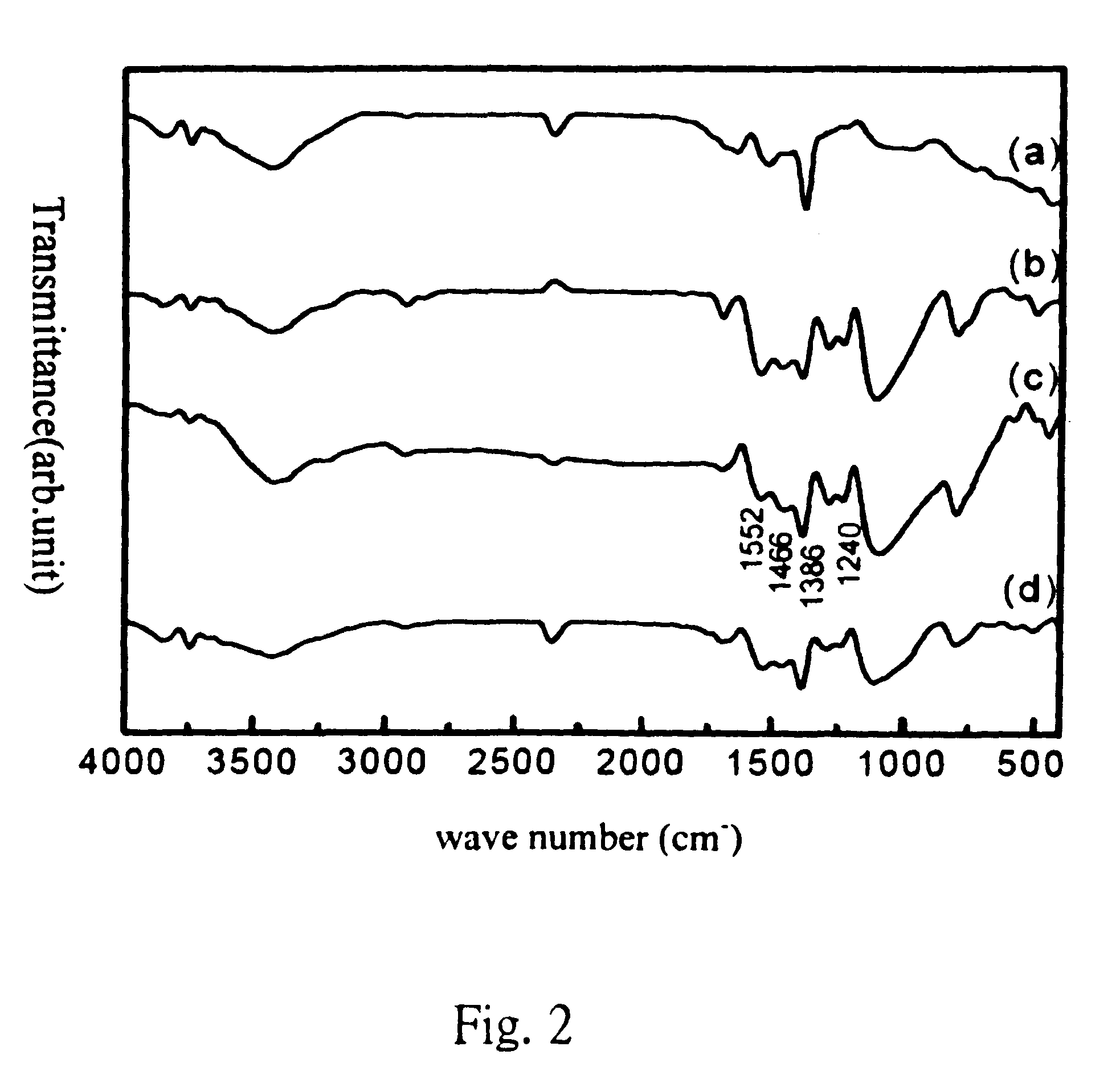

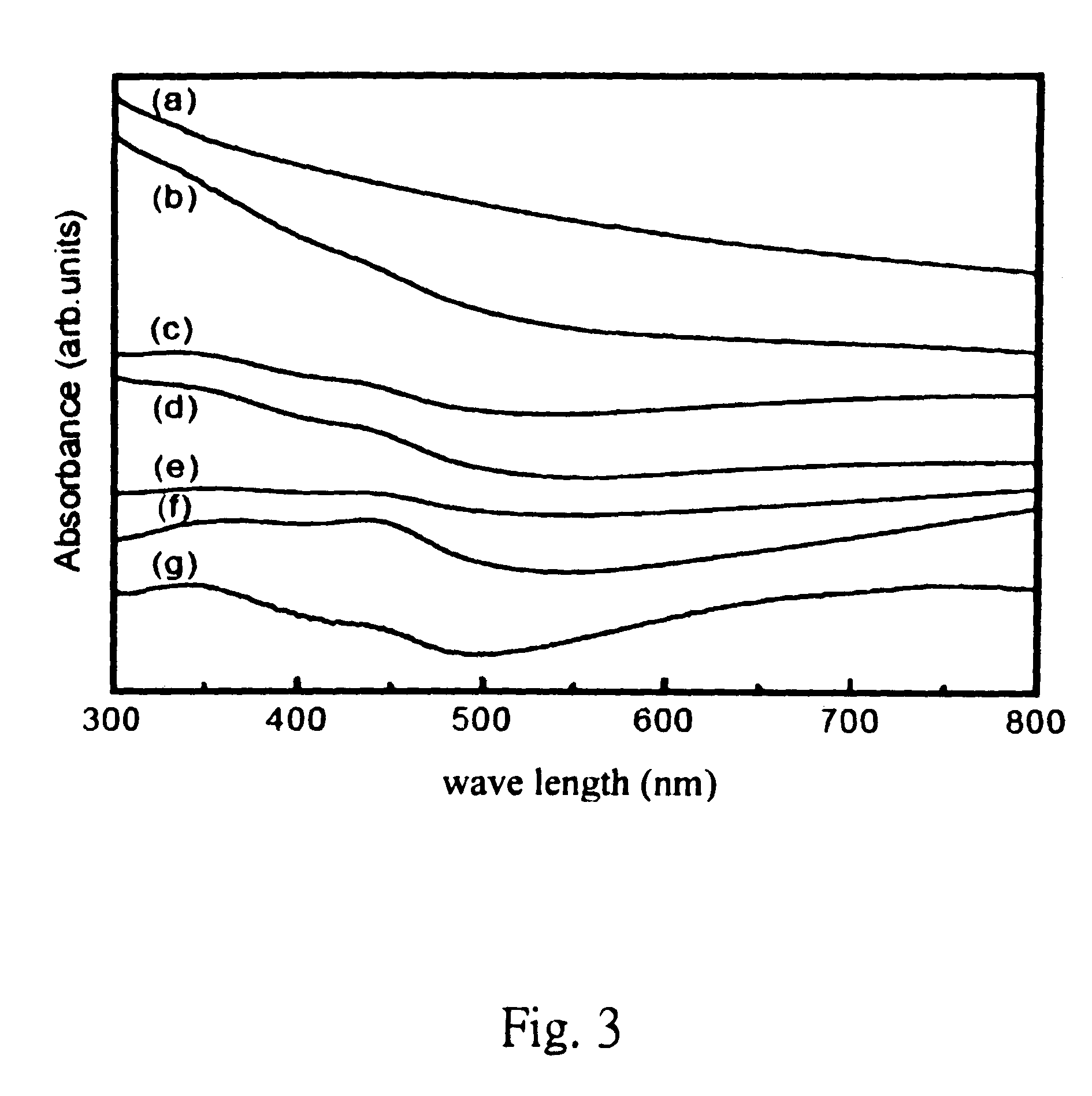

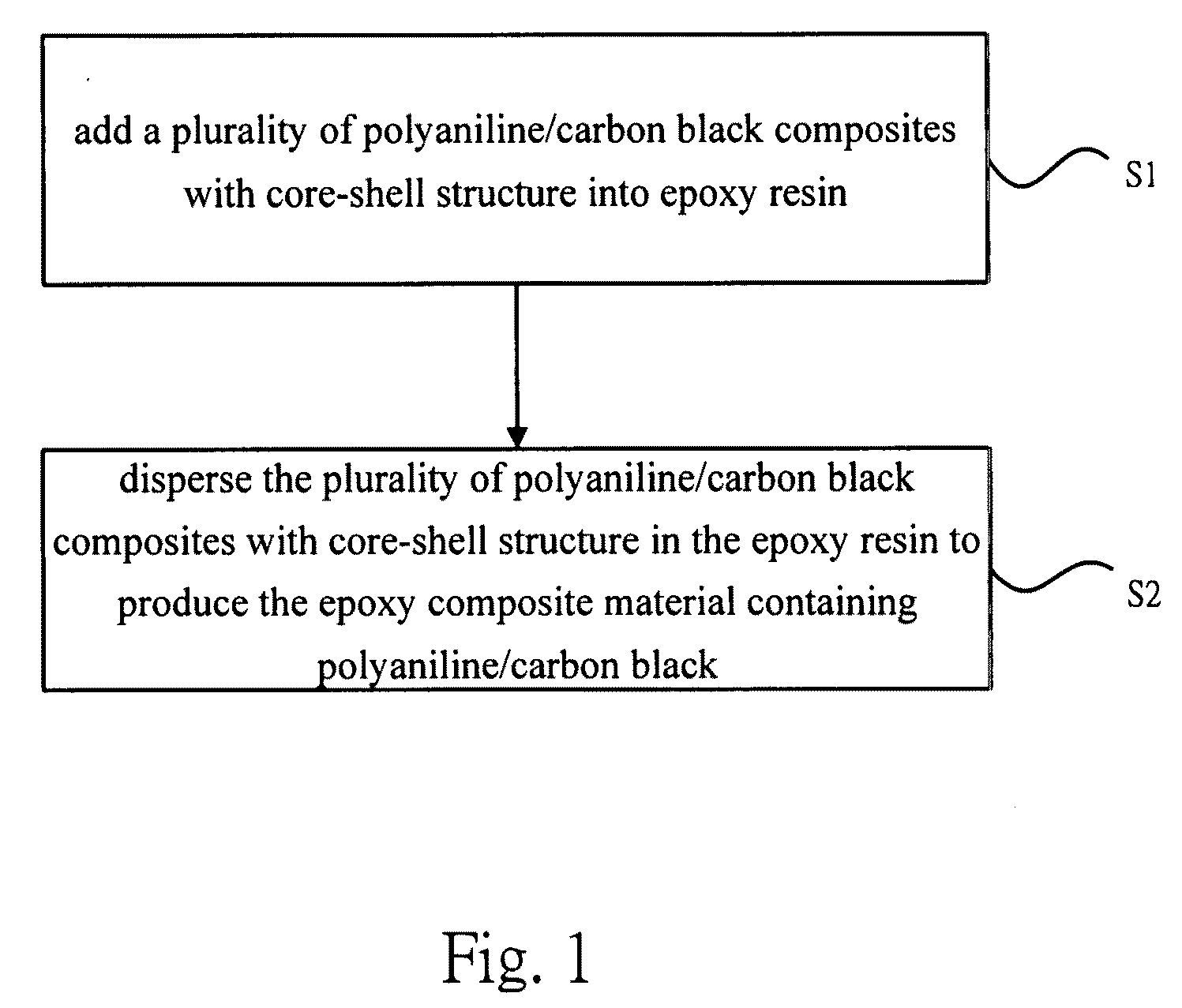

Epoxy composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS20090109791A1High absorption effectImprove conductivityNon-metal conductorsShaking/oscillating/vibrating mixersMicrowaveConductive coating

An epoxy composite material containing polyaniline / carbon black and preparation method thereof are disclosed. The epoxy composite material containing polyaniline / carbon black includes a plurality of polyaniline / carbon black composite with core-shell structure distributed in epoxy resin while polyaniline covers on surface of nanoscale carbon black to form the polyaniline / carbon black composite with core-shell structure. The polyaniline / carbon black composite with core-shell structure contains 10˜30 wt. % of nanoscale carbon black. A method for preparing an epoxy composite material containing polyaniline / carbon black includes steps of: adding a plurality of polyaniline / carbon black composites with core-shell structure into epoxy resin; and dispersing the plurality of polyaniline / carbon black composites with core-shell structure in the epoxy resin to produce the epoxy composite material containing polyaniline / carbon black being applied to conductive coating or microwave absorbing elements.

Owner:NAT CHUNG SHAN INST SCI & TECH

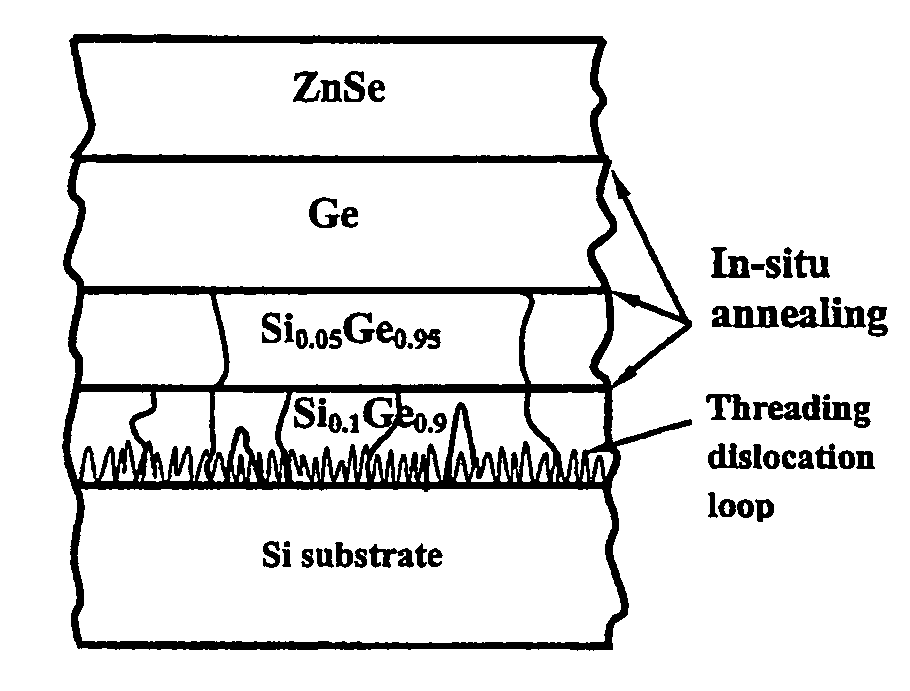

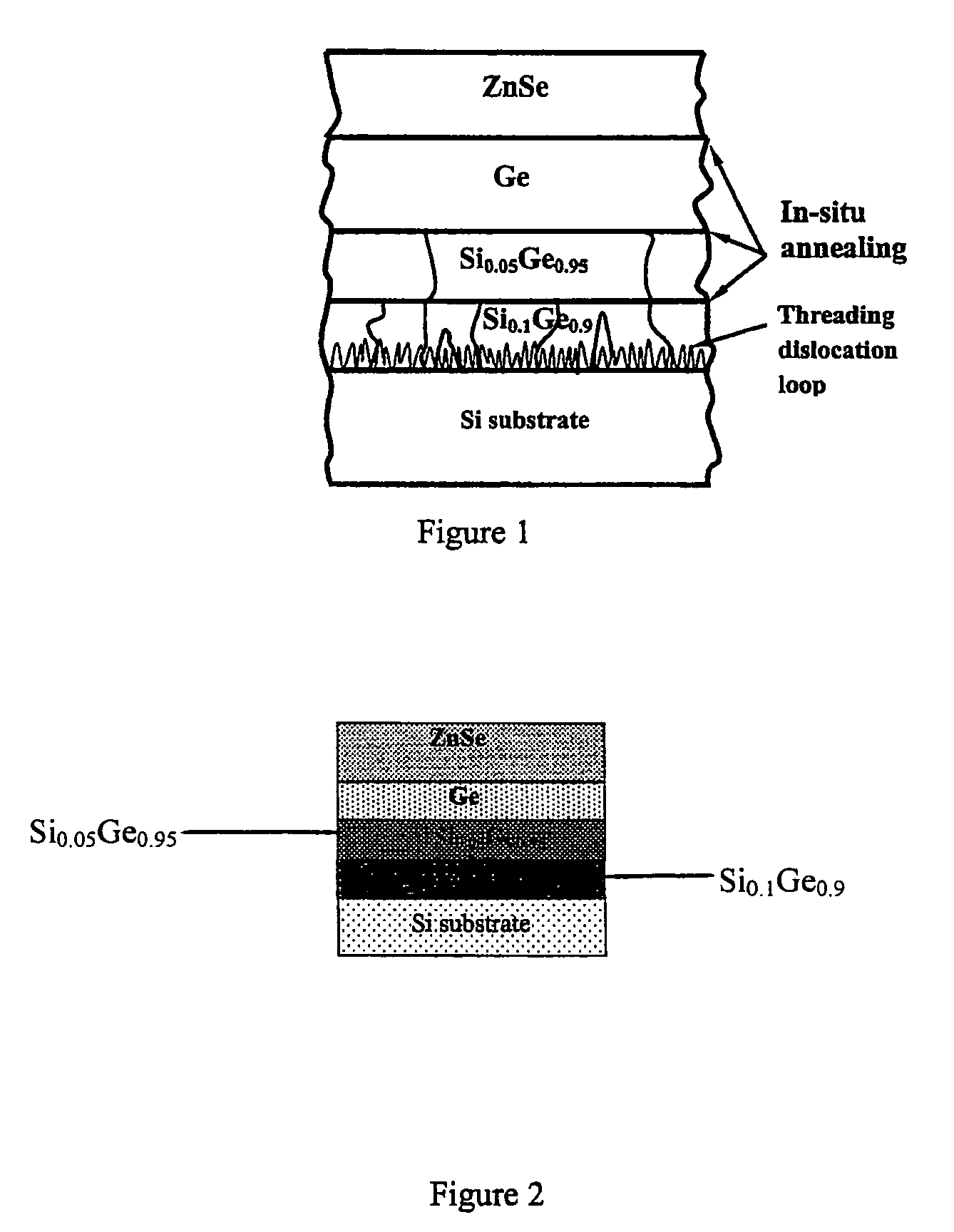

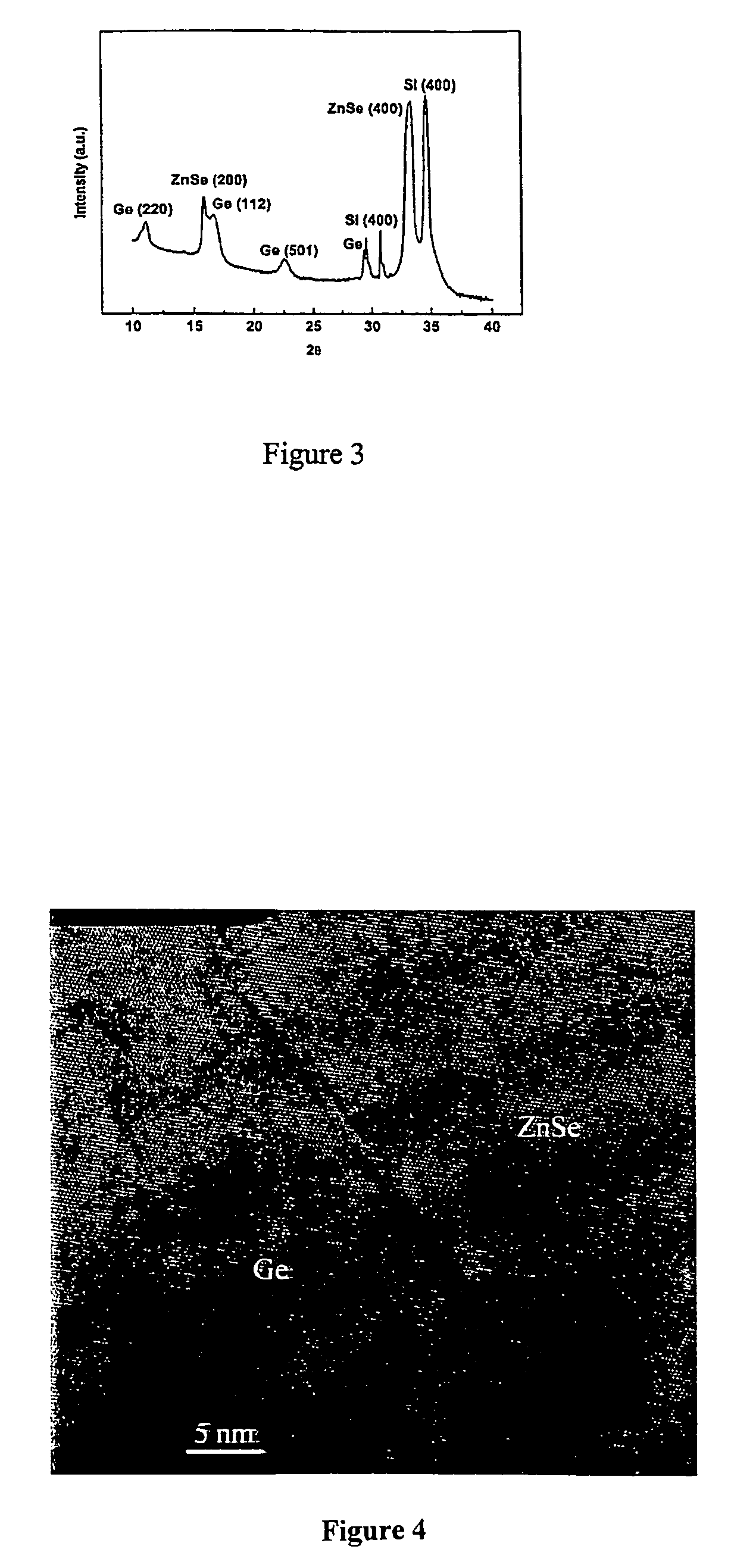

Technique to grow high quality ZnSe epitaxy layer on Si substrate

InactiveUS7071087B2Improve photoelectric performanceReduce threading dislocation densityPolycrystalline material growthVacuum evaporation coatingDiffusionUltra-high vacuum

A technique to grow high quality and large area ZnSe layer on Si substrate is provided, comprising growing GexSi1−x / Ge epitaxial layers on Si substrate by using ultra-high vacuum chemical vapor deposition (UHVCVD), and finally growing a ZnSe film on top Ge buffer layers.Two concepts are applied in the process of this invention, the first one is to block the dislocations generated from GexSi1−x epitaxial layers and to terminate the propagated upward dislocations by using strained interfaces, accordingly the dislocation density of ZnSe layer is greatly reduced and the surface roughness is improved; the second concept is to solve the problems of anti-phase domain due to growth of polar materials on non-polar material using off-cut angle Si substrate, and that is free from diffusion problems between different atoms while generally growing ZnSe layers on Si substrate.

Owner:WITTY MATE CORP

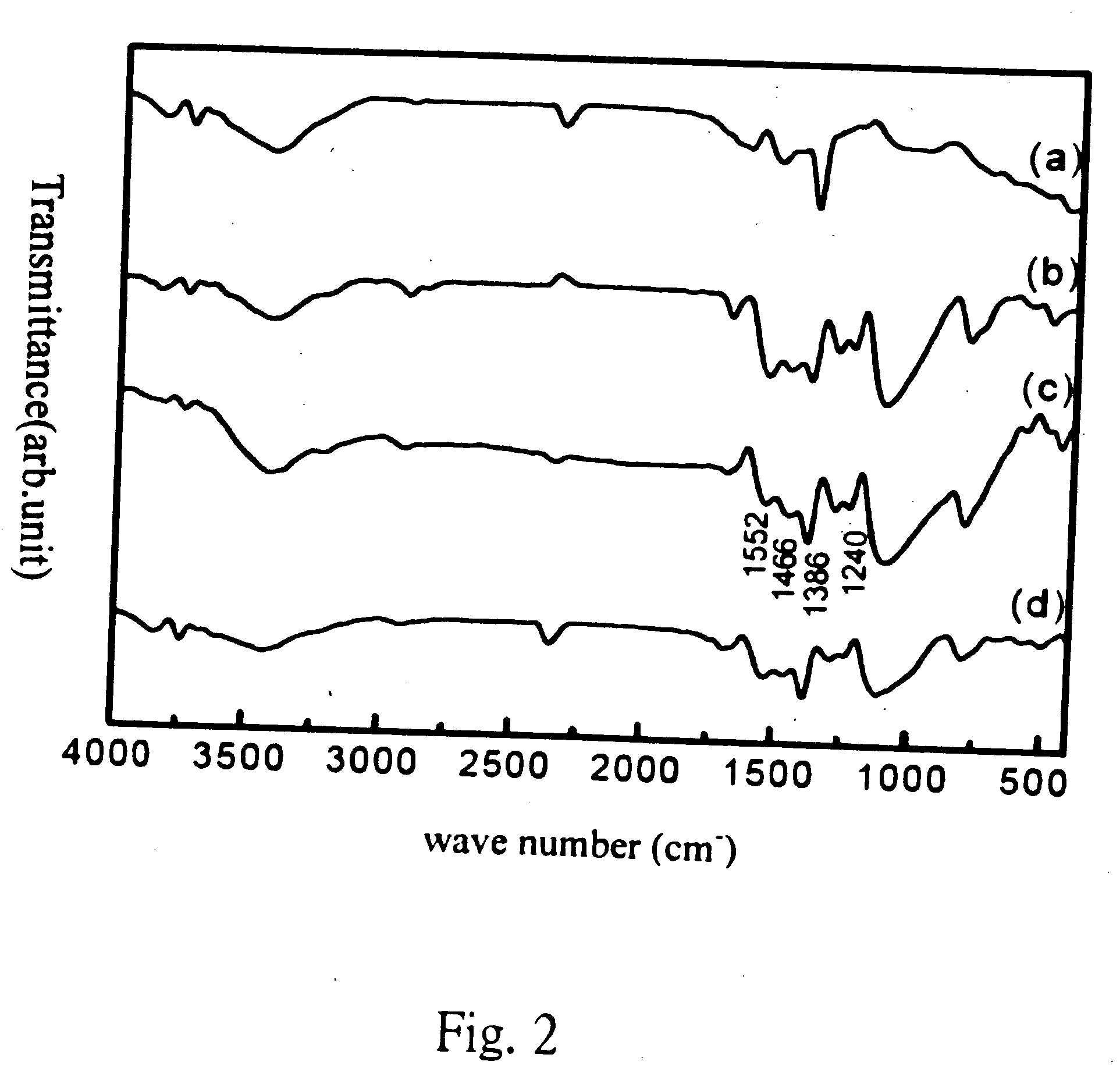

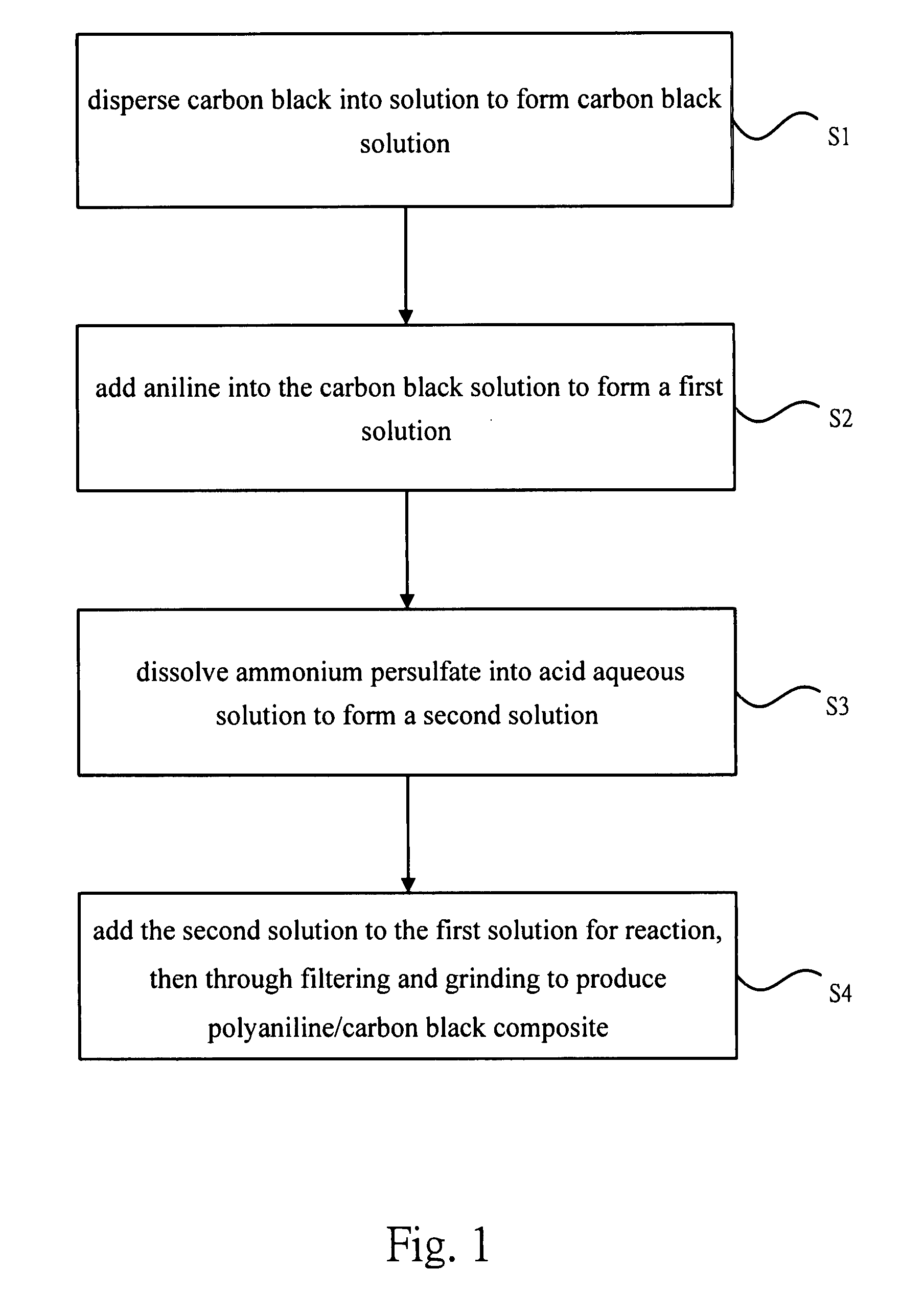

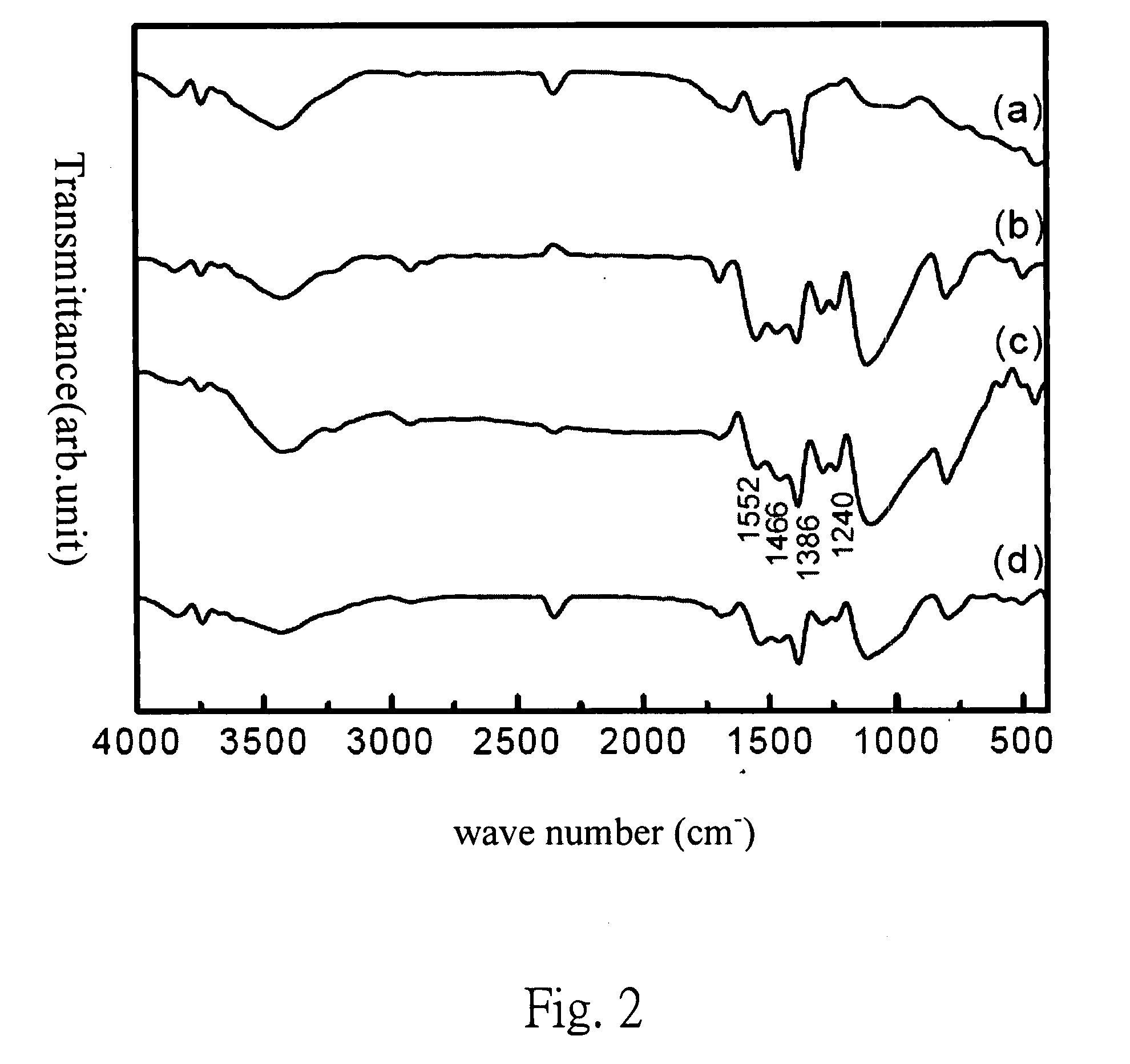

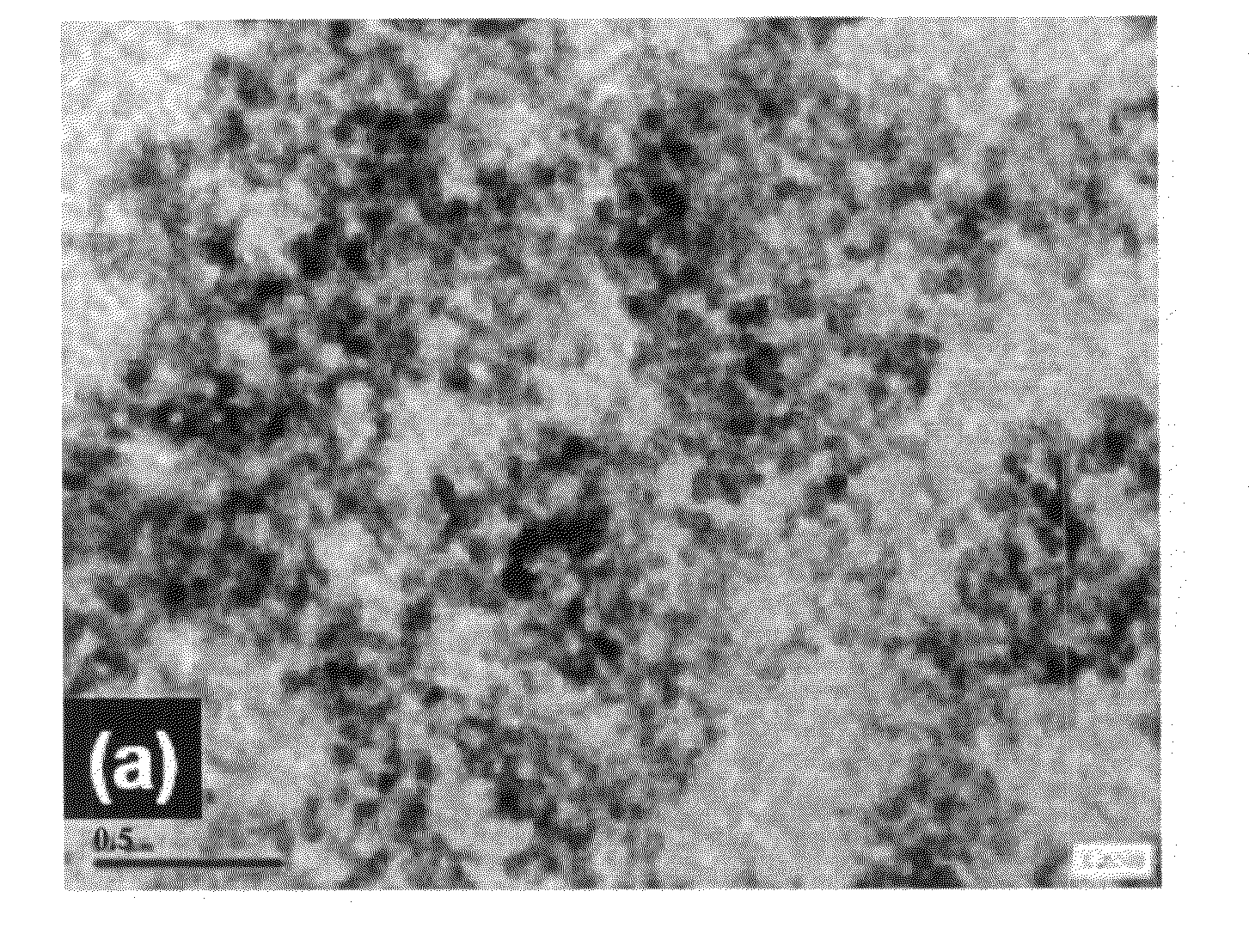

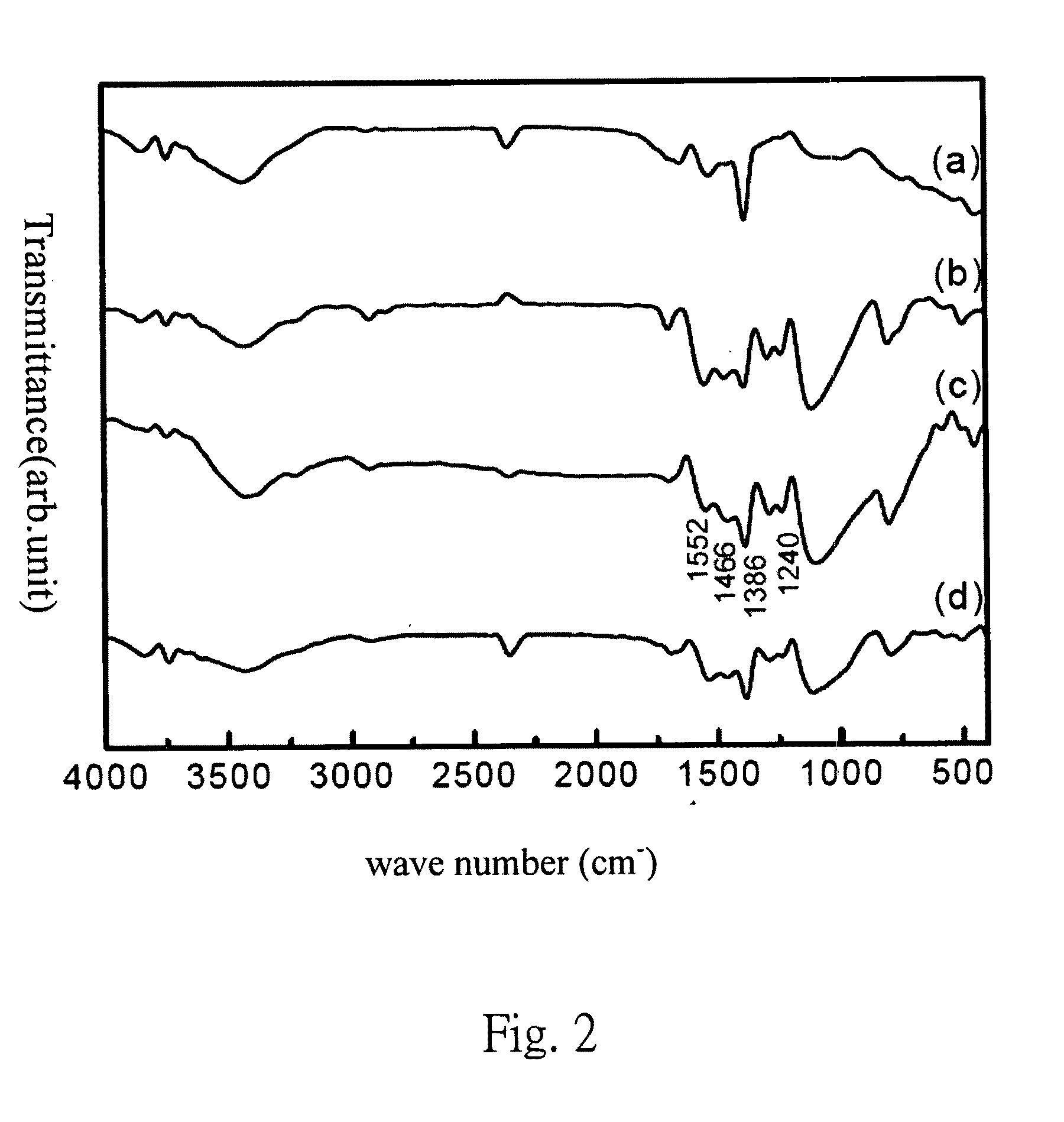

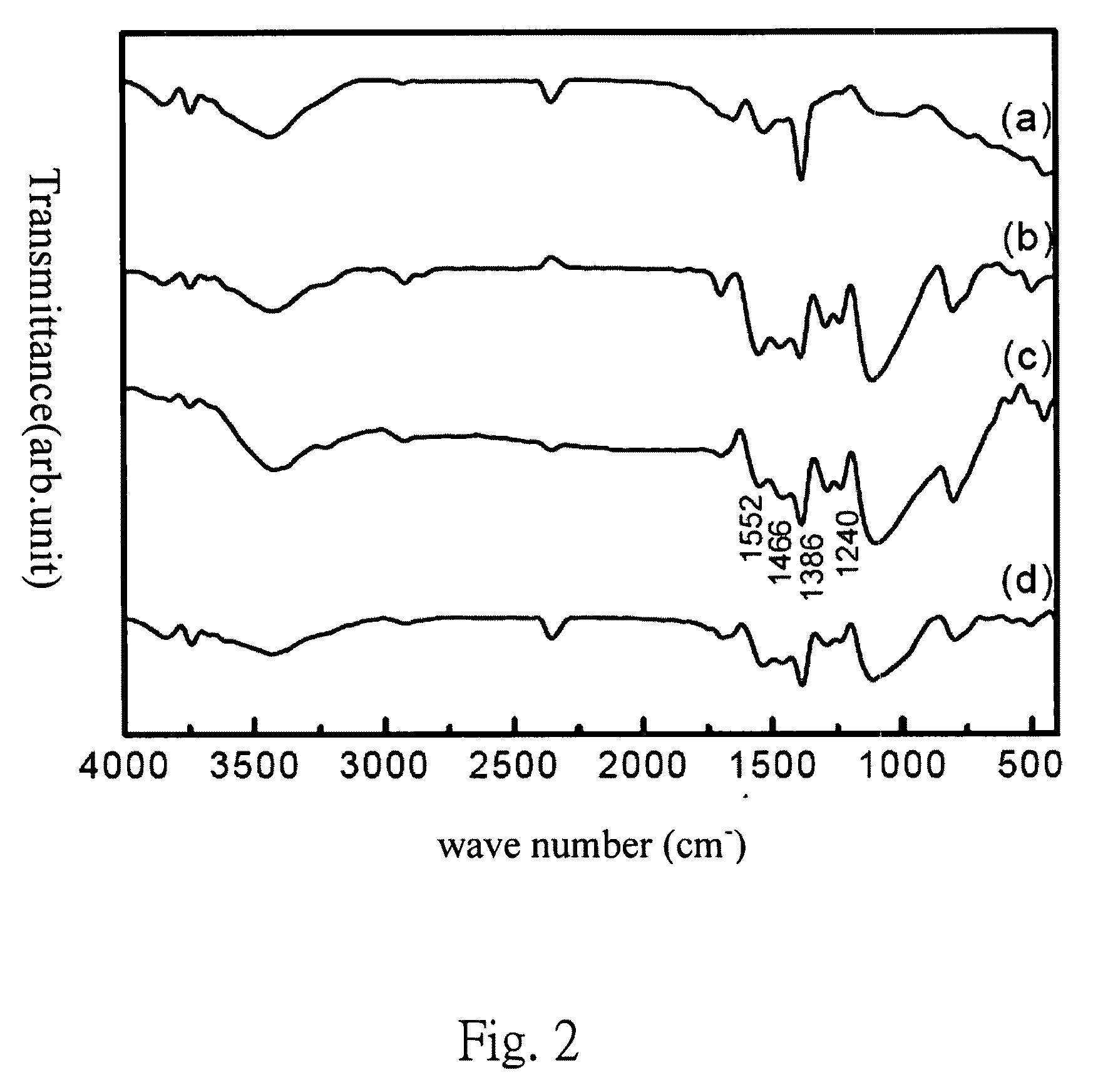

Polyaniline/carbon black composite and preparation method thereof

InactiveUS20090110932A1Improve conductivityOvercomes shortcomingConductive materialSynthetic resin layered productsCarbon blackAqueous solution

A polyaniline / carbon black composite and a preparation method thereof are disclosed The polyaniline / carbon black composite is formed by polyaniline covering carbon black and is with core-shell structure while the polyaniline / carbon black composite contains 10-30 wt. % of carbon black. The preparation method of polyaniline / carbon black composite includes the steps of: disperse carbon black into solution to form carbon black solution, add aniline into the carbon black solution to form a first solution; dissolve ammonium persulfate into acid aqueous solution to form a second solution; add the second solution to the first solution, after reaction, through filtering and grinding to produce polyaniline / carbon black composite.

Owner:CHUNG-SHAN INSTITUTE OF SCIENCE & TECHNOLOGY; MINISTRY OF NATIONAL DEFENSE

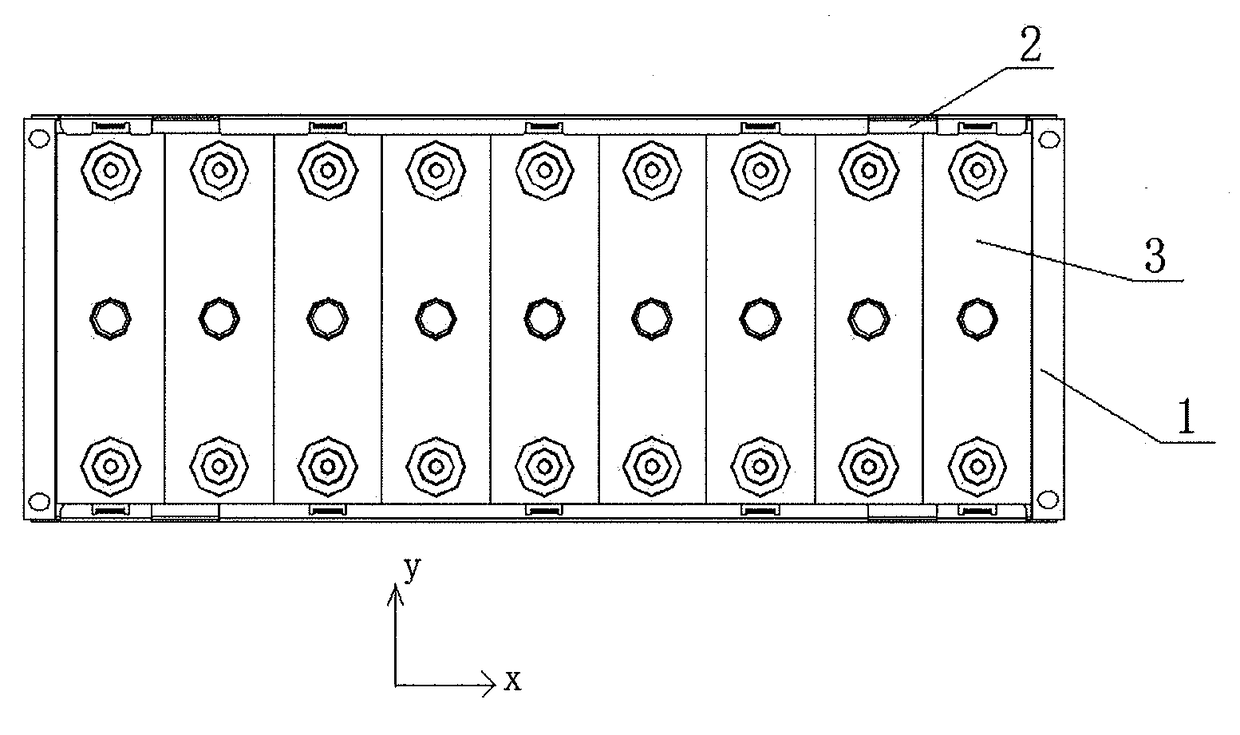

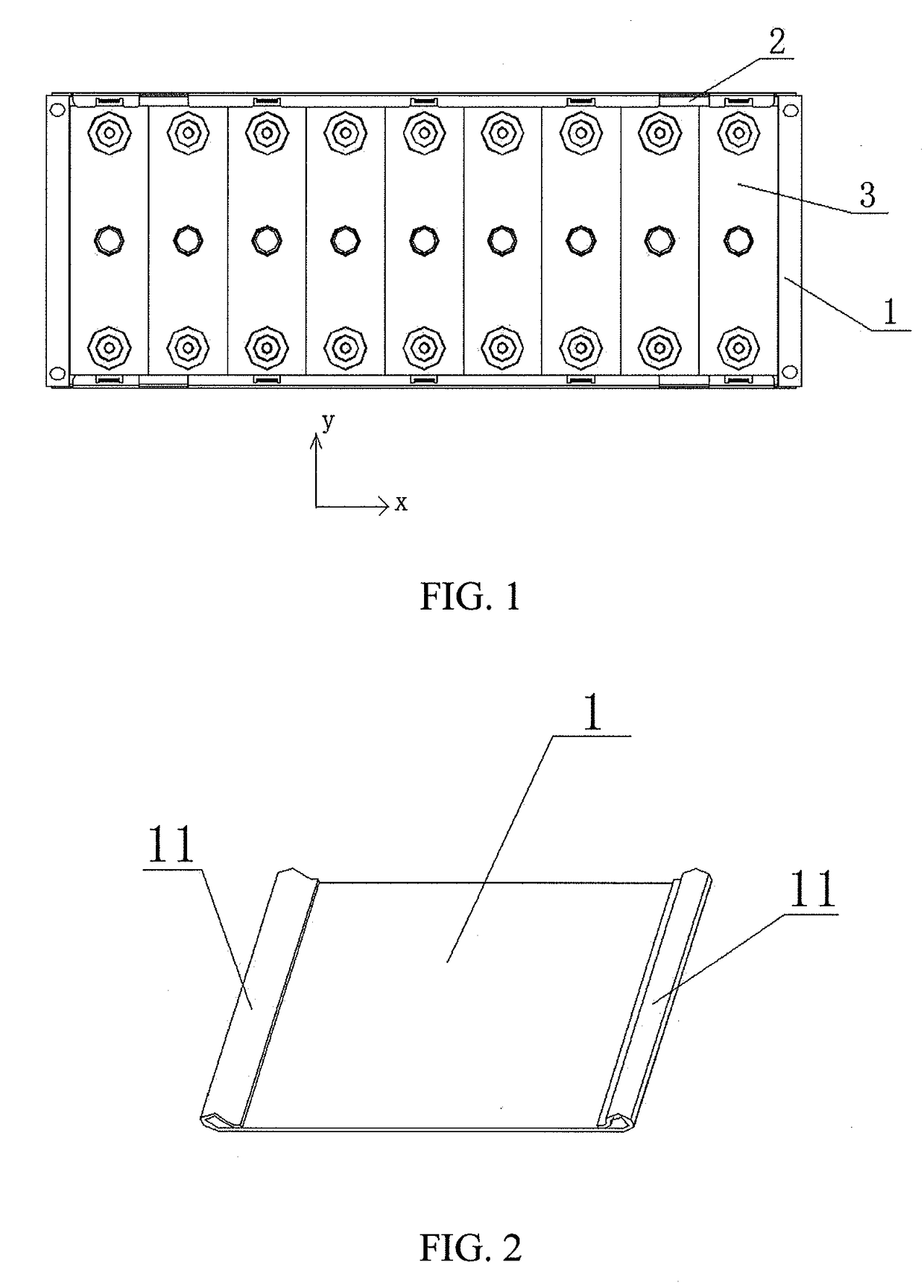

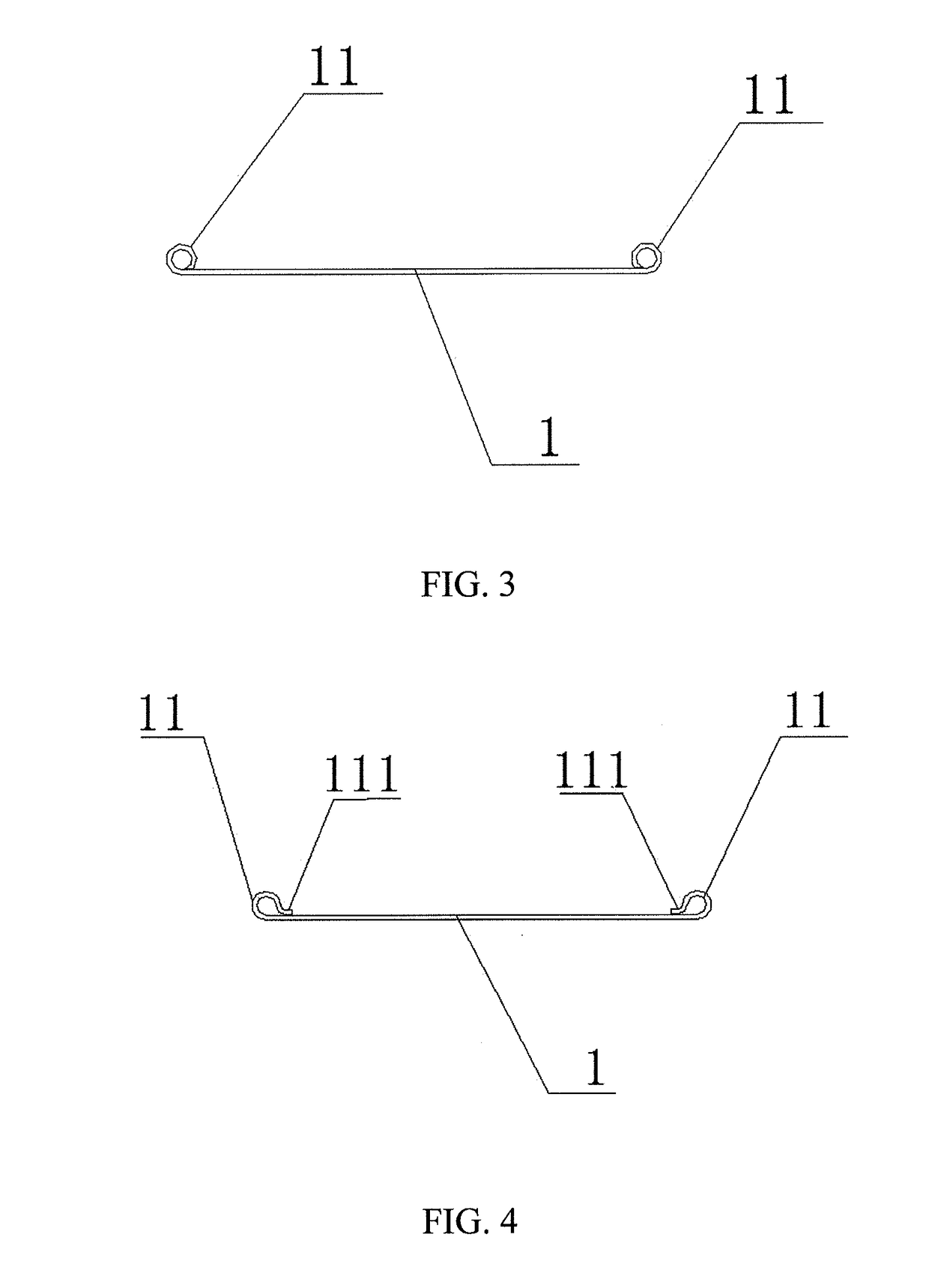

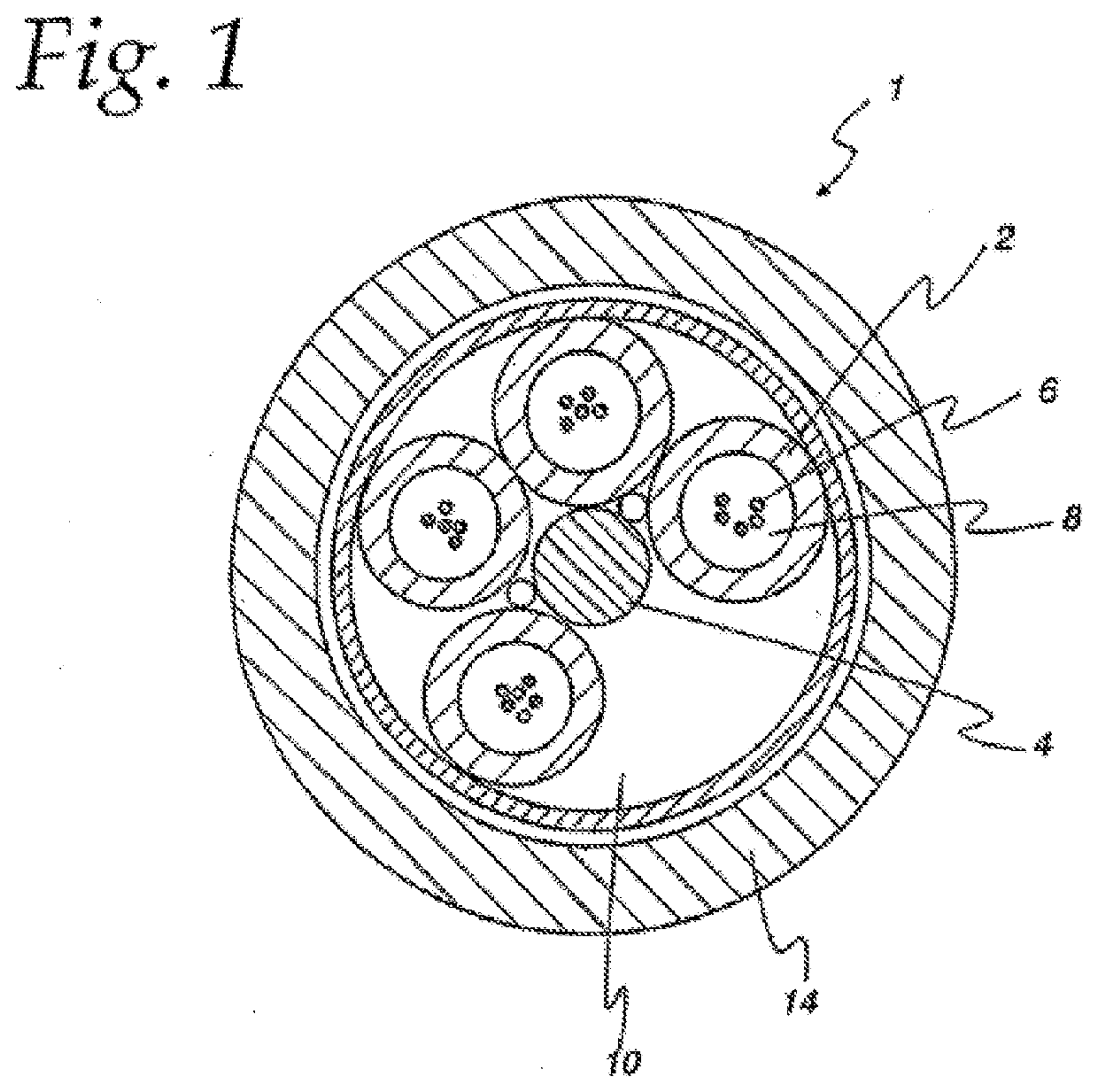

Battery module

ActiveUS20170309877A1Poor intermediate mechanical propertyMore pressure resistantFinal product manufactureBattery isolationElectrical batteryEngineering

This application relates to a battery module, including a substrate, battery units, end plates, side plates and fastening pieces; the end plates are respectively located on two sides of the battery units in their stacking direction, adjacent to outermost ones of the battery units and extend along a length direction of the battery unit; an end of the end plate in the length direction is curled into a pipe and forms a curling pipe section, an axial direction of the curling pipe section is the same with a height direction of the battery unit; the fastening piece is inserted in the curling pipe section, extends in the curling pipe section toward the substrate and protrudes out of the curling pipe section, and are fixed on the substrate; by configuring curling pipe sections, fastening strength is improved, so as to realize reliable fixation of the battery module on the substrate.

Owner:CONTEMPORARY AMPEREX TECH CO

Blocky chlorinated polyolefins, process for making and use as impact modifier compatibilizer for PVC or CPVC

Blocky chlorinated polyolefins are disclosed as compatibilizers of PVC and / or CPVC resins with polyolefin elastomers. The blocky chlorinated polyolefins facilitate the dispersion of the elastomers as a dispersed phase with the proper size for impact modification of the PVC and / or CPVC. The blocky chlorinated polyolefin provides better adhesion between the elastomer and the PVC and / or CPVC providing better physical properties such as impact strength as measured by Notched Izod and variable height impact testing (VHIT) than did the randomly chlorinated polyolefins, often used as processing aids and as impact modifiers in PVC or CPVC. The differences in properties achieved with blocky chlorinated polyolefins versus randomly chlorinated polyolefins are attributed to the individual blocks of the blocky polyolefin being compatible (and / or co-crystalizable) with either the polyolefin elastomer or the PVC / CPVC resulting in better adhesion between phases. Also disclosed is a process for making optimal blocky chlorinated polyolefins.

Owner:NOVEON INC

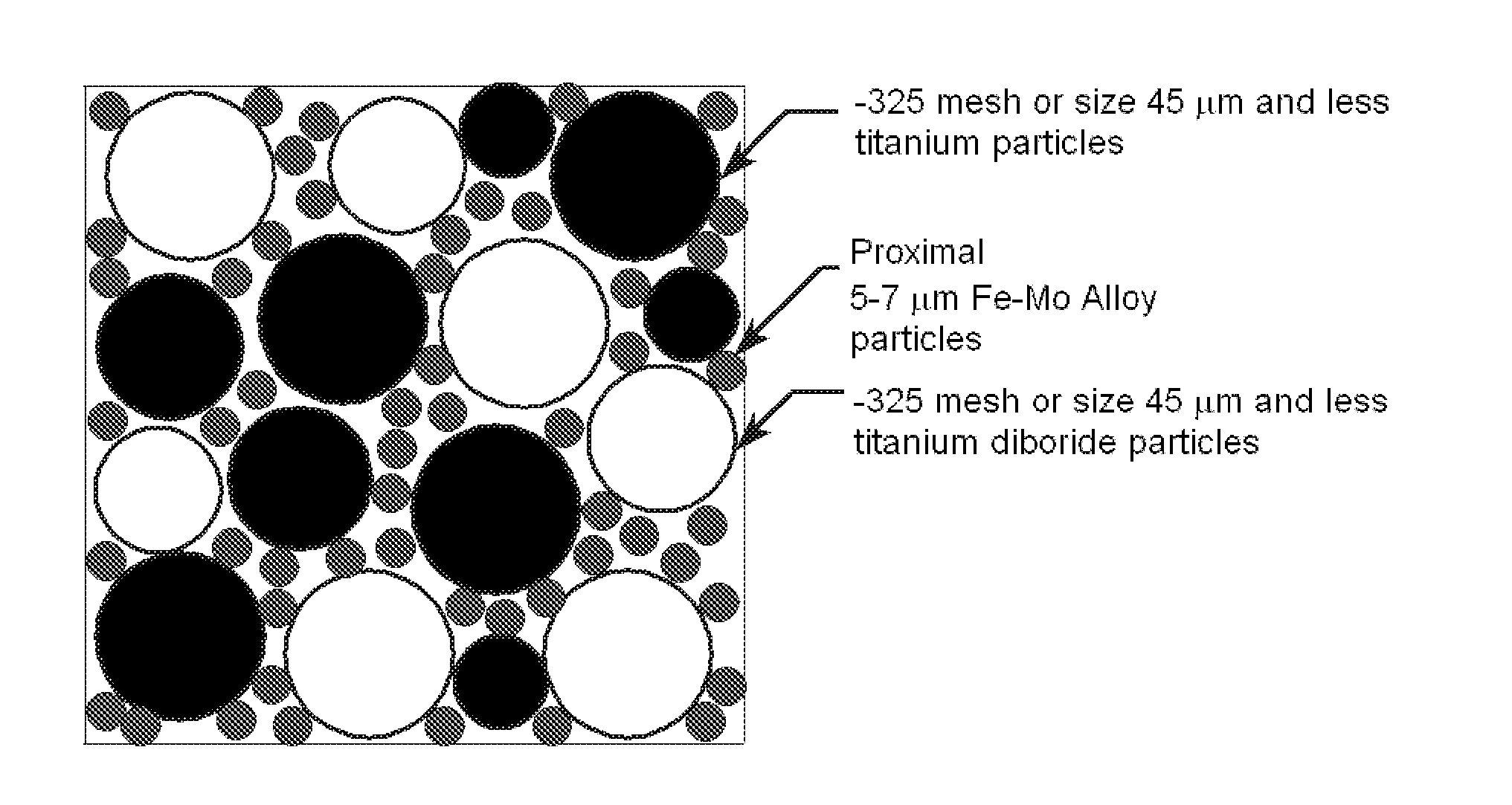

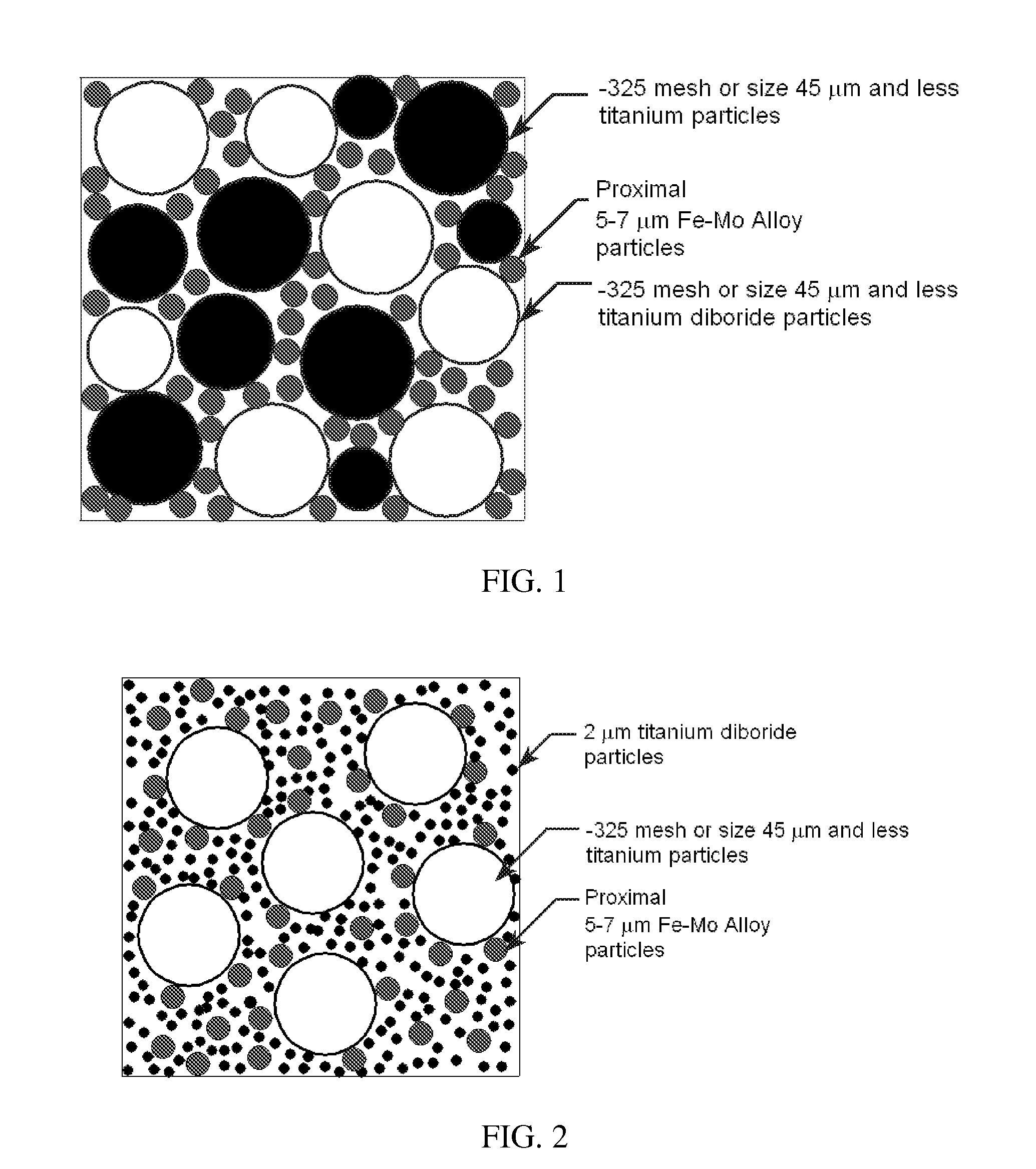

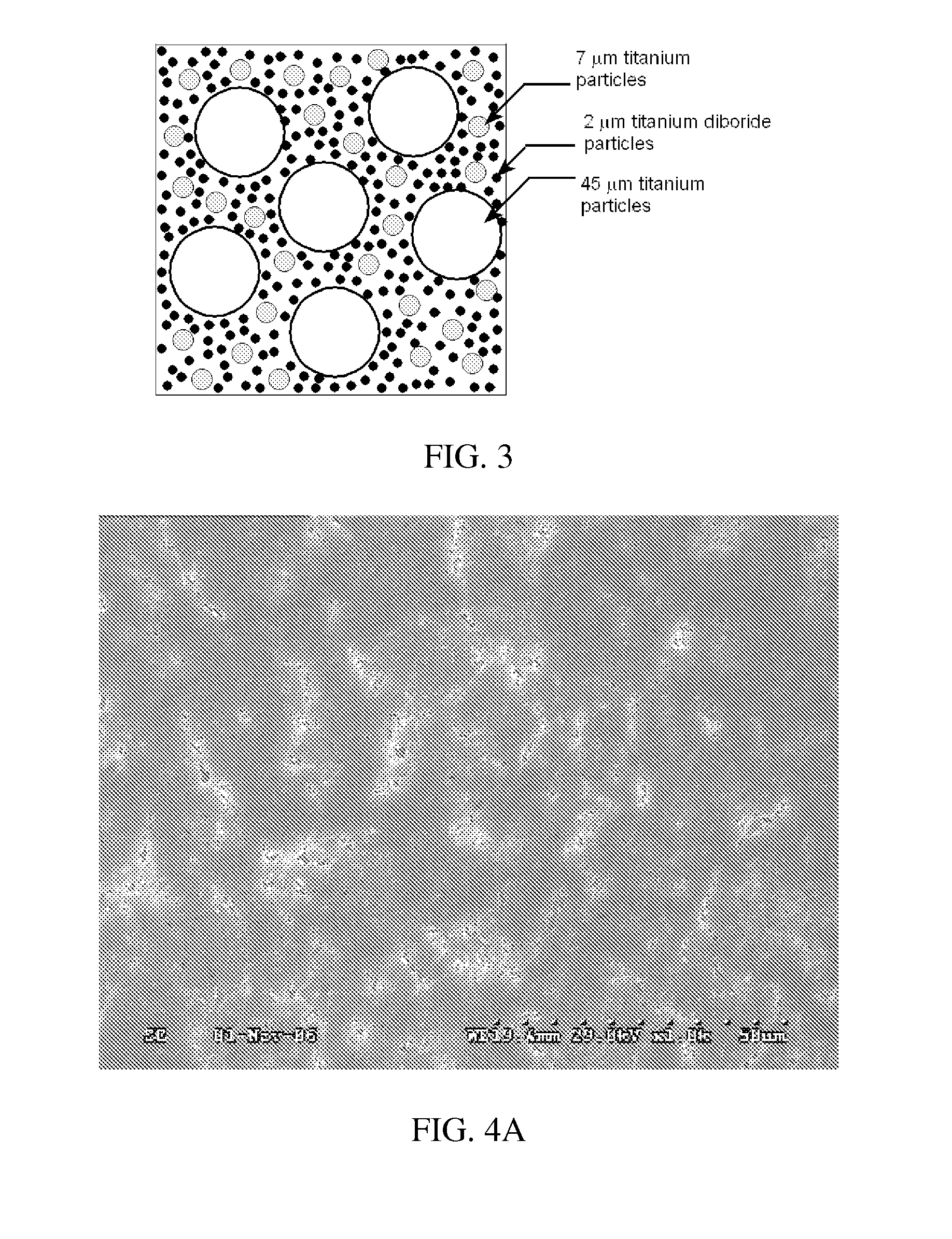

Jewelry having titanium boride compounds and methods of making the same

InactiveUS20100176339A1Solution to short lifePoor mechanical propertyOther chemical processesMetal boridesBorideTitanium boride

An article of jewelry can include a main body can comprise or consist essentially of a titanium boride. The main body can be a titanium boride such as titanium monoboride, titanium diboride, ternary boride, or quaternary boride. Additionally, a method of forming an article of jewelry having a titanium boride microstructure can include forming a powder precursor of a predetermined shape corresponding to a desired jewelry shape, growing titanium boride microstructure from the powder precursor to form a titanium boride main body, recovering the titanium boride main body, and finishing the recovered titanium boride main body into the jewelry shape.

Owner:UNIV OF UTAH RES FOUND

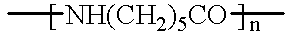

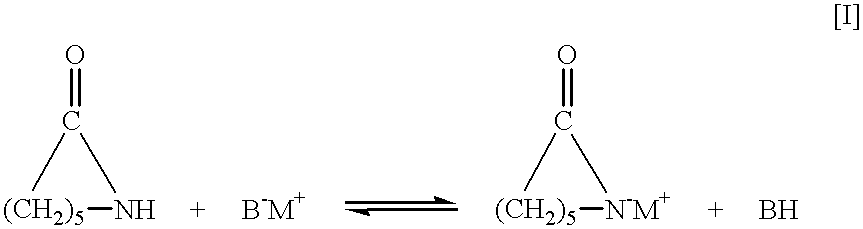

Process for the production of a polymerized material and the product produced thereby

A polymerized material produced by the polymerization of an organic amide monomer in the presence of an organic carbonate and a process for the preparation thereof. The process comprises the steps of: heating an amount of the organic anide monomer to a temperature above its melting point; first mixing an amount of an anionic initiator with at least a portion of the amount of heated organic amide mnonomer to produce an amount of activated monomer, wherein the anionic initiator is not comprised of an alkali metal; second mixing an amount of the organic carbonate with at least a portion of the amount of heated organic amide monomer to produce an amount of dissolved organic carbonate; and polymerizing the amounts of heated organic amide monomer and activated monomer in the presence of the amount of dissolved organic carbonate to produce the polymerized material.

Owner:WILLIAMS MICHAEL C +2

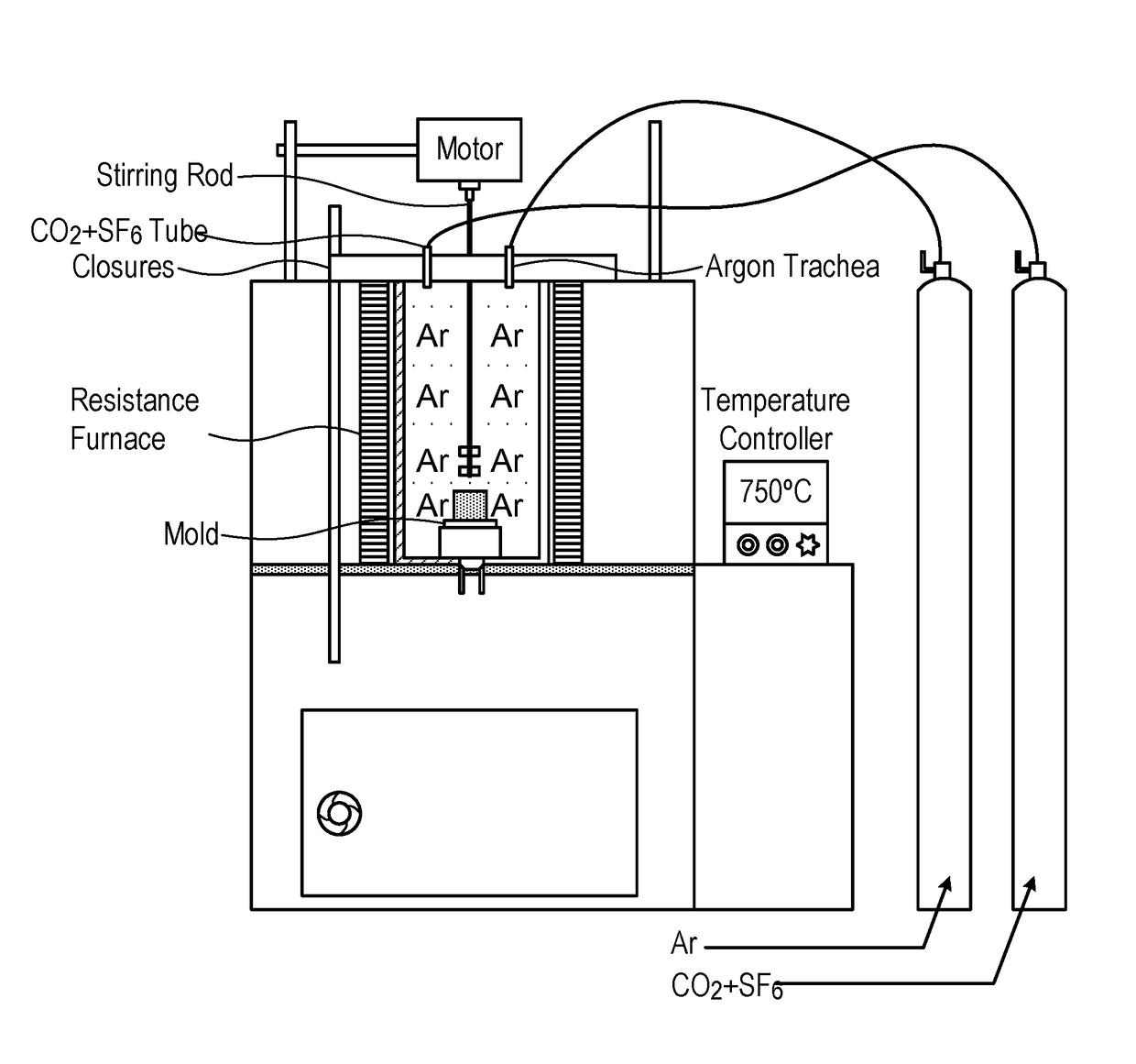

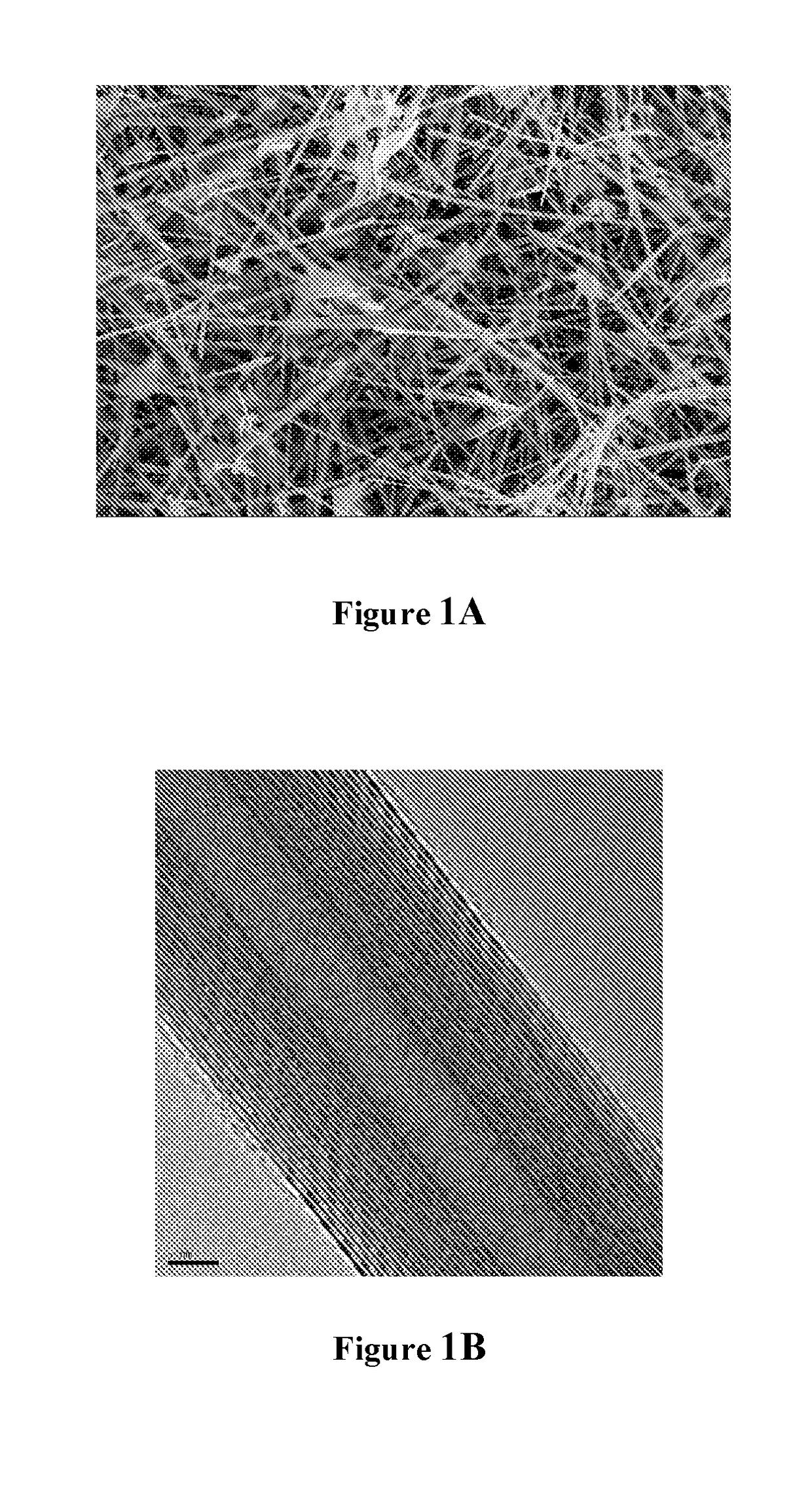

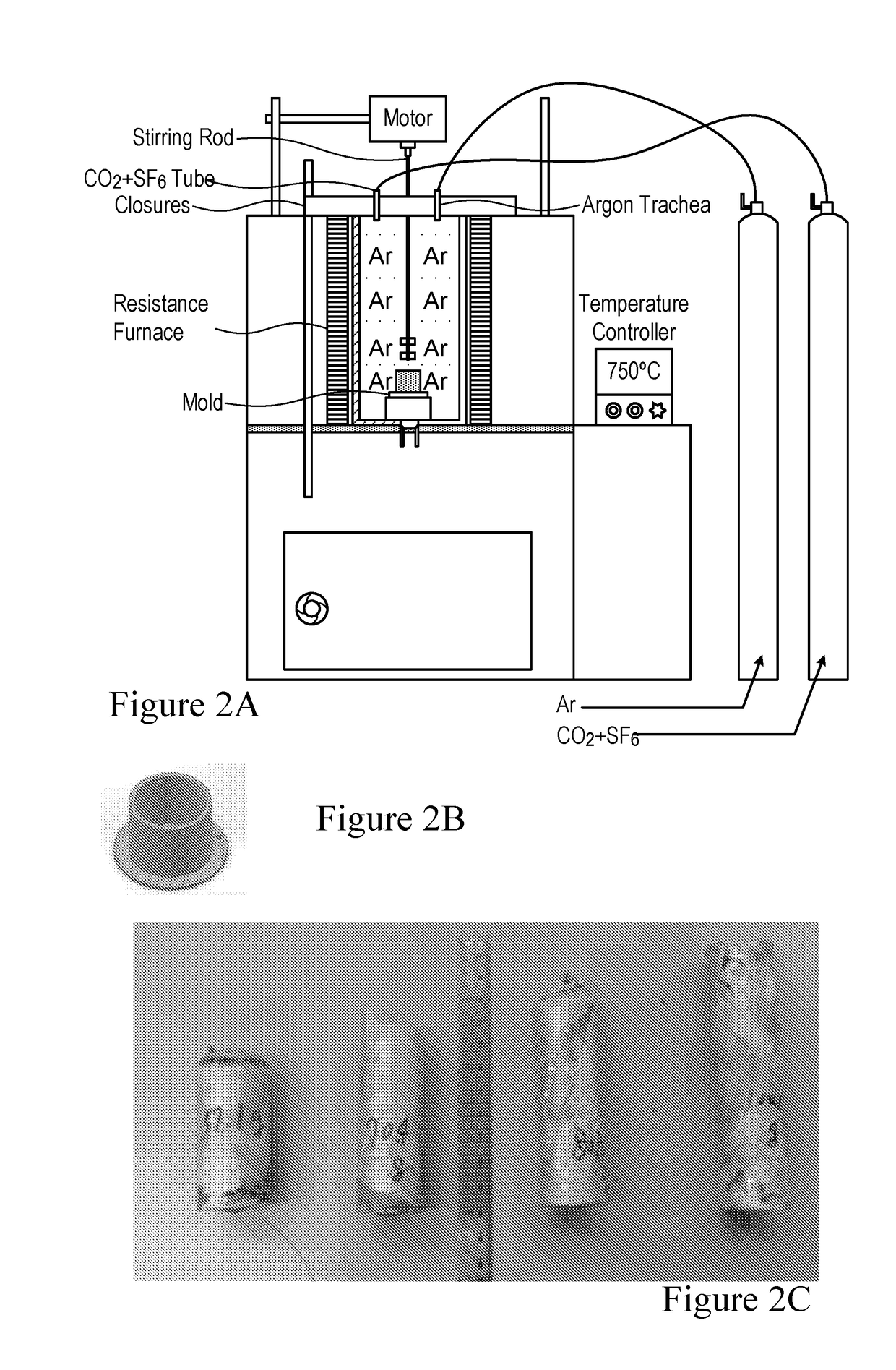

Metal alloy composites

This invention relates to metal composites and to metal-alloy composites. Metal-alloy composites of this invention comprise a metal alloy and layered inorganic nanostructures or nanoparticles such as nanotubes, nanoscrolls, spherical or quasi-spherical nanoparticles, nano-platelets or combinations thereof. Methods of producing the metal composites and the metal-alloy composites are demonstrated. The layered inorganic nanostructure serves as a strengthening phase. The layered inorganic nanostructure provides reinforcement to the metal alloy.

Owner:YEDA RES & DEV CO LTD

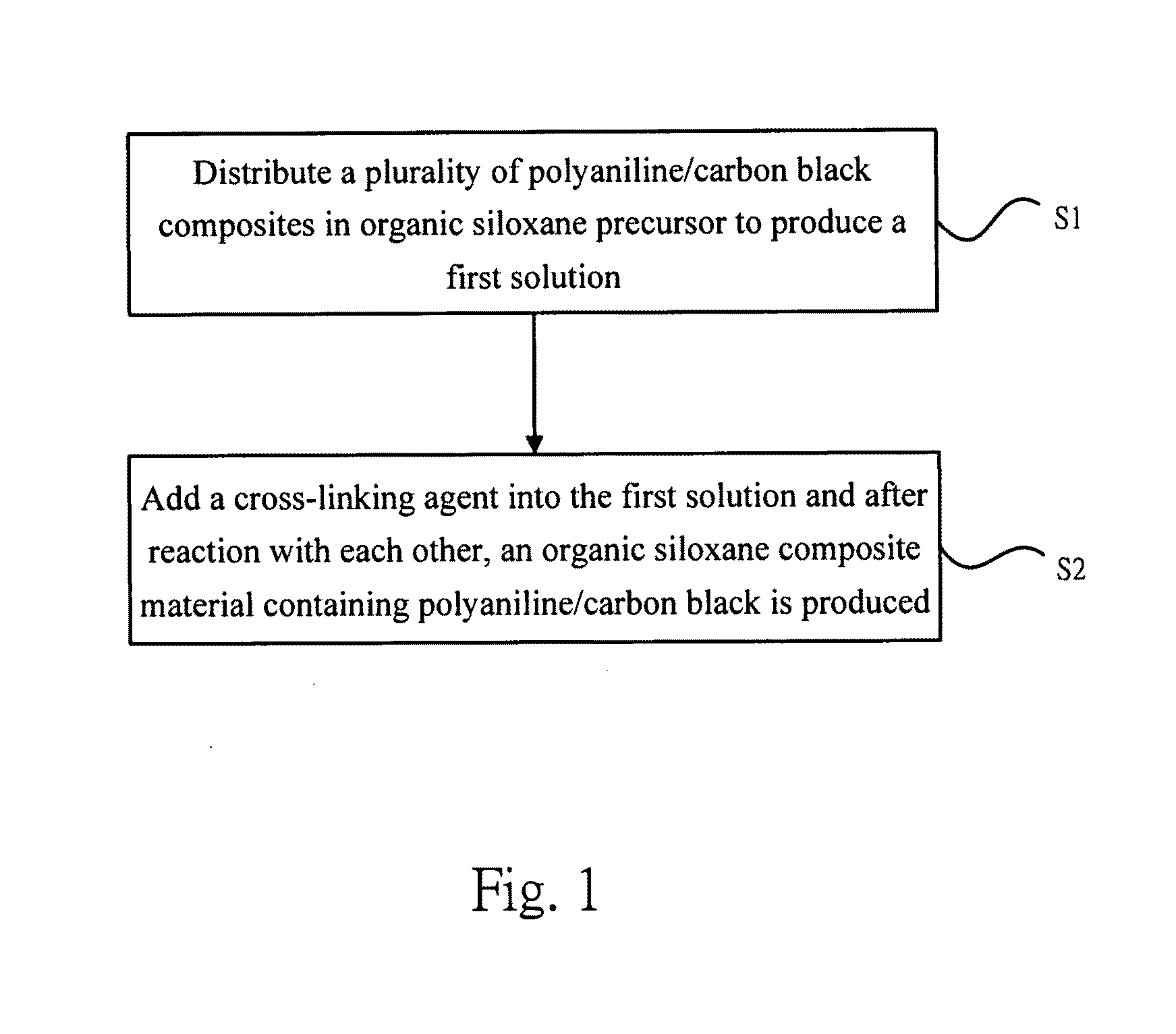

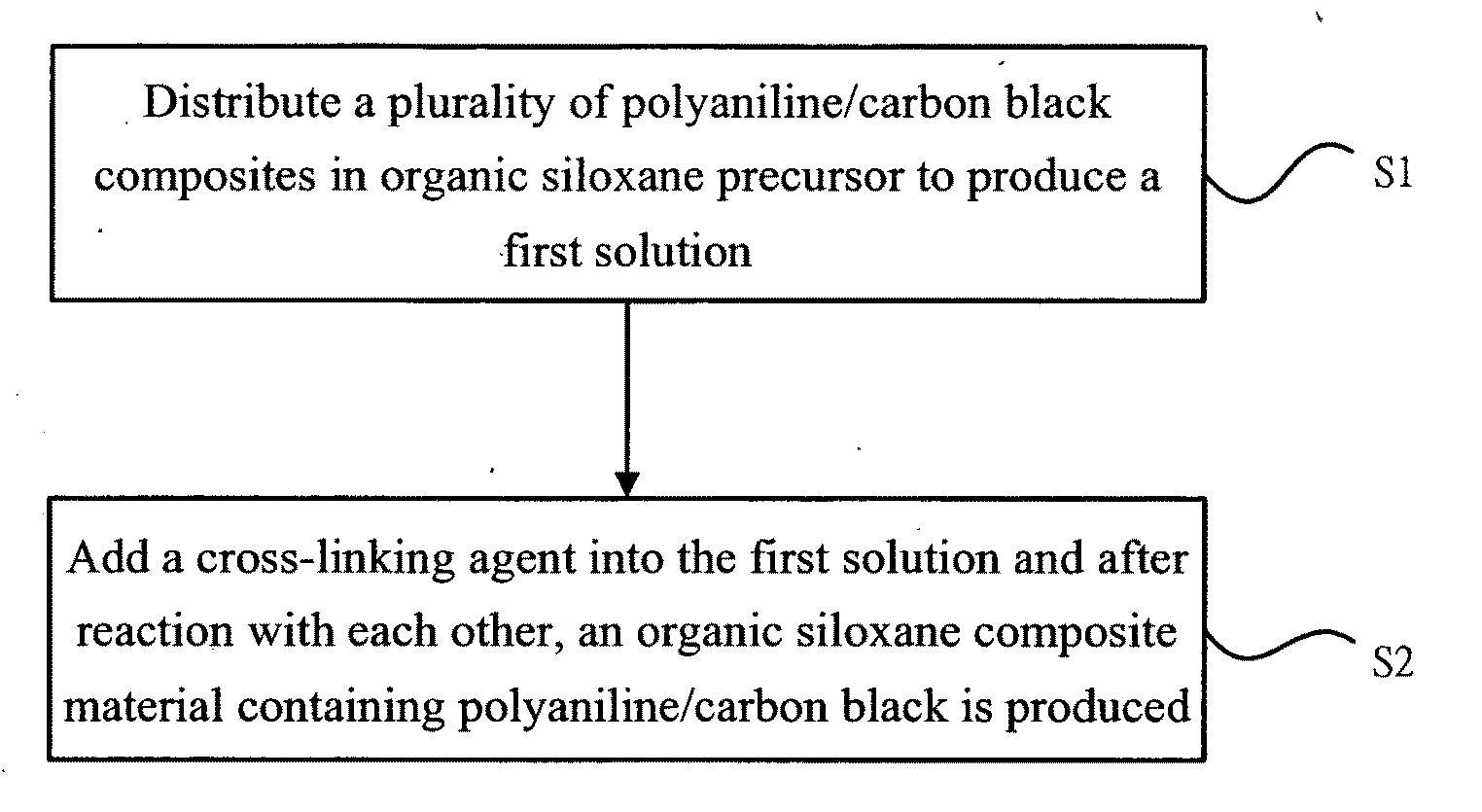

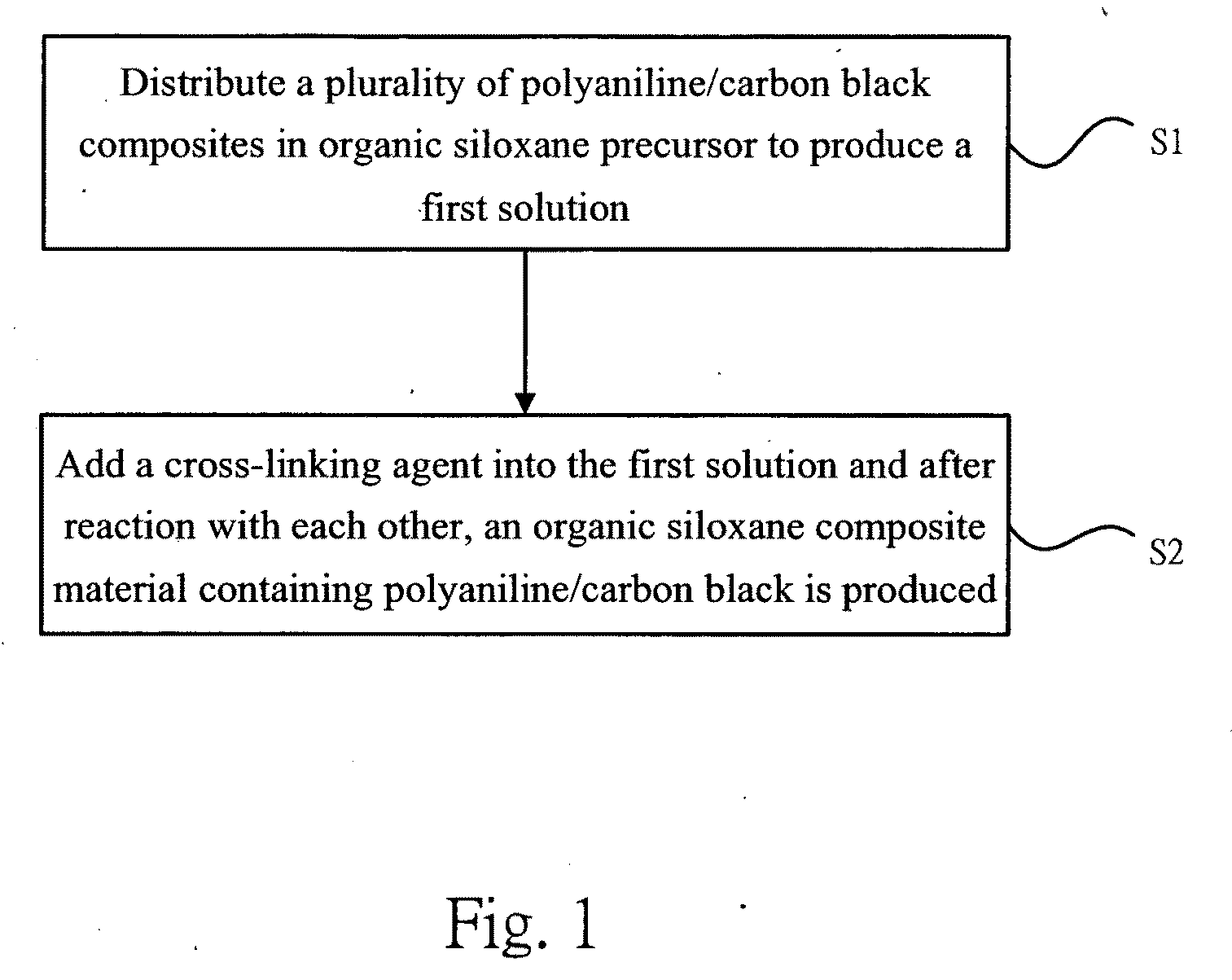

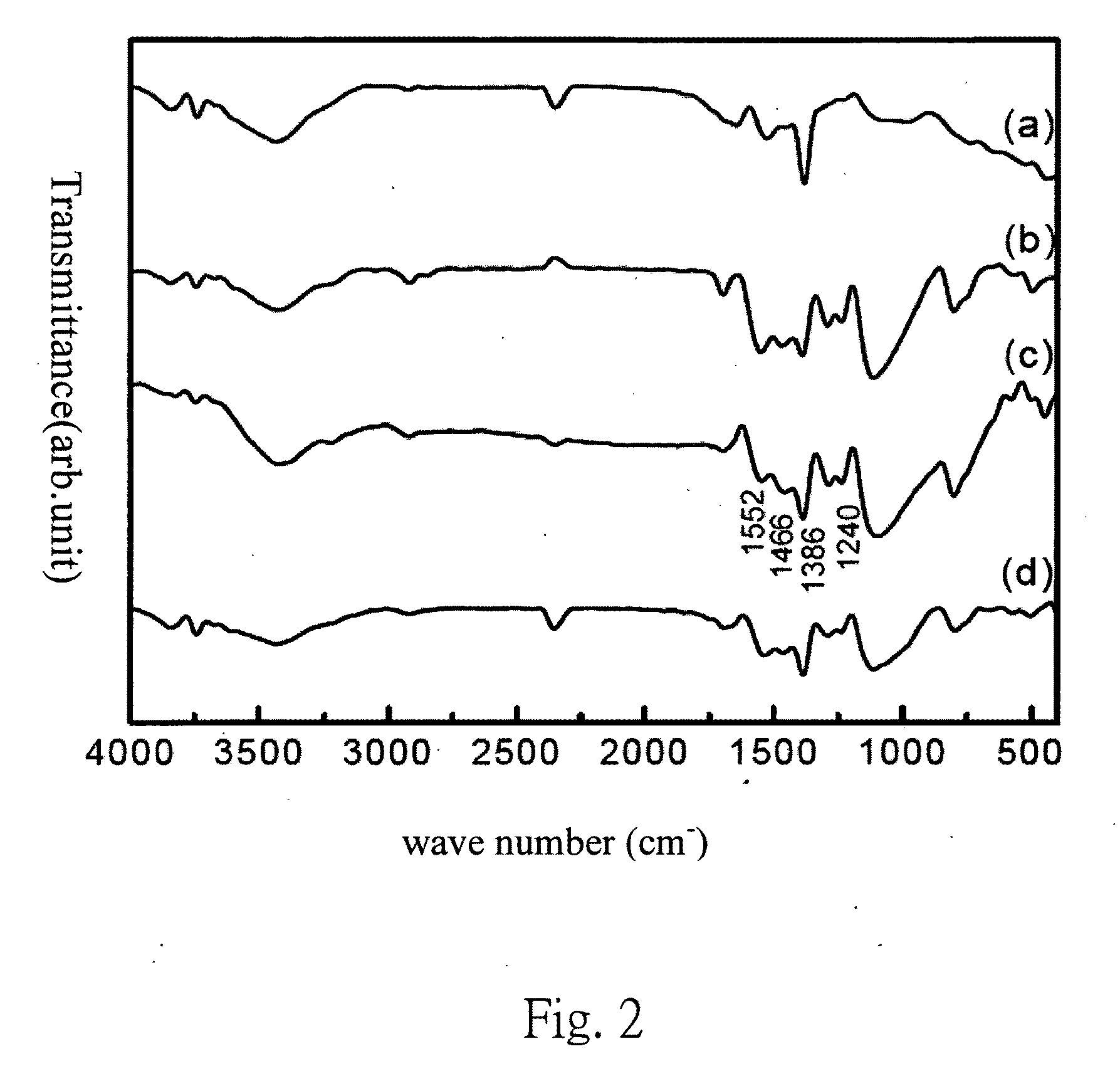

Organic siloxane composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS20090110931A1Improve conductivityImprove corrosion resistanceNon-metal conductorsSynthetic resin layered productsCross-linkPolyaniline

An organic siloxane composite material containing polyaniline / carbon black and a preparation method thereof are disclosed. The organic siloxane composite material containing polyaniline / carbon black consists of a plurality of polyaniline / carbon black composites distributed in organic siloxane precursor while the organic siloxane composite material containing polyaniline / carbon black includes from 10 to 30 weight percent of polyaniline / carbon black composites. The preparation method of organic siloxane composite material containing polyaniline / carbon black includes the steps of: distributing a plurality of polyaniline / carbon black composites in organic siloxane precursor to produce a first solution; and adding a cross-linking agent into the first solution, after reaction with each other, an organic siloxane composite material containing polyaniline / carbon black is produced.

Owner:NAT CHUNG SHAN INST SCI & TECH

Organic siloxane composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS20090131580A1Improve conductivityImprove corrosion resistanceNon-metal conductorsConductive materialCross-linkPolyaniline

An organic siloxane composite material containing polyaniline / carbon black and a preparation method thereof are disclosed. The organic siloxane composite material containing polyaniline / carbon black consists of a plurality of polyaniline / carbon black composites distributed in organic siloxane precursor while the organic siloxane composite material containing polyaniline / carbon black includes from 10 to 30 weight percent of polyaniline / carbon black composites. The preparation method of organic siloxane composite material containing polyaniline / carbon black includes the steps of: distributing a plurality of polyaniline / carbon black composites in organic siloxane precursor to produce a first solution; and adding a cross-linking agent into the first solution, after reaction with each other, an organic siloxane composite material containing polyaniline / carbon black is produced.

Owner:NAT CHUNG SHAN INST SCI & TECH

Epoxy composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS7799850B2Improve conductivityHigh effectNon-metal conductorsConductive materialMicrowaveConductive coating

An epoxy composite material containing polyaniline / carbon black and preparation method thereof are disclosed. The epoxy composite material containing polyaniline / carbon black includes a plurality of polyaniline / carbon black composite with core-shell structure distributed in epoxy resin while polyaniline covers on surface of nanoscale carbon black to form the polyaniline / carbon black composite with core-shell structure. The polyaniline / carbon black composite with core-shell structure contains 10˜30 wt. % of nanoscale carbon black. A method for preparing an epoxy composite material containing polyaniline / carbon black includes steps of: adding a plurality of polyaniline / carbon black composites with core-shell structure into epoxy resin; and dispersing the plurality of polyaniline / carbon black composites with core-shell structure in the epoxy resin to produce the epoxy composite material containing polyaniline / carbon black being applied to conductive coating or microwave absorbing elements.

Owner:NAT CHUNG SHAN INST SCI & TECH

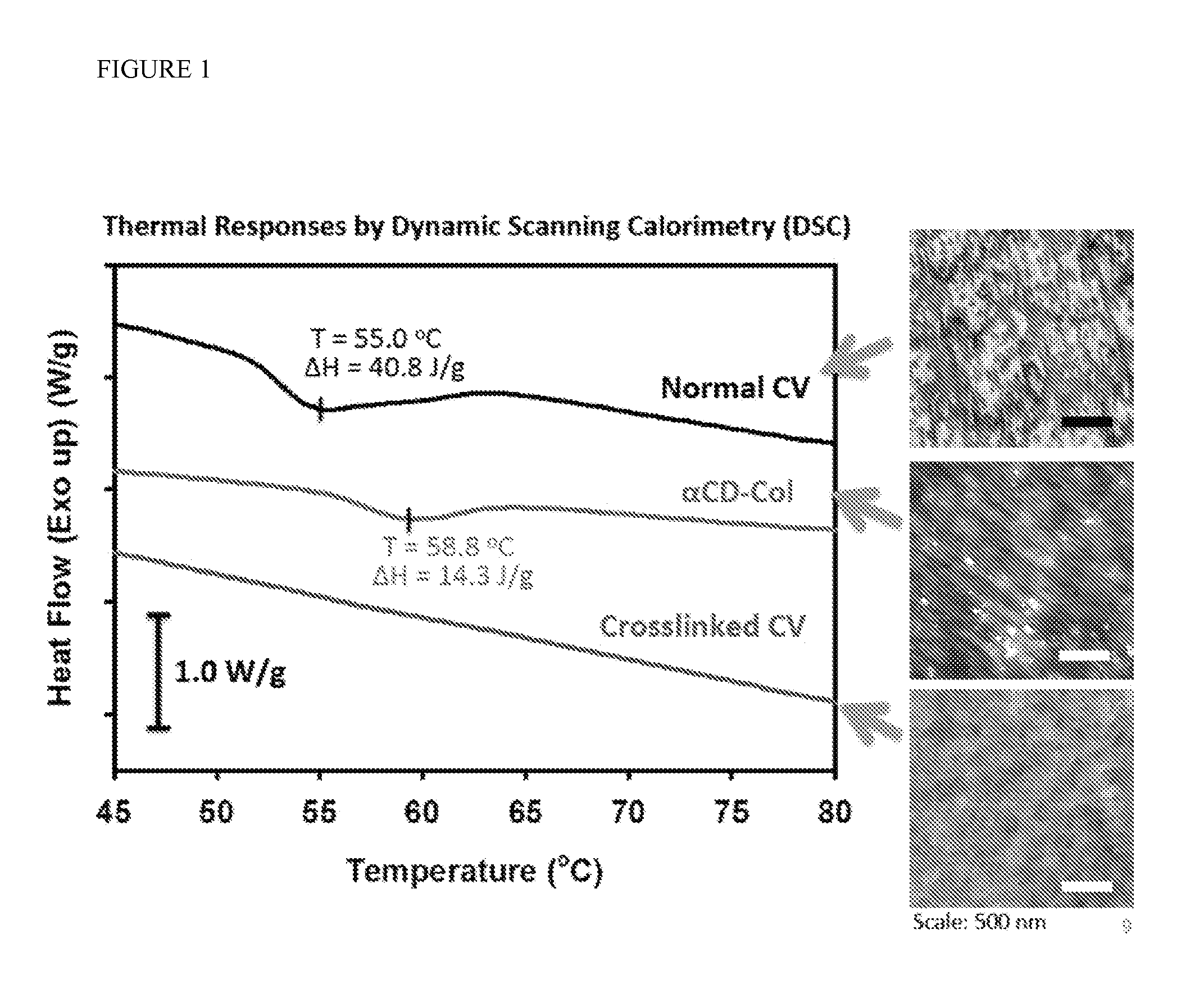

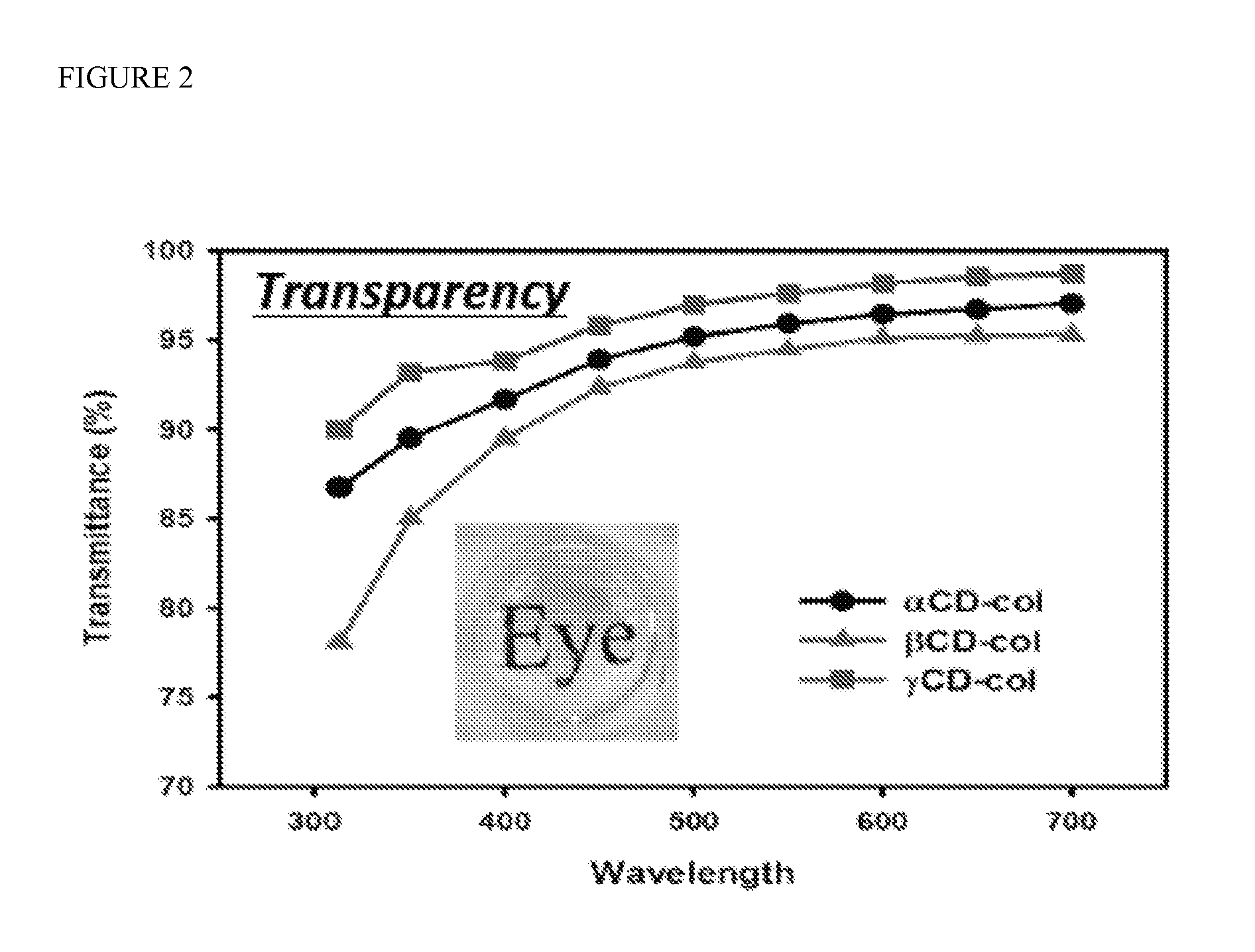

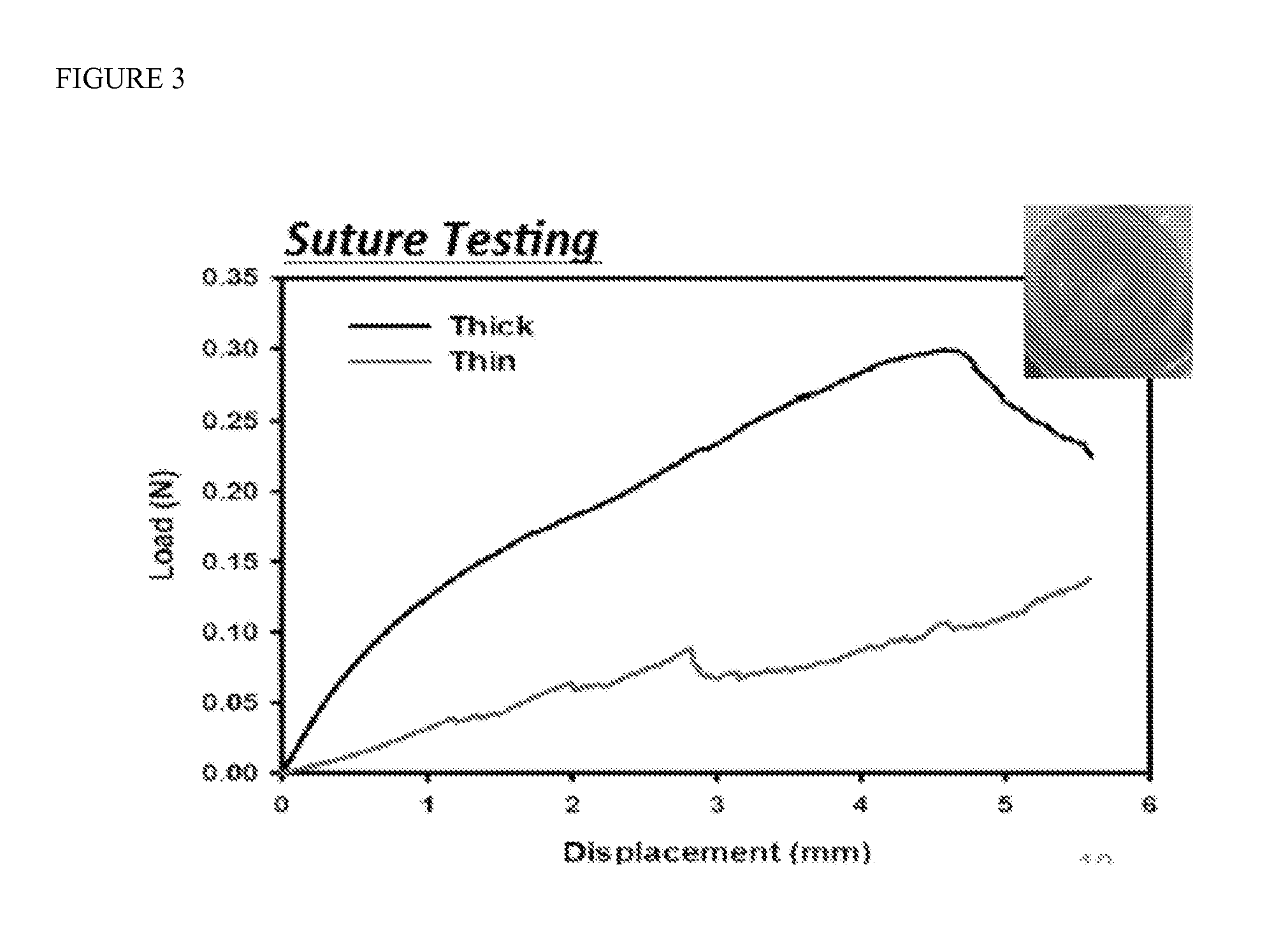

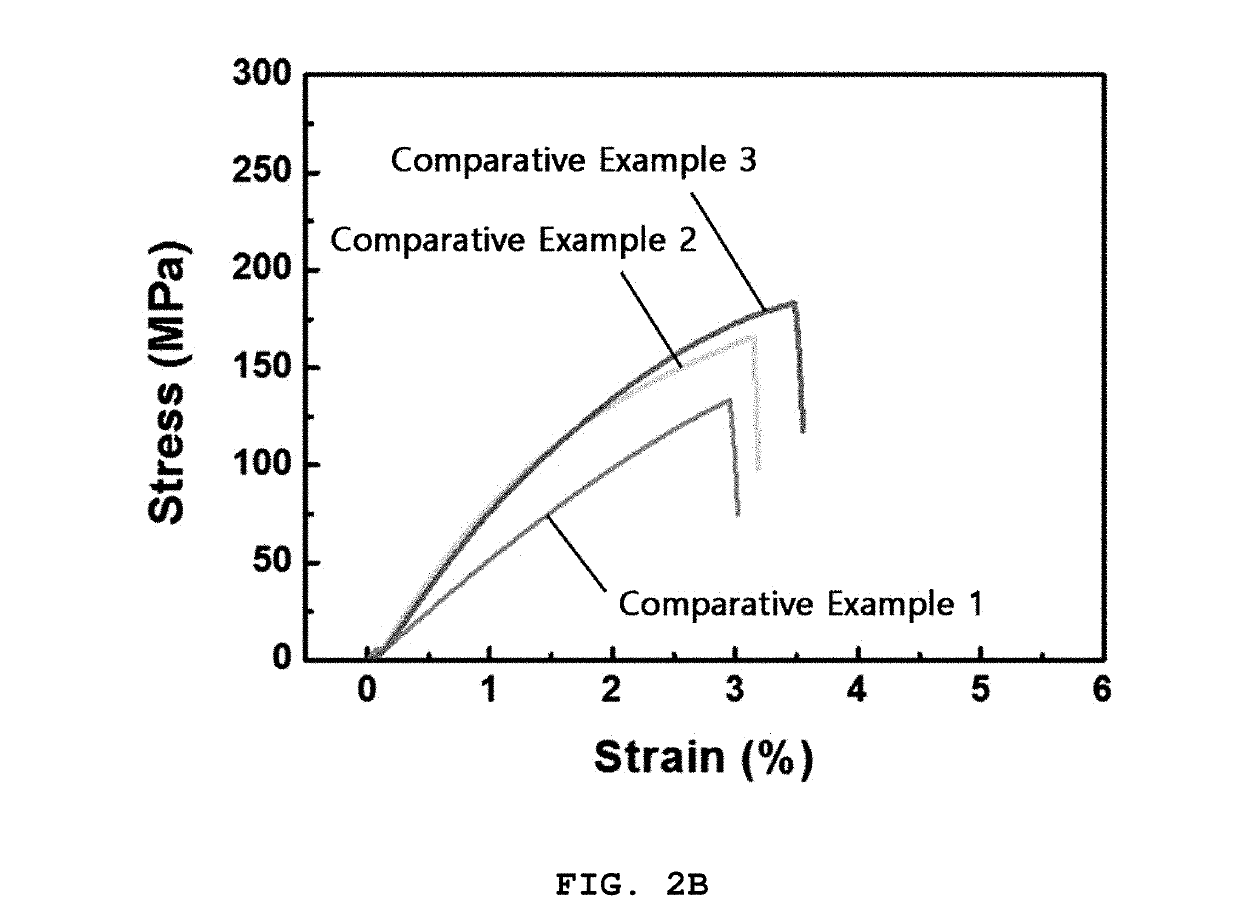

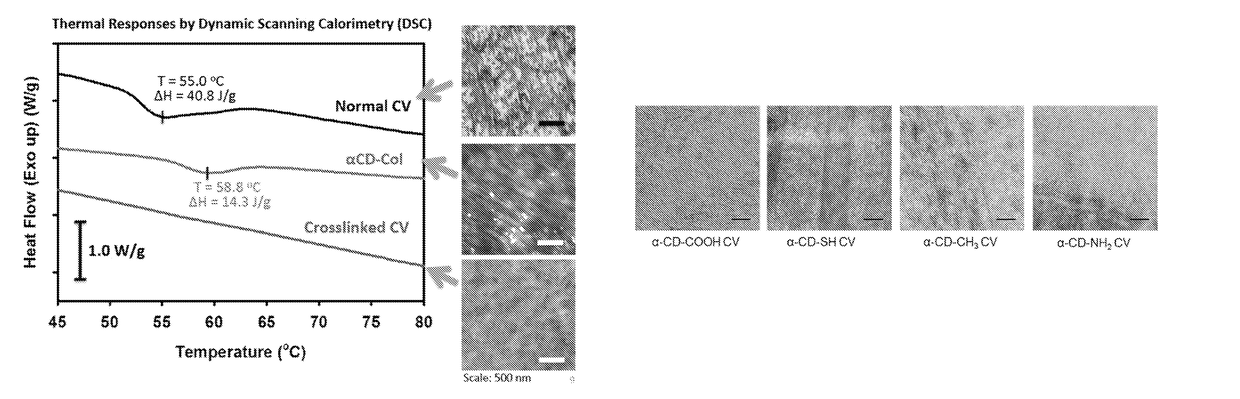

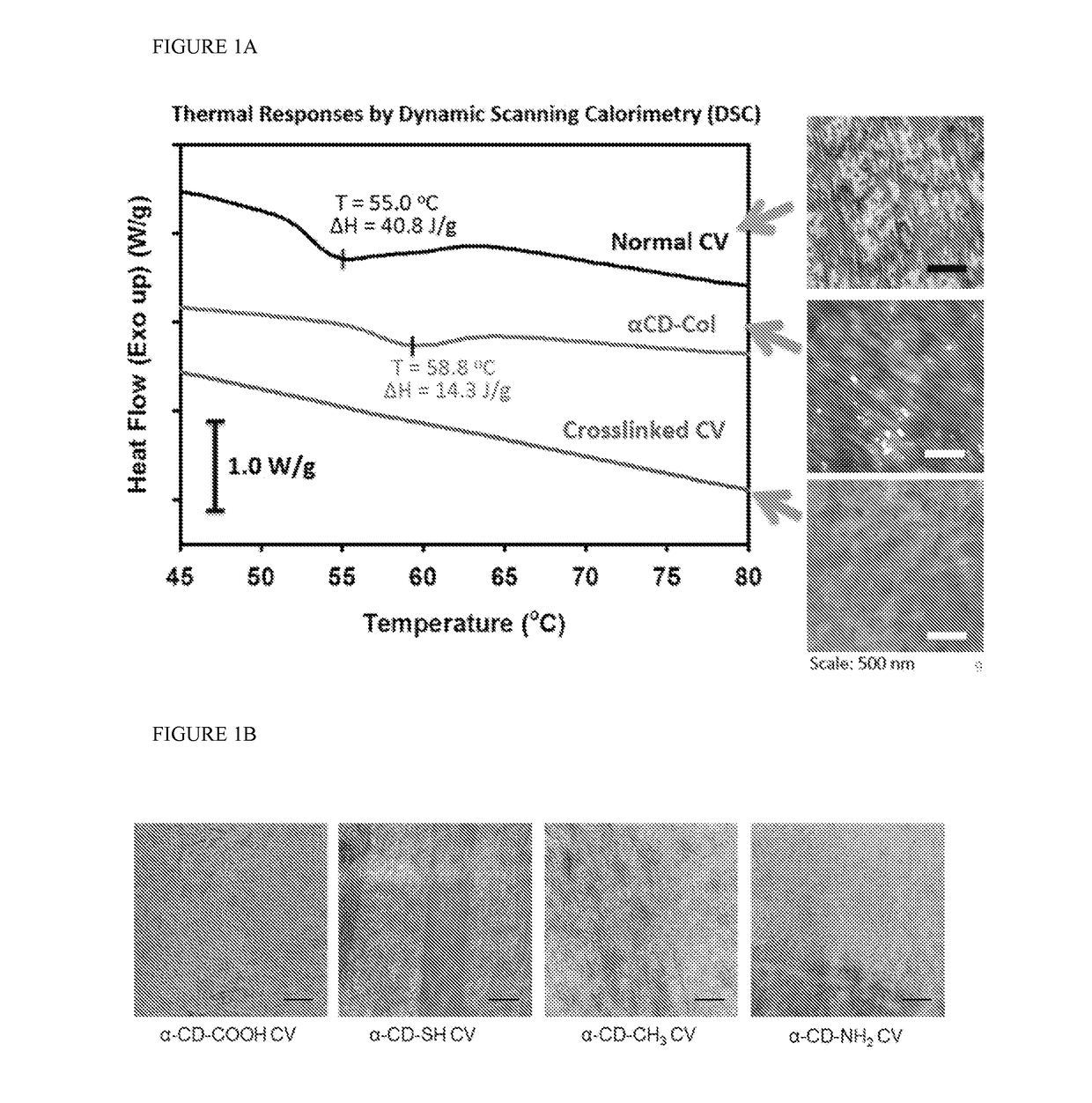

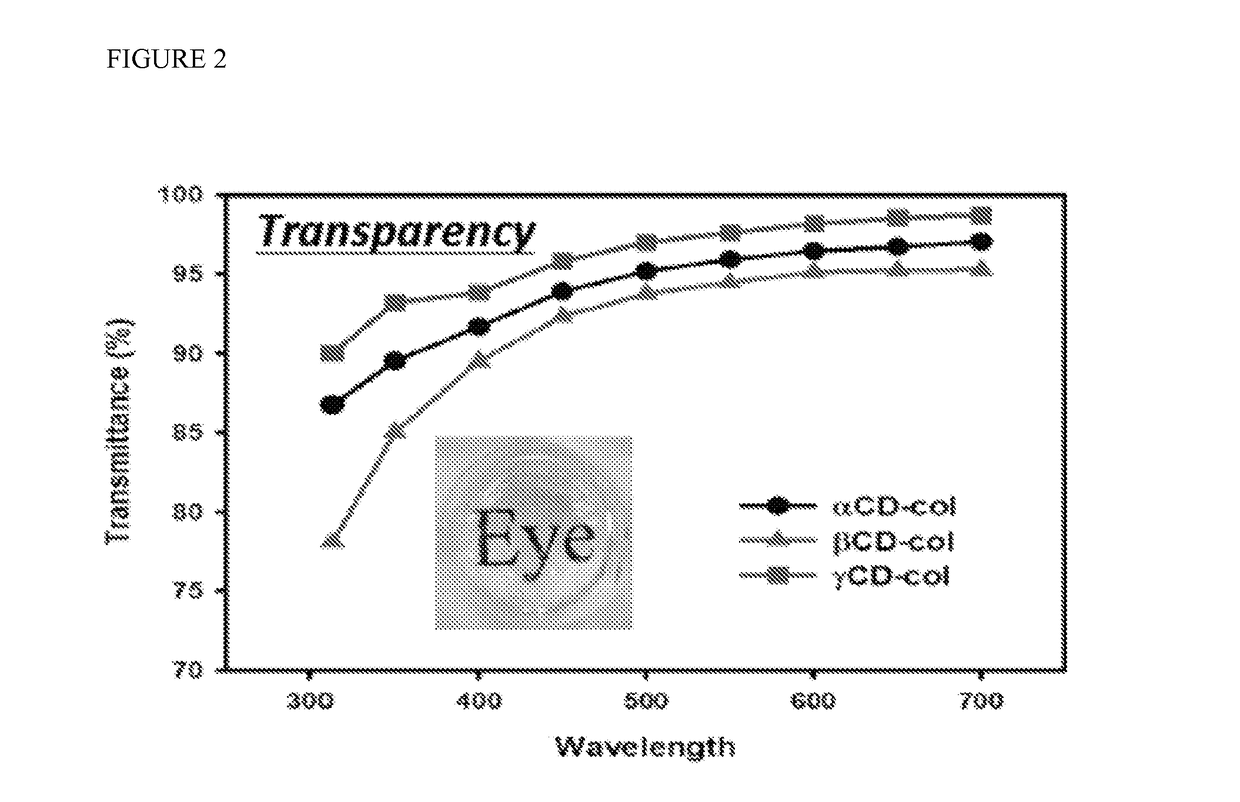

Compositions comprising cyclodextrin incorporated collagen matrices for use in biomedical applications

PendingUS20170043021A1Poor mechanical propertyOptimization propertiesSenses disorderAerosol deliveryChemistry

The present inventors employed cyclodextrins for use as a proteoglycan substitute to engineer a biomimetic collagen-based matrix composition. The resulting incorporation of cyclodextrin in the inventive collagen compositions increased collagen thermal stability and reduced collagen fibrogenesis. As a result, a thick, transparent and mechanically strong collagen-based composition was formed. This cyclodextrin-collagen composition holds a great potential to be used as a therapeutic eye patch for corneal repair. Methods for making these inventive compositions and their use are also provided.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

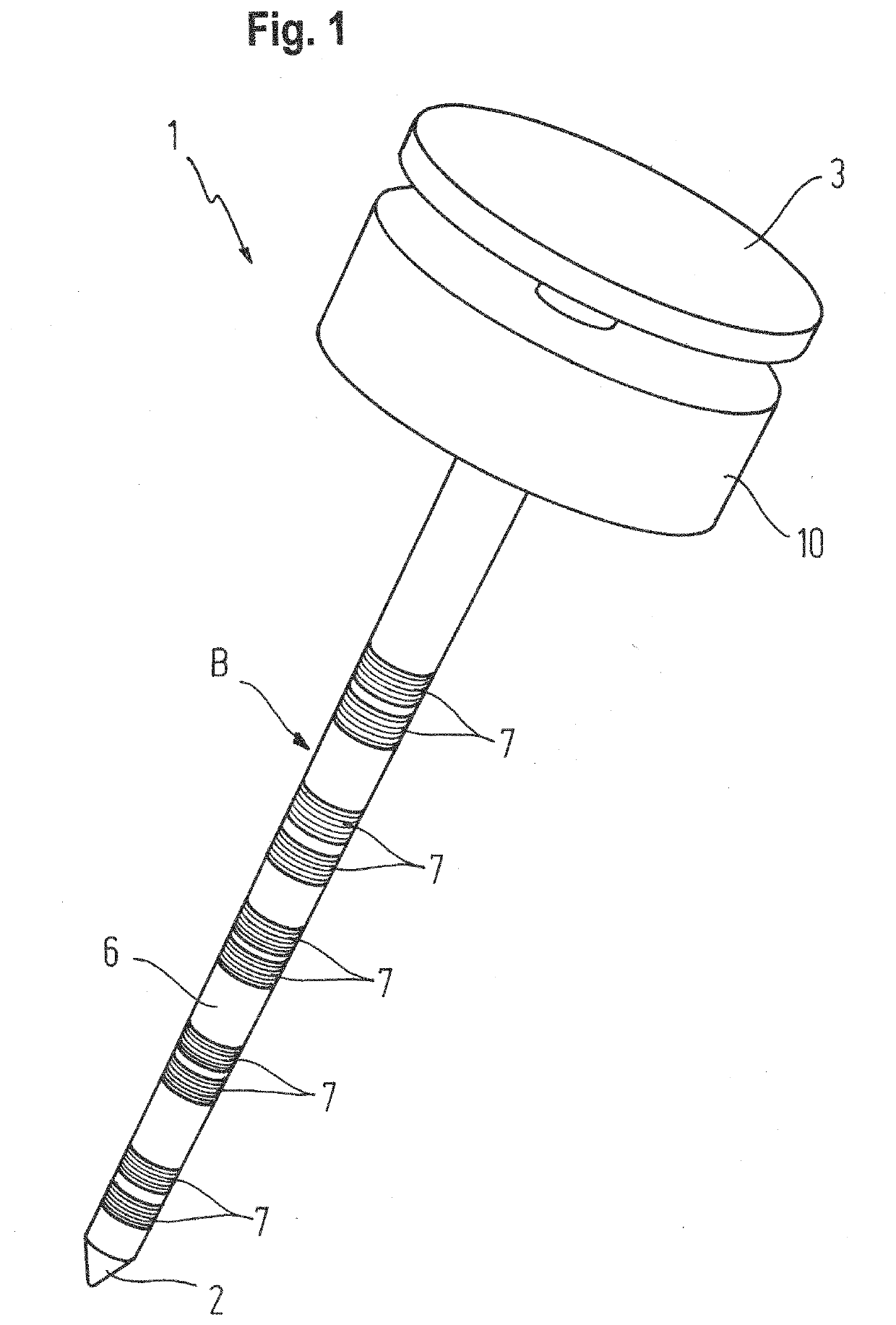

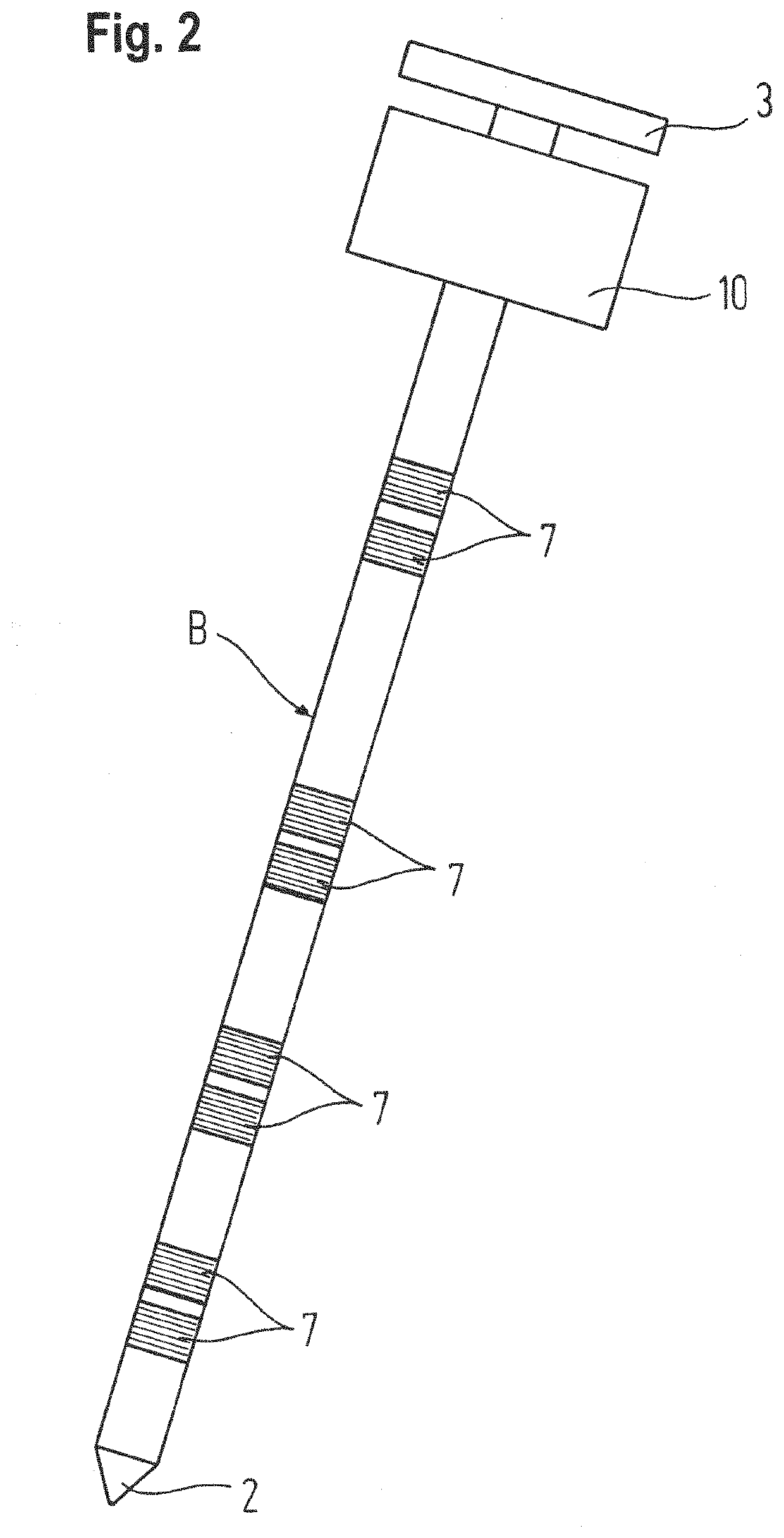

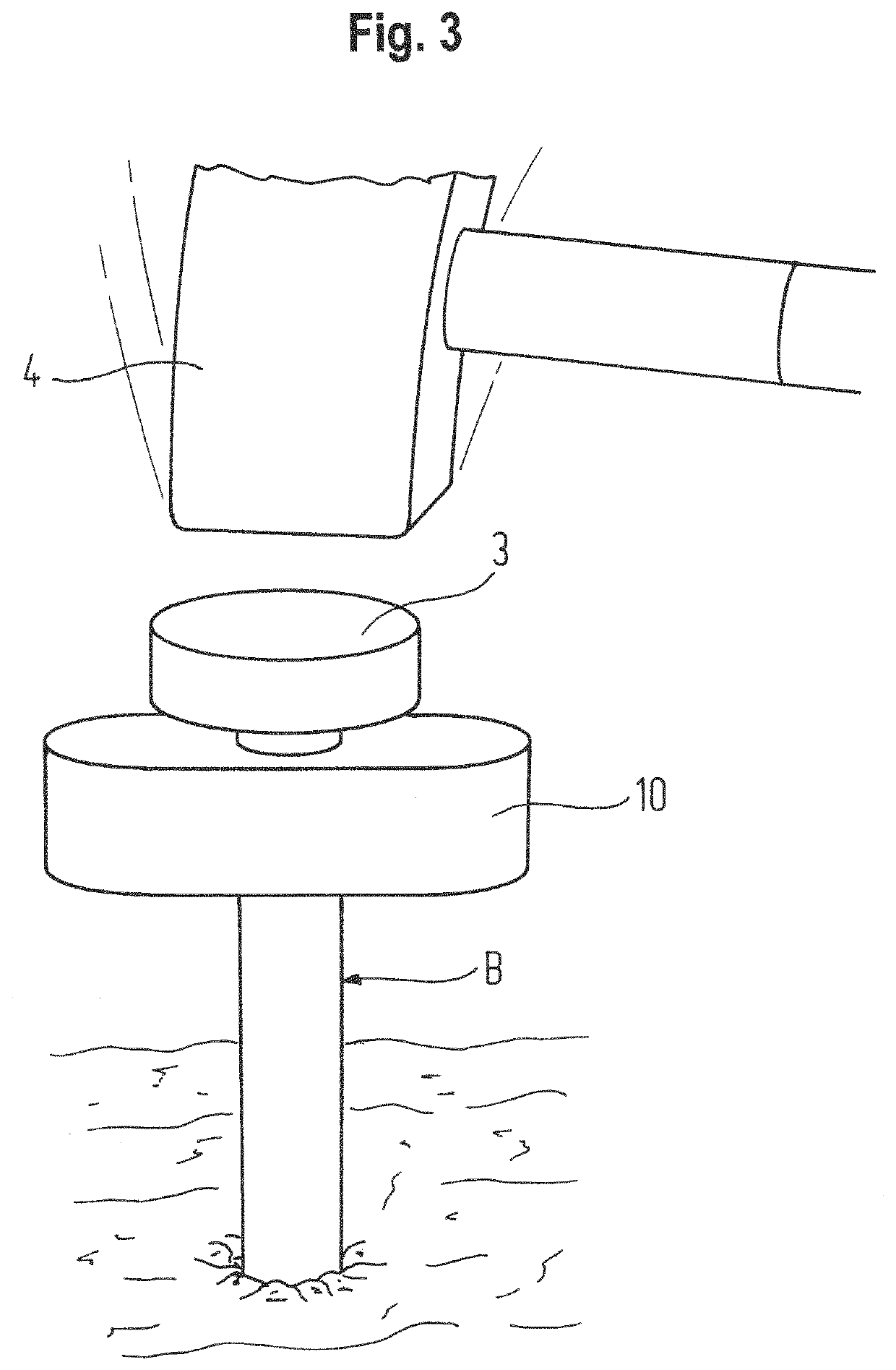

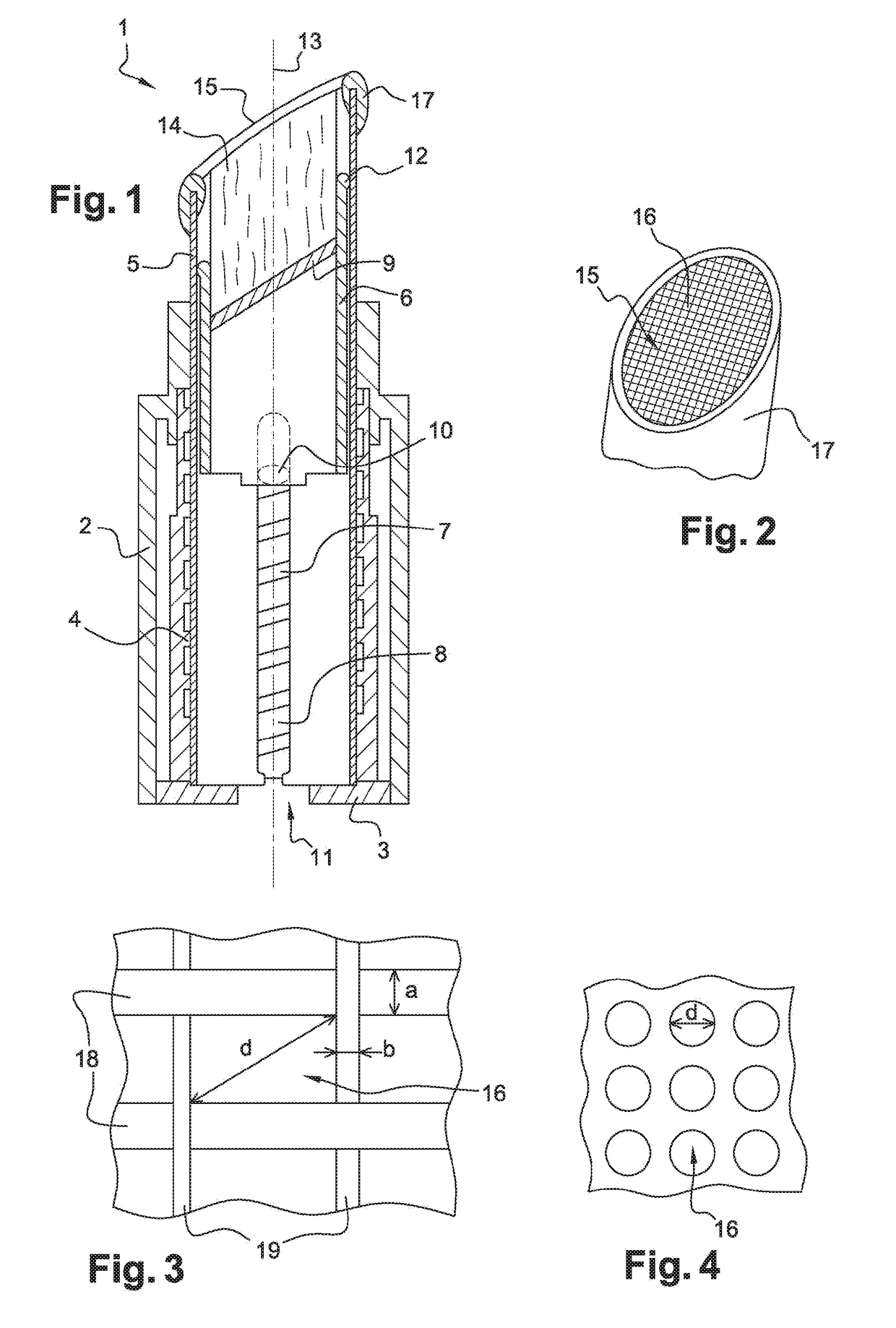

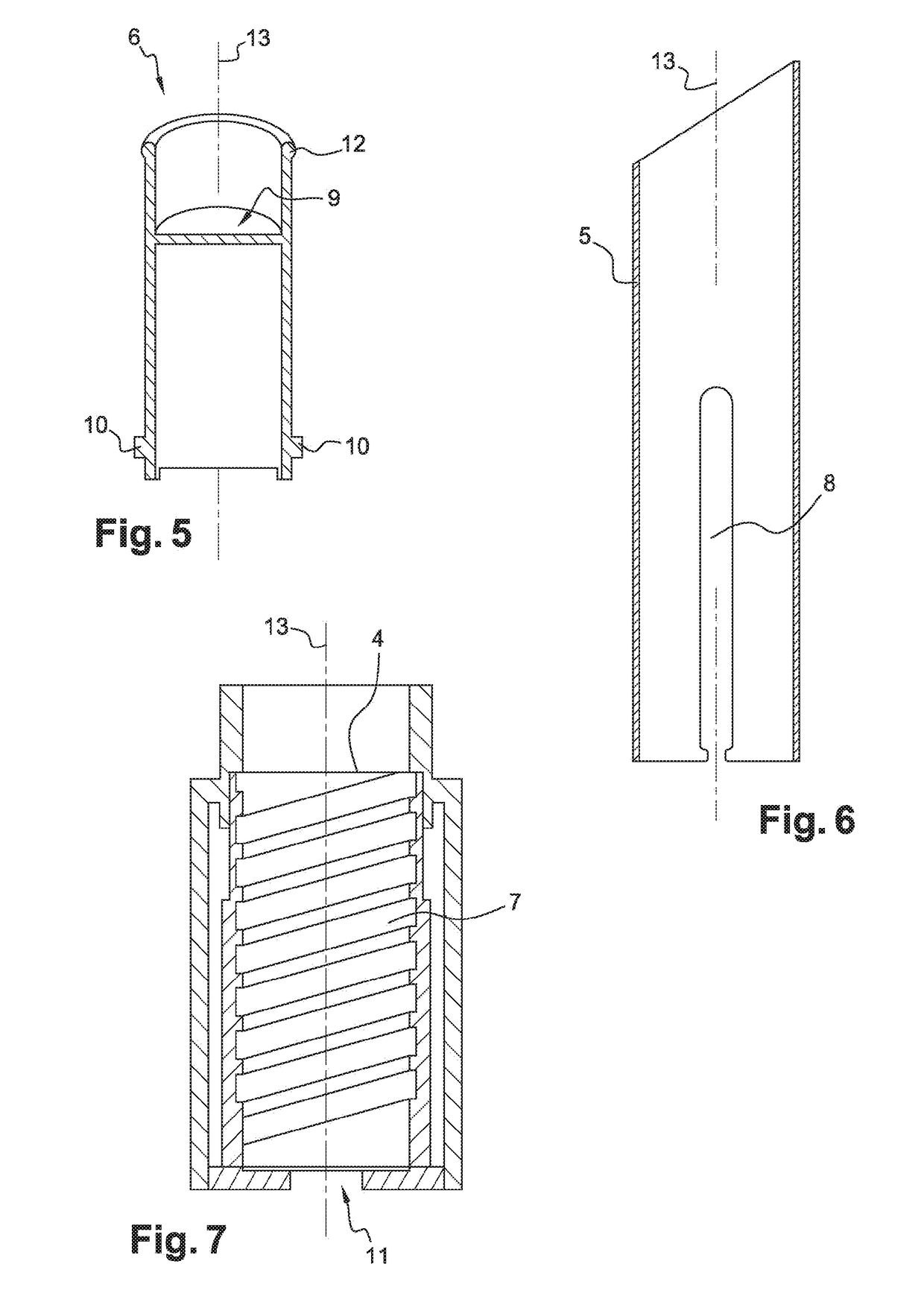

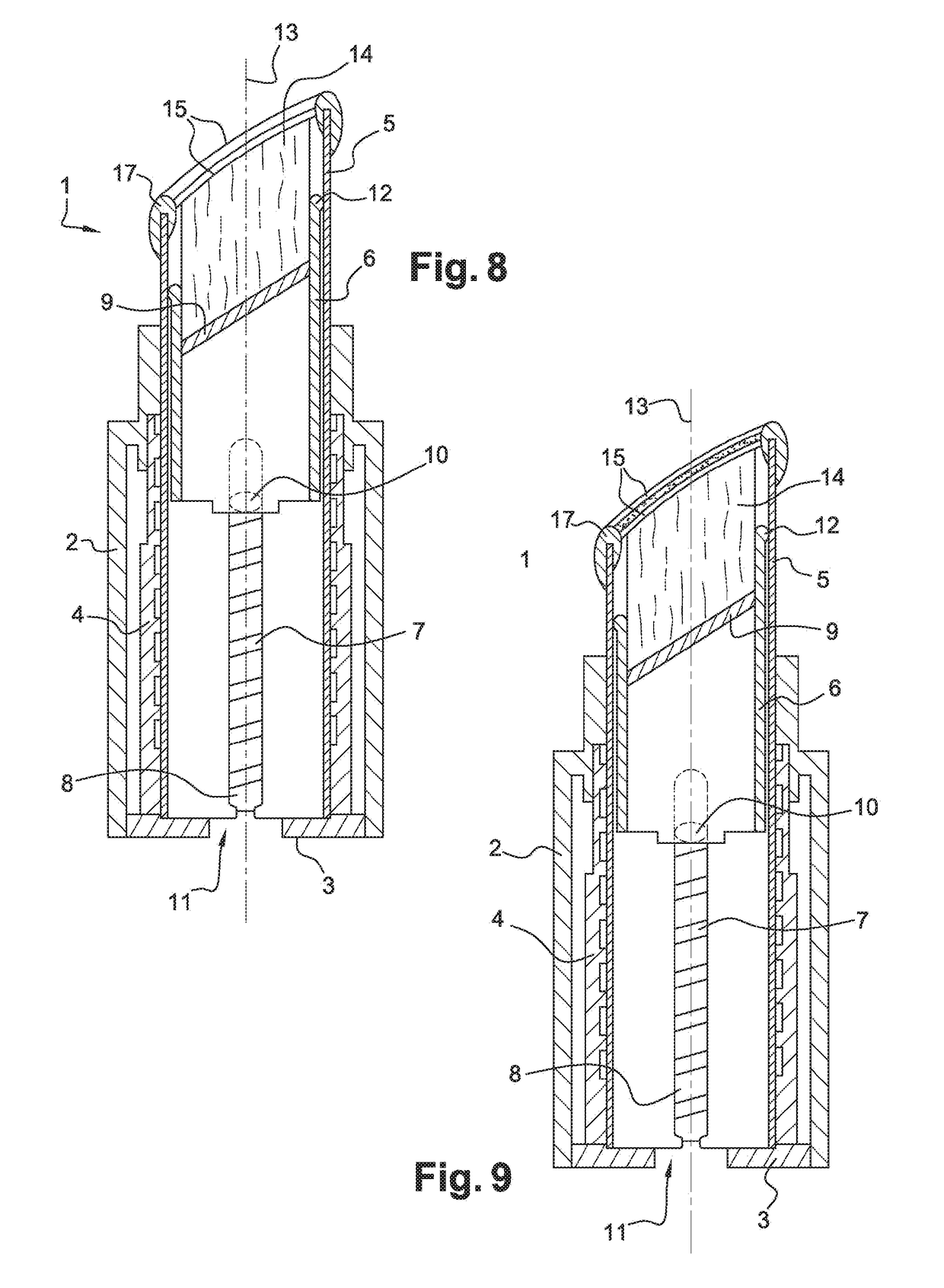

Measuring probe for measuring in ground a parameter and a method for making such a probe

ActiveUS20200150067A1High impact strengthPoor mechanical propertyEarth material testingMaterial resistanceMechanical engineeringPhysics

Owner:SENSOTERRA INT HLDG BV

Composition for hydrogel sheet, hydrogel sheet manufactured therefrom, and method for manufacturing same

ActiveUS20180214354A1Unique hydrophilicityUnique flexibilityCosmetic preparationsToilet preparationsCelluloseEther

The present invention relates to a composition for a hydrogel sheet including a cellulose ether, a gelling agent, and a gelling promoter, a hydrogel sheet prepared therefrom, and a method of preparing the hydrogel sheet. According to the present invention, the composition for a hydrogel sheet can be used to prepare a hydrogel sheet capable of maintaining the shape thereof without a support by limiting a type of the gelling agent and / or a viscosity of the cellulose ether included in the composition.

Owner:LOTTE FINE CHEM CO LTD

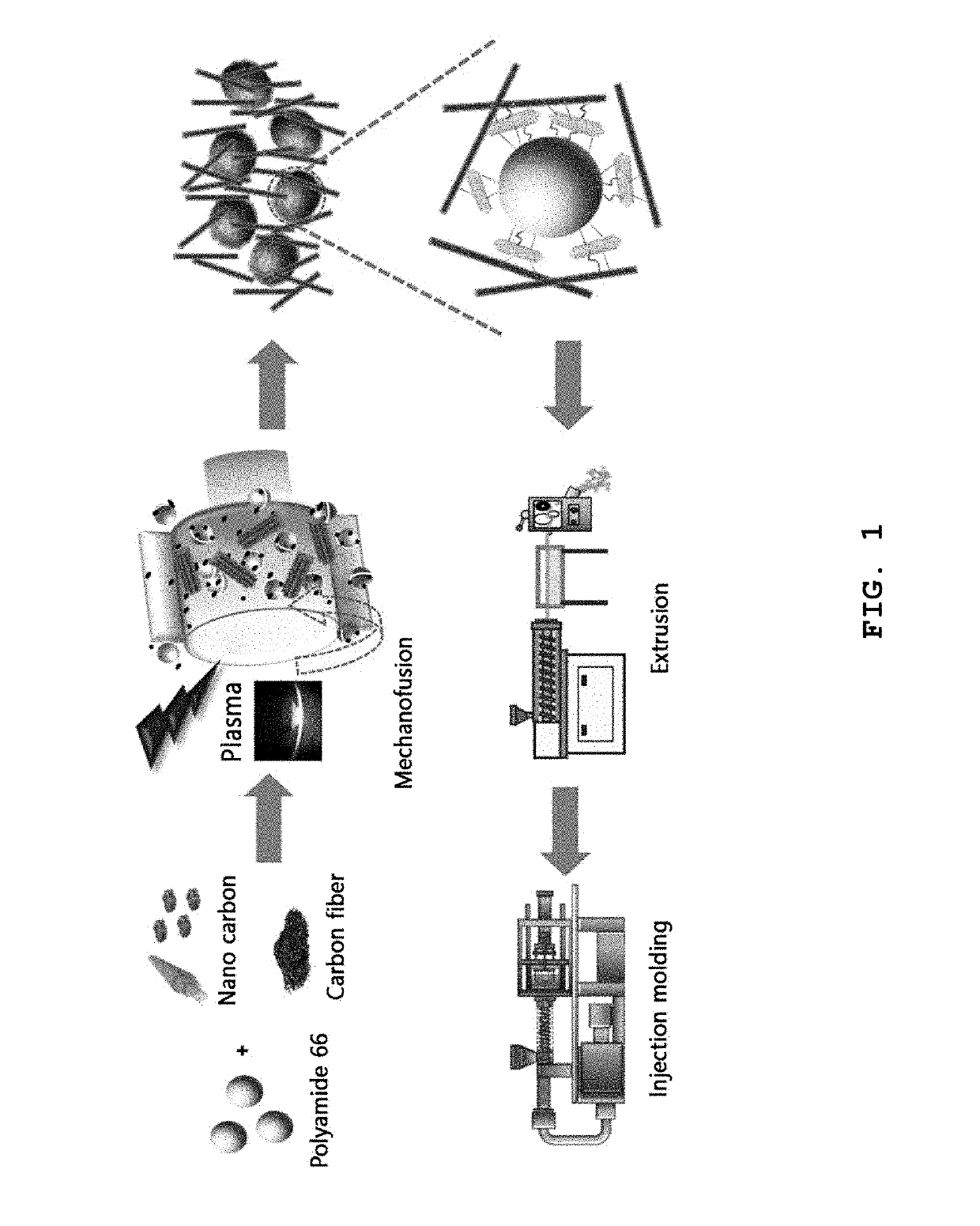

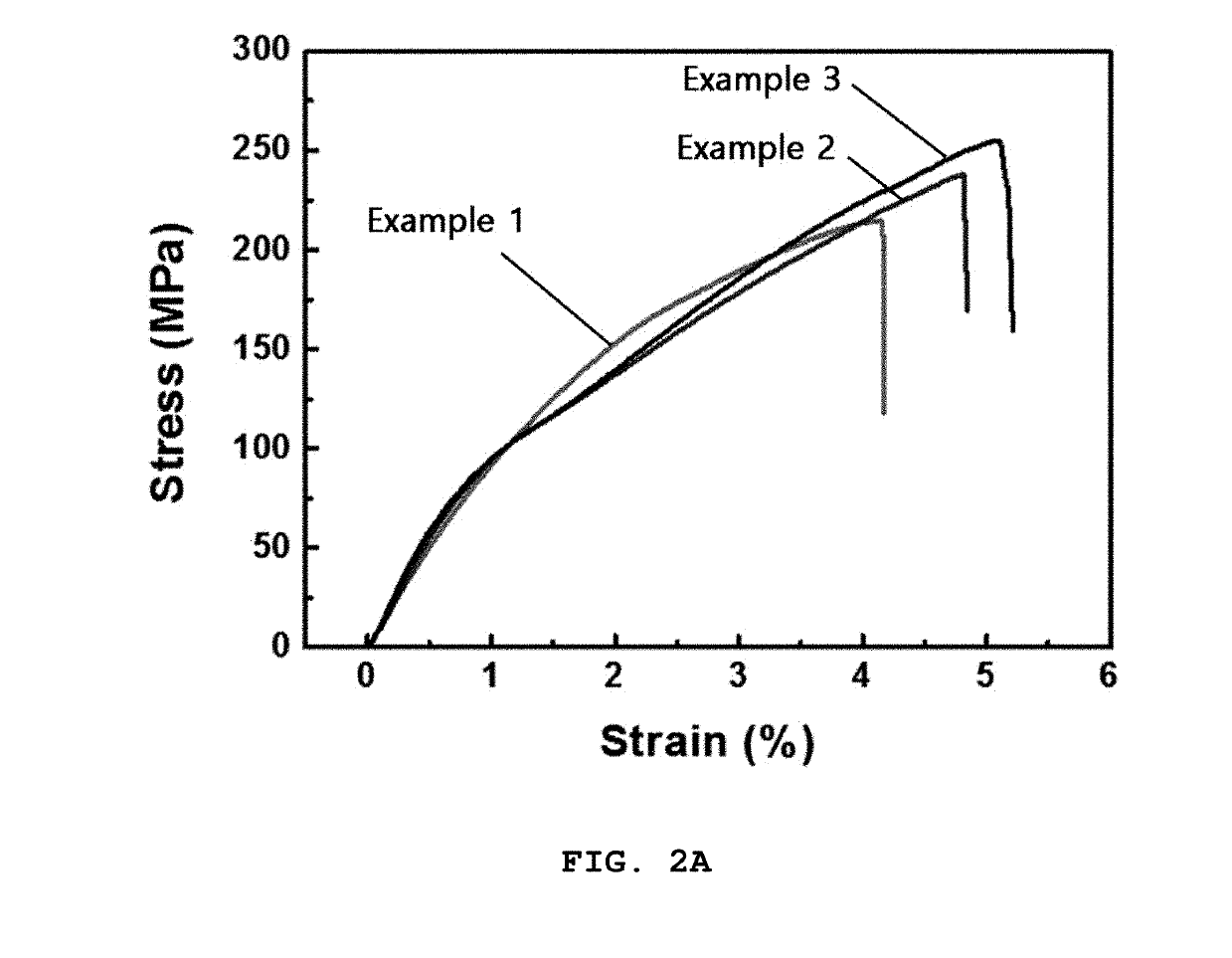

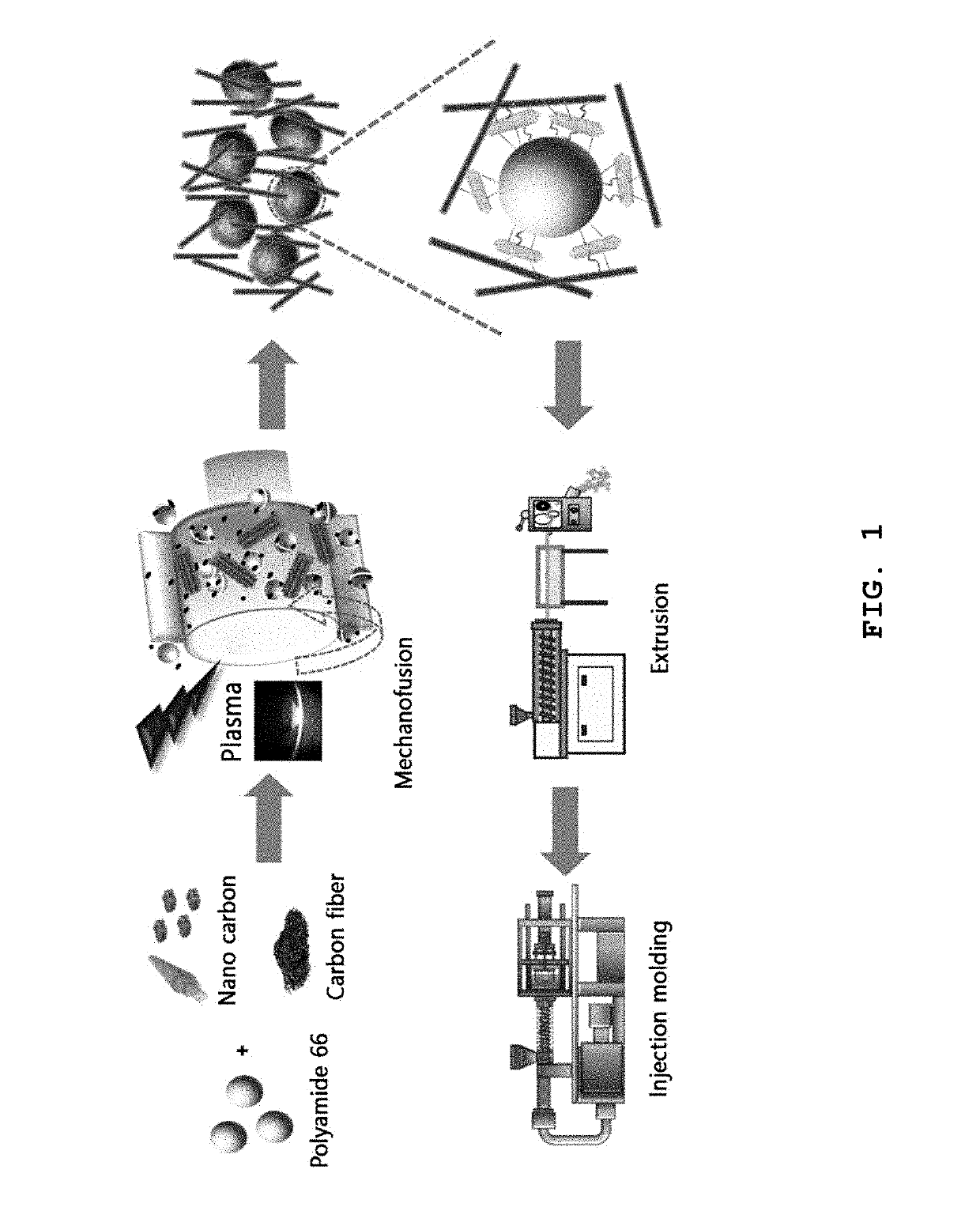

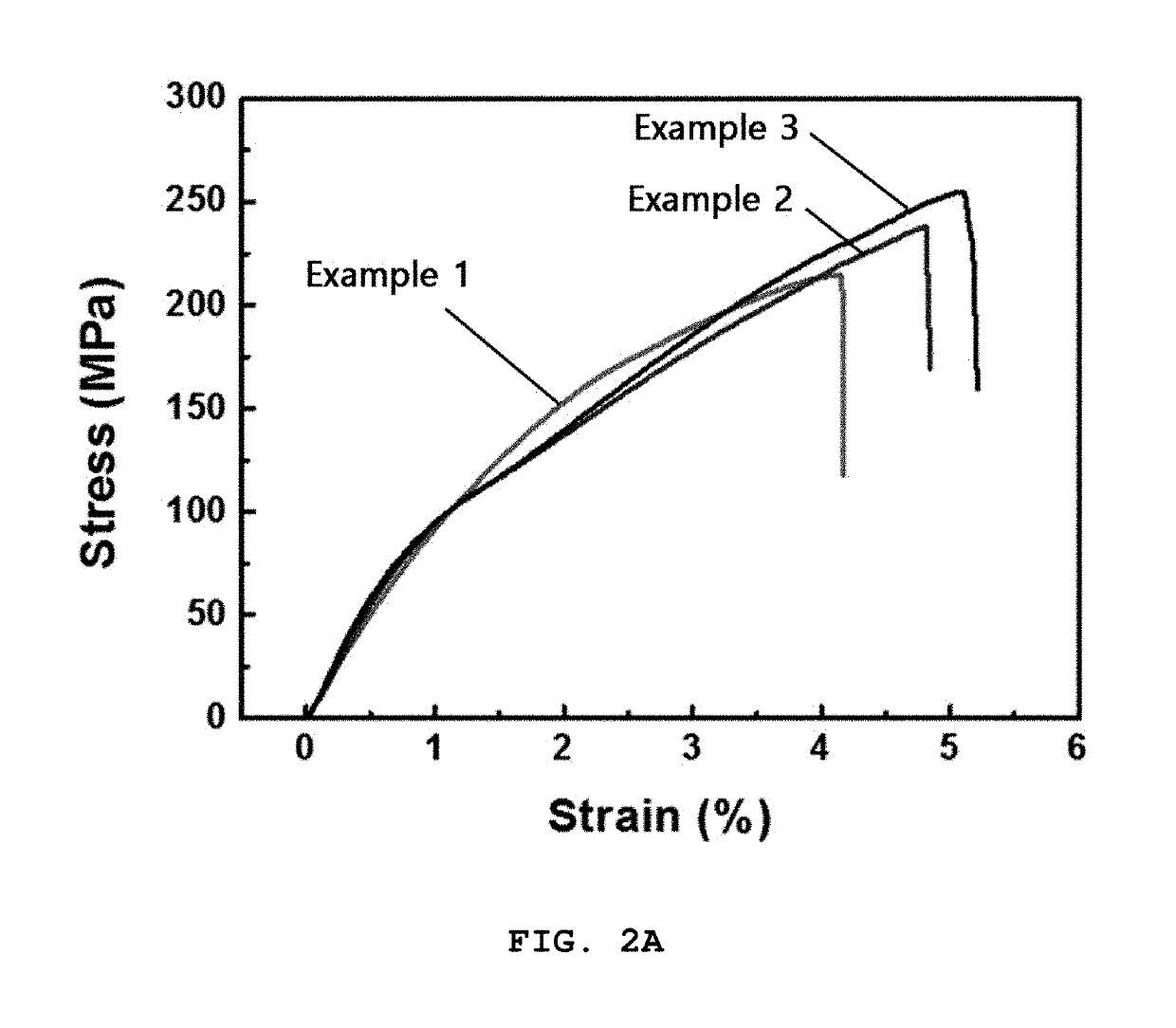

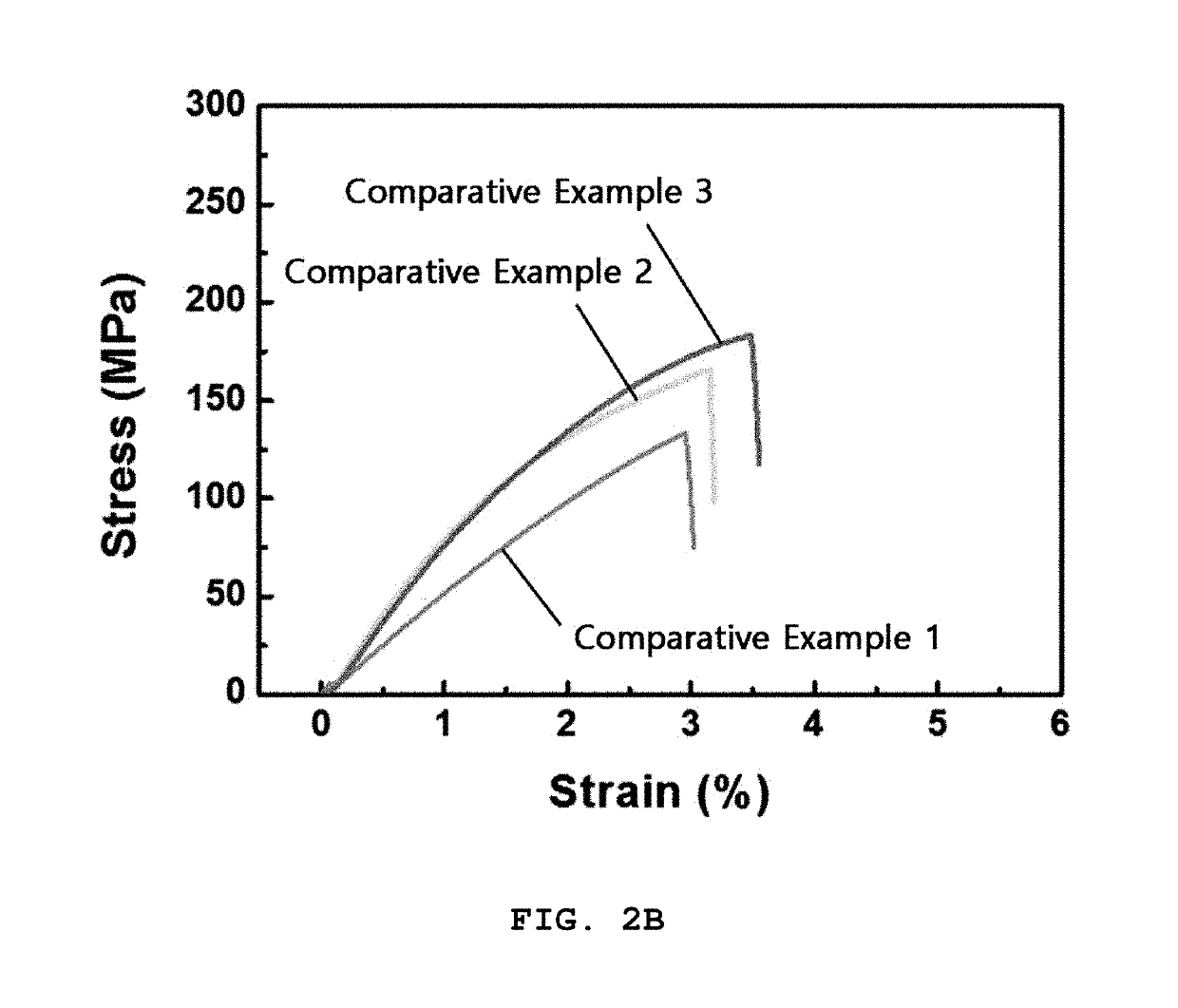

Polymer-hybrid carbon filler composite and method for preparing the same

A polyamide / hybrid carbon filler composite is disclosed. The composite includes a polyamide as a matrix and a hybrid carbon filler dispersed in and bonded to the polyamide matrix. The hybrid carbon filler is composed of a nano carbon and a carbon fiber. Also disclosed is a method for preparing the polyamide / hybrid carbon filler. The method includes simultaneously subjecting a mixture of a polyamide and a hybrid carbon filler to mechanofusion and plasma treatments.

Owner:KOREA INST OF SCI & TECH

Cornea mimetic biomaterials: vitrified collagen-cyclodextrin implants

PendingUS20170182213A1Better mimicOptimization propertiesEye implantsTissue regenerationFiberBiological property

The present inventors employed cyclodextrins for use as a proteoglycan substitute to engineer a biomimetic collagen-based matrix composition. The resulting incorporation of cyclodextrin in the inventive collagen compositions increased collagen thermal stability and reduced collagen fibrogenesis. As a result, a thick, transparent and mechanically strong collagen-based composition was formed. This cyclodextrin-collagen composition holds a great potential to be used as a therapeutic eye patch for corneal repair. Additionally, the composition can support development of multi-layered structures, with different layers promoting different biological properties. Methods for making these inventive compositions and their use are also provided.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Method of manufacturing porous ceramic body and composition for porous ceramic body

ActiveUS9828481B2Good strength and leaching propertyExcellent dimensional stability and shape stabilityCeramic shaping apparatusCeramicwareUltimate tensile strengthSilicon dioxide

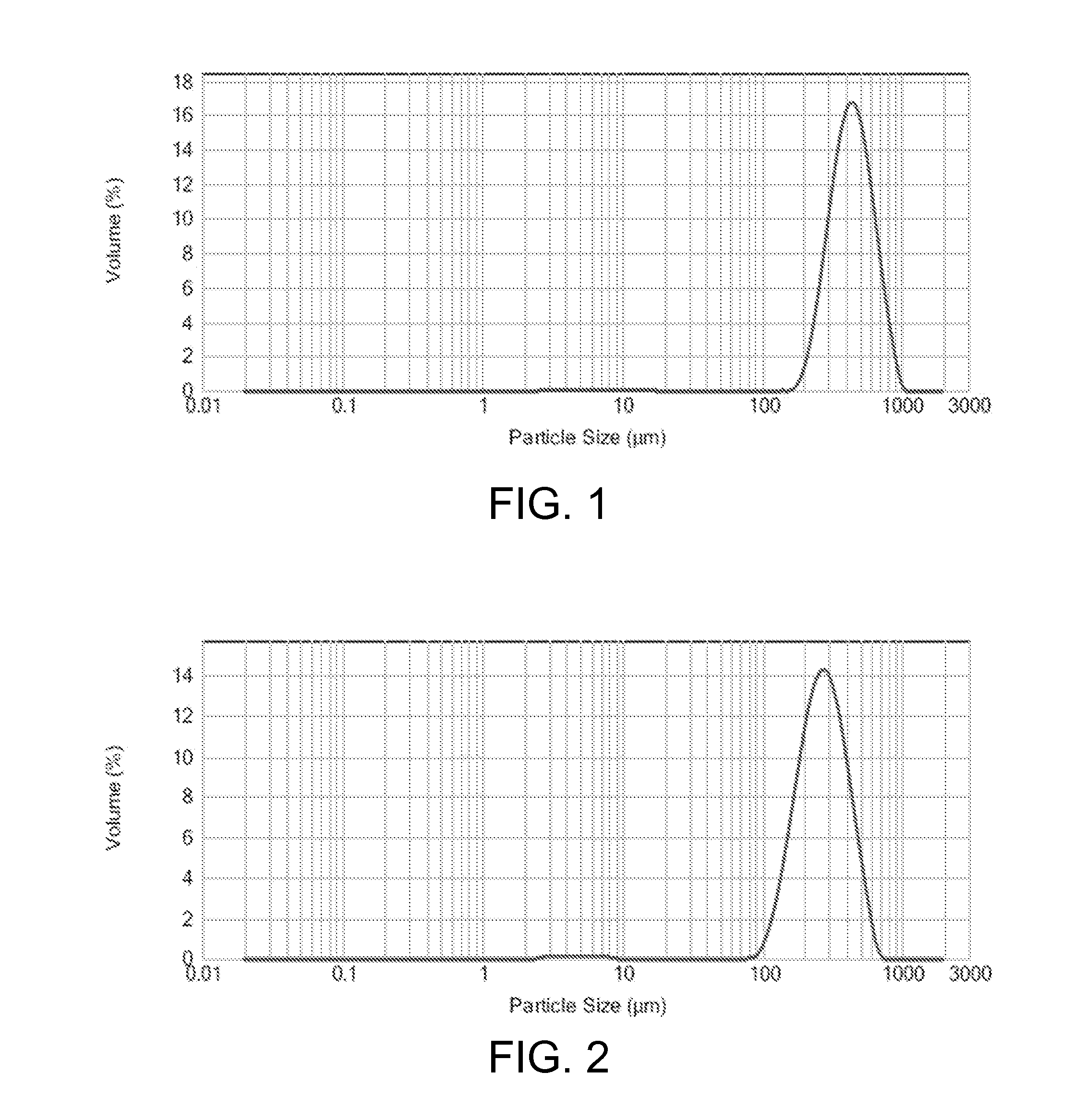

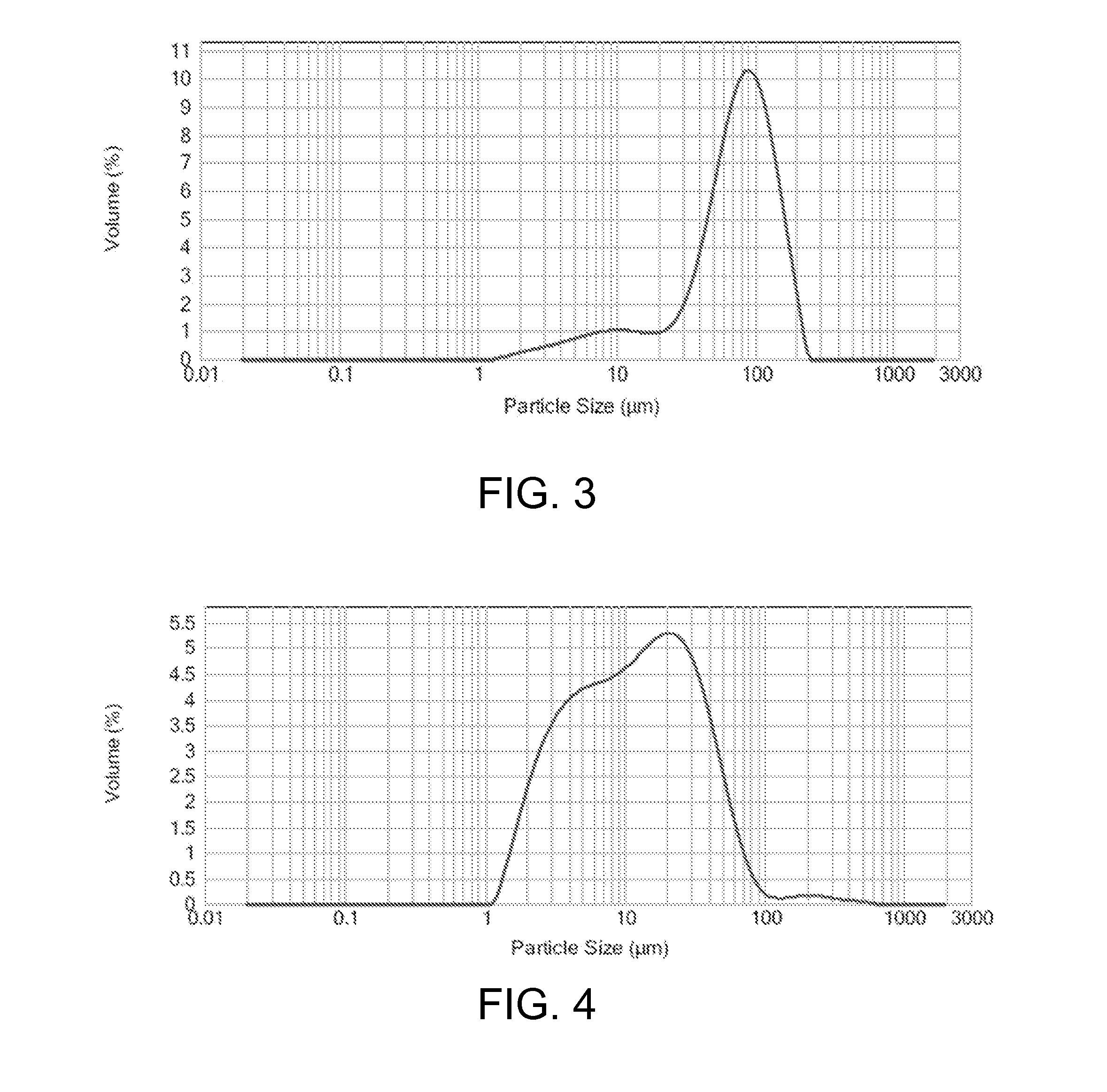

Disclosed is a method of manufacturing a porous ceramic body, which includes: (S1) mixing silica powders having a particle size of 0.045˜0.5 mm, zircon flour and wax, thus preparing a ceramic mixture; (S2) placing the ceramic mixture into a mold, thus producing a green body; and (S3) sintering the green body at high temperature, thus obtaining a porous ceramic body, wherein the silica having a particle size of 0.1˜0.5 mm is contained in an amount of 50˜80 wt % based on the total weight of the porous ceramic body; and also which produces a bulk porous ceramic body having good strength and leaching properties with excellent dimensional stability and shape stability.

Owner:KOREA INST OF ENERGY RES

Method of manufacturing porous ceramic body and composition for porous ceramic body

ActiveUS20150137407A1High strengthGood leaching propertiesCeramic shaping apparatusCeramicwareWaxUltimate tensile strength

Disclosed is a method of manufacturing a porous ceramic body, which includes: (S1) mixing silica powders having a particle size of 0.045˜0.5 mm, zircon flour and wax, thus preparing a ceramic mixture; (S2) placing the ceramic mixture into a mold, thus producing a green body; and (S3) sintering the green body at high temperature, thus obtaining a porous ceramic body, wherein the silica having a particle size of 0.1˜0.5 mm is contained in an amount of 50˜80 wt % based on the total weight of the porous ceramic body; and also which produces a bulk porous ceramic body having good strength and leaching properties with excellent dimensional stability and shape stability.

Owner:KOREA INST OF ENERGY RES

Epoxy composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS20090111922A1High absorption effectImprove conductivityNon-metal conductorsConductive materialConductive coatingPolyaniline

An epoxy composite material containing polyaniline / carbon black and preparation method thereof are disclosed. The epoxy composite material containing polyaniline / carbon black includes a plurality of polyaniline / carbon black composite with core-shell structure distributed in epoxy resin while polyaniline covers on surface of nanoscale carbon black to form the polyaniline / carbon black composite with core-shell structure. The polyaniline / carbon black composite with core-shell structure contains 10˜30 wt. % of nanoscale carbon black. A method for preparing an epoxy composite material containing polyaniline / carbon black includes steps of: adding a plurality of polyaniline / carbon black composites with core-shell structure into epoxy resin; and dispersing the plurality of polyaniline / carbon black composites with core-shell structure in the epoxy resin to produce the epoxy composite material containing polyaniline / carbon black being applied to conductive coating or microwave absorbing elements.

Owner:NAT CHUNG SHAN INST SCI & TECH

Additives for improving natural oil based polyurethane foam performance

Polyurethane foam compositions and processes to make flexible polyurethane foams are disclosed. Polyurethane foam is produced in the presence of additives comprising guanidine derivatives. Improvements in physical properties such as air flow, dimensional stability, tensile, tear, elongation and foam hardness is observed when these additives are present in polyurethane formulations. In addition, these additives can minimize polymer degradation under humid ageing conditions resulting in foam products with better mechanical properties.

Owner:EVONIK OPERATIONS GMBH

Polymer-hybrid carbon filler composite and method for preparing the same

Owner:KOREA INST OF SCI & TECH

Cosmetic Article Comprising A Mesh

InactiveUS20190038002A1Broaden applicationSatisfactory make-upPackaging toiletriesPackaging cosmeticsEngineeringMesh grid

The cosmetic product article including a solid block of cosmetic product with a breakage index measured at 20° C. of between 0.2 and 20 N, and at least one mesh, arranged such that the product passes therethrough and having through-holes, the largest dimension of which is between 50 and 300 μm.

Owner:CHANEL PARFUMS BEAUTE SAS

Process for producing flexible polyurethane foam using natural oil polyols

ActiveUS9145466B2Low usage levelLess corrosive mixtureOther chemical processesSulfolaneCyanoacetamide

A composition and process useful to make flexible polyurethane foams and in particular flexible molded polyurethane foams is disclosed. The usage of dipolar aprotic liquids such as DMSO, DMI, sulfolane, N-methyl-acetoacetamide, N,N-dimethylacetoacetamide as well as glycols containing hydroxyl numbers OH#≦1100 as cell opening aides for 2-cyanoacetamide or other similar molecules containing active methylene or methine groups to make a polyurethane foam is also disclosed. The advantage of using cell opener aids results in a) no foam shrinkage; b) lower use levels of cell opener; c) foam performance reproducibility d) optimum physical properties. In addition, combining the acid blocked amine catalyst together with the cell opener and the cell opener aid results in a less corrosive mixture as well as provides a method that does not require mechanical crushing for cell opening.

Owner:EVONIK OPERATIONS GMBH

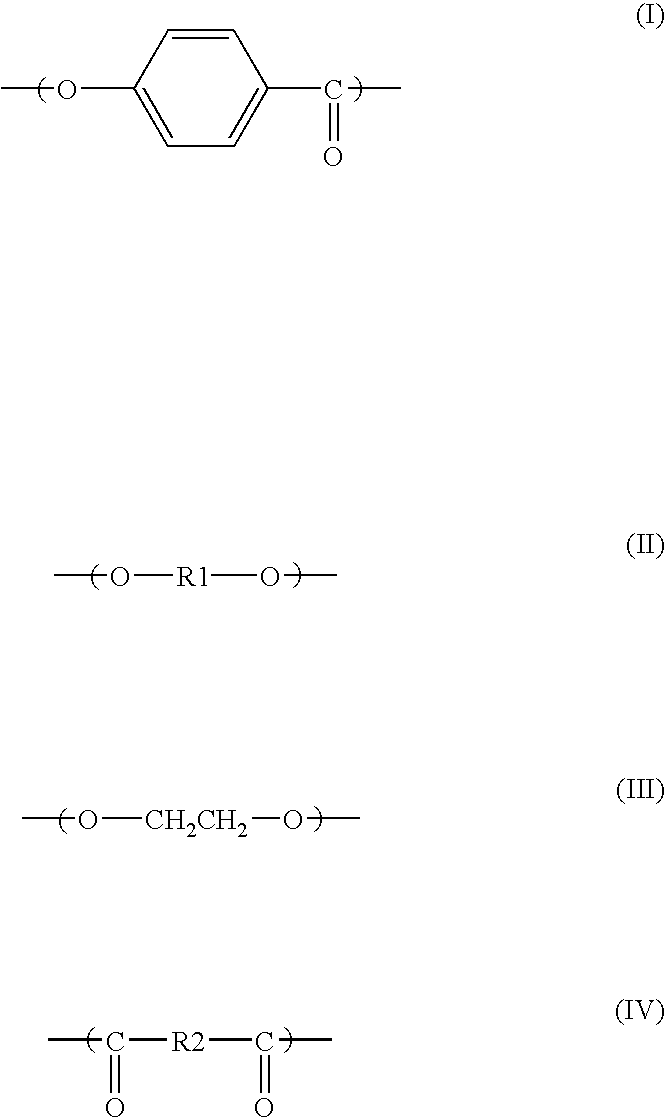

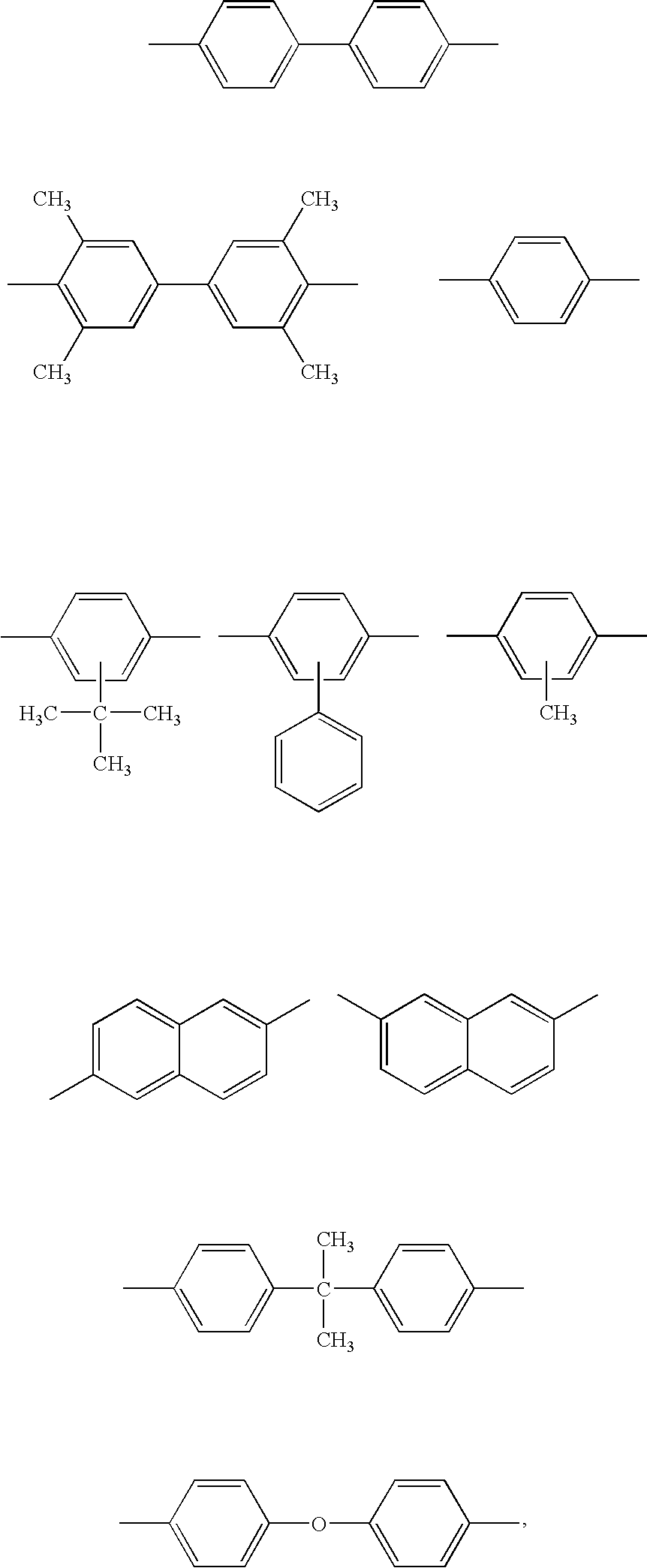

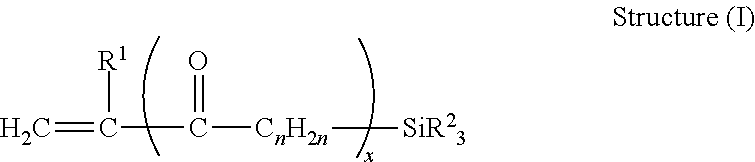

Polymeric compositions for optical fiber cable components

PendingUS20220298345A1Increase zero-shear viscosityMaintain dimensional stabilityOptical light guidesPolytetramethylene terephthalatePolymer science

A method includes steps of (a) blending a polymeric composition, including: (i) 5 wt % to 45 wt % of a silanol-functionalized polyolefin based on a total weight of the polymeric composition; (ii) 55 wt % to 90 wt % of a polybutylene terephthalate based on a total weight of the polymeric composition having a melt flow index from 21 g / 10 min. to 35 g / 10 min. at 250° C. and 2.16 kg; (iii) a condensation catalyst; and (iv) 0.5 wt % to 10 wt % of hydroxy terminated poly(dimethylsiloxane) based on a total weight of the polymeric composition; and (b) extruding the polymeric composition.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com