Polyaniline/carbon black composite and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

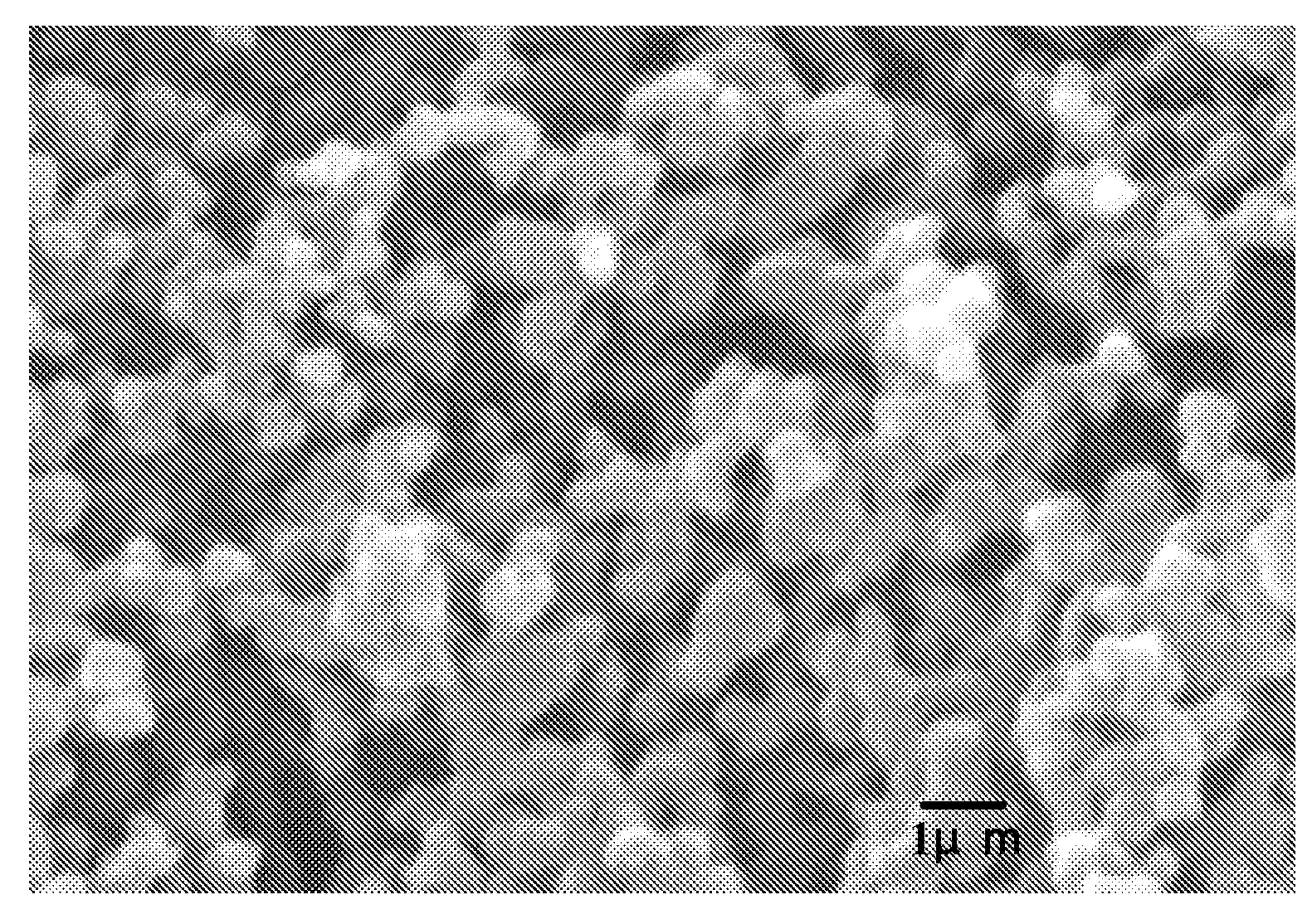

[0030]The polyaniline / carbon black composite is formed by polyaniline covering carbon black and is with core-shell structure while the polyaniline / carbon black composite contains 10˜30 wt. % of carbon black.

[0031]The particle diameter of the carbon black particle is 10˜80 nm and the particle diameter of the polyaniline / carbon black core-shell particle ranges from 50 to 250 nm (from observation of Transmission electron microscopy (TEM)). The preferable weight percent of carbon black in the polyaniline / carbon black composite is 20 wt. %.

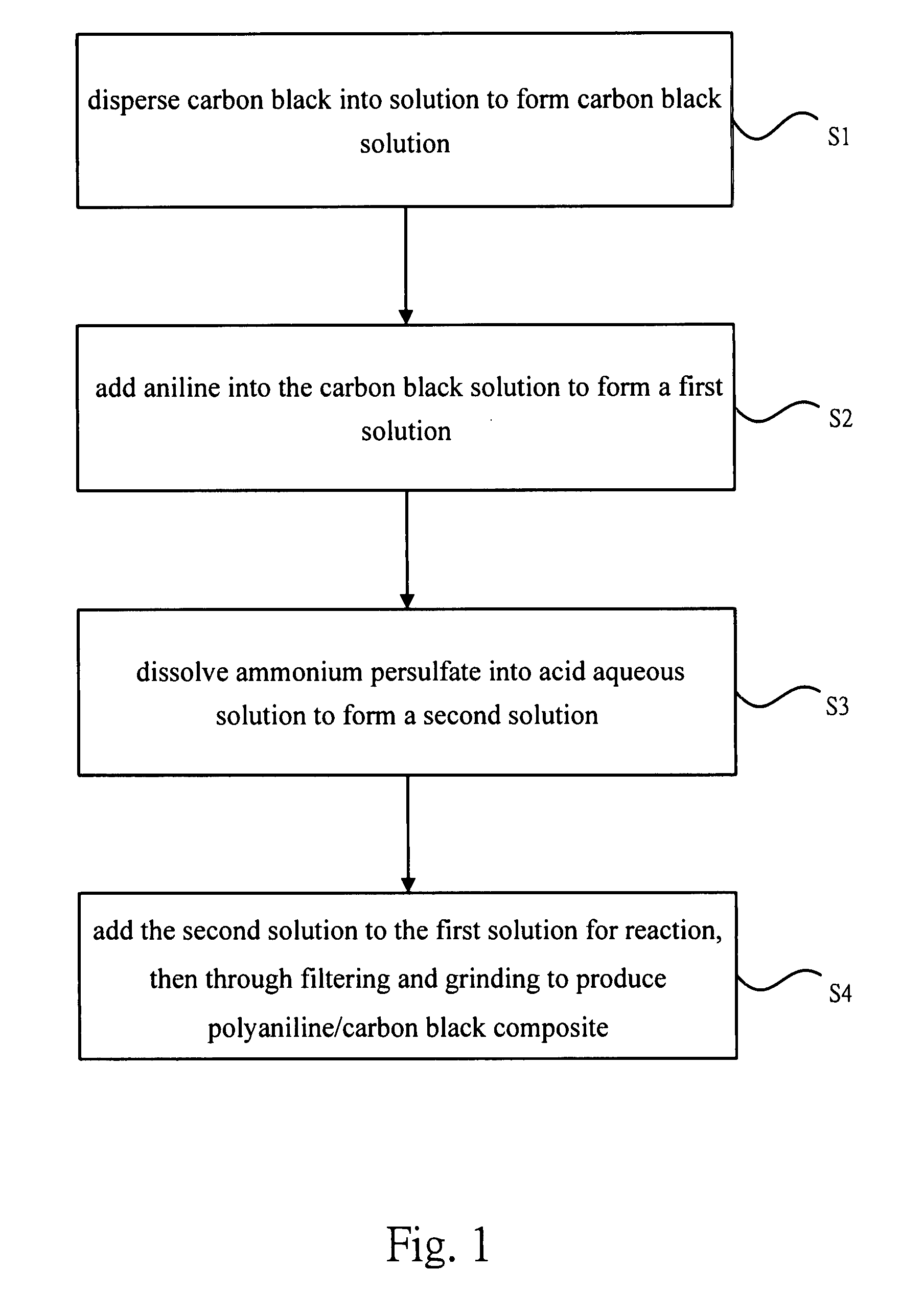

[0032]Refer to FIG. 1, a preparation method of polyaniline / carbon black composite according to the present invention includes the steps of:

[0033]S1 disperse carbon black into solution to form carbon black solution;

[0034]S2 add aniline into the carbon black solution to form a first solution;

[0035]S3 dissolve ammonium persulfate into acid aqueous solution to form a second solution;

[0036]S4 add the second solution to the first solution for reaction, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com