A kind of high-strength heat-conducting magnesium alloy and preparation method thereof

A magnesium alloy and high-strength technology, which is applied in the field of high-strength thermal conductivity magnesium alloy and its preparation, can solve problems such as the inability to meet the performance requirements of high-strength and high thermal conductivity magnesium alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The composition of a high-strength thermally conductive magnesium alloy is designed as:

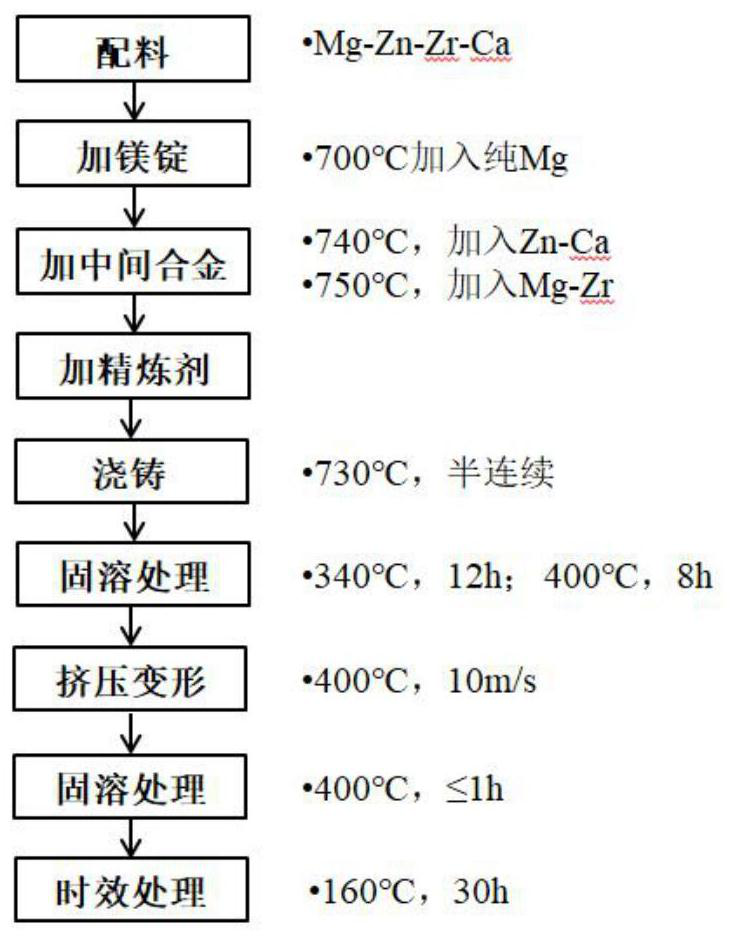

[0040]Zr: 0.4wt.%, Zn: 4wt.%, Ca: 0.4wt.%, and the balance is Mg. Its preparation method is as figure 1 , including the following steps:

[0041] (1) Using 99.99% pure magnesium ingot, Zn-10wt.% Ca master alloy, pure zinc and Mg-Zr master alloy as raw materials, according to the above Zr: 0.4wt.%, Zn: 4wt.%, Ca: 0.4wt. %, the balance is Mg for batching;

[0042] (2) First, preheat the resistance furnace at 700°C, then, after spreading the flux at the bottom of the resistance furnace, put 99.99wt% pure magnesium ingots into the resistance furnace, and spread the flux (55-60wt.% KCl, 2~5wt.% CaF 2 , and the rest are BaCl 2 ), then the magnesium ingot is heated up to 740°C with the resistance furnace;

[0043] (3) Preheat the required magnesium ingot, Zn-10wt.% Ca master alloy, pure zinc and magnesium Mg-Zr master alloy at 180°C. After the magnesium block is completely melted, a...

Embodiment 2

[0050] The composition design of a high-strength heat-conducting magnesium alloy is: Zr: 0.5wt.%, Zn: 5wt.%, Ca: 0.6wt.%, and the balance is Mg. Its preparation method is as figure 1 , including the following steps:

[0051] (1) Using 99.99% pure magnesium ingot, Zn-30wt.% Ca master alloy, pure zinc and Mg-Zr master alloy as raw materials, according to the above Zr: 0.5wt.%, Zn: 5wt.%, Ca: 0.6wt. %, the balance is Mg for batching;

[0052] (2) First, preheat the resistance furnace at 700°C, then, after spreading the flux at the bottom of the resistance furnace, put 99.99wt% pure magnesium ingots into the resistance furnace, and spread the flux (55-60wt.% KCl, 2~5wt.% CaF 2 , and the rest are BaCl 2 ), then the magnesium ingot is heated up to 740°C with the resistance furnace;

[0053] (3) Preheat the required magnesium ingots, Zn-30wt.% Ca master alloy, pure zinc and Mg-Zr master alloy at 180°C, and add preheating when the furnace temperature is 740°C after the magnesium ...

Embodiment 3

[0060] The composition design of a high-strength heat-conducting magnesium alloy is as follows: according to the above Zr: 0.6wt.%, Zn: 6wt.%, Ca: 0.8wt.%, and the balance is Mg. Its preparation method is as figure 1 , including the following steps:

[0061] (1) Using 99.99% pure magnesium ingot, Zn-20wt.% Ca master alloy, pure zinc and Mg-Zr master alloy as raw materials, according to the above Zr: 0.6wt.%, Zn: 6wt.%, Ca: 0.8wt. %, the balance is Mg for batching;

[0062] (2) First, preheat the resistance furnace at 700°C, then, after spreading the flux at the bottom of the resistance furnace, put 99.99wt% pure magnesium ingots into the resistance furnace, and spread the flux (55-60wt.% KCl, 2~5wt.% CaF 2 , and the rest are BaCl 2 ), then the magnesium ingot is heated up to 740°C with the resistance furnace;

[0063] (3) Preheat the required magnesium ingot, Zn-20wt.% Ca master alloy and magnesium Mg-Zr master alloy at 180°C. After the magnesium block is completely melte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com