A composite modificator for regeneration of adc12 aluminum alloy and preparation method thereof

A composite modifier and ADC12 technology, applied in the field of metal materials, can solve the problems of easy recession, poor mechanical properties of ADC12 aluminum alloy, and unstable refining effect of modifier, and achieve the effect of eliminating gas, improving mechanical properties and casting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

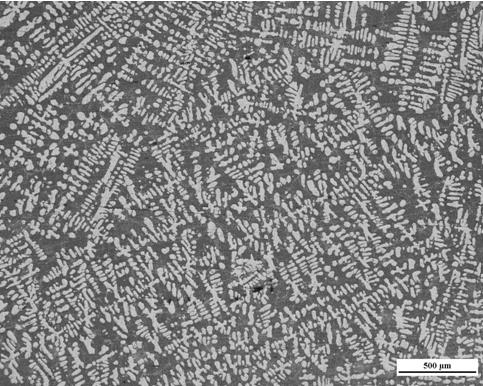

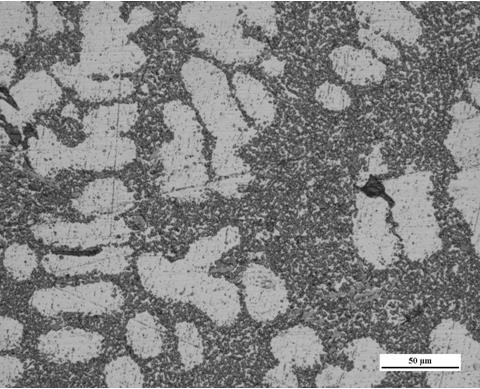

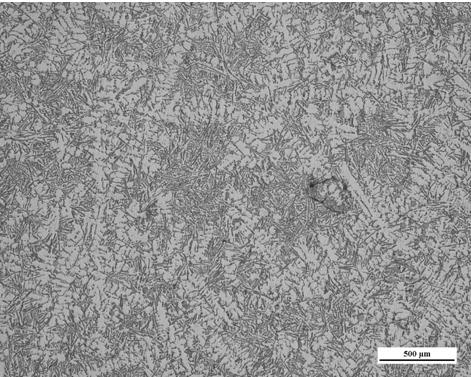

Image

Examples

Embodiment 1

[0018] After melting the pure aluminum in the corundum crucible, add Al-Te master alloy and YbCl at 730°C 3 After 5 minutes of insulation, the amount of Te added was 12% of the total weight of the modificator, and YbCl 3 0.5%; Stir with a graphite rod for 3 minutes, when the furnace temperature drops to 700°C, pour argon into the melt for refining, keep warm for 10 minutes; remove surface scum, pour the molten metal into a metal mold to solidify.

Embodiment 2

[0020] After melting the pure aluminum in the corundum crucible, add Al-Te master alloy and YbCl at a temperature of 735°C 3 After 5 minutes of insulation, the amount of Te added was 14% of the total weight of the modificator, and YbCl 3 2%; Stir with a graphite rod for 3 minutes, when the furnace temperature drops to 705°C, pour argon into the melt for refining, keep warm for 10 minutes; remove surface scum, pour the molten metal into a metal mold to solidify.

Embodiment 3

[0022] After melting the pure aluminum in the corundum crucible, add Al-Te master alloy and YbCl at a temperature of 740°C 3 After the insulation for 5 minutes, the amount of Te added was 16% of the total weight of the modificator, and YbCl 3 Stir with a graphite rod for 3 minutes. When the furnace temperature drops to 710°C, pour argon into the melt for refining and keep it warm for 10 minutes. Remove surface scum and pour the molten metal into a metal mold to solidify.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com