Method for improving strength of soldered seams on basis of thin-melt ultrasonic fine crystallization treatment in narrow gaps

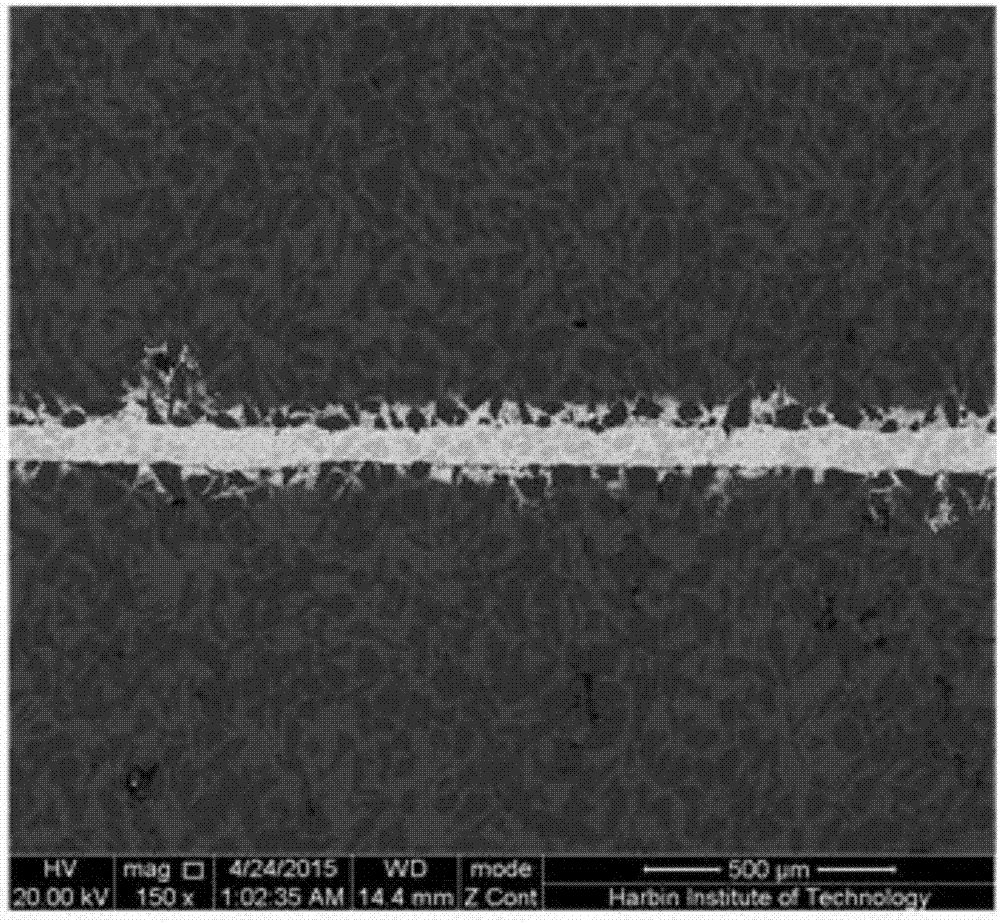

A welding seam strength and ultrasonic brazing technology, which is applied in the field of material welding, can solve the problems of low metal strength of brazing seam, coarsening of weld metal grains, and high brazing temperature, so as to avoid dissolution and corrosion, weld seam The effect of obvious metal refinement and improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

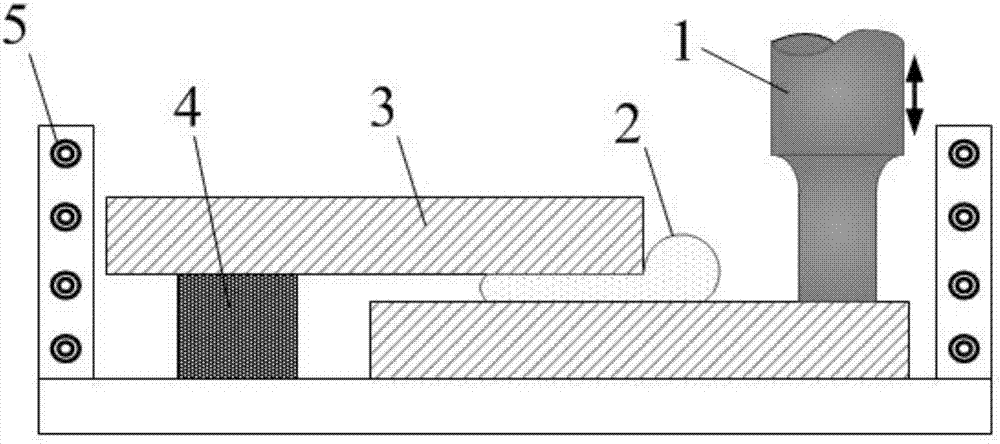

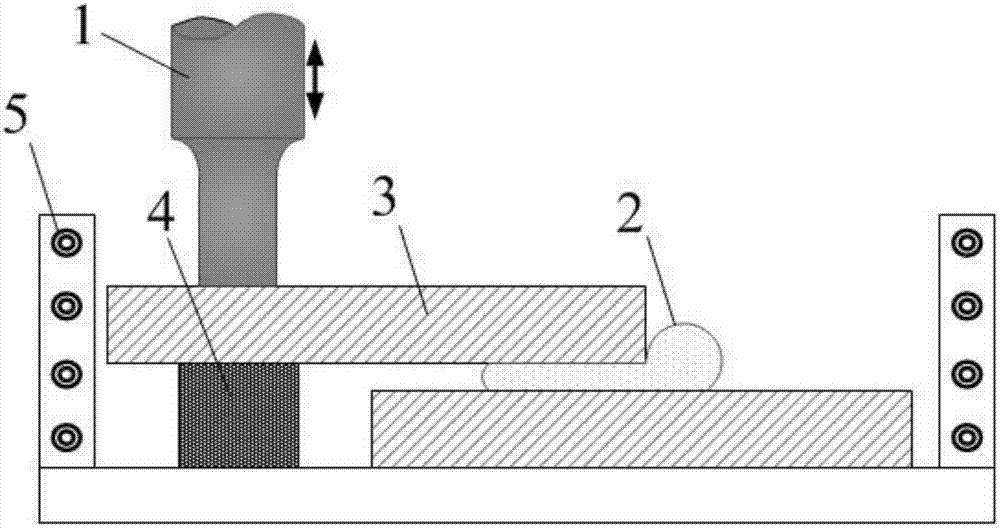

[0030]Specific Embodiment 1: In this embodiment, a method for improving the strength of a brazing weld based on ultrasonic fine-graining treatment of a thin layer of melt in a narrow gap is specifically implemented through the following steps:

[0031] 1. Assemble the base metal and solder into the parts to be welded, and adjust the lap gap of the base metal to 0.05-2mm;

[0032] 2. Control the ultrasonic frequency to 20-100kHz, the amplitude to 1-50μm, and the brazing temperature to 220-720°C, and conduct ultrasonic brazing for 1-60s on the part to be welded to complete the preliminary brazing;

[0033] 3. Adjust the brazing temperature to 180-550°C, keep it for 5-20 minutes, then control the ultrasonic frequency to 20-100kHz and the amplitude to 1-50μm, apply ultrasonic vibration to the brazing part, the ultrasonic vibration time is 1s-10min, and then Cooling in the furnace or air cooling to room temperature completes the method for improving the strength of the brazed seam ...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the brazing filler metal is an aluminum-based alloy, a zinc-based alloy or a tin-based alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the gap between base metals is 0.1 mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com