High-strength-and-toughness magnesium alloy with controllable long-period phase size and preparation method thereof

A long-period, magnesium alloy technology, applied in temperature control, metal rolling, elongation control, etc., can solve the problems of difficult to obtain 18R long-period phase, kink deformation, etc., to avoid cracking of samples, improve plasticity and formability , Improve the effect of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

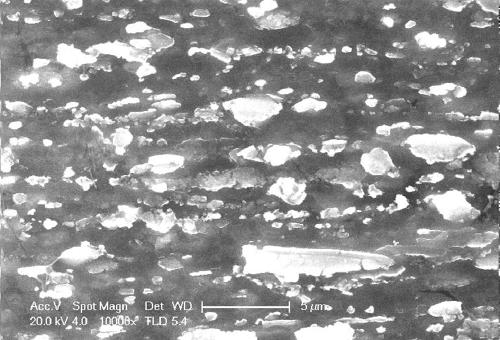

Embodiment 1

[0025] Cut an alloy ingot with a composition of Mg-6.84wt%Y-2.52wt%Zn, and an atomic ratio of Y:Zn of 2 into a rod-shaped sample with a diameter of 14 mm, and place it in a mold with a cylindrical cavity with an inner diameter of 15 mm , the sample was thermally compressed by an indenter at 420°C with a compression ratio of 10%, and an alloy rod with kinked 18R long-period phase was obtained. The above alloy rod was subjected to multi-pass hot drawing processing, the drawing temperature was 390°C, the single-pass deformation was 15%, the drawing speed was 4mm / s, and the strain was 5.4. After the drawing was completed, a High strength and toughness magnesium alloy.

Embodiment 2

[0027] Cut an alloy ingot with a composition of Mg-6.84wt%Y-2.52wt%Zn, and an atomic ratio of Y:Zn of 2 into a rod-shaped sample with a diameter of 12 mm, and place it in a mold with a cylindrical cavity with an inner diameter of 15 mm , the sample was thermally compressed by the indenter at 420 ℃, the compression rate was 30%, and the alloy rod with kinked 18R long-period phase was obtained. The above alloy rod was subjected to multi-pass hot drawing processing, the drawing temperature was 390°C, the single-pass deformation was 15%, the drawing speed was 4mm / s, and the strain was 5.4. After the drawing was completed, a High strength and toughness magnesium alloy.

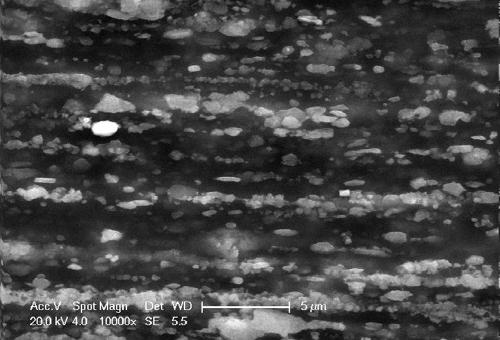

Embodiment 3

[0029] Cut an alloy ingot with a composition of Mg-6.84wt%Y-2.52wt%Zn, and an atomic ratio of Y:Zn of 2 into a rod-shaped sample with a diameter of 10 mm, and place it in a mold with a cylindrical cavity with an inner diameter of 15 mm , the sample was thermally compressed by the indenter at 420 ℃, the compression rate was 50%, and the alloy rod with kinked 18R long-period phase was obtained. The above alloy rod was subjected to multi-pass hot drawing processing, the drawing temperature was 390°C, the single-pass deformation was 15%, the drawing speed was 4mm / s, and the strain was 5.4. After the drawing was completed, a High strength and toughness magnesium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com