Copper conic liner and preparation method thereof

A technology of drug-type cover and cover-top, applied in the field of drug-type cover, which can solve problems such as uneven internal structure of drug-type cover, large material consumption, unfavorable metal jet extension, etc., to improve penetration performance and material utilization The effect of high rate and dense tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

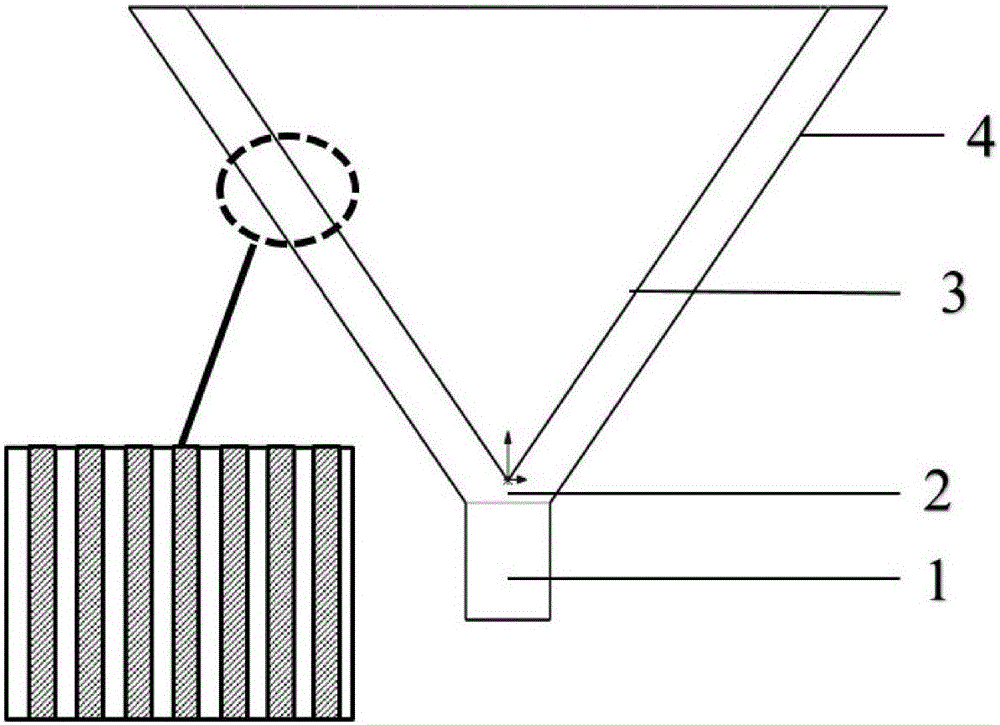

[0025] A preparation method of a copper medicine-shaped cover, the steps are as follows:

[0026] Step 1, establishing a solid model of the drug-type cover, and then processing the solid model to obtain the geometric information of each section, and converting the geometric information of each section into the information of the movement track of the CNC workbench;

[0027] Step 2: Fix the substrate on the CNC workbench with five-axis linkage, and use the synchronous powder feeding method to send the copper powder into the irradiation range of the laser beam through the powder feeder and coaxial nozzle for melting. At this time, the CNC workbench according to The movement trajectory information obtained in step 1 moves, and the molten copper forms the first layer of cladding layer on the substrate after cooling and solidification, and the cladding layer is rapidly cooled by the water cooling system under the substrate to increase the temperature gradient while keeping the heat ...

Embodiment 1

[0032] A kind of preparation method of copper drug type cover, its preparation steps are as follows:

[0033] (1) Put the 150-325 mesh spherical copper powder into a vacuum drying oven for drying treatment to remove the moisture adsorbed on the powder surface. The holding temperature is 100°C and the holding time is 20 hours.

[0034] (2) Use DZ22 directionally solidified nickel-based superalloy as the substrate, cut it into a cylindrical sample with a diameter of 30 mm and a thickness of 10 mm, and use a metallographic sample pre-grinder and 400# water sandpaper to remove the surface of the substrate. Rust and surface treatment. Finally, place the substrate in an ultrasonic cleaning machine, add acetone solution, and wash for 10 minutes to degrease the substrate.

[0035] (3) Generate the solid model of the medicine mask through CAD and store it as an STL format file, and then process the solid model with layered software to obtain the geometric information of each section a...

Embodiment 2

[0040] A kind of preparation method of copper drug type cover, its preparation steps are as follows:

[0041] (1) Dry the spherical copper powder with a mesh size of 150-325 according to the method described in Example 1.

[0042] (2) DZ22 directionally solidified nickel-based superalloy was used as the substrate, and the surface of the substrate was derusted and degreased according to the method described in Example 1.

[0043] (3) Generate the solid model of the medicine mask through CAD and store it as an STL format file, and then process the solid model with layered software to obtain the geometric information of each section and convert it into the information of the movement track of the CNC workbench.

[0044] (4) Install the substrate on a five-axis linkage workbench, use a fiber laser with a rated power of 2kW as the laser equipment, and adopt the synchronous powder feeding method, the laser beam rapidly heats and melts the copper powder ejected from the coaxial powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com