Steam heating and spray humidifying device used before tow curling and pretreatment process

A humidification device and tow technology, applied in spray/jet textile material processing, liquid/gas/vapor yarn/filament processing, textile and papermaking, etc. Process requirements, the specific surface area of the tow is not large enough, etc., to achieve the effect of non-adhesion in appearance, improvement of tow performance and elastic modulus, and obvious curling effect and bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

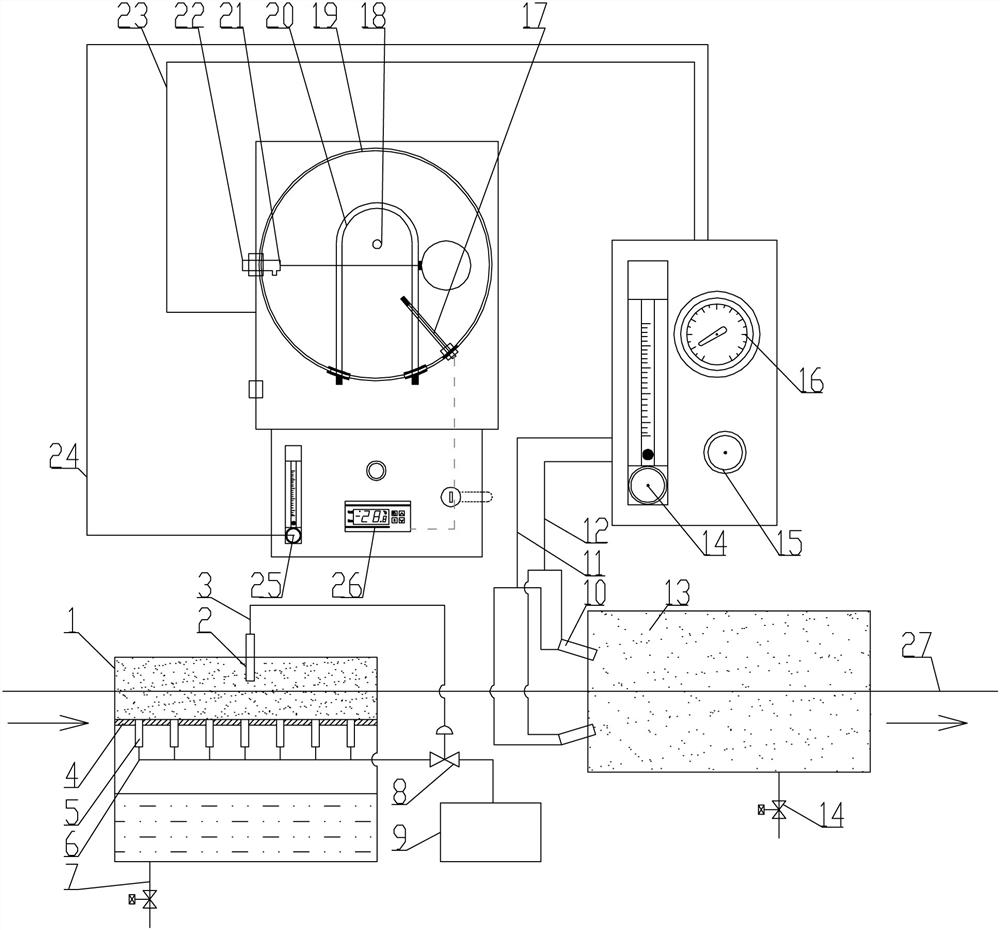

[0030] see figure 1 , steam heating and spray humidification device before the tow is crimped, it includes a steam box 1 for preliminary heating of the tow, the inside of the steam box 1 is provided with a porous partition 4, and a plurality of steam nozzles are installed on the porous partition 4 5. The steam nozzle 5 is connected to the steam generator 9 through the steam pipe 6; after the steam box 1, a spray box 13 for spraying and humidifying the tow is arranged, and the wire feeding end of the spray box 13 is symmetrically arranged with atomizing nozzles 10. The atomizing nozzle 10 is connected with an air inlet pipe 12 and a water inlet pipe 11 at the same time; the air inlet pipe 12 is connected with a high-pressure air supply device, and the water inlet pipe 11 is connected with a constant temperature water supply device. By using the above-mentioned device, the steam heating process and the spray humidification process are combined to realize the pretreatment of the ...

Embodiment 2

[0043] Process impact before and after the humidifier is put into use:

[0044] 1. The temperature control of the dryer needs to be adjusted. After the tow is humidified and put into the dryer, its moisture content increases, so it is necessary to increase the temperature of the dryer to ensure that the moisture content of the tow before and after humidification is consistent;

[0045] 2. Water is the wetting agent for cellulose acetate to improve crimpability. Under the same crimping performance index, the platen pressure and counter-roll pressure will decrease, and the crimp damage will decrease, which is manifested as a decrease in the amount of comparable fly; or the pressure of the crimper is not high. Change, the tow crimp can increase year-on-year, and the stability of suction resistance is improved.

[0046] 3. Control the atomization water temperature, the lower the better, this is determined by the characteristics of cellulose acetate, it is recommended not to excee...

Embodiment 3

[0053] The pretreatment process before the tow curling is carried out by using the steam heating and spray humidification device before the tow curling, including the following steps:

[0054] Step 1: Start the steam generator 9, supply constant-temperature steam to the upper part of the steam box 1 through the steam generator 9, and control the steam valve 8 to ensure that the steam temperature inside the steam box 1 is constant;

[0055] Step 2: Start the high-pressure air supply device and the constant temperature water supply device, supply water and air to the atomizing nozzle 10 at the same time, and then generate spray inside the spray box 13, and adjust it through the glass rotameter regulating valve 14 and the air pressure control valve 15 Water flow and air pressure ensure the best spray effect;

[0056] Step 3: first pass the tow 27 through the steam box 1, and heat the tow 27 through the steam box 1 to fully volatilize excess acetone, make the orientation of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com