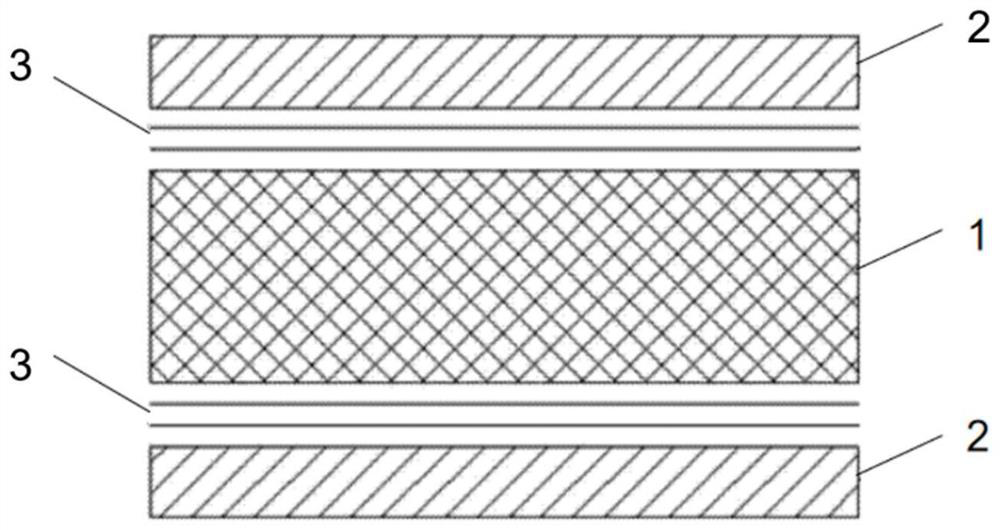

Fiber-plastic profile container bottom plate and preparation method thereof

A container bottom plate, fiber-plastic technology, applied in chemical instruments and methods, packaging, household packaging, etc., can solve the problems of insufficient environmental protection, poor utilization rate of waste textiles, etc., to avoid uneven feeding, excellent mechanical properties, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1: Fiber-plastic composite material and preparation method thereof

[0072] This embodiment provides a fiber-plastic composite material, the preparation method of which includes:

[0073] (1) Breaking the woven fabric, then breaking the fabric into a fluffy state and repeating 3 times, using airflow separation to remove metal fragments and particles in the fabric, and finally combing 2 times to obtain the treated textile fiber, The volume of the treated textile fiber is three times that of the textile, and it is a uniform and completely separated single fiber or a fiber in a yarn structure;

[0074] (2) Extrude the processed textile fibers, plastics and auxiliary materials under the conditions of 200°C and 100r / min for mixing and volume reduction to obtain a bulk fiber-plastic mixture with a density of 1200kg / m 3 , and then cool the fiber-plastic mixture to 140°C; wherein the weight ratio of textile fibers, plastics, and auxiliary materials is 1:0.5:0.2.

...

Embodiment 2

[0077] Embodiment 2: fiber-plastic composite material and preparation method thereof

[0078] This embodiment provides a fiber-plastic composite material, the preparation method of which includes:

[0079] (1) Breaking the woven fabric, then breaking the fabric into a fluffy state and repeating 4 times, using air separation to remove metal fragments and particles in the fabric, and finally combing 3 times to obtain the treated textile fiber, The volume of the treated textile fiber is 4 times that of the textile, and it is a uniform and completely separated single fiber or a fiber in a yarn structure;

[0080] (2) Extrude the treated textile fibers, plastics and auxiliary materials under the conditions of 180°C and 110r / min for mixing and volume reduction to obtain a bulk fiber-plastic mixture with a density of 1100kg / m 3 , and then cool the fiber-plastic mixture to 120°C; wherein the weight ratio of textile fibers, plastics, and auxiliary materials is 1:0.4:0.15.

[0081] (3...

Embodiment 3

[0083] Embodiment 3: fiber-plastic composite material and preparation method thereof

[0084] This embodiment provides a fiber-plastic composite material, the preparation method of which includes:

[0085] (1) Breaking the woven fabric, then breaking the fabric into a fluffy state and repeating twice, using air separation to remove metal fragments and particles in the fabric, and finally combing once to obtain the treated textile fiber, The volume of the treated textile fiber is twice that of the textile, and it is a uniform and completely separated fiber and a yarn structure;

[0086] (2) Extrude the treated textile fibers, plastics and auxiliary materials under the conditions of 170°C and 100r / min for mixing and volume reduction to obtain a bulk fiber-plastic mixture with a density of 1200kg / m 3 , and then cool the fiber-plastic mixture to 140°C; wherein the weight ratio of textile fibers, plastics, and auxiliary materials is 1:0.5:0.2.

[0087] (3) Mix the fiber-plastic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com