Patents

Literature

30results about How to "Avoid Fragmentation Incomplete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

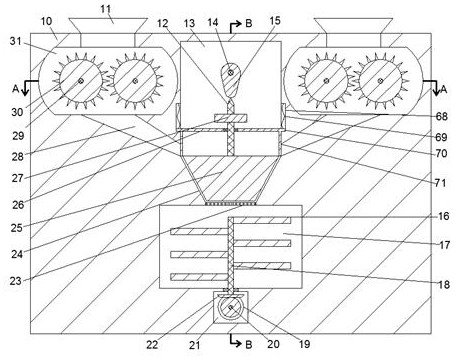

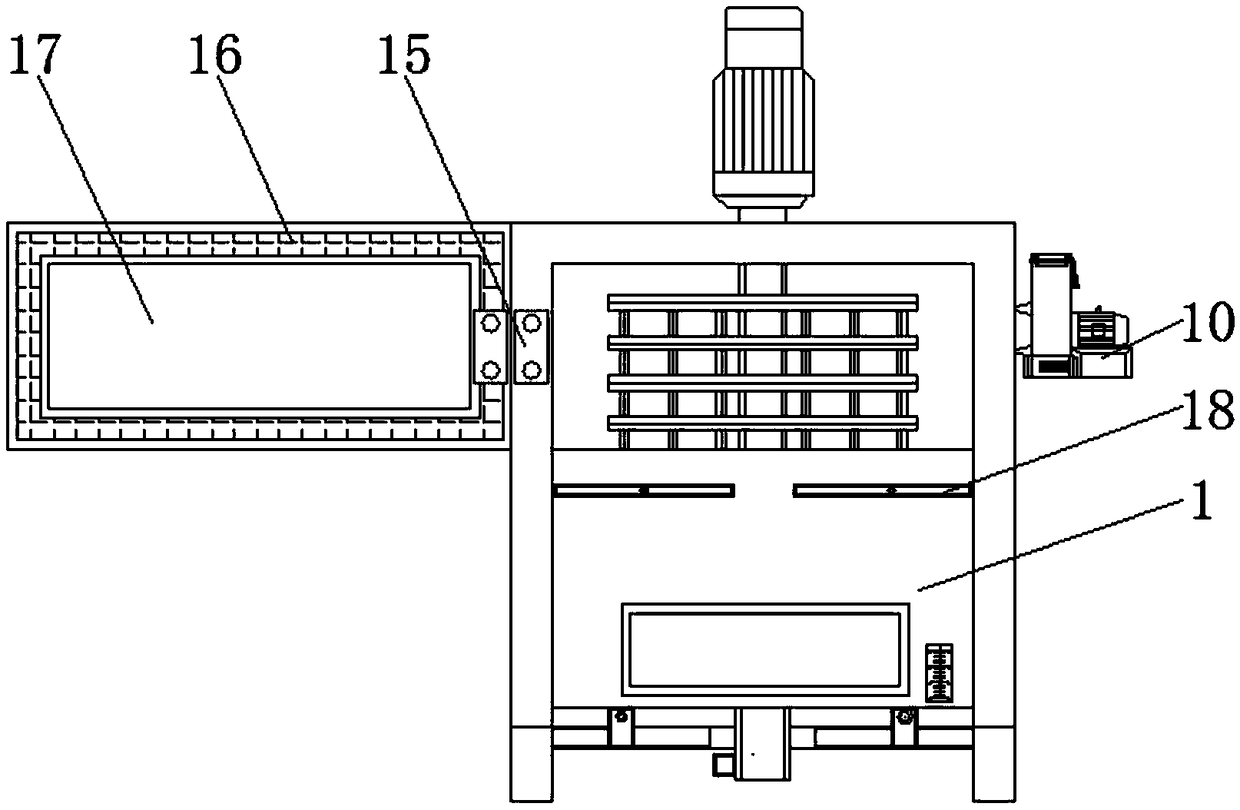

Chemical raw material grinding-mixing device

InactiveCN111659304APrevents damage to the crushing rollersPrevent the particles from being too small and incompletely brokenRotary stirring mixersTransportation and packagingEngineeringRaw material

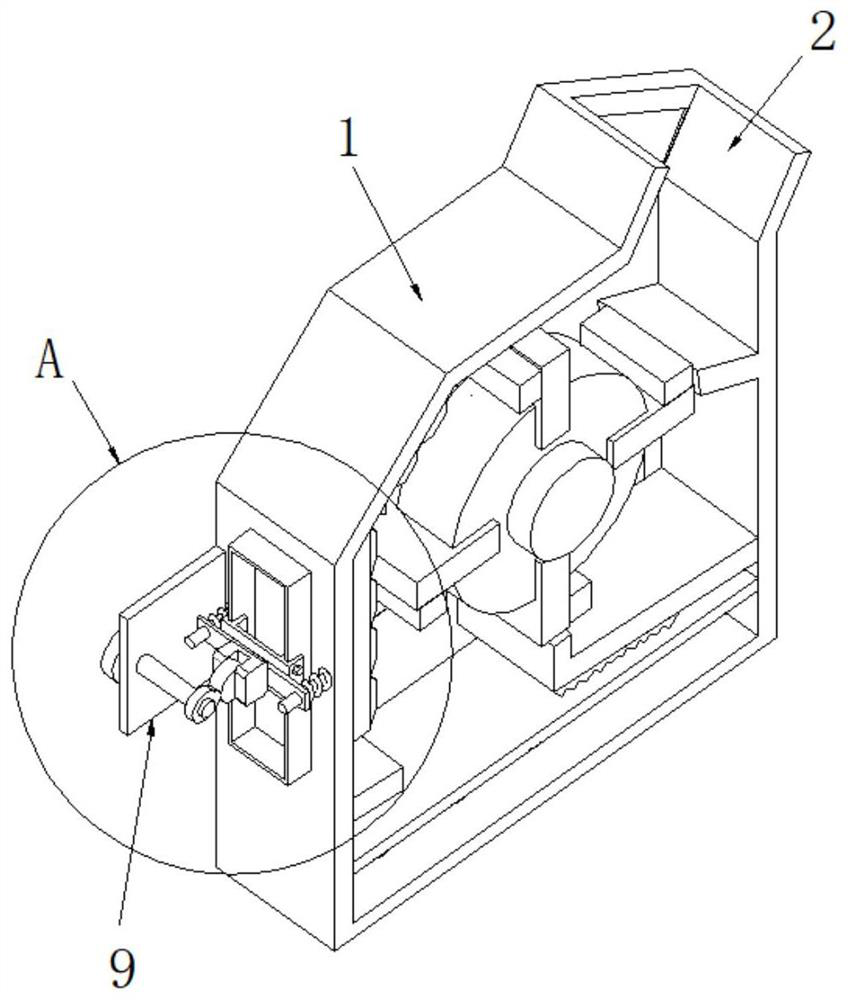

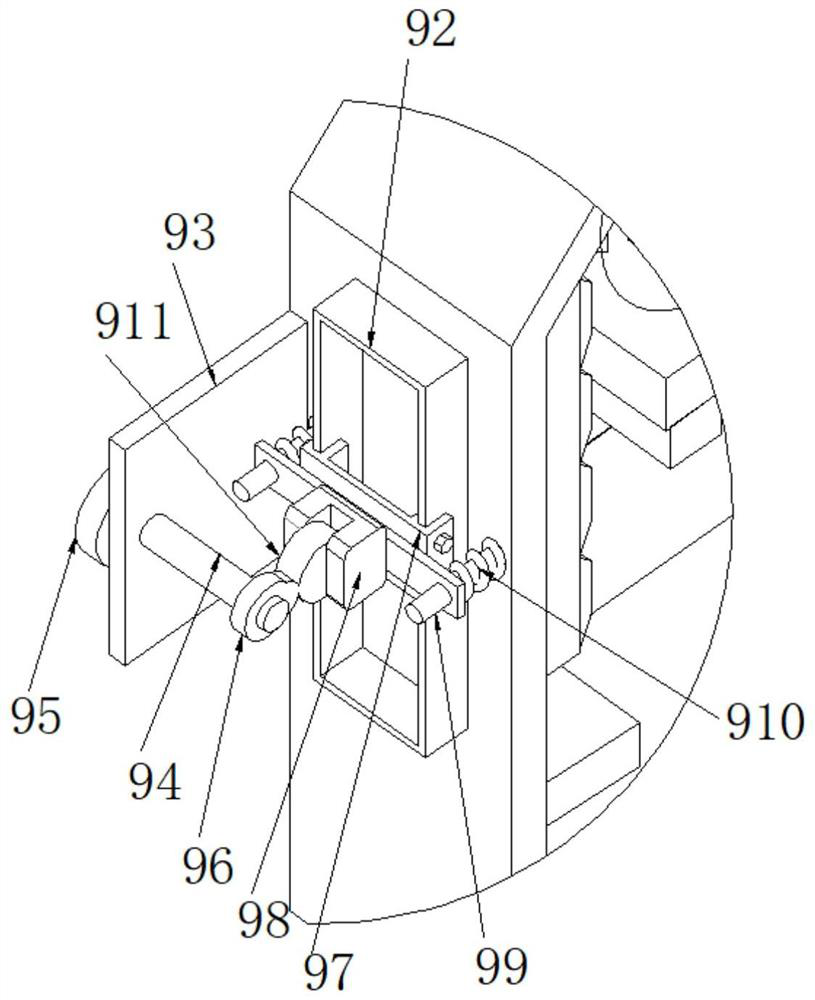

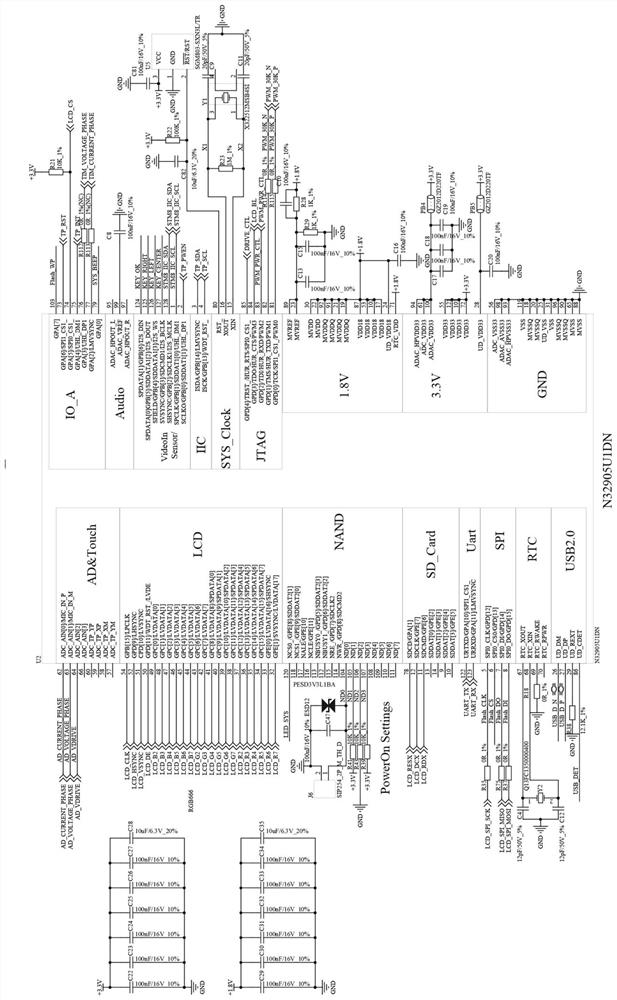

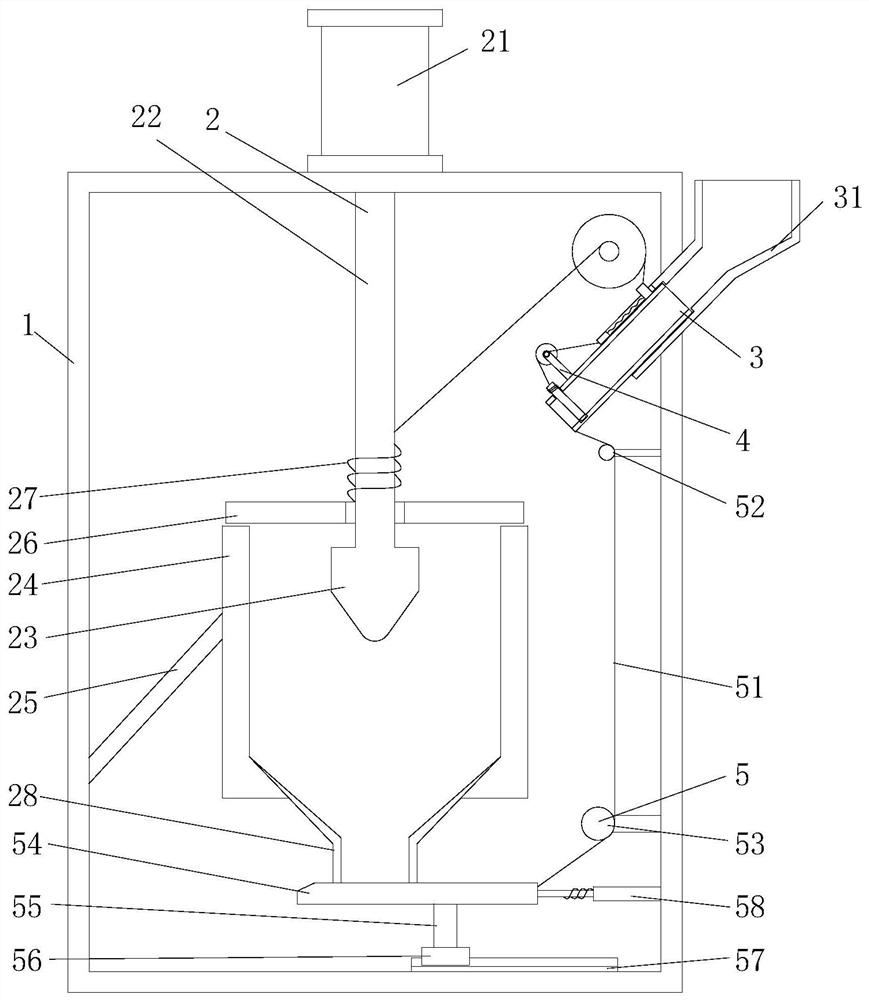

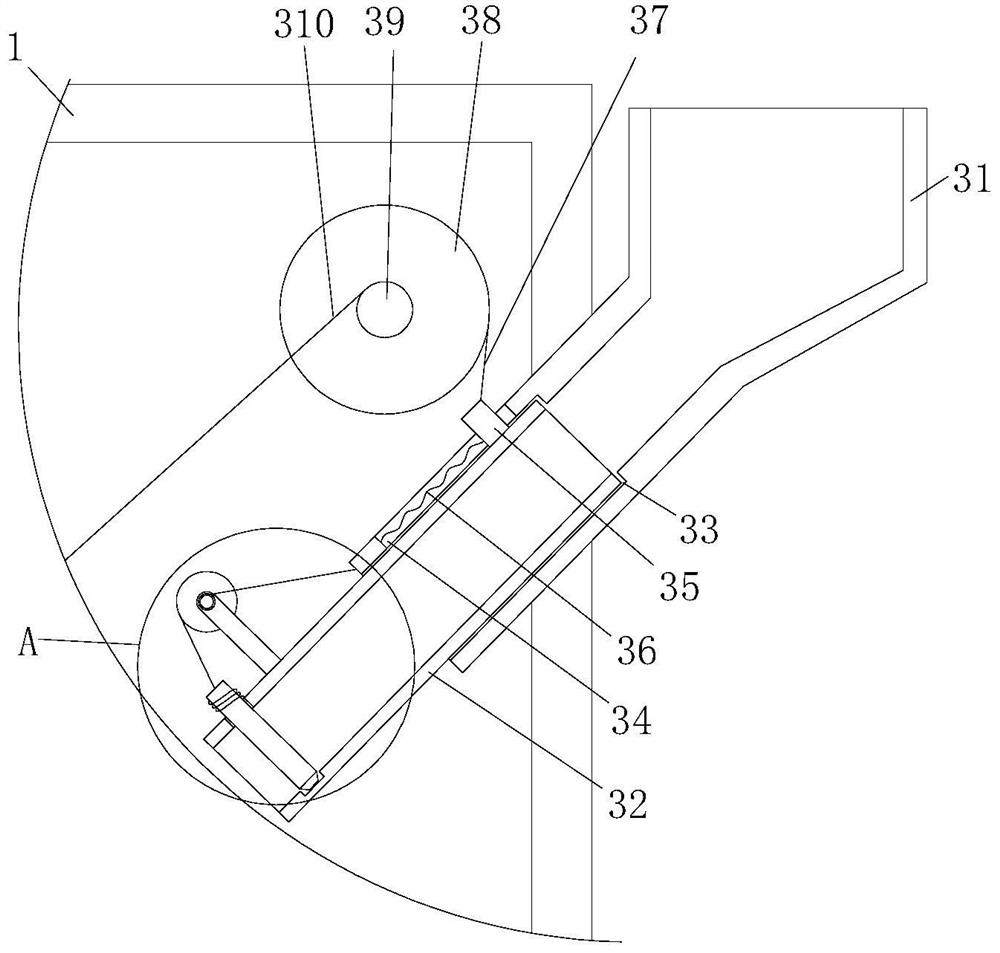

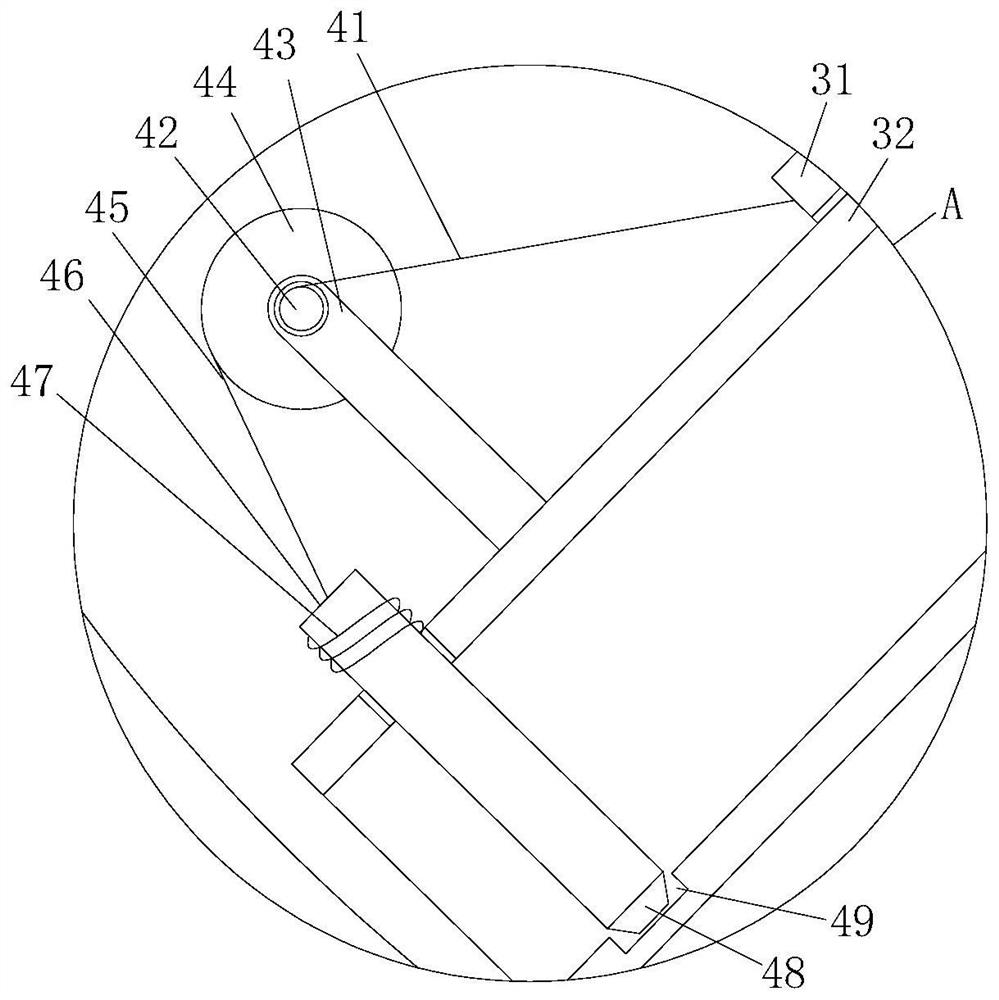

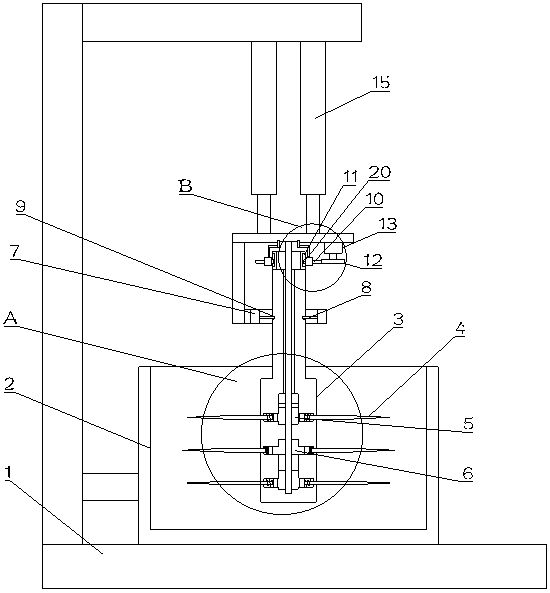

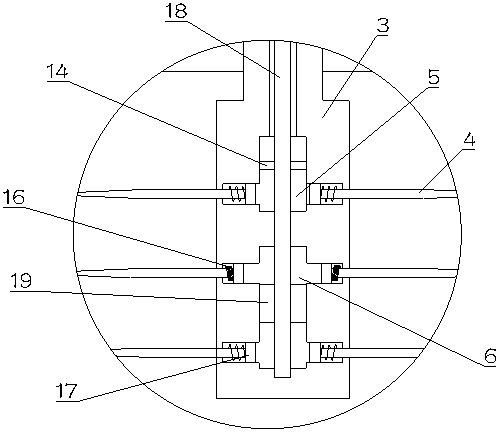

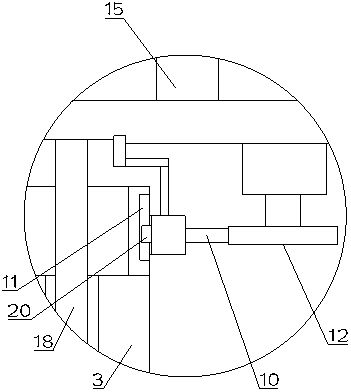

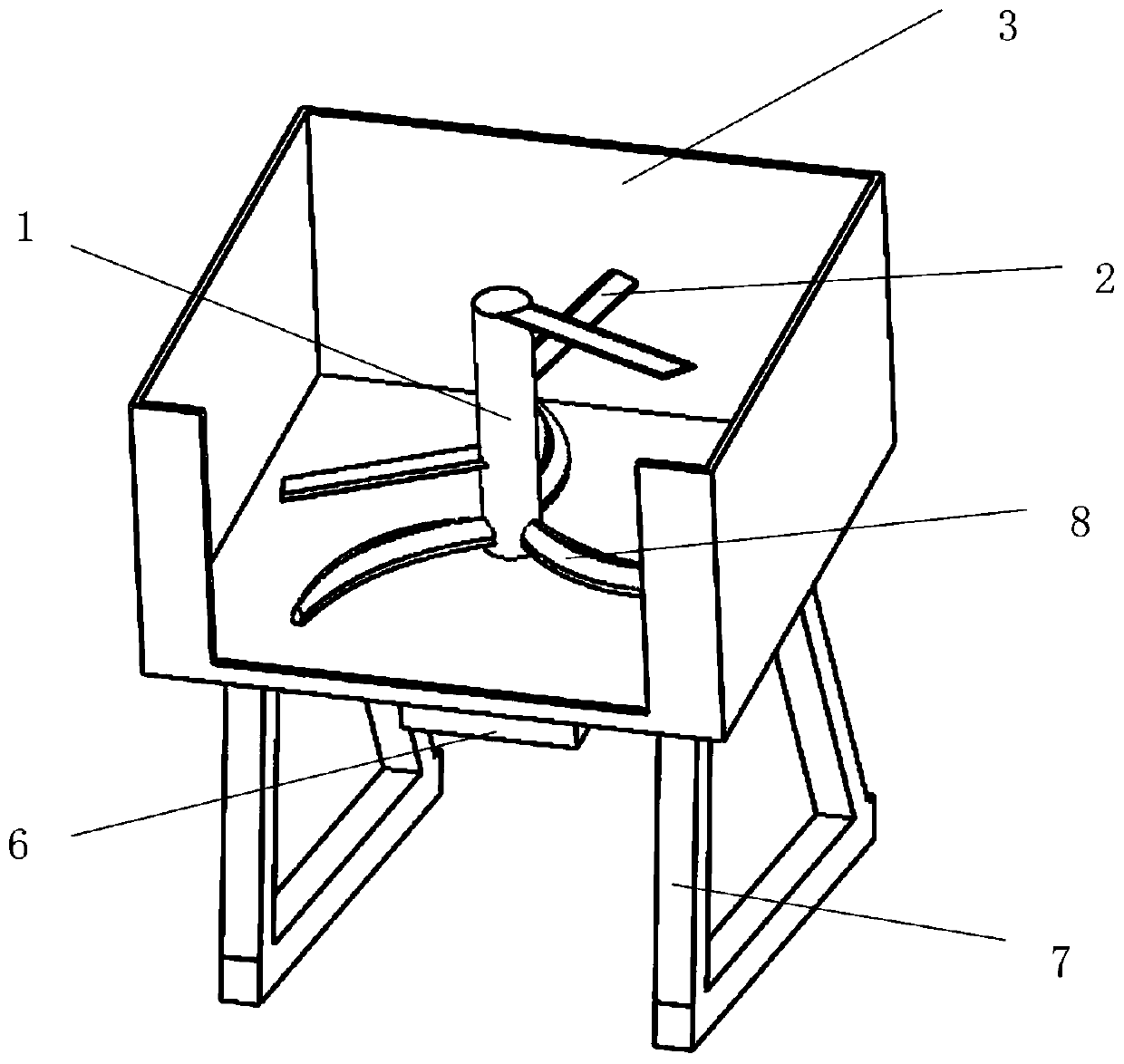

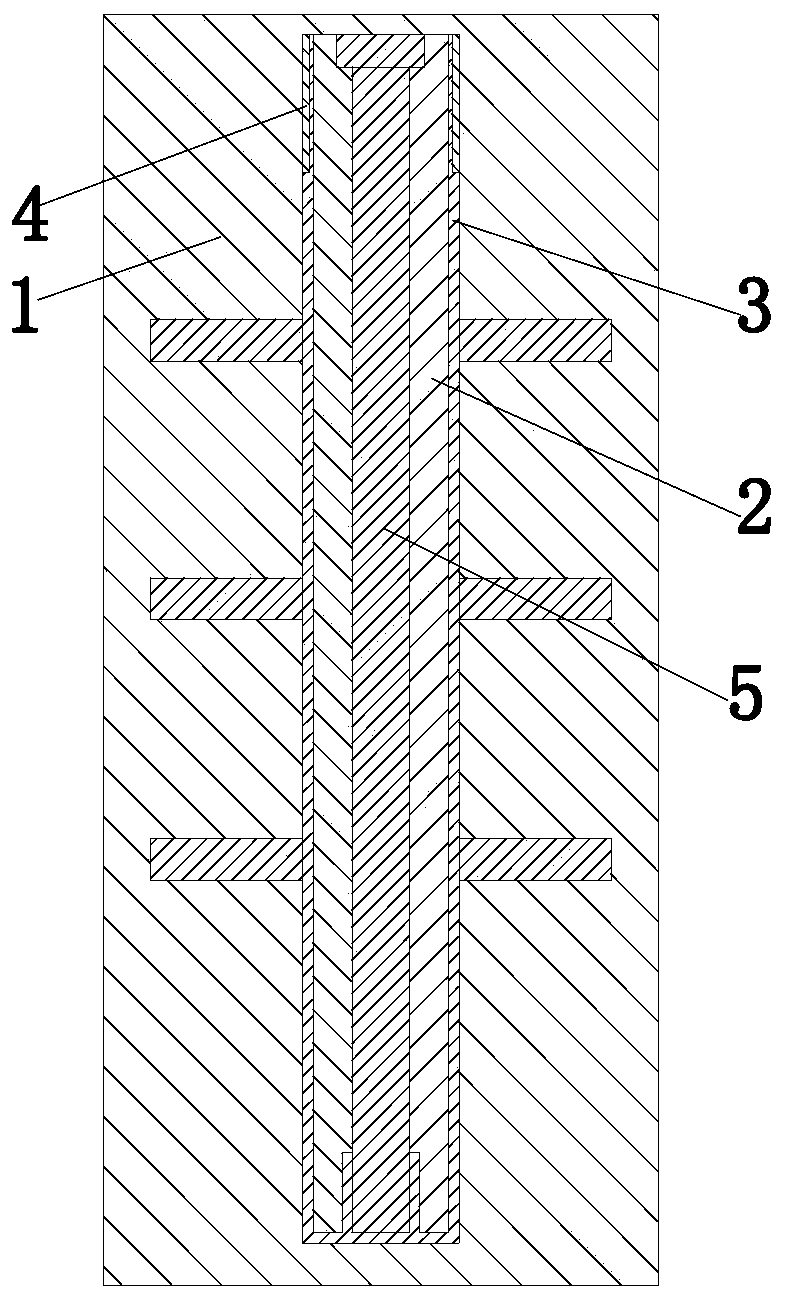

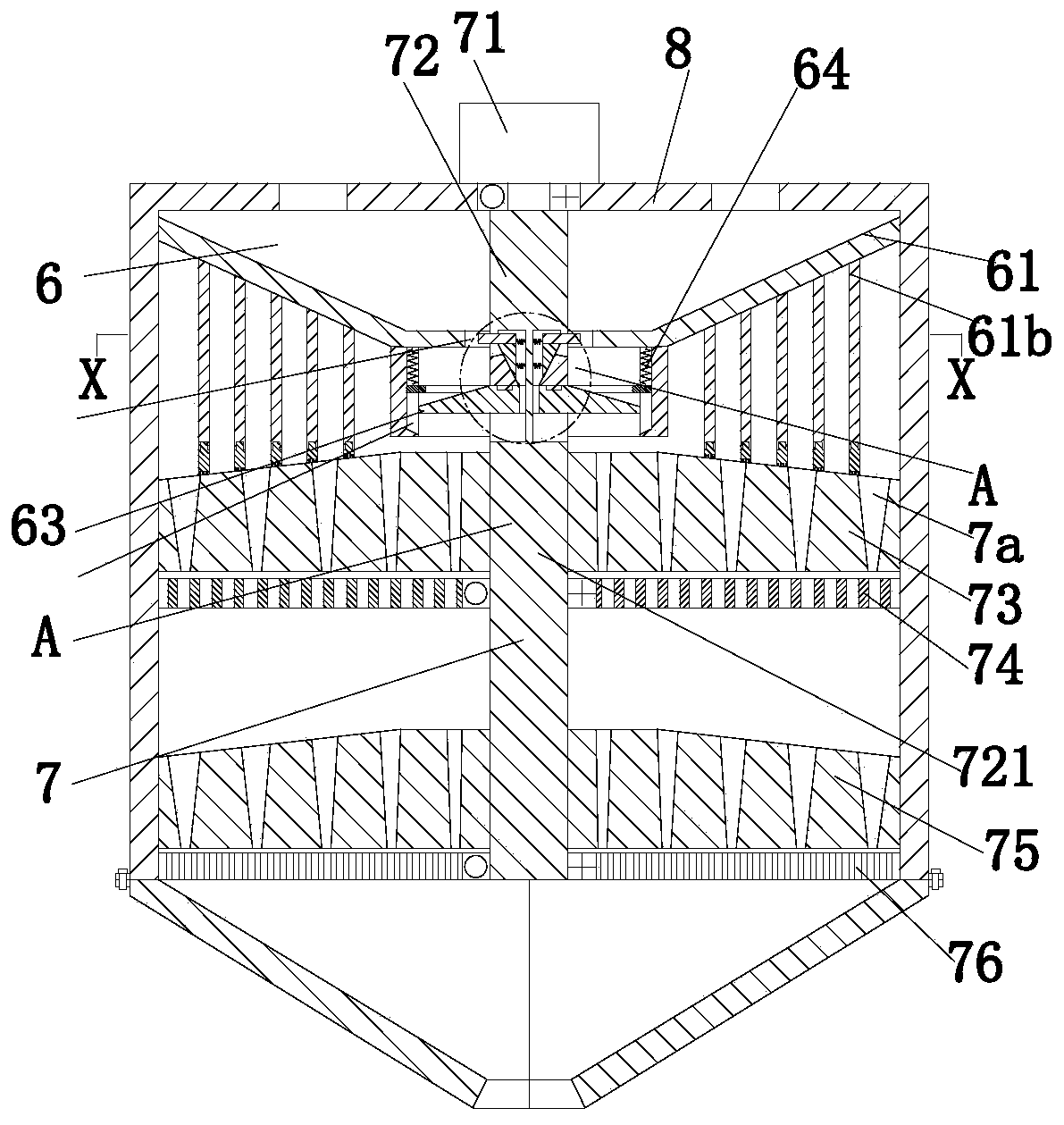

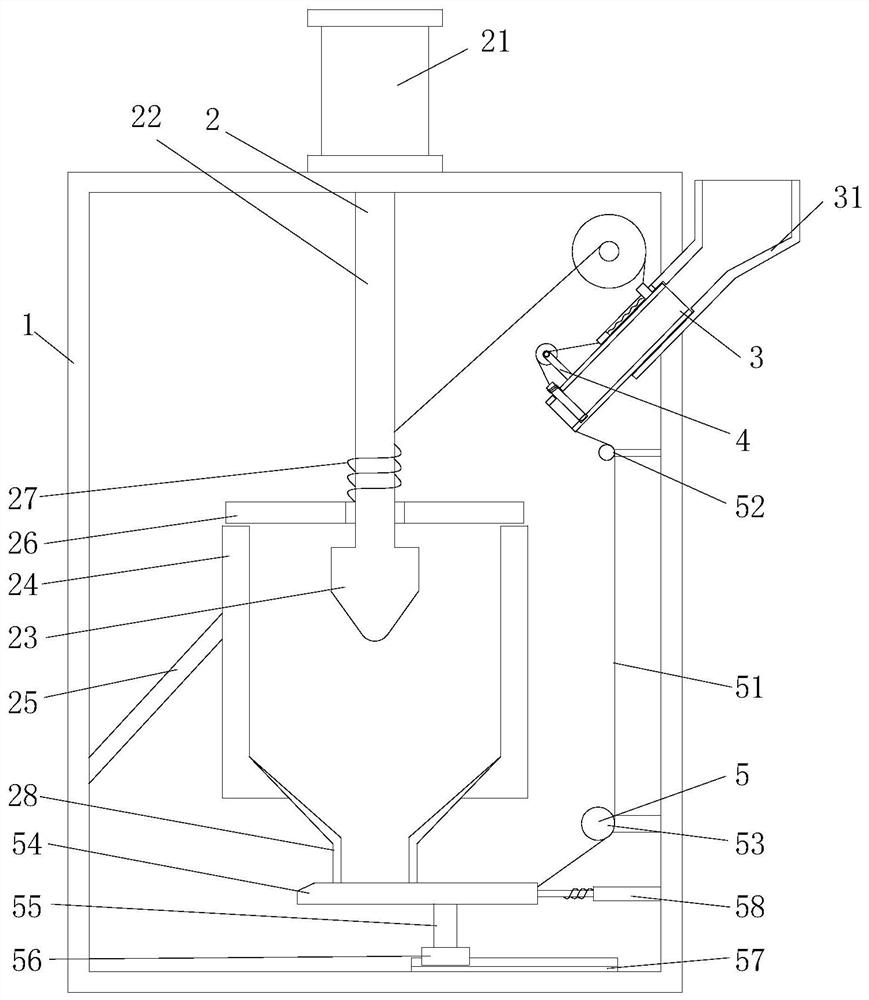

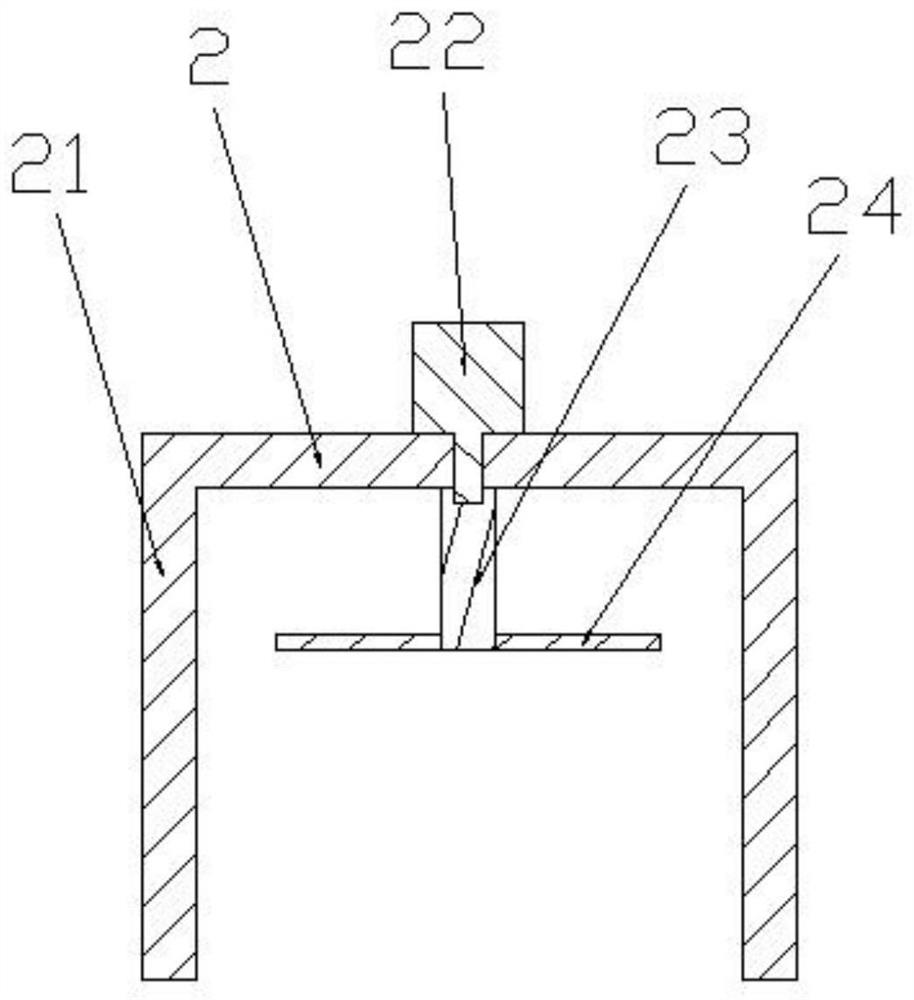

The invention discloses a chemical raw material grinding and mixing device, which comprises a main body, wherein a grinding cavity is formed in the main body; a grinding transmission cavity is formedin the upper side of the grinding cavity; a grinding assembly is arranged in the grinding transmission cavity; a stirring cavity is formed in the lower side of the grinding cavity in a communicating manner; a stirring assembly is arranged in the stirring cavity; crushing cavities are symmetrically formed in the left side and the right side of the grinding transmission cavity; a feeding hole is formed in the upper side of the crushing cavity; crushing assemblies taking the grinding transmission cavity as a symmetric axis are arranged in the crushing cavities on the left side and the right side;a crushing transmission cavity is formed in the rear side of the crushing cavity in a communicating manner; according to the device, the distance between crushing rollers of the crushing assembly andthe extending length of crushing teeth can be adjusted according to the particle size of chemical raw materials; and after crushing is completed, the grinding assembly grinds the chemical raw materials, and the ground chemical raw materials fall into the stirring wall to be stirred and used for being stirred and mixed with the chemical raw materials of different types and different particle sizes.

Owner:温州厦贤科技有限公司

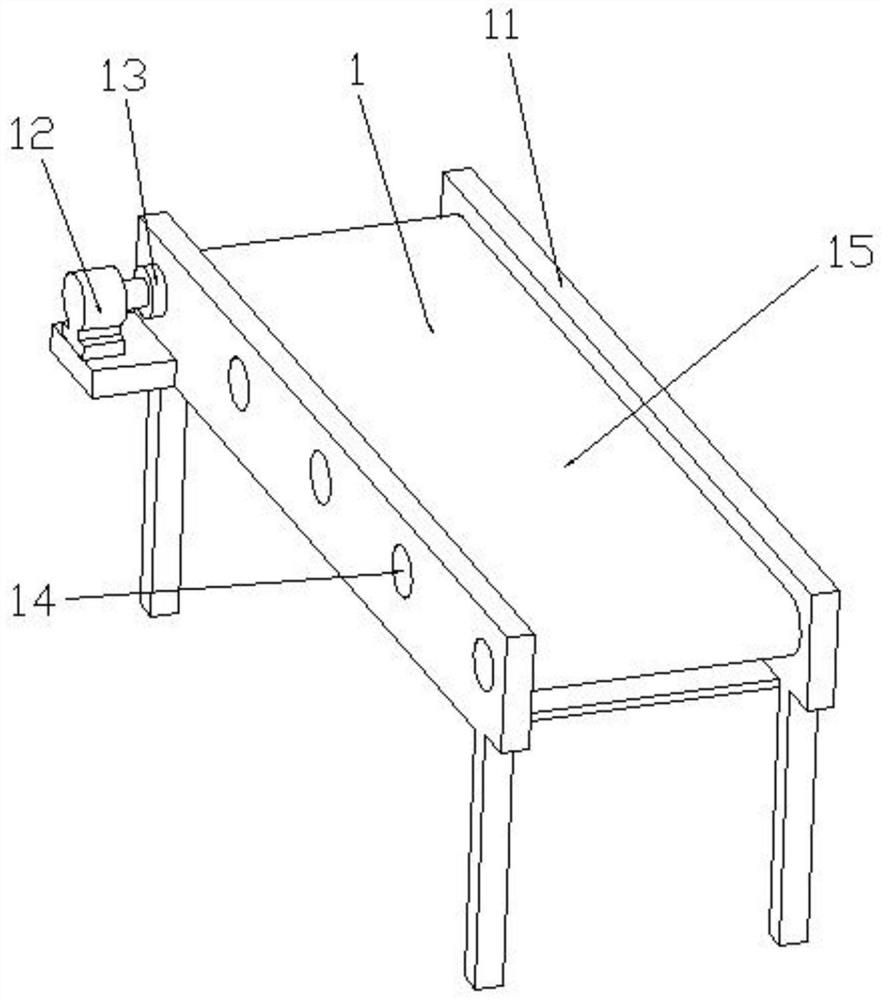

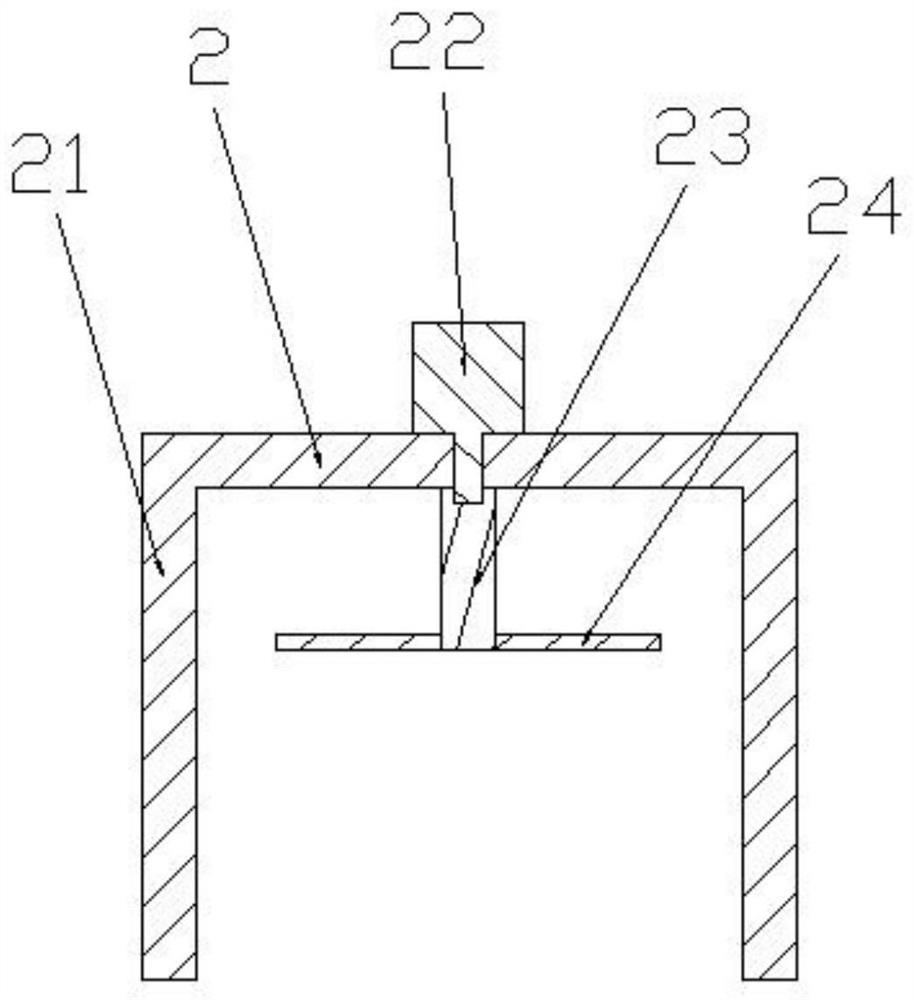

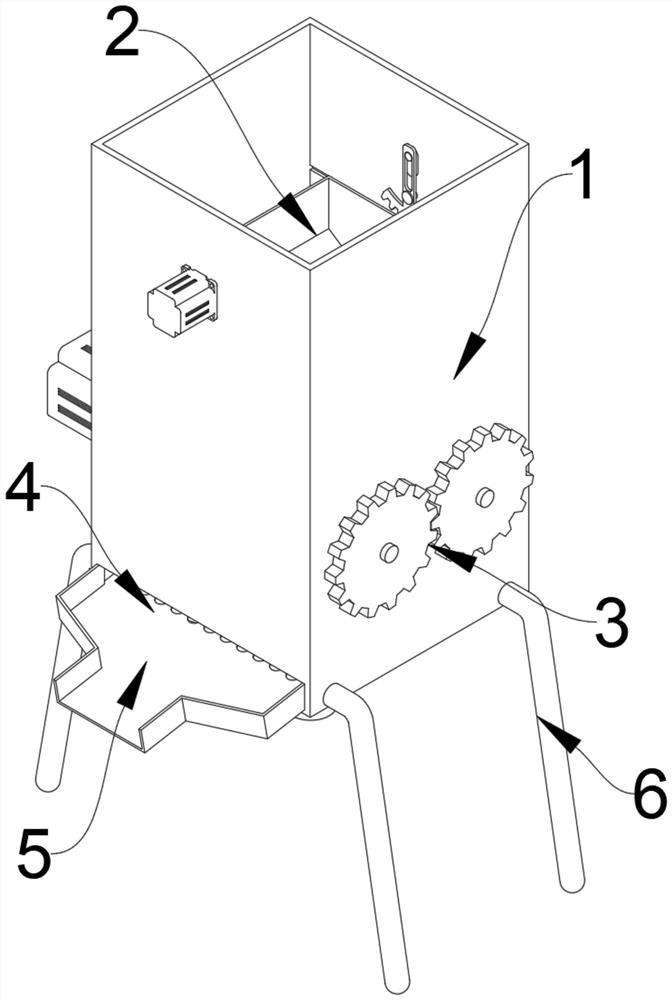

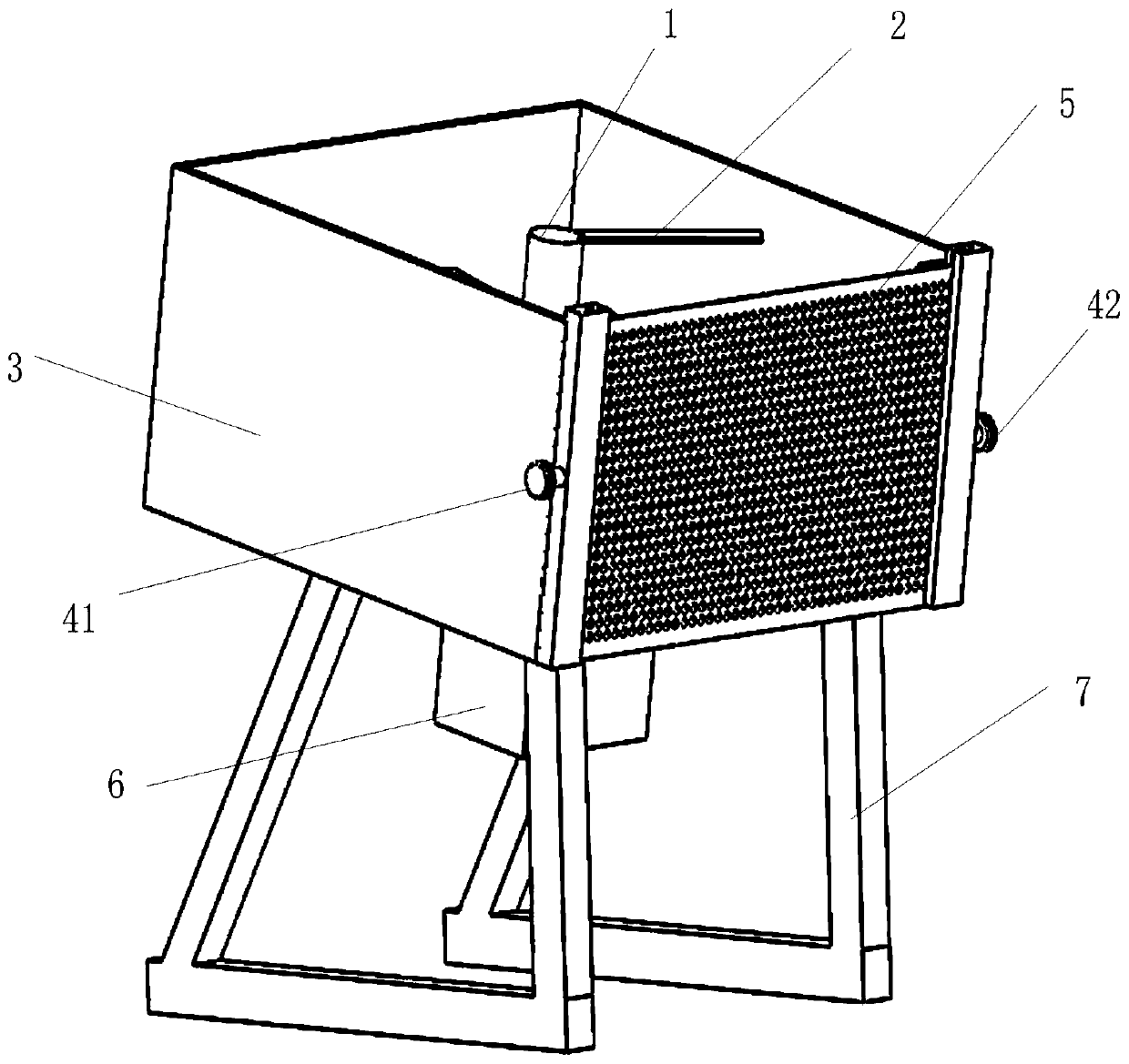

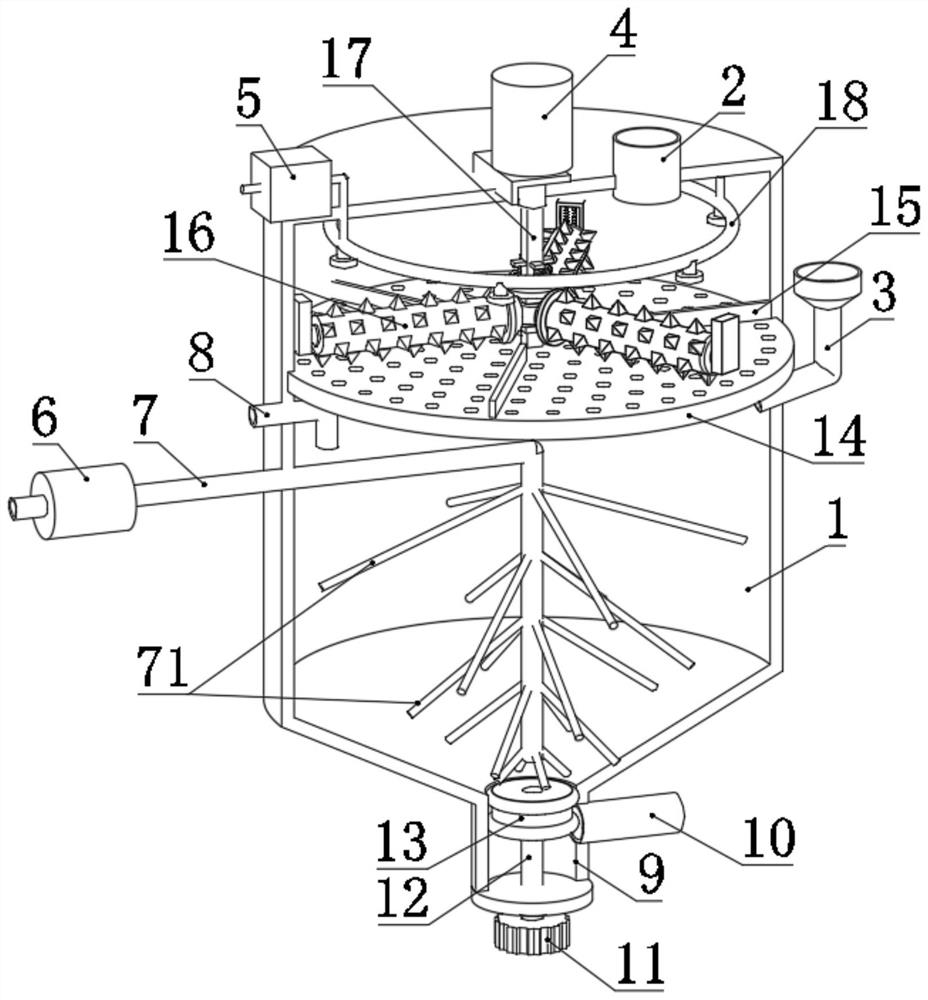

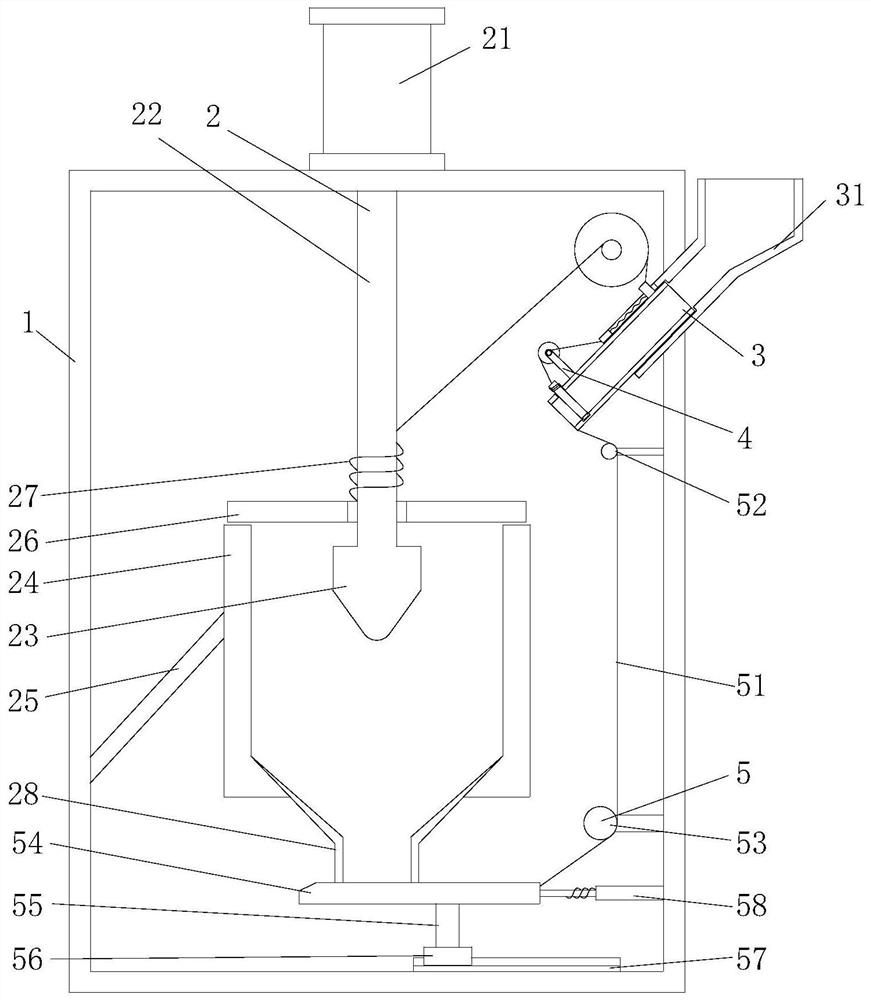

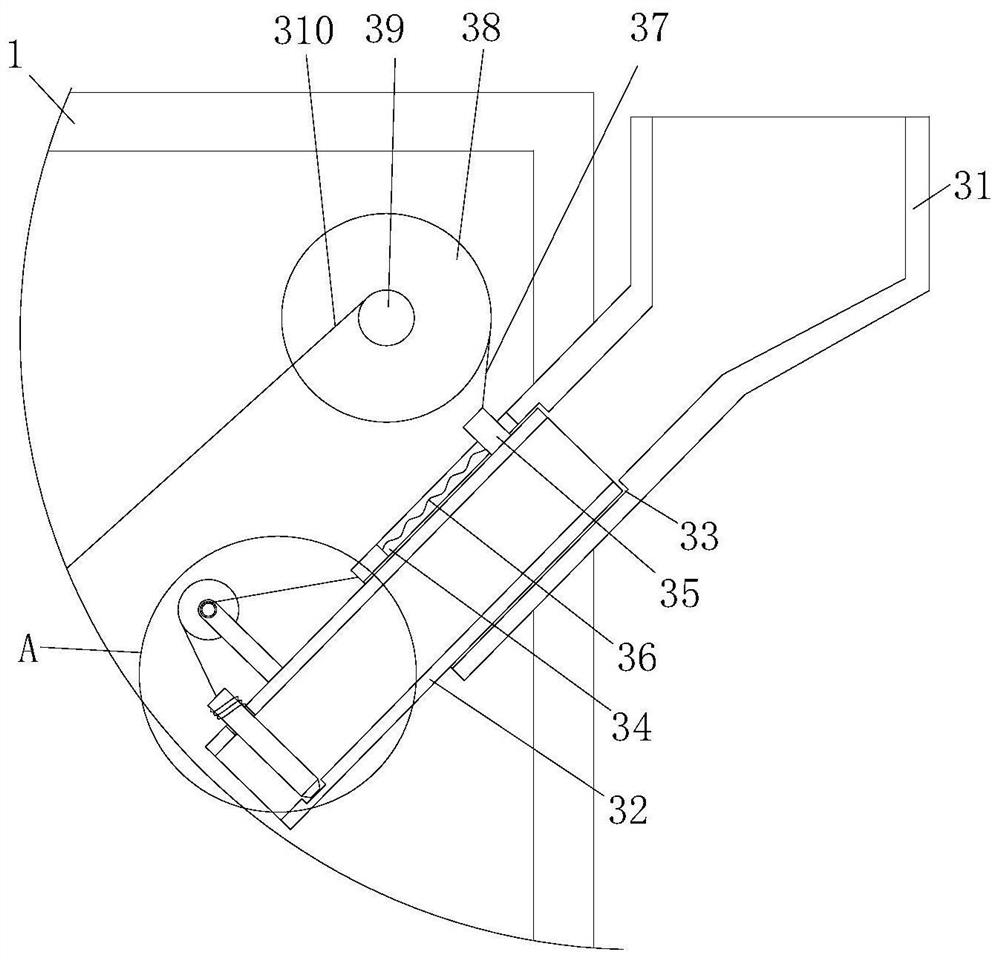

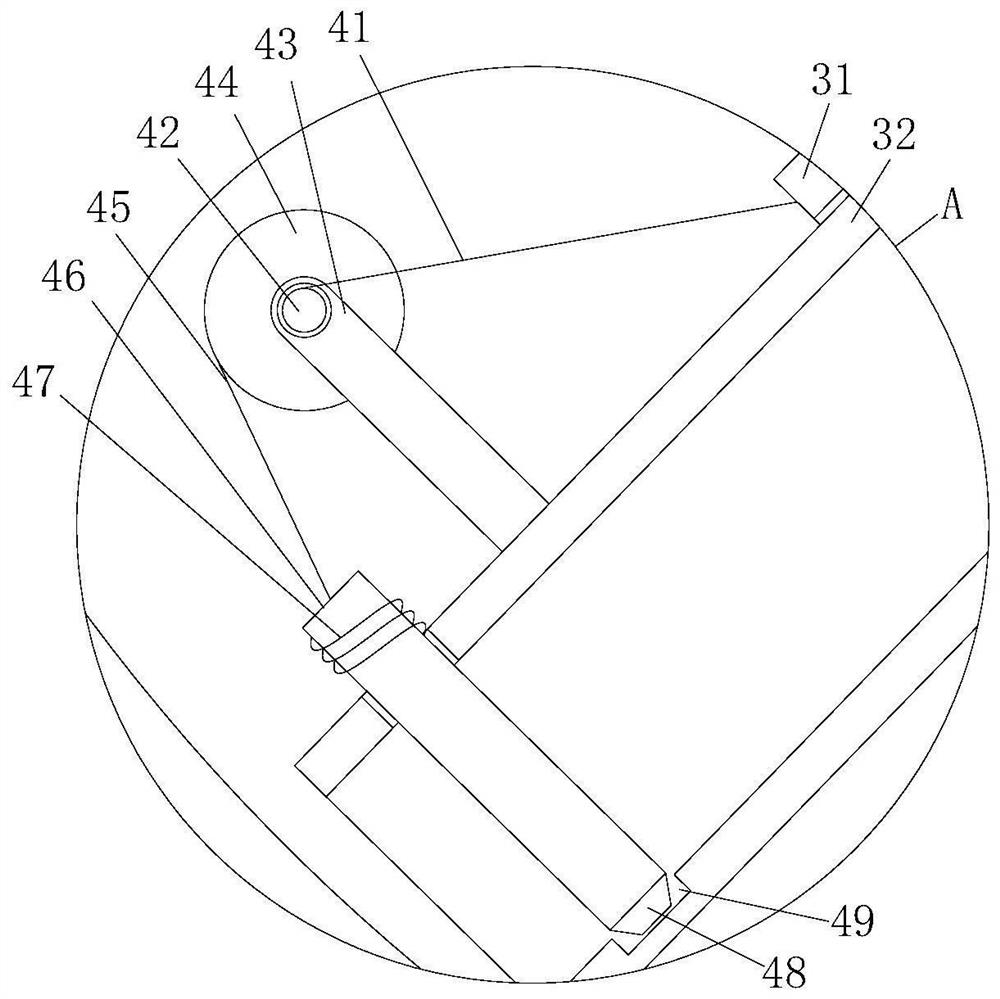

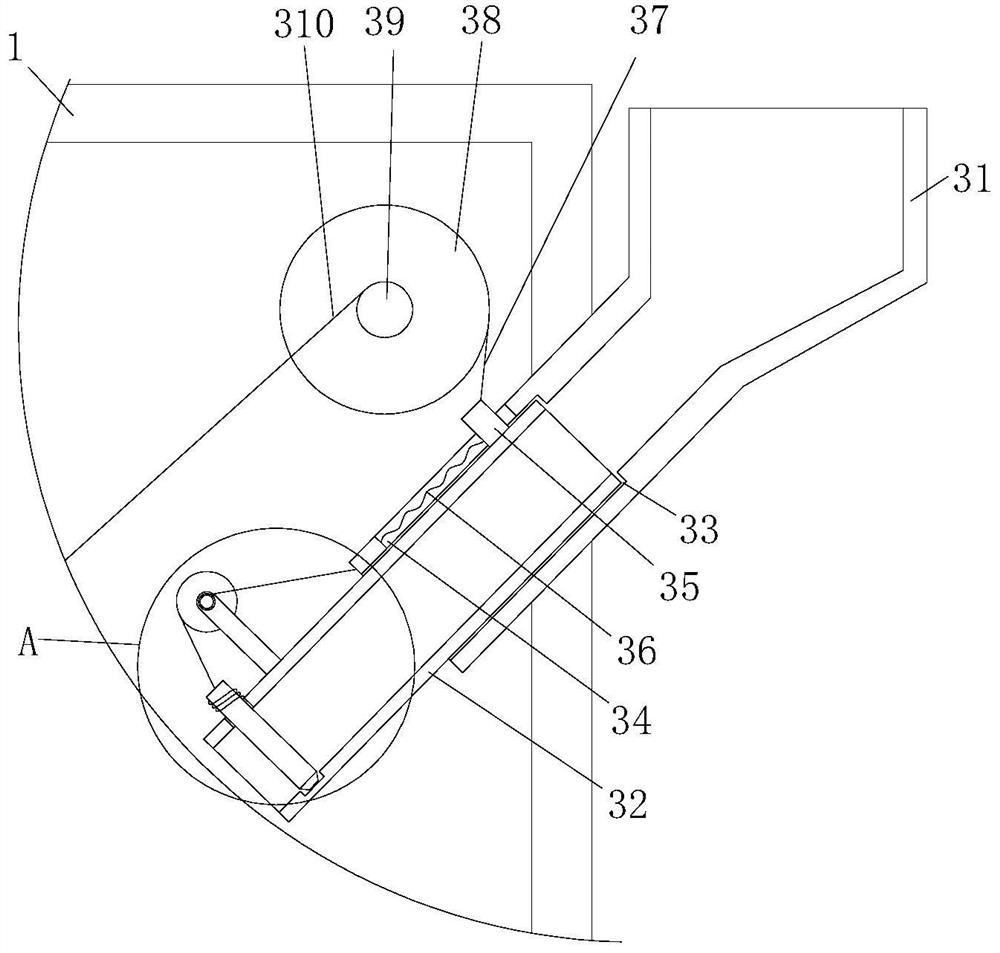

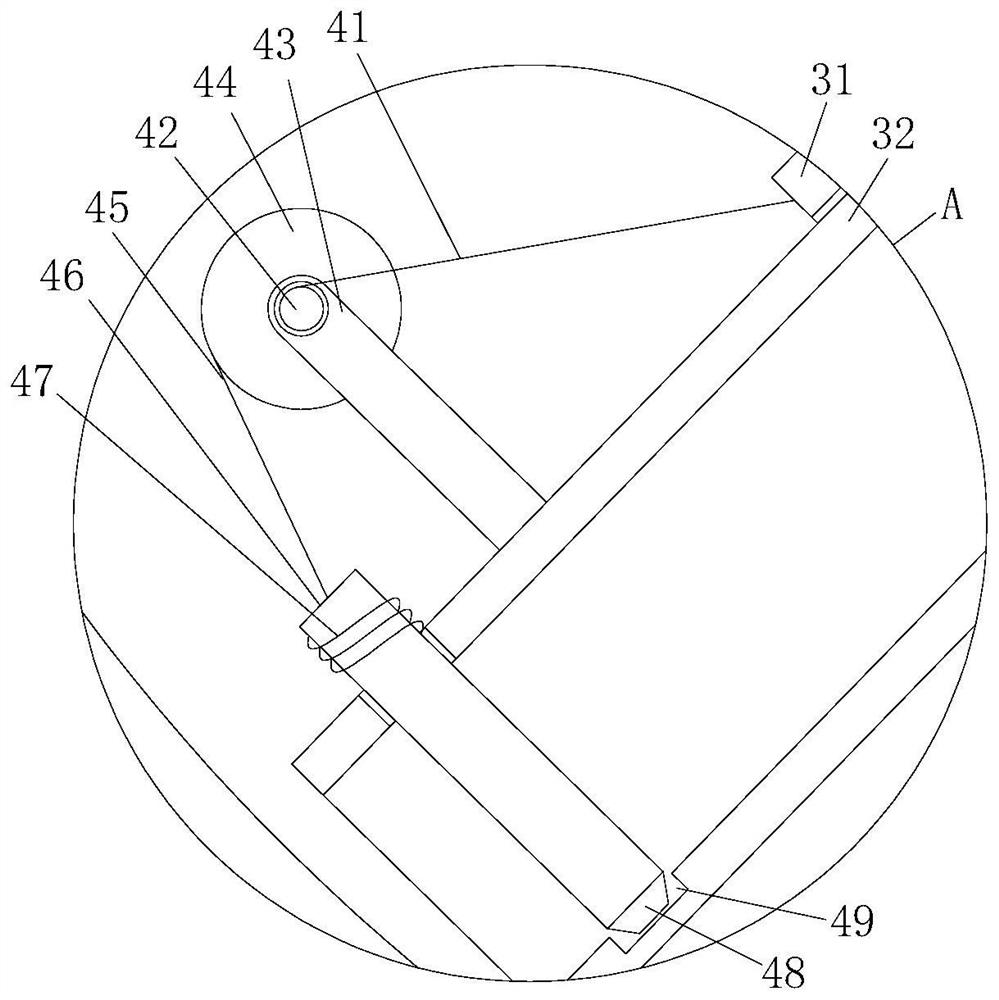

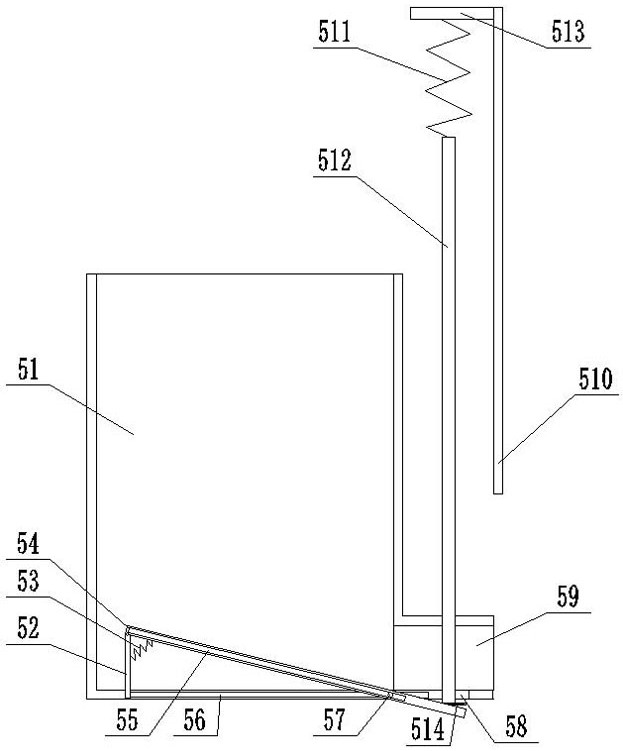

Feeding device for production of non-woven fabric

ActiveCN108642586AAutomatically control the amount of inputImprove rationalityFilament forming substance formingSpinning head liquid feederAutomatic controlCombustion

The invention relates to a feeding device for production of a non-woven fabric. The feeding device comprises a body and a combustion flue. A pulling port is formed in the middle of the body. By meansof a feeding port, a rotating shaft, a connecting plate, a rotating handle and a cylinder, the rotating angle of the connecting plate can be automatically controlled to control the openness of a feeding port, so that the feeding amount of a raw material for producing the non-woven fabric can be controlled, the feeding rationality and high efficiency are improved. At the same time, the raw materialprocessing efficiency is improved, and the waste is avoided. At the same time, the area of the connecting plate is larger than that of the feeding port, the inside of a feeding pipe in the idle statecan be protected from dust and moisture, the raw material is protected from pollution in the conveying process, and the processing quality of the non-woven fabric is ensured. By means of a crushing plate in a tip net structure, the raw material entering the body can be crushed, the contact area between the raw material and the bottom of the body is increased, so that the melting rate of the raw material is increased, and the working efficiency is improved by means of an elastic plate.

Owner:翰诠特种纺织品(平湖)有限公司

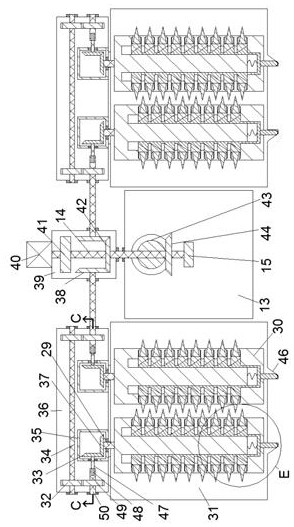

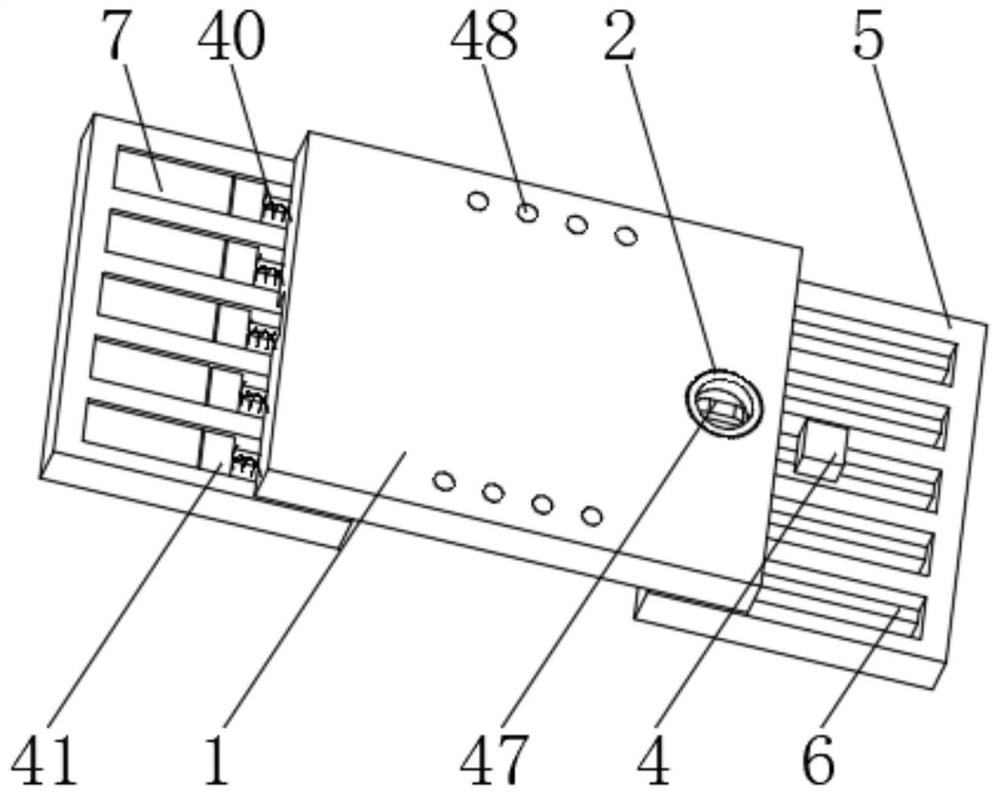

Lead-acid battery crushing and sorting device and sorting method

ActiveCN112058373AImprove qualityImprove transmission efficiencyDirt cleaningWaste accumulators reclaimingElectrical batteryStructural engineering

The invention discloses a lead-acid battery crushing and sorting device and a sorting method. The lead-acid battery crushing and sorting device comprises a conveying mechanism, wherein a cleaning mechanism is arranged at the top of the conveying mechanism; a moving mechanism is arranged on one side of the cleaning mechanism and is located at the top of the conveying mechanism; a crushing mechanismis arranged on one side of the conveying mechanism and is located under one end of the moving mechanism; a sorting mechanism is arranged on one side of the crushing mechanism; the crushing mechanismcomprises a first mounting table; a crushing machine shell is placed on the first mounting table; the top of the crushing machine shell is covered with a cover plate; a mounting groove is formed in the middle of the top of the cover plate; a feeding port is fixedly formed in the mounting groove; and two second air cylinders are fixedly arranged on the two sides of the top of the cover plate. Afterthe structure is adopted, the lead-acid battery crushing and sorting device can fully crush waste lead-acid batteries, and meanwhile can conveniently sort different crushed materials.

Owner:太和县大华能源科技有限公司

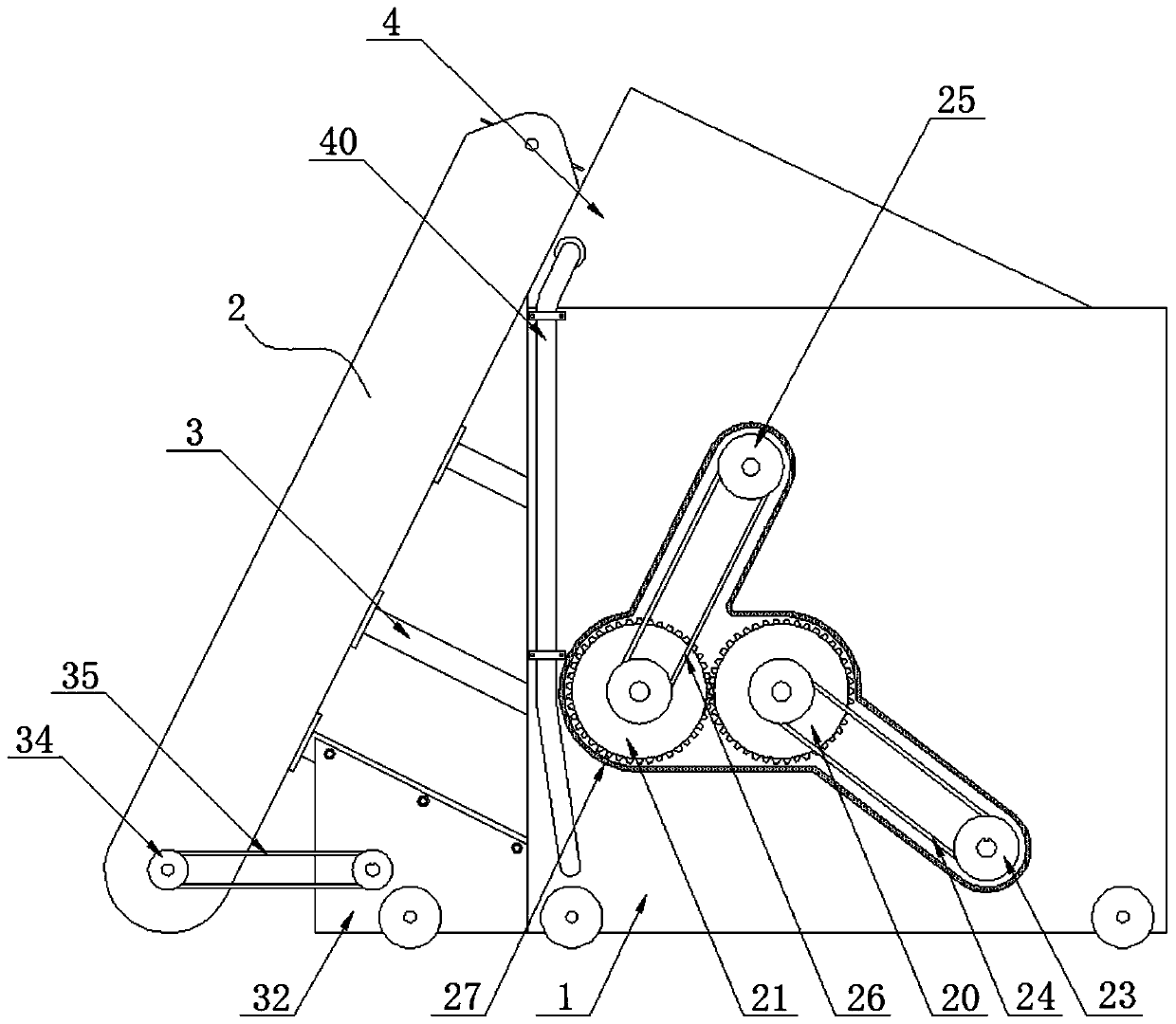

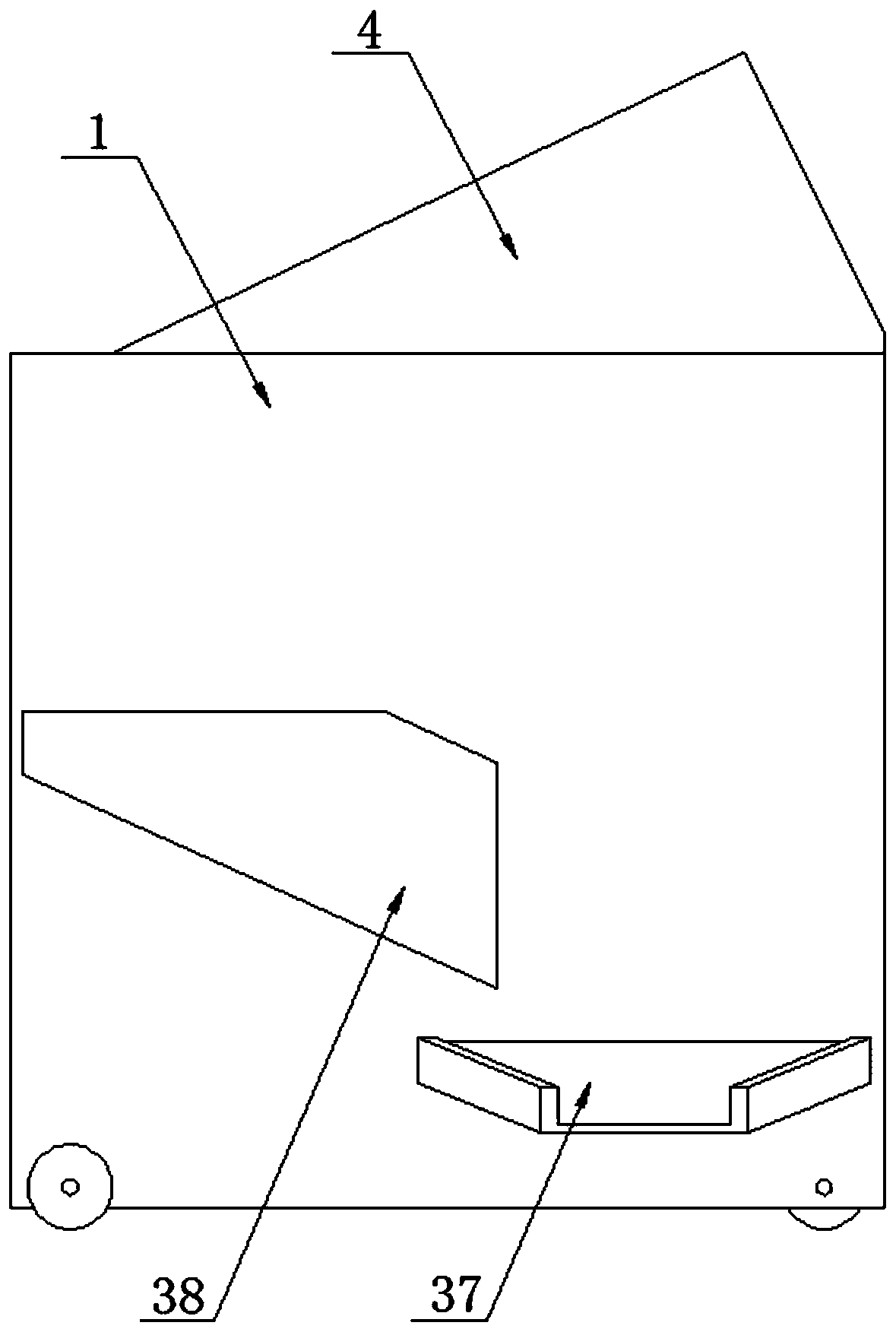

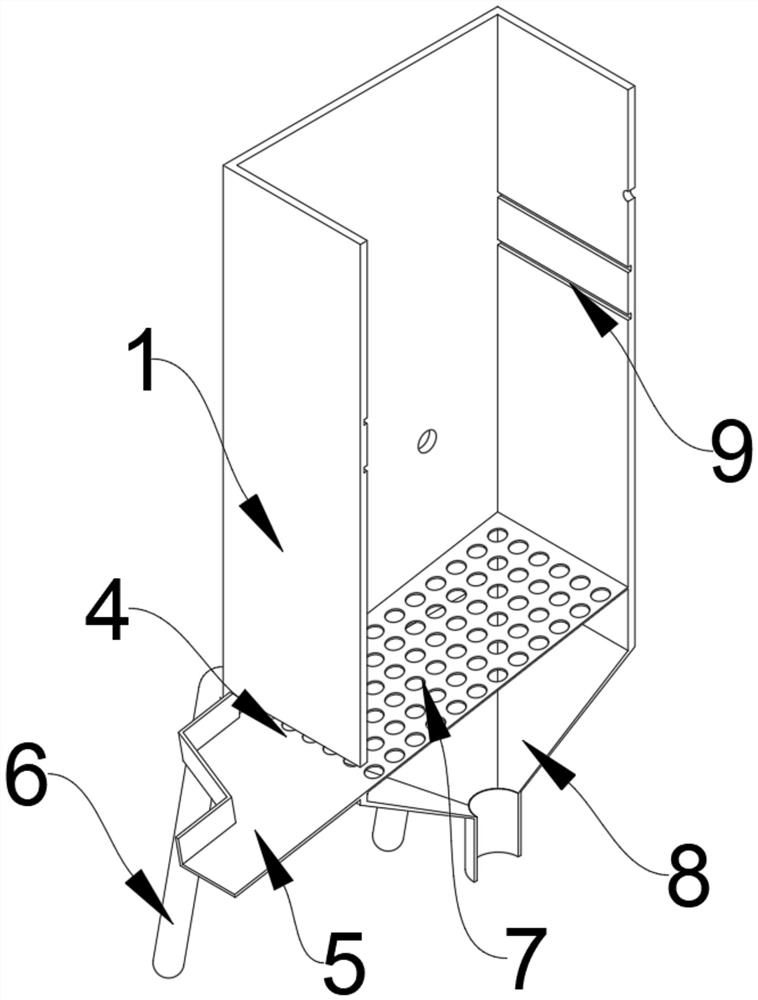

Forestry waste recycling device

InactiveCN111570040AAchieve separationImprove work efficiencyGrain treatmentsForest industryEnvironmental engineering

The invention relates to the technical field of forestry waste recycling, and discloses a forestry waste recycling device which comprises a machine box and a feeding mechanism. A support is fixedly connected between the left side of the feeding mechanism and the right side of the machine box, a feeding hopper is fixedly connected to the top of the machine box, and the top end of the feeding mechanism extends into an inlet of the top of the right side of the feeding hopper. According to the forestry waste recycling device, the feeding mechanism is arranged to directly feed waste into the feeding hopper, the phenomenon that waste is manually poured into the high feeding hopper is not needed, labor is saved, a shell separation frame and an air blowing barrel are arranged in the feeding hopper, the shell separation frame can separate out small and heavy objects such as shells in the waste, the air blowing barrel can blow light leaves in the waste leftwards, the shell separation frame and the air blowing barrel are matched, leaves, branches and shells can be separated and are treated separately, the work efficiency is greatly improved, and the problem of incomplete crushing is avoided.

Owner:李成

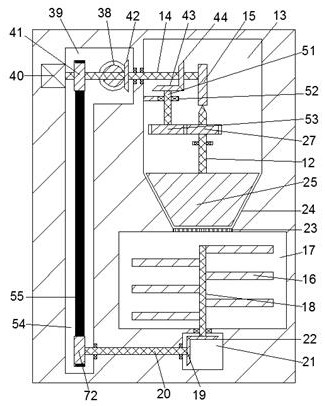

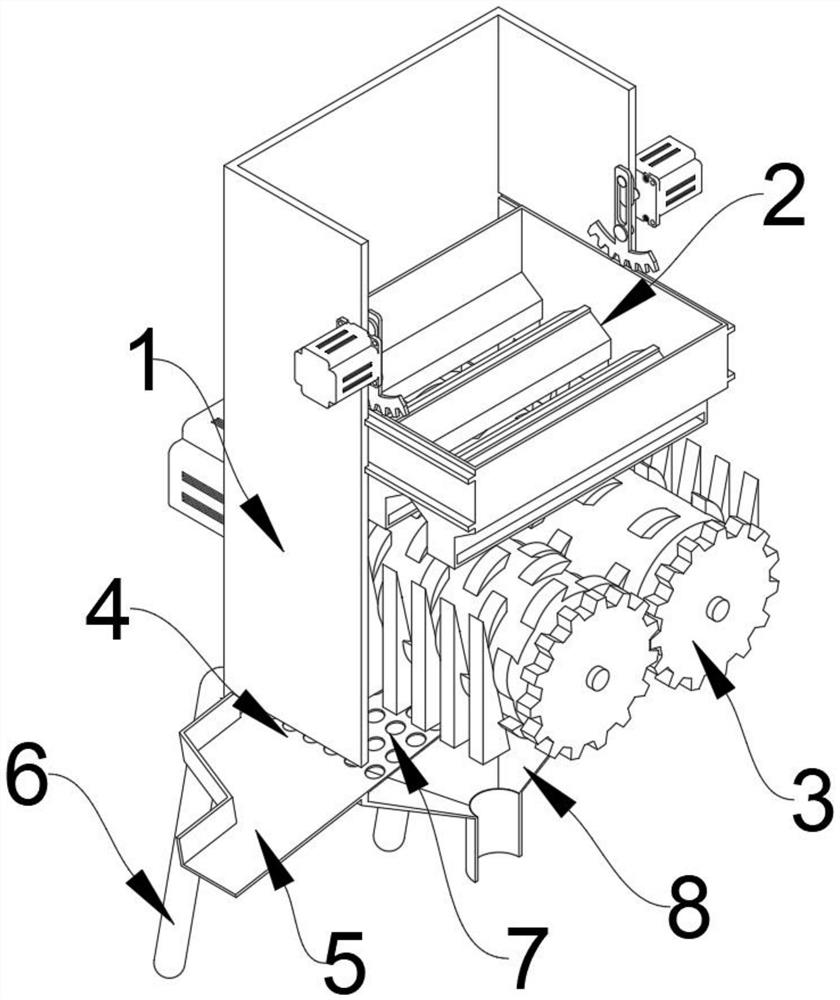

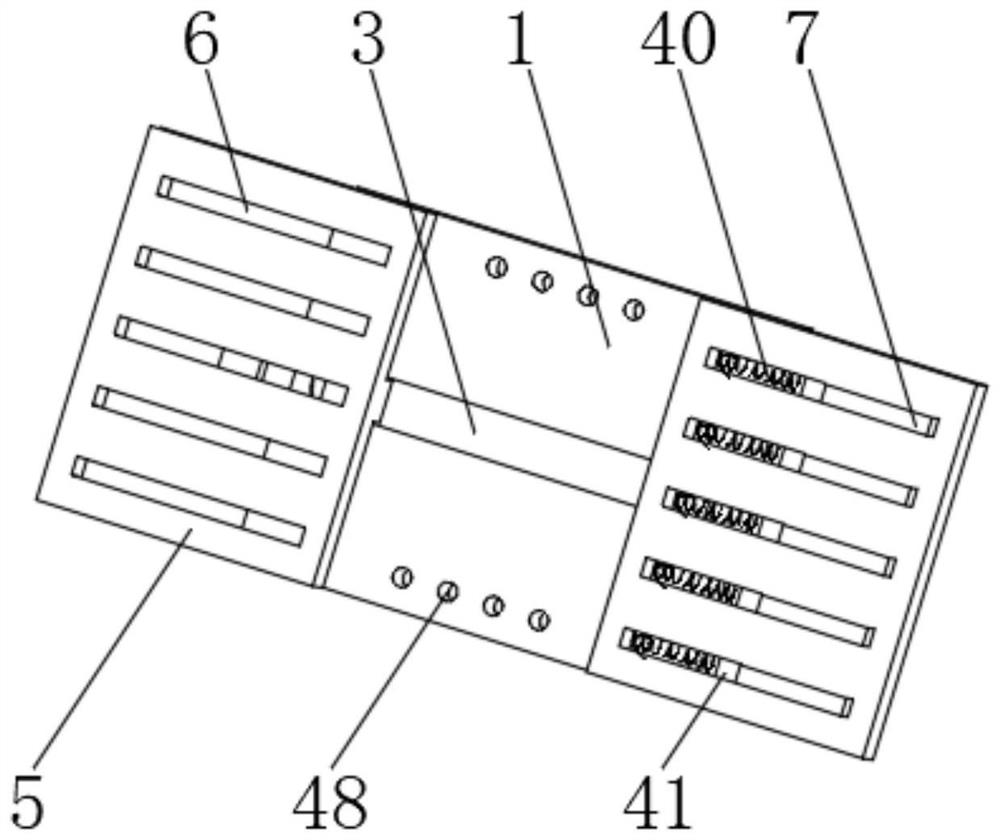

Batch crushing device for raw materials of plastic woven bags

ActiveCN113276313AGrinding at a uniform speedImprove efficiencyPlastic recyclingGrain treatmentsProcess engineeringRaw material

The invention discloses a batch crushing device for raw materials of plastic woven bags, and relates to the technical field of plastic woven bag production. The batch crushing device comprises a machine body; a screening net is obliquely arranged at the bottom end of the interior of the machine body; a qualified product collecting hopper is fixedly connected to the lower end of the machine body; and an unqualified product discharging port matched with the screening net is formed in one side of the machine body. A raw material leveling mechanism and a raw material crushing mechanism are further included. The raw material leveling mechanism is configured to pretreat the raw materials, and the raw material crushing mechanism is configured to crush the raw materials. The raw material leveling mechanism is arranged to evenly scatter the raw materials to the upper end of the raw material crushing mechanism, the raw material crushing mechanism is enabled to crush the raw materials at a constant speed, and therefore the raw material crushing efficiency and effect of the device are greatly improved, through cooperation of all accessories, the raw materials which are not completely crushed can be effectively screened, and the raw materials which are not completely crushed are subjected to secondary crushing, so that the phenomenon that the raw materials are not completely crushed can be effectively avoided.

Owner:温州品豪包装有限公司

Cement slab scene granulation regeneration construction process

InactiveCN104818659AAvoid Fragmentation IncompleteEasy maintenanceIn situ pavingsRoads maintainencePavement maintenanceChipseal

The invention relates to a cement slab scene granulation regeneration construction process. The process comprises the following specific steps: (1) pre-crushing: a cement slab is crushed by a pickaxe machine; (2) watering by a watering cart: before the granulation crushing is performed, the watering cart is used for watering the crushed cement slab to reduce the dust; (3) cement blocks are granulated by a PTH granulator; (4) a pavement is locally mixed by a regenerator; (5) the pavement is leveled by a floor leveler; (6) the pavement is compacted by a road roller; and (7) the pavement is maintained. The process can locally finish deep crushing of old cement concrete without needing complex tools and material transporting flows of traditional construction modes; the cement slab can be added with cement to form a mixture after the granulation to prevent the weak effect of conventional stone crushing; the process realizes once solution, and is a green low-carbon process; the renewedly stabilized mixture has the characteristic of cement stabilized macadam; and a traditional cement slab pavement can be changed to a conventional cement stabilized macadam base pavement so as to bring convenience for subsequent pavement maintenance.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

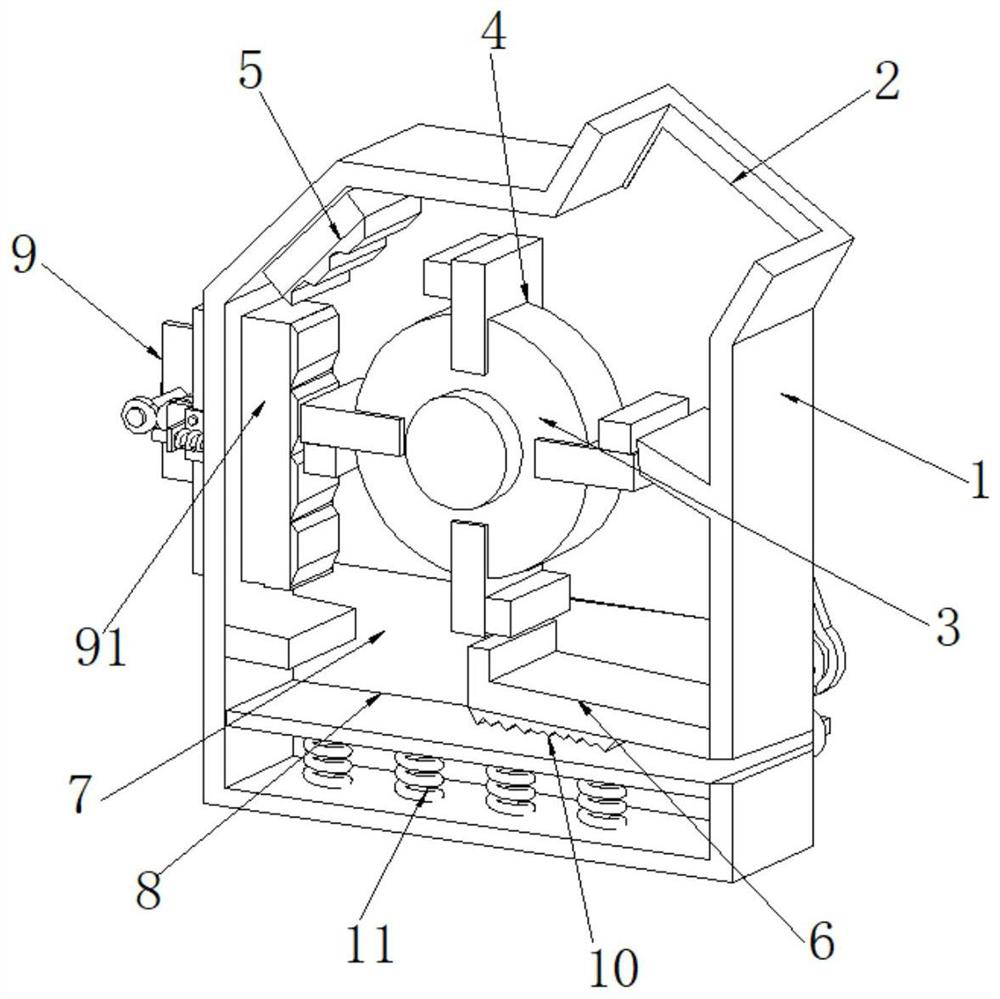

Hammer crusher

InactiveCN113976249AAvoid Fragmentation IncompleteImprove crushing effectGrain treatmentsStructural engineeringCrusher

The invention discloses a hammer crusher which comprises a shell. A main shaft is rotatably arranged on the shell, one end of the main shaft extends into the shell and is coaxially connected with a rotating disc, the other end of the main shaft extends out of the shell and is coaxially connected with a first belt wheel, a plurality of crushing hammers are arranged on the rotating disc, a fixed striking lining plate and a movable striking lining plate are arranged on the inner wall of the shell, a first driving assembly connected with the movable striking lining plate is arranged on the shell, and the first driving assembly can drive the movable striking lining plate to be close to or away from the rotary disc. The problems that an existing internal striking plate is often fixedly installed, the distance between the striking plate and a rotary disc is difficult to adjust, and some materials such as stones are not crushed completely are solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

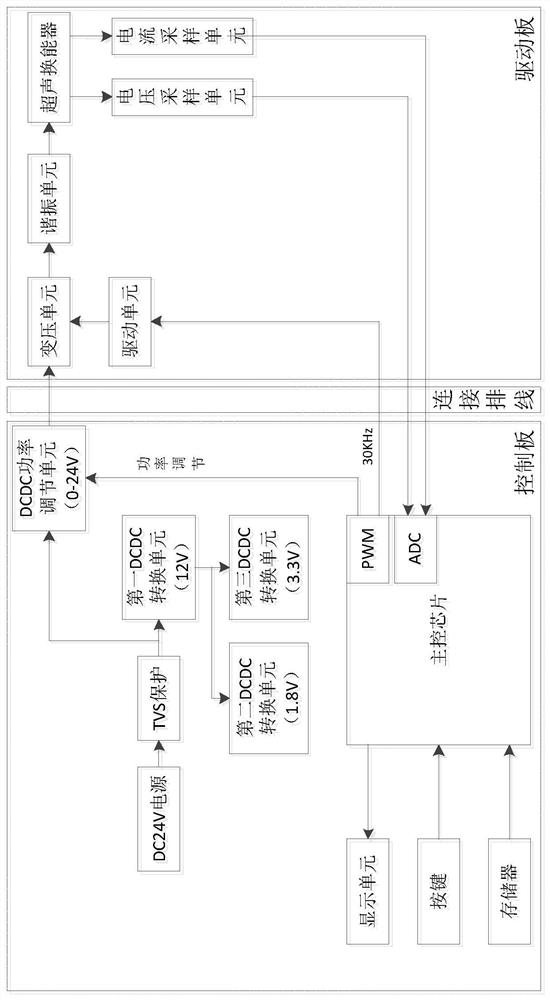

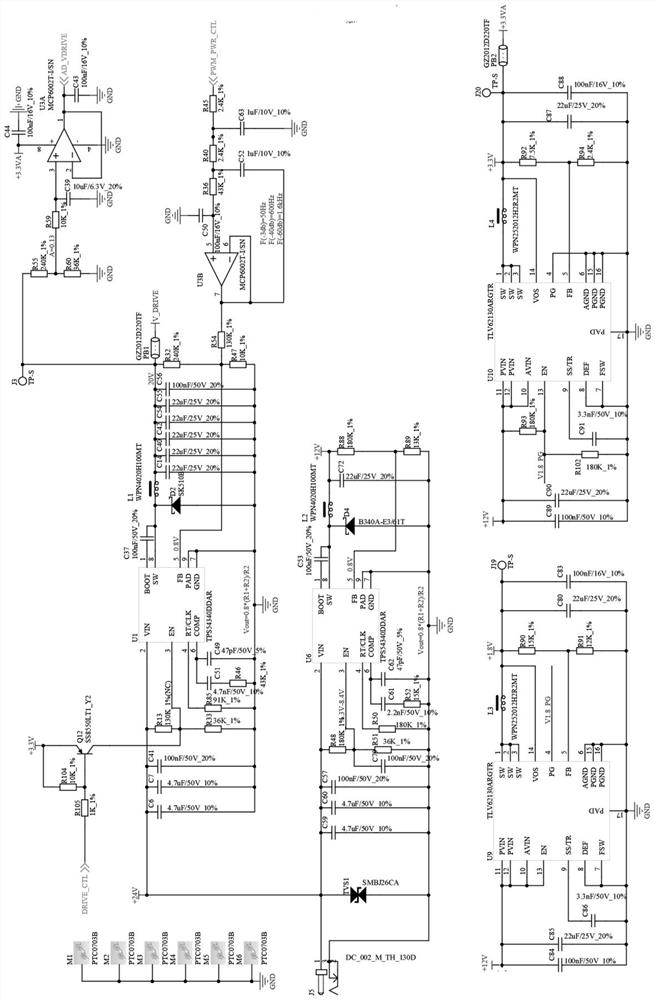

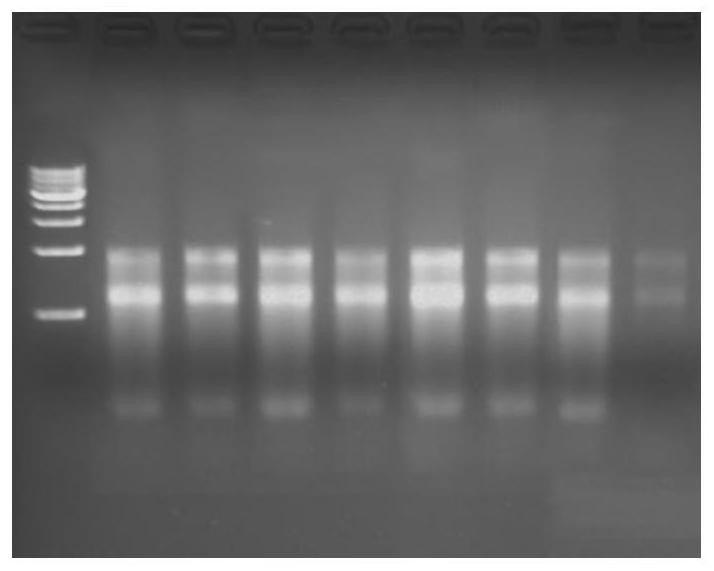

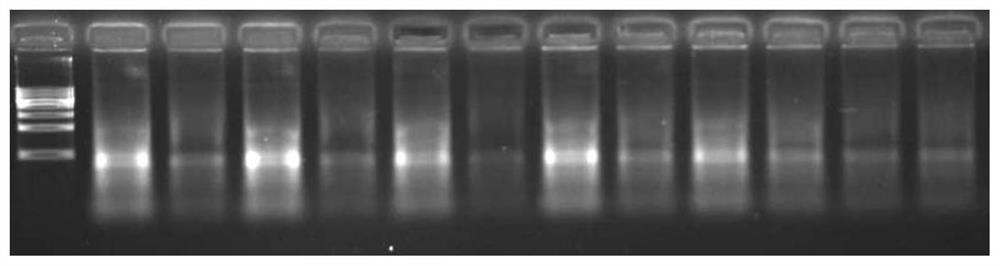

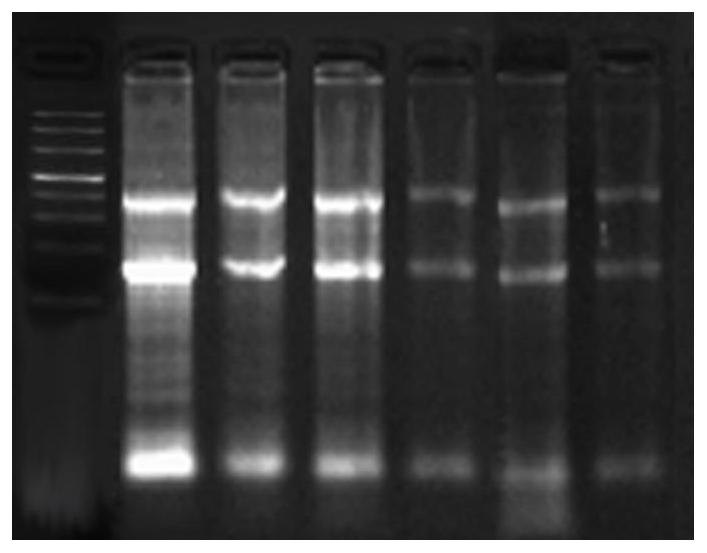

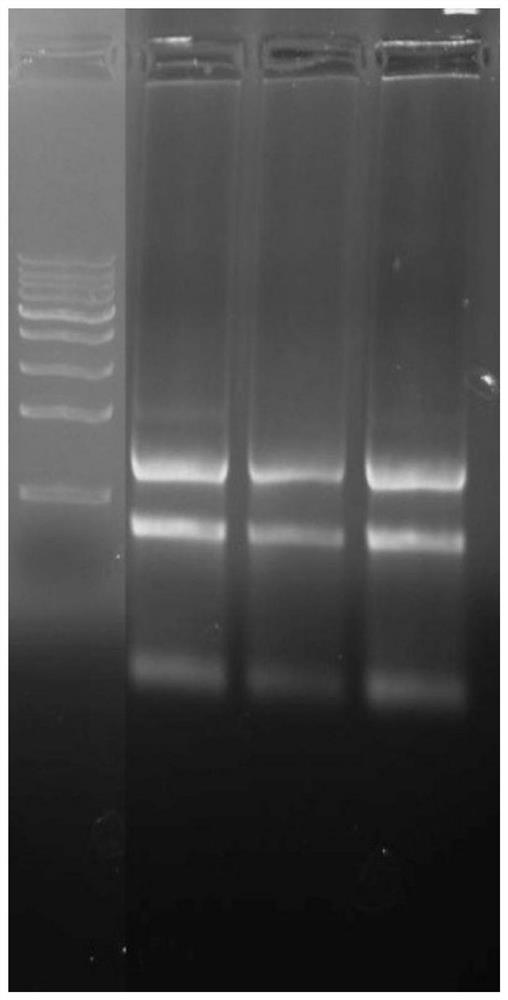

A method for rapid extraction of rna using an animal and plant tissue ablation instrument based on the principle of ultrasound

ActiveCN109609500BEliminate cleaning operationsEasy to operateMicrobiological testing/measurementDNA preparationCell extractionPlant tissue

A method for rapidly extracting RNA using an ultrasonic principle-based animal and plant tissue ablation instrument, comprising: 1) first preserving tissues or cells using an extracting liquid A and then adding an extracting liquid B into the tissues or cells preserved using the extracting liquid A, and uniformly mixing to obtain a mixture; 2) performing ultrasonic crushing on the mixture when extracting RNA from the tissues; 3) directly performing the operation in step 5) below when extracting RNA from the cells; 4) uniformly mixing the mixture subjected to ultrasonic crushing by inversion; 5) in the mixture of RNA extracted from the cells in step 3) or the mixture of step 4), adding chloroform for centrifugation, and taking an upper layer of liquid; 6) adding isopropanol into the upper layer of liquid, and then performing centrifugation to obtain a precipitate; 7) adding an ethanol solution into the precipitate, uniformly mixing, centrifuging, and discarding the liquid; 8) finally, adding water for dissolution.

Owner:CHENGDU DAOSHENG BIOTECH CO LTD

Method of crushing stones for building or highway construction

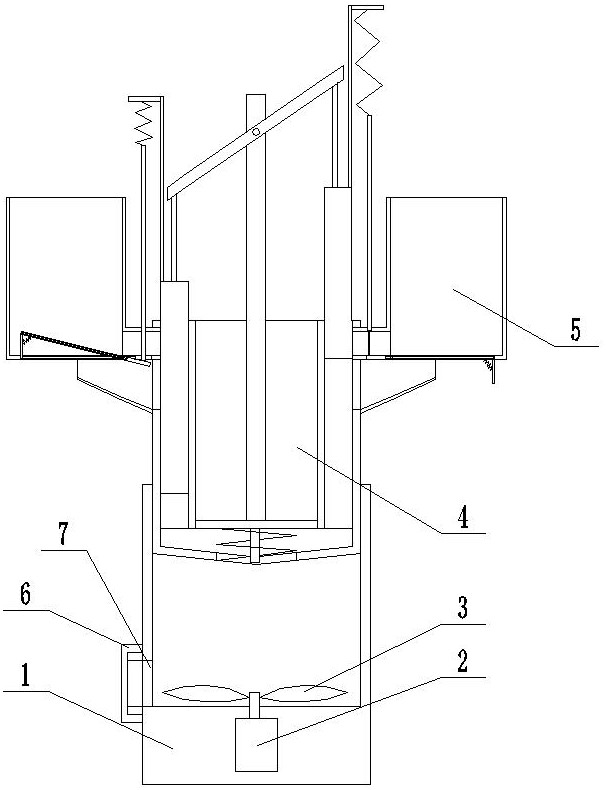

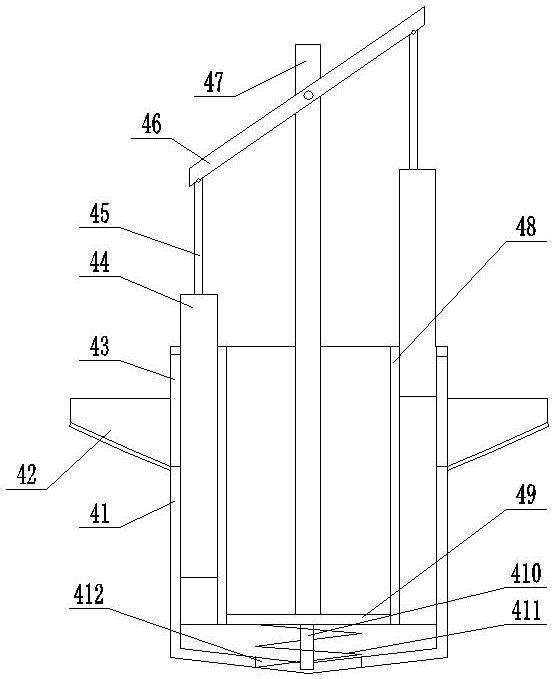

ActiveCN112774774APrevent splashGuaranteed to be completely brokenGrain treatmentsHydraulic cylinderArchitectural engineering

The invention relates to a method of crushing stones for building or highway construction. The method comprises the following six steps that 1, crushing equipment is designed, the crushing equipment comprises a support frame and a crushing mechanism, the crushing mechanism is arranged in the support frame, the crushing mechanism comprises a hydraulic cylinder and an air cylinder arm, the hydraulic air cylinder is fixedly arranged on the supporting frame, the air cylinder arm is connected to the driving end of the hydraulic air cylinder, the lower end of the air cylinder arm is fixedly connected to a breaking hammer, and the breaking hammer extends into a breaking barrel. According to the method, existing crushing equipment is optimized, in a using process of the optimized equipment, stone splashing in the crushing process can be effectively avoided, the continuous crushing effect can be achieved through the crushing equipment, the crushing efficiency is improved accordingly, meanwhile, the crushing equipment can guarantee that crushed powder is clean, and complete stone crushing can be further ensured, so that the crushing equipment has a better market prospect.

Owner:上海闸航路基材料有限公司

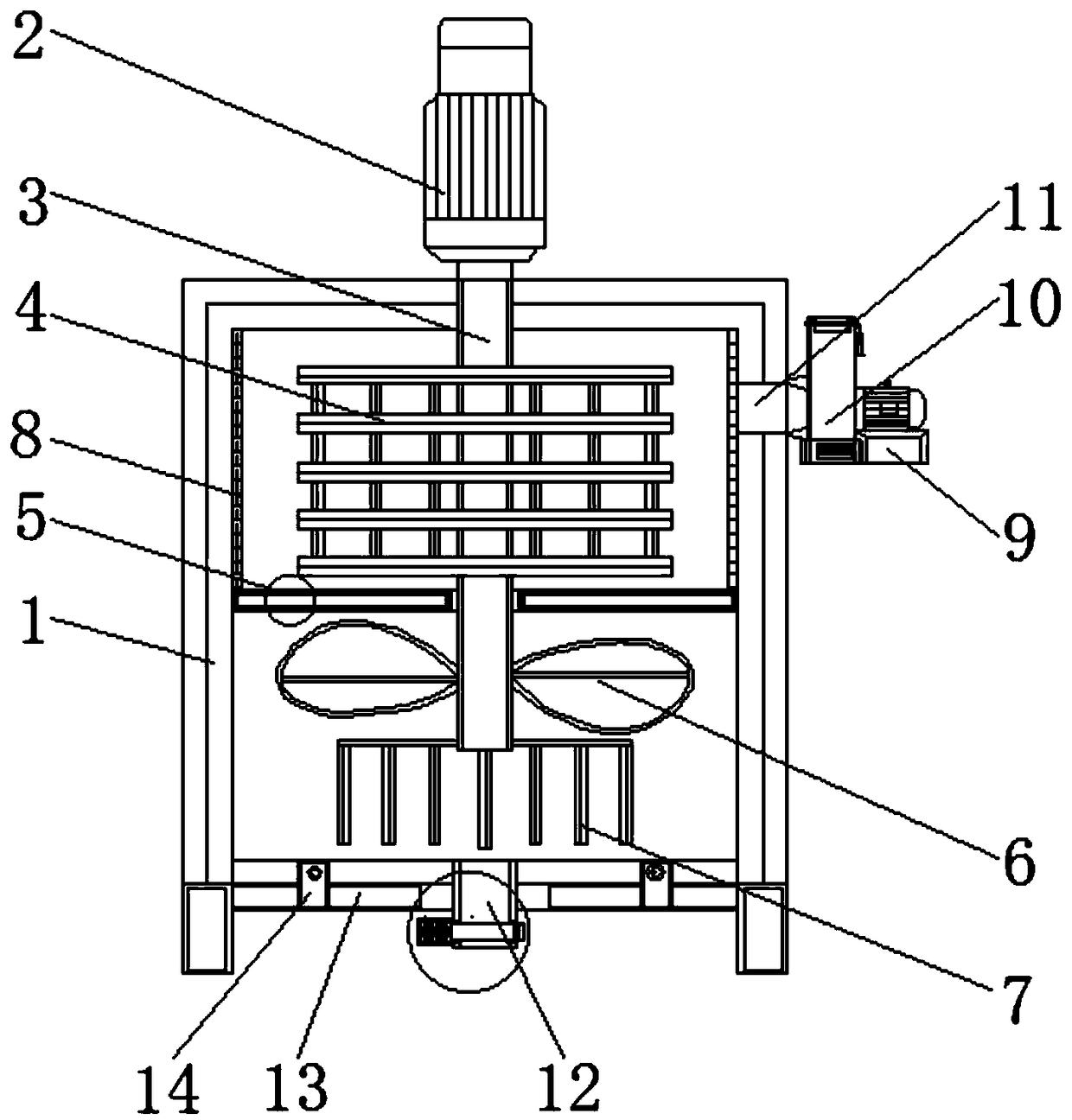

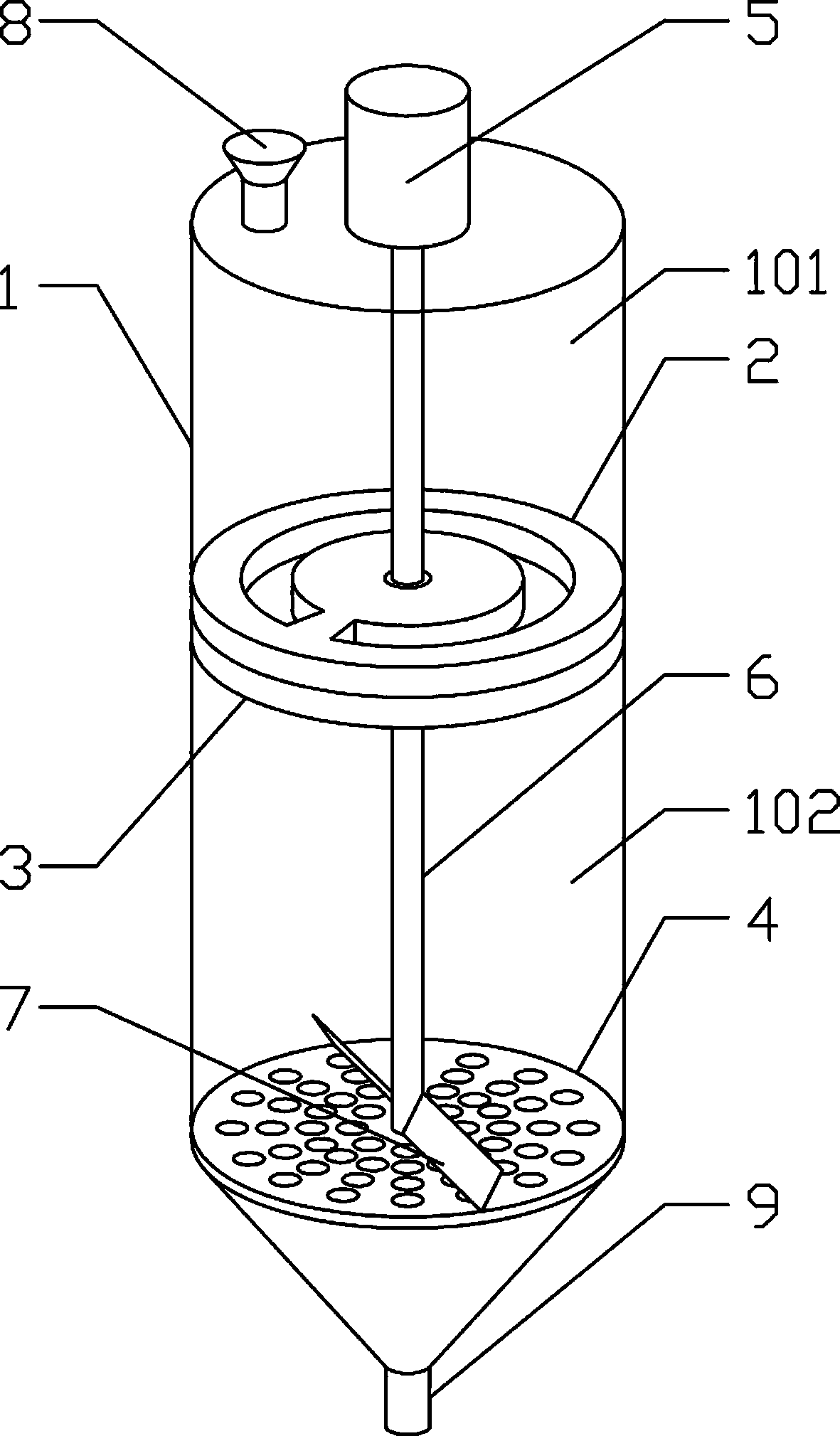

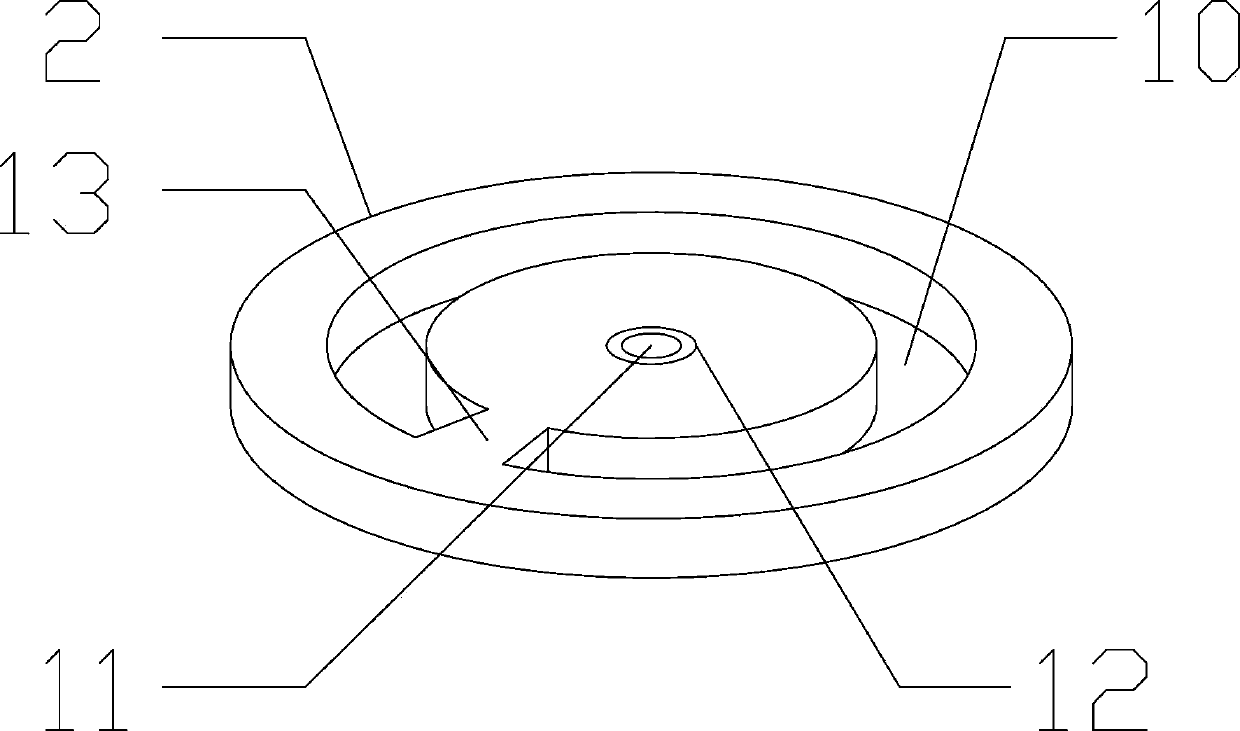

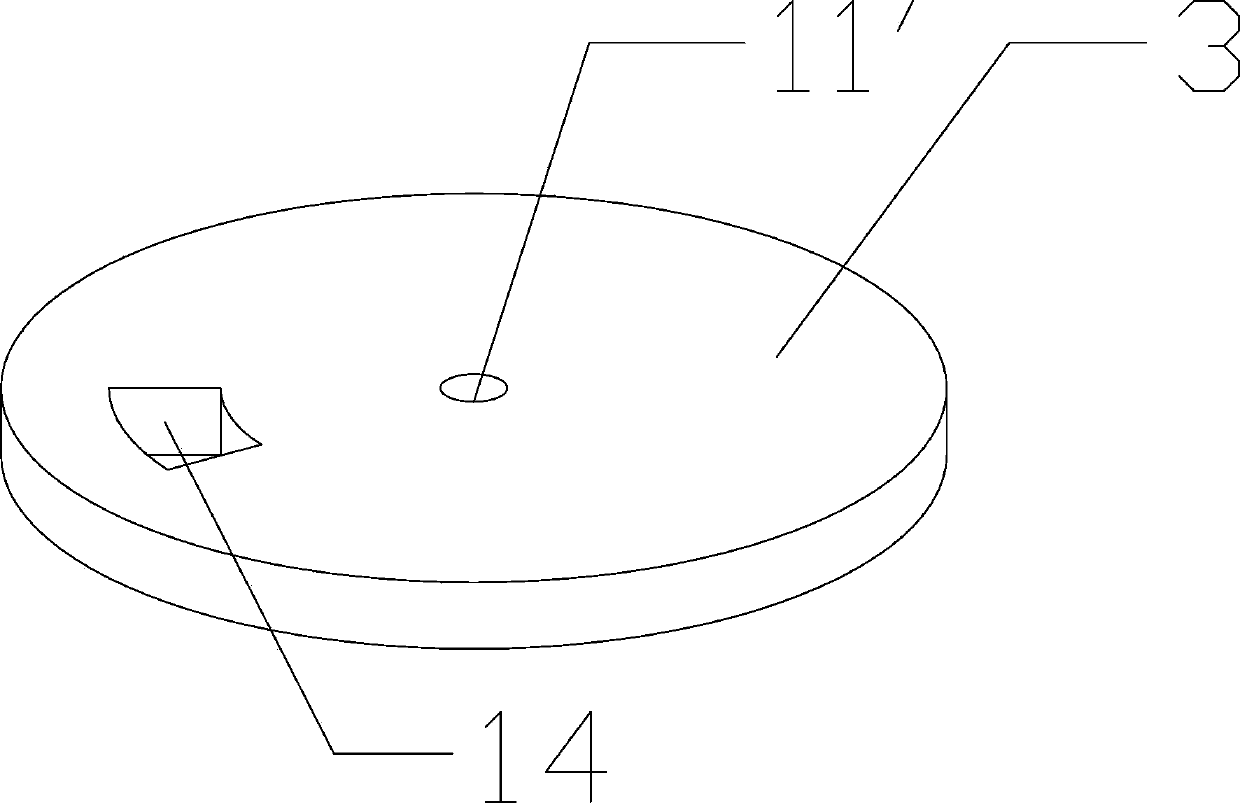

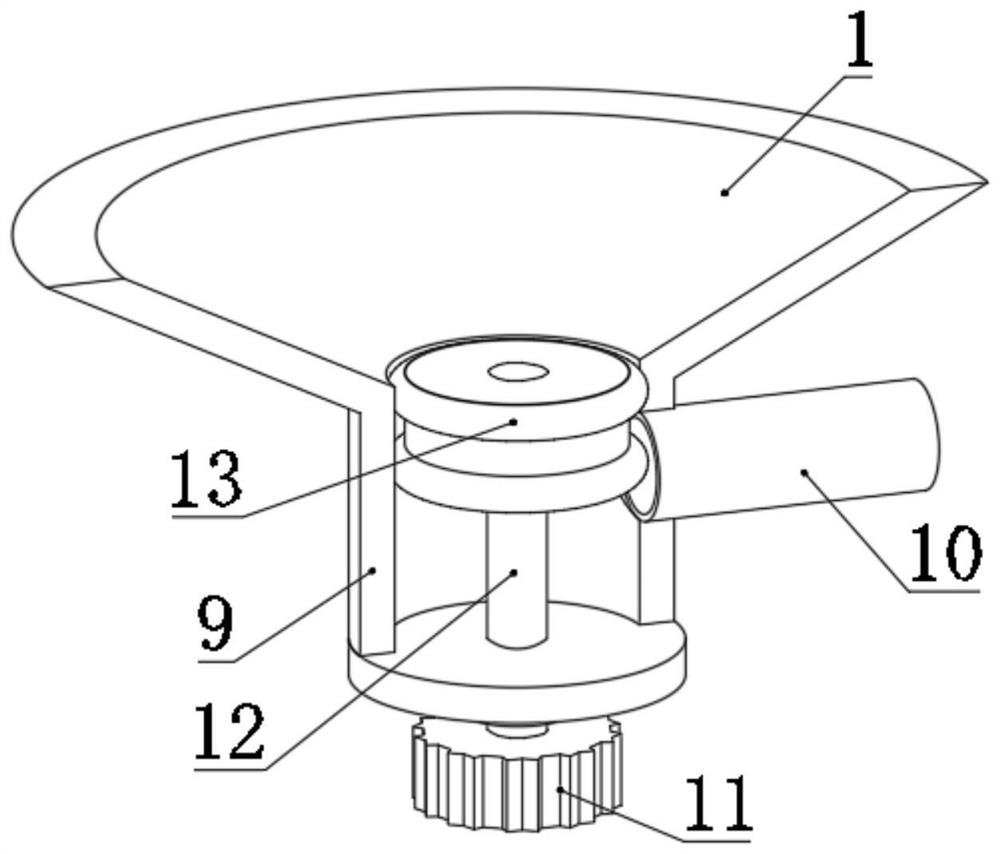

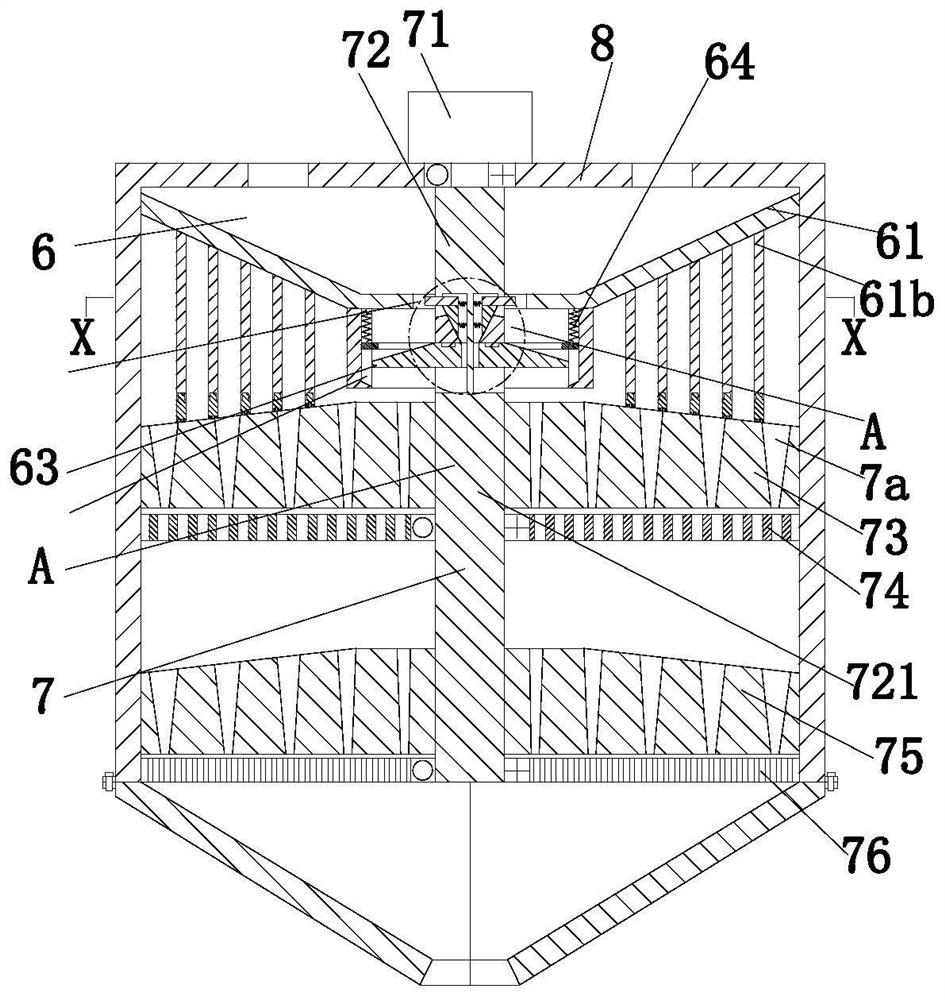

Bio-organic fertilizer crushing apparatus

InactiveCN109908830AAchieve blanking uniformityUniform feedingGranulation by material expressionEngineeringDrive motor

The invention relates to a bio-organic fertilizer crushing apparatus, which comprises a cylinder body, wherein a material collecting bin fixing bottom plate is arranged in the cylinder body, the cylinder body is divided into an upper chamber and a lower chamber by the material collecting bin fixing bottom plate, the cylinder body above the material collecting bin fixing bottom plate is a materialcollecting bin, the cylinder body below the material collecting bin fixing bottom plate is a crushing bin, the material collecting bin fixing bottom plate is provided with a first material discharge hole, a material collecting bin moving bottom plate is arranged below the material collecting bin fixing bottom plate, and is provided with a second material discharge port, a crushing plate is arranged in the crushing bin, and is provided with a plurality of extruding holes, the top portion of the cylinder body is provided with a driving motor, the rotating shaft of the driving motor penetrates through the material collecting bin fixing bottom plate, the material collecting bin moving bottom plate and the crushing plate, and is provided with extruding plates and cutting cutter blades, and theextruding plates and the cutting cutter blades are respectively are attached to the top surface and the bottom surface of the crushing plate. According to the present invention, by using the structure, the raw materials of the organic fertilizer can be crushed and form the uniform organic fertilizer granules so as to improve the quality of the final organic fertilizer product and avoid the waste of the organic fertilizer.

Owner:宜昌金旺肥业有限责任公司

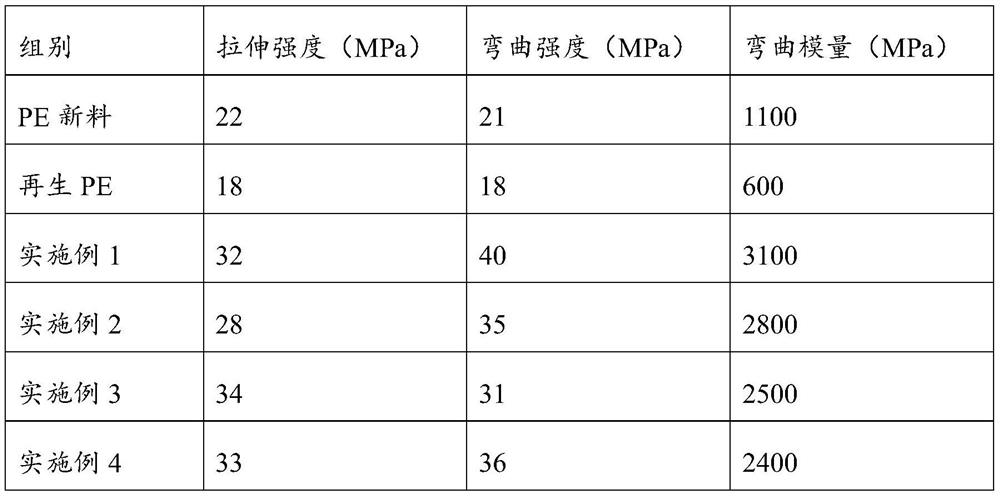

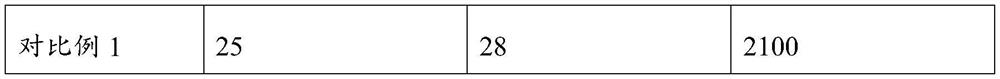

Fiber-plastic profile floor tile and preparation method thereof

The invention discloses a fiber-plastic profile floor tile and a preparation method thereof, and belongs to the technical field of composite materials. According to the fiber-plastic profile floor tile, a fiber-plastic composite material prepared from a waste textile fabric and waste plastic serves as the raw material, the cost is low, the floor tile is green and environmentally friendly, and meanwhile, recycling of the waste textile fabric and the waste plastic is achieved, so the floor tile has extremely high application prospects in the aspects of ground decoration and the like; the fiber-plastic composite material used by the fiber-plastic profile floor tile provided by the invention has more excellent mechanical properties than a single component in the fiber-plastic composite material, so that the floor tile is longer in service life; the fiber-plastic profile container bottom plate is provided with the anti-abrasion layer made of the fiber-plastic composite material doped with the anti-abrasion agent as the raw material, and therefore the service life of the floor tile is further prolonged; and the fiber-plastic profile floor tile provided by the invention is provided with a waterproof layer, and the waterproof layer can effectively prevent liquid from corroding the fiber-plastic composite material, so that the service life of the floor tile is further prolonged.

Owner:上海纤苏新材料科技有限公司

Crushing device for soil improvement

InactiveCN113634337AIncrease the crushing areaAvoid incomplete fragmentationGrain treatmentsSoil treatmentAgricultural engineering

The invention is applicable to the technical field of soil treatment equipment, and provides a crushing device for soil improvement. The crushing device comprises a supporting seat, a crushing cylinder and a crushing part, wherein the crushing cylinder is fixedly arranged on the supporting seat; the crushing part is arranged on the supporting seat; the crushing part comprises a rotating shaft; the rotating shaft can jump up and down in the rotating process; a plurality of crushing cutters are arranged on the surface of the rotating shaft in an array mode; a fixing rod is arranged in the rotating shaft in a sliding mode; the fixing rod is fixedly arranged on the supporting seat; and the fixing rod drives the crushing cutters to extend out intermittently through a transmission mechanism. The crushing device is thorough in crushing and good in crushing effect.

Owner:江苏进化树生物科技有限公司

Production method of distilled crab apple liquor

PendingCN109943444AImprove crushing effectAvoid Fragmentation IncompleteAlcoholic beverage preparationYeastCrab Apples

The invention relates to a production method of distilled crab apple liquor and belongs to the technical field of distilled liquor. The production method solves the problem that the quality and mouthfeel of products cannot reach the expected standards when distilled liquor brewing technologies in the prior art are applied to brewing of distilled crab apple liquor. According to the production method, in a brewing process of the distilled liquor, after crab apples are crushed by a crushing machine, the crushed crab apples are put into a fermentation tank for fermentation, and during fermentation, 20-30 g / T pectinase and 200-300 g / T yeast are separately added; after fermentation is completed, bentonite is added for clarification, obtained raw liquor is frozen for 15-20 days and then put intoa distilling pot for distilling, and then the distilled liquor is extracted for storage at the storage temperature of 15-25 DEG C under the relative humidity of 75-85%; the distilled liquor which is sufficient in storage age limit is adjusted and then filtered for filling production. The production method of the distilled crab apple liquor achieves brewing and production of the distilled crab apple liquor which is mellow in mouthfeel and contains a unique fragrance of crab apples.

Owner:内蒙古宝润红酒有限公司

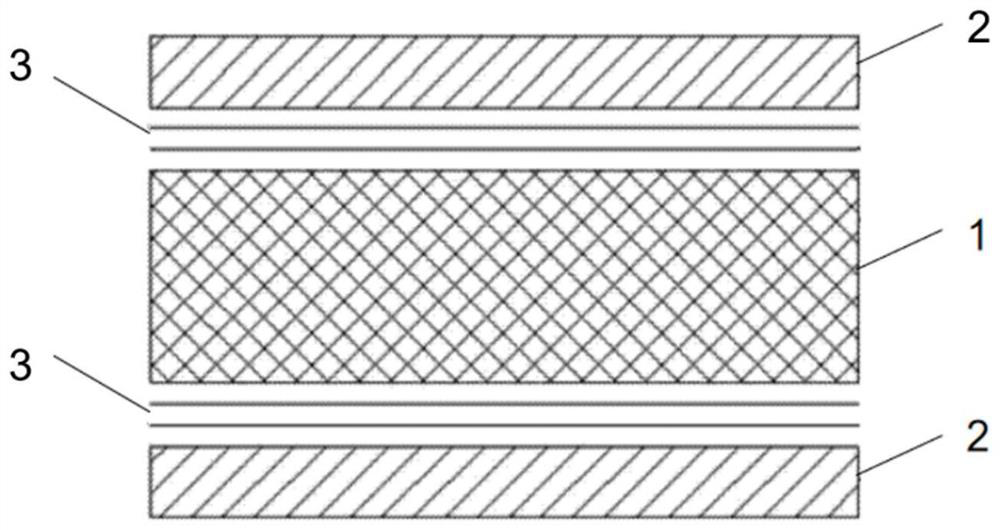

Fiber-plastic profile container bottom plate and preparation method thereof

PendingCN113831753AGood mechanical propertiesAchieve reuseSynthetic resin layered productsFibre cleaning/openingFiberWear resistance

The invention discloses a fiber-plastic profile container bottom plate and a preparation method thereof, and belongs to the technical field of composite materials. The bottom plate body of the fiber-plastic profile container bottom plate provided by the invention takes the fiber-plastic composite material prepared from the waste textile fabric and the waste plastic as a raw material, so that the cost is low, the fiber-plastic profile container bottom plate is green and environment-friendly, and meanwhile, the waste textile fabric and the waste plastic are recycled, and therefore, the container bottom plate has an extremely high application prospect in the field of containers; the fiber-plastic composite material used by the fiber-plastic profile container bottom plate provided by the invention has more excellent mechanical properties than a single component in the fiber-plastic composite material, so that article loss caused by damage of the container bottom plate can be reduced to a certain extent by using the container bottom plate; the fiber-plastic profile container bottom plate further comprises the hard wear-resistant layer, the hard wear-resistant layer has the advantage of being high in wear resistance, and the risk that the container bottom plate is damaged can be further reduced.

Owner:上海纤苏新材料科技有限公司

Medicine sampling device for medicine analysis

PendingCN113970461AEffective dissolutionImprove crushing efficiencyWithdrawing sample devicesPreparing sample for investigationPharmacy medicineElectric machinery

The invention discloses a medicine sampling device for medicine analysis, and belongs to the field of medicine sampling. The medicine sampling device comprises a tank body, the top of the tank body is provided with a feeding pipe, the bottom of the tank body is bucket-shaped and is provided with a piston pipe, one side of the upper end of the piston pipe is provided with a liquid discharge pipe, and the piston pipe is internally provided with a piston mechanism; a motor is mounted at the top of the tank body, a mesh plate is rotatably mounted in the tank body, a plurality of cleaning strips are fixed on the inner wall of the tank body, the bottom walls of the cleaning strips are in friction contact with the top surface of the mesh plate, and a solvent pipe is mounted on the outer side of the tank body. Solid medicine is rapidly and efficiently crushed through the crushing mechanism to form powder, then the medicine powder and a solvent are fully mixed through the aeration mechanism to be dissolved to form medicine liquid, and the medicine liquid can be used for analysis and detection after being taken out; and the device can be conveniently cleaned and dried when used and can be conveniently put into use again.

Owner:李洪臣

A reciprocating impact type road snow cleaning device using electromagnetic force

ActiveCN111560906BPrevent looseningAccelerate the speed of hitting the snow on the roadSnow cleaningVibration amplitudeSnowpack

The invention discloses a reciprocating impact type road snow cleaning device using electromagnetic force, which relates to the technical field of road maintenance, and includes a mounting plate, a top end of which is inlaid with a turning plate, and the turning plate is rotationally connected with the mounting plate. A track groove is opened at the bottom of the mounting plate, and the track groove runs through the steering plate. A slider is slidably connected between both sides of the inner wall of the track groove, and a working plate is fixedly connected to the bottom of the slider. The reciprocating impact type road snow cleaning device using electromagnetic force solves the problem that the existing road snow cleaning device produces a relatively large vibration amplitude when it hits the ice on the road surface, and the connection of the transmission structure is likely to cause a large degree of wear and tear. It is easy to loosen, the service life is low, and the efficiency of ice breaking cannot be improved. At the same time, hitting the ice block vertically and vertically is likely to cause damage to the road below the ice block. It is impossible to control the direction of the hitting and avoid damage to the road surface.

Owner:TAIZHOU HUAFENG AIR CONDITIONER VALVE

A kind of lysate and its application in preserving tissue or cell and extracting rna

ActiveCN107475251BEliminate cleaning operationsEasy to operateMicrobiological testing/measurementDead animal preservationSodium acetatePhenol

The invention discloses a lysate and its application in preserving tissues or cells and extracting RNA. ‑10mmol / L, potassium chloride 10‑15mmol / L, magnesium chloride 5‑10mmol / L, lysate B includes guanidine isothiocyanate 2‑4mol / L, spermidine 1‑5mmol / L, water-saturated phenol 30‑ 40vt%, ammonium thiocyanate 0.4‑0.5mol / L, glycerin 7‑8vt%, sodium acetate 0.1‑0.5mol / L, SDS 0.2‑0.5wt%. The lysate A of the present invention can be used to preserve tissues or cells. When the lysates A and B are used to extract RNA, it is not necessary to clean the tissues or cells, which significantly improves the extraction efficiency, and the synergistic effect of each component increases the purity of the extracted RNA. High and high yield, it can achieve the purpose of rapid, low-cost, high-quality and large-scale extraction of animal RNA in the laboratory.

Owner:CHENGDU DAOSHENG BIOTECH CO LTD

Stone crushing system for highway construction

ActiveCN112844548APrevent splashGuaranteed to be completely brokenGrain treatmentsArchitectural engineeringStructural engineering

The invention relates to a stone crushing system for highway construction. The stone crushing system comprises a supporting frame and a crushing mechanism, wherein the crushing mechanism is arranged in the supporting frame and comprises a hydraulic air cylinder and an air cylinder arm, the hydraulic air cylinder is fixedly arranged on the supporting frame, the air cylinder arm is connected with the driving end of the hydraulic air cylinder, the lower end of the air cylinder arm is fixedly connected with a crushing hammer, and the crushing hammer extends into a crushing cylinder. According to the stone crushing system, existing crushing equipment is optimized, and the optimized equipment can effectively prevent stones from splashing in the crushing process in the using process; in addition, the crushing equipment can achieve the continuous crushing effect, so that the crushing efficiency is improved; and meanwhile, the crushing equipment can guarantee cleanliness of crushed powder and can also guarantee complete crushing of the stones, so that the crushing equipment has a better market prospect.

Owner:CHECC DATA CO LTD +2

Scaffold with safety protection function

PendingCN114308336AImprove crushing effectAvoid incomplete fragmentationSievingConstruction waste recoveryHydraulic cylinderEngineering

The invention relates to the technical field of constructional engineering, and discloses a scaffold with a safety protection function, which comprises a crushing box, a partition plate is arranged in the crushing box, two pressing plates are arranged at the top of the partition plate, the two pressing plates are symmetrically arranged, two connecting plates are fixedly connected to the top of the partition plate, and the two connecting plates are fixedly connected to the top of the partition plate. And hydraulic cylinders are arranged on the sides, away from each other, of the two connecting plates correspondingly, the two hydraulic cylinders are fixedly connected with the side wall of the crushing box correspondingly, and the outer surfaces of the two hydraulic cylinders are sleeved with fixing sleeves correspondingly. The hydraulic cylinder is started to enable the pressing plate to preliminarily crush the construction waste through the crushing teeth, and the preliminarily crushed waste falls down from the partition net I and is crushed again by the crushing roller I and the crushing roller II, so that the crushing effect on the construction waste is relatively good, and the phenomenon of incomplete crushing is avoided.

Owner:扬州市崇鑫机械制造有限公司

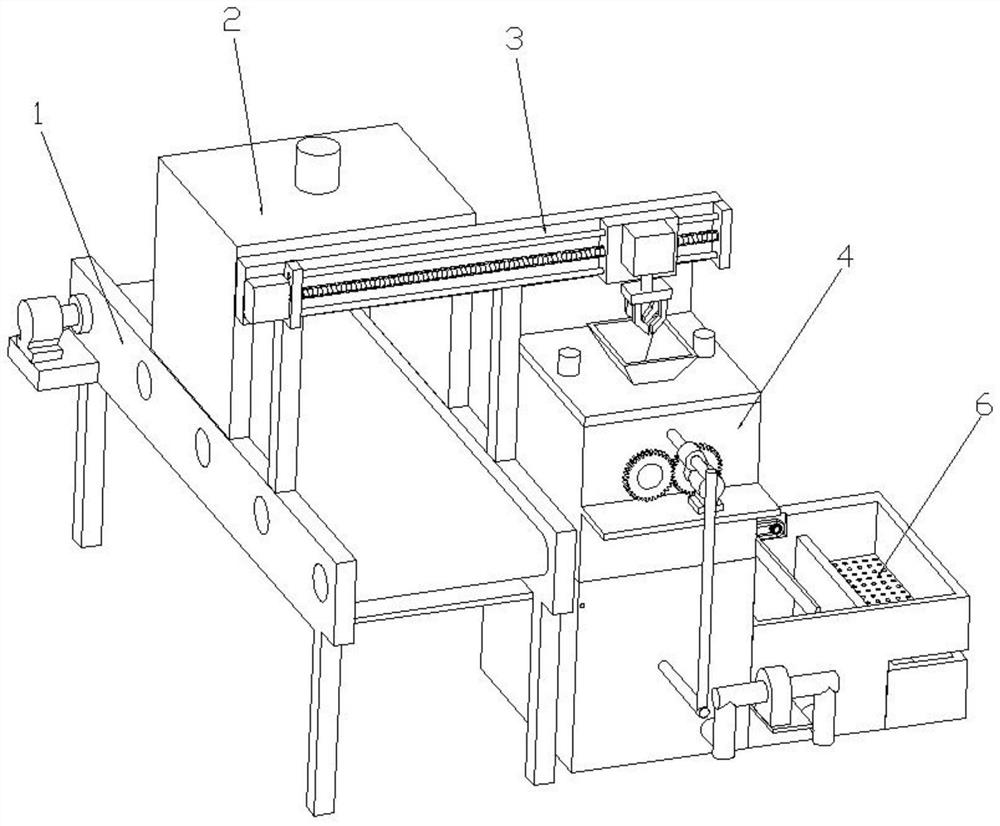

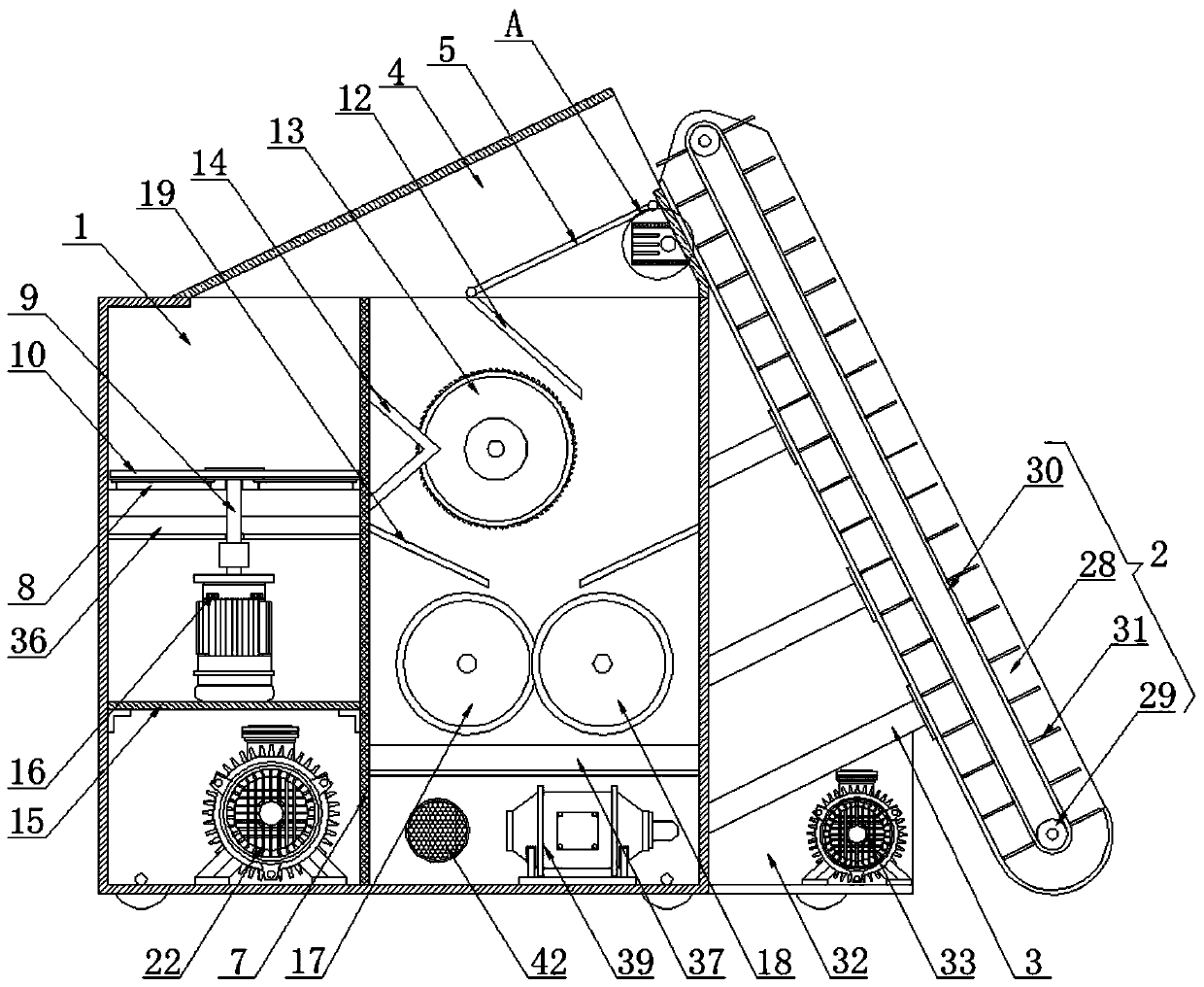

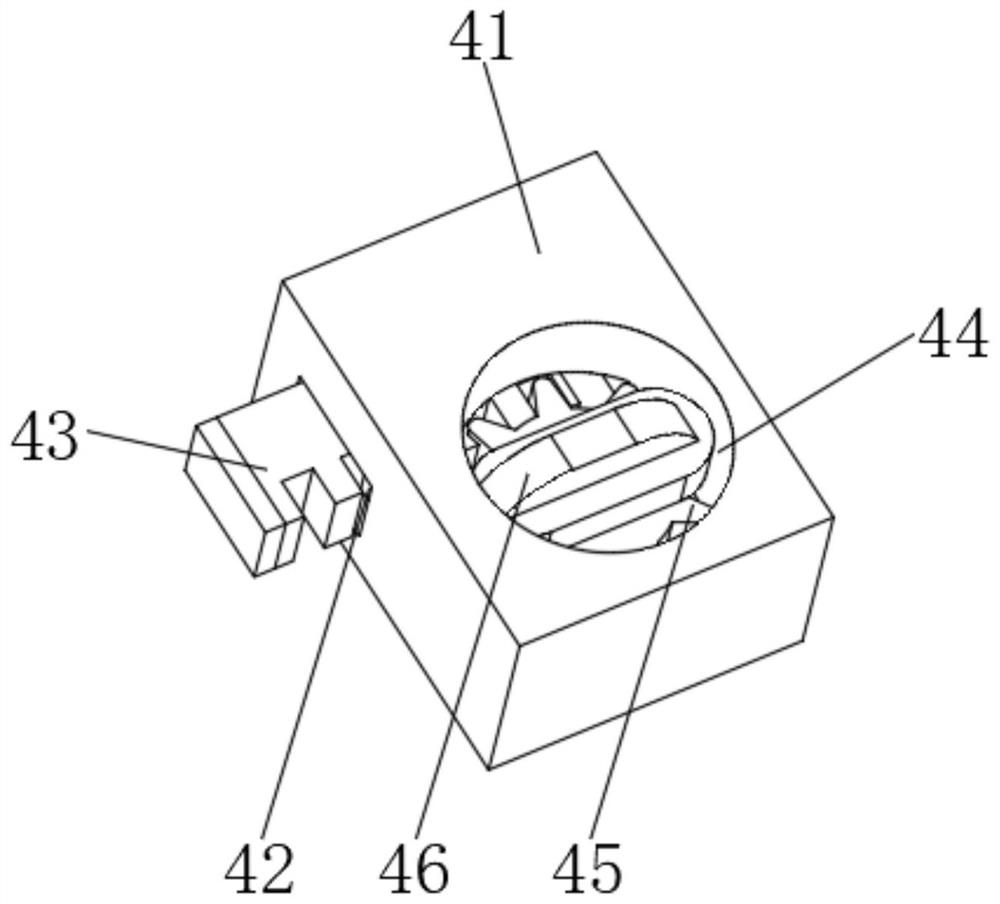

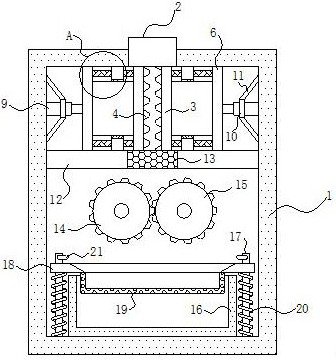

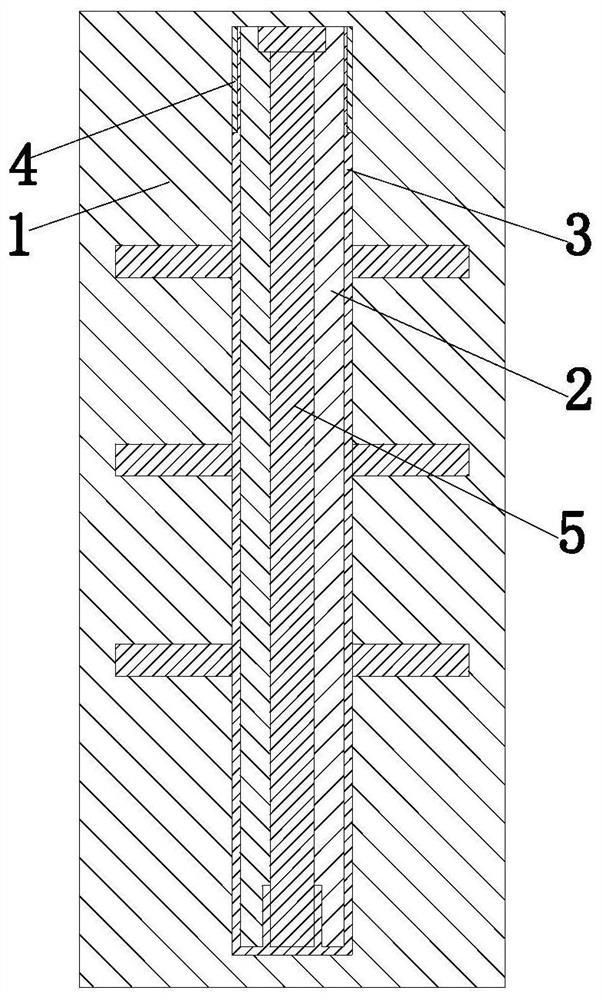

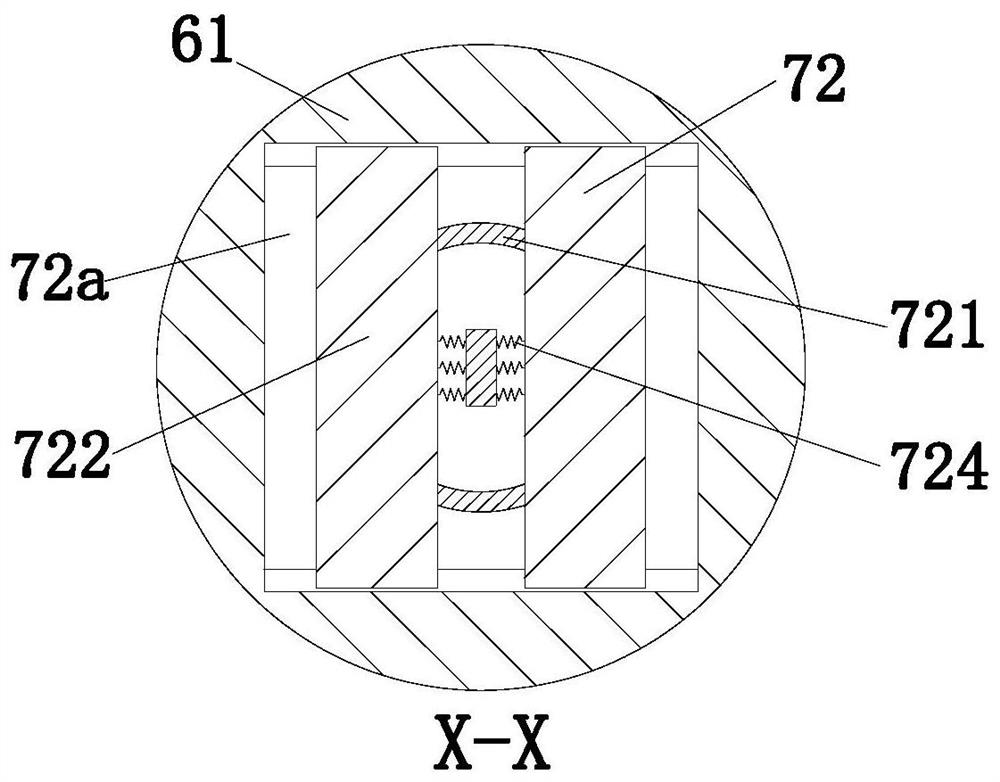

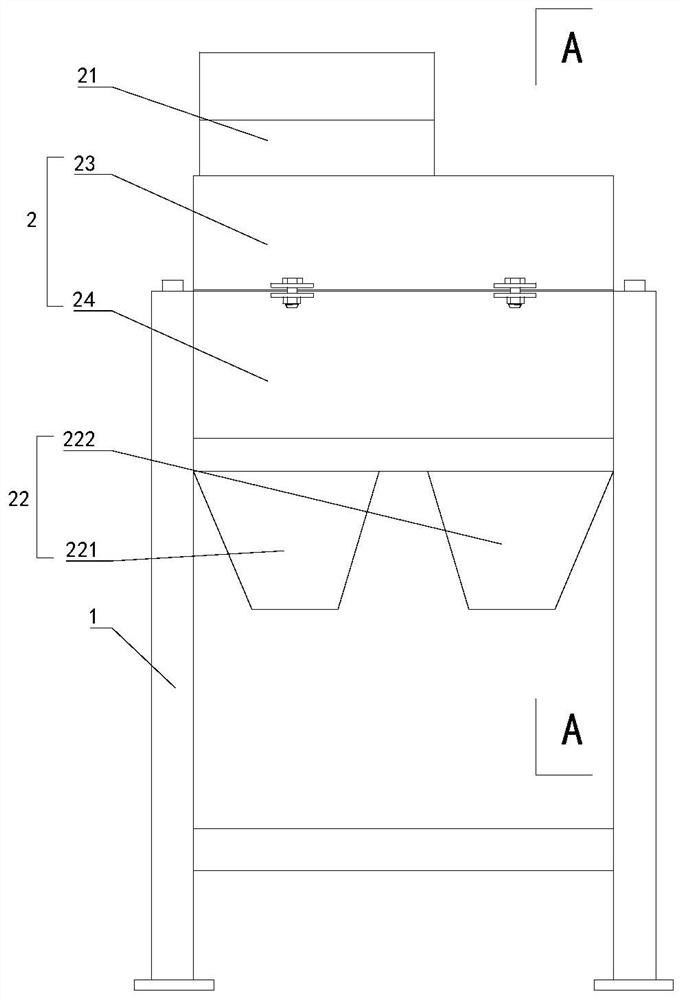

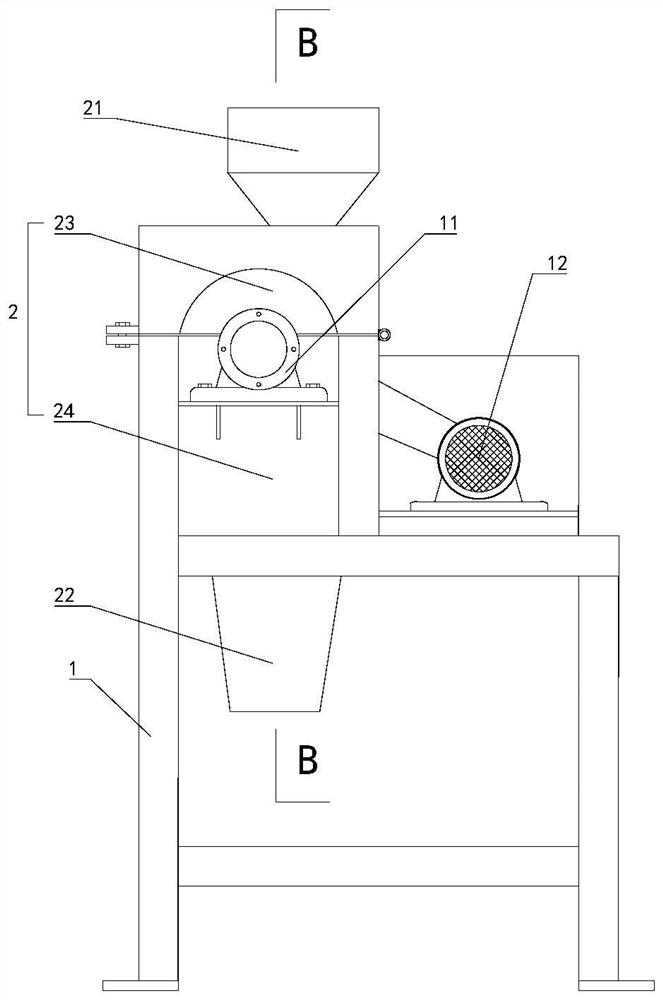

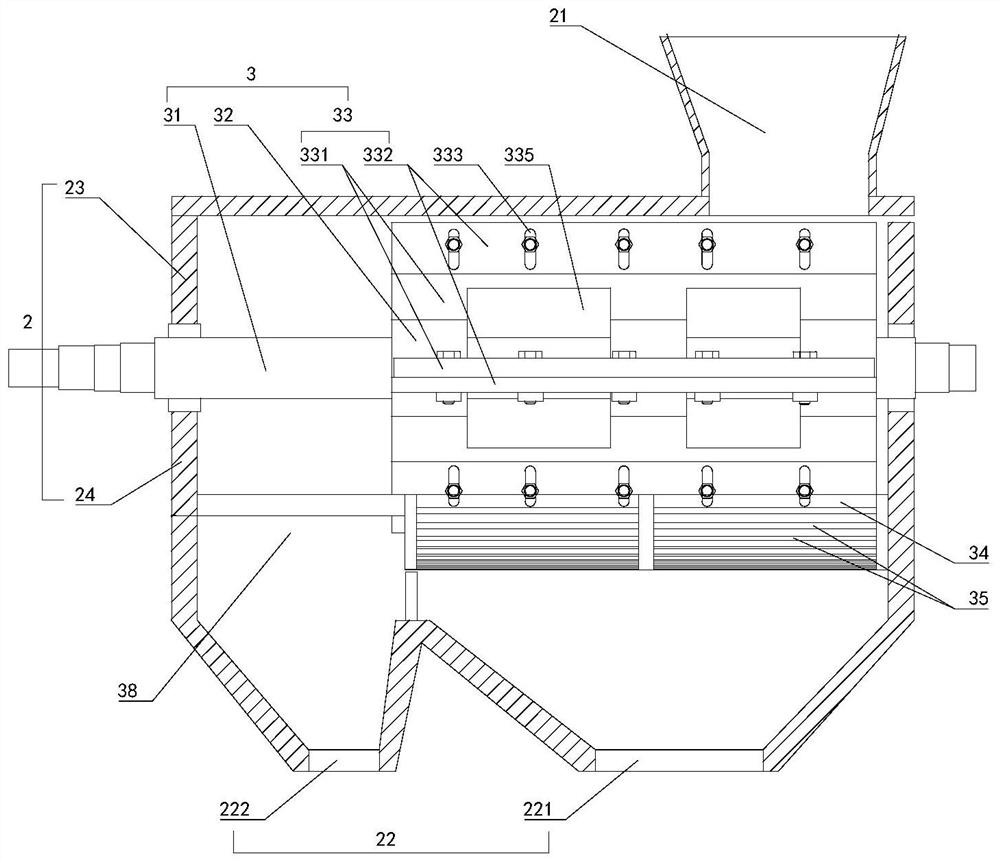

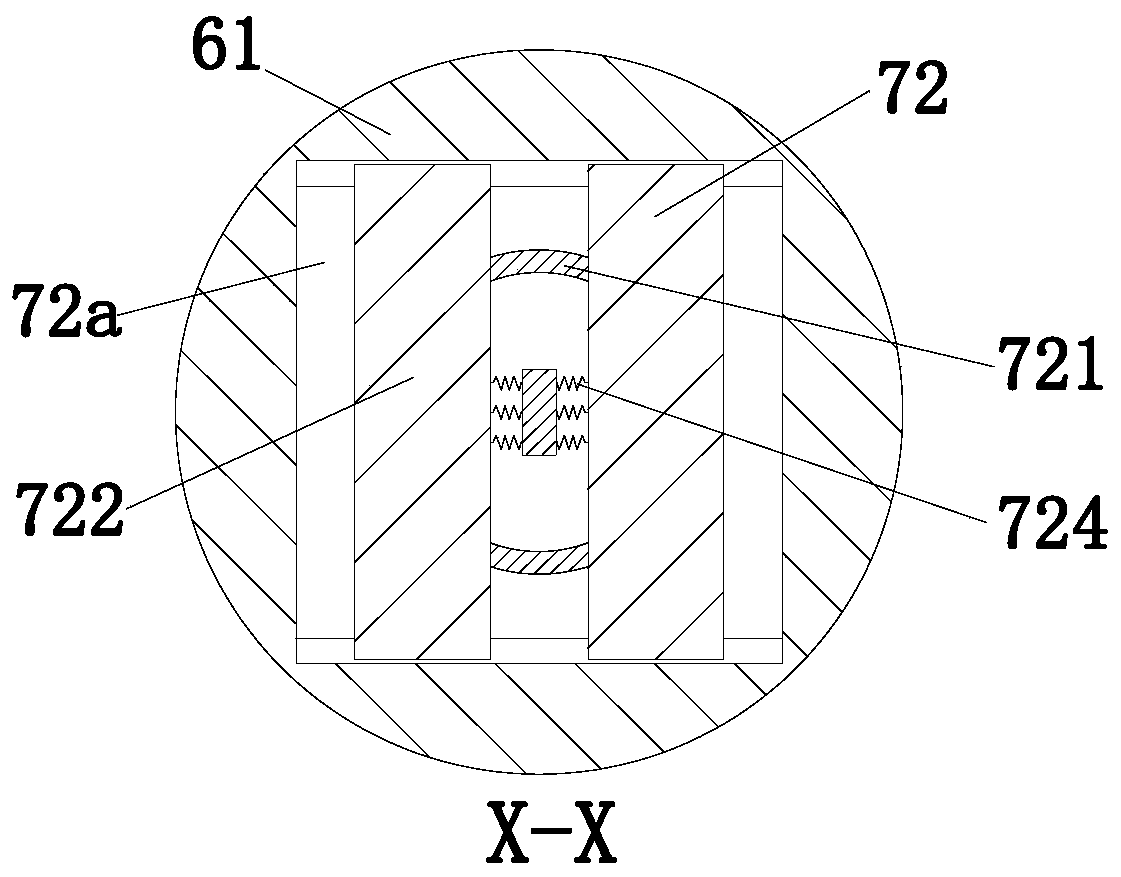

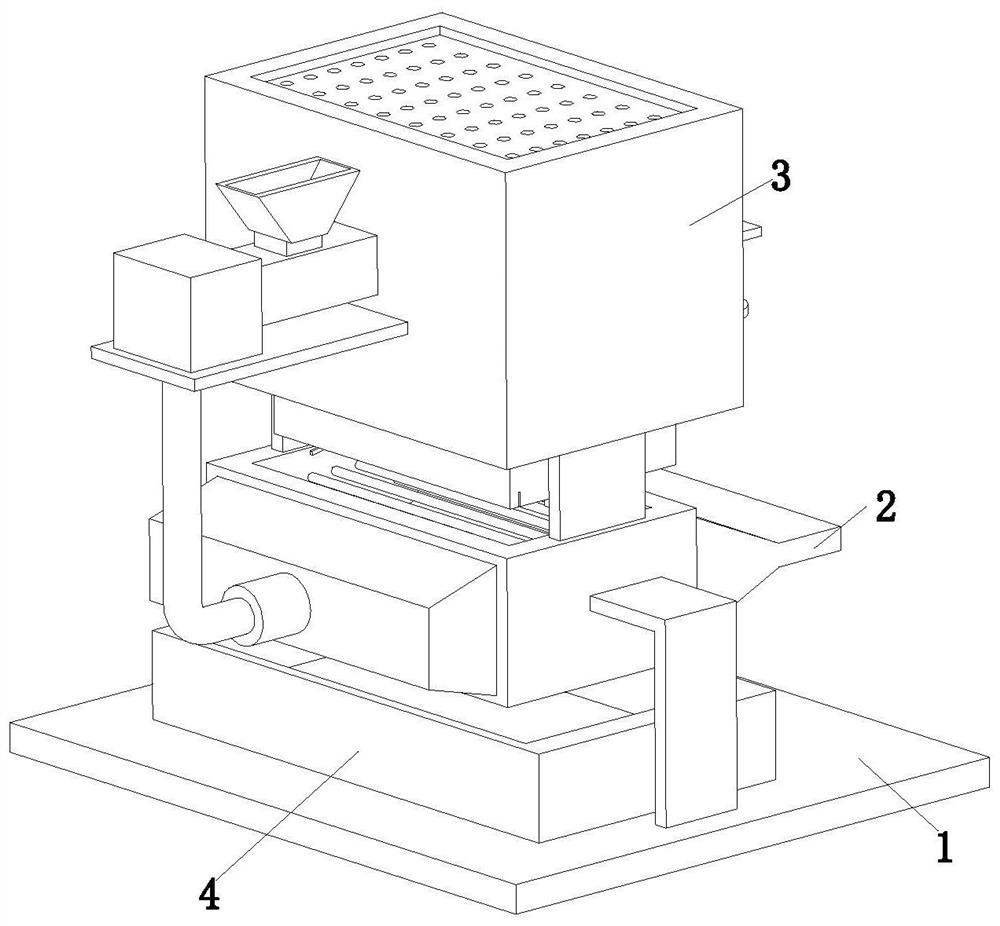

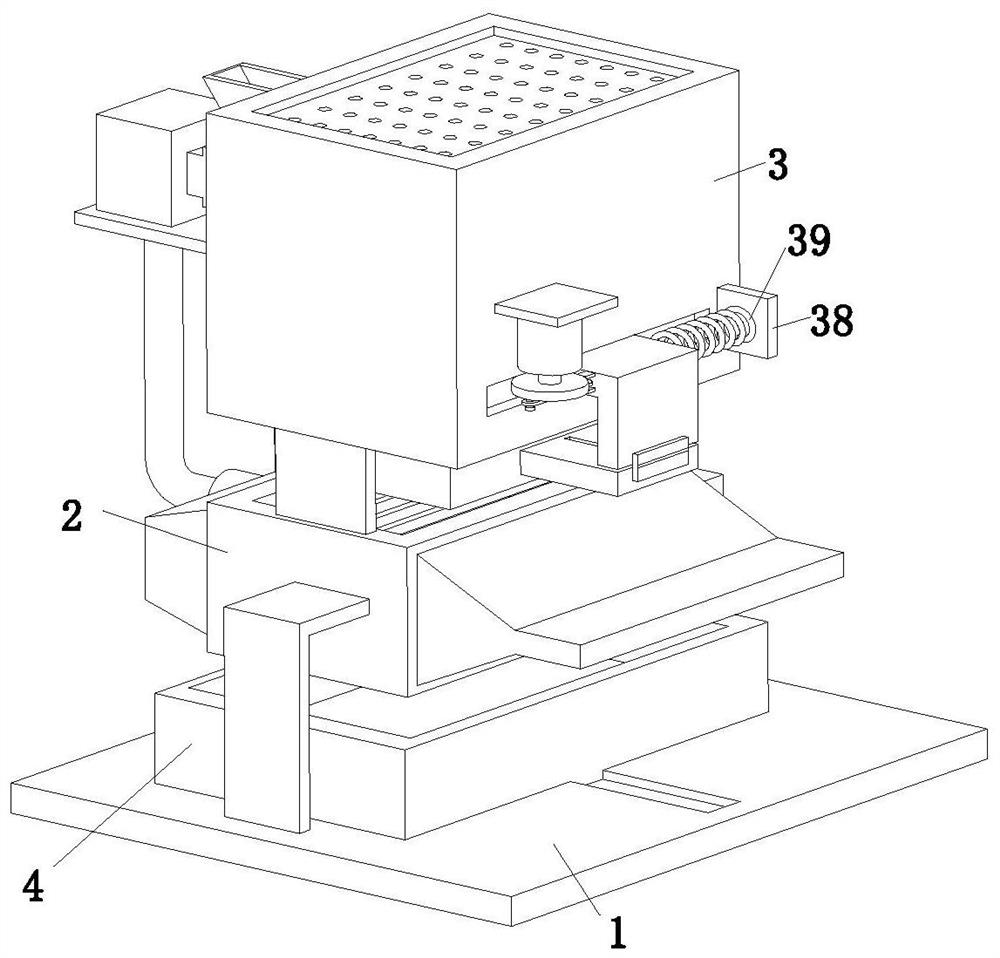

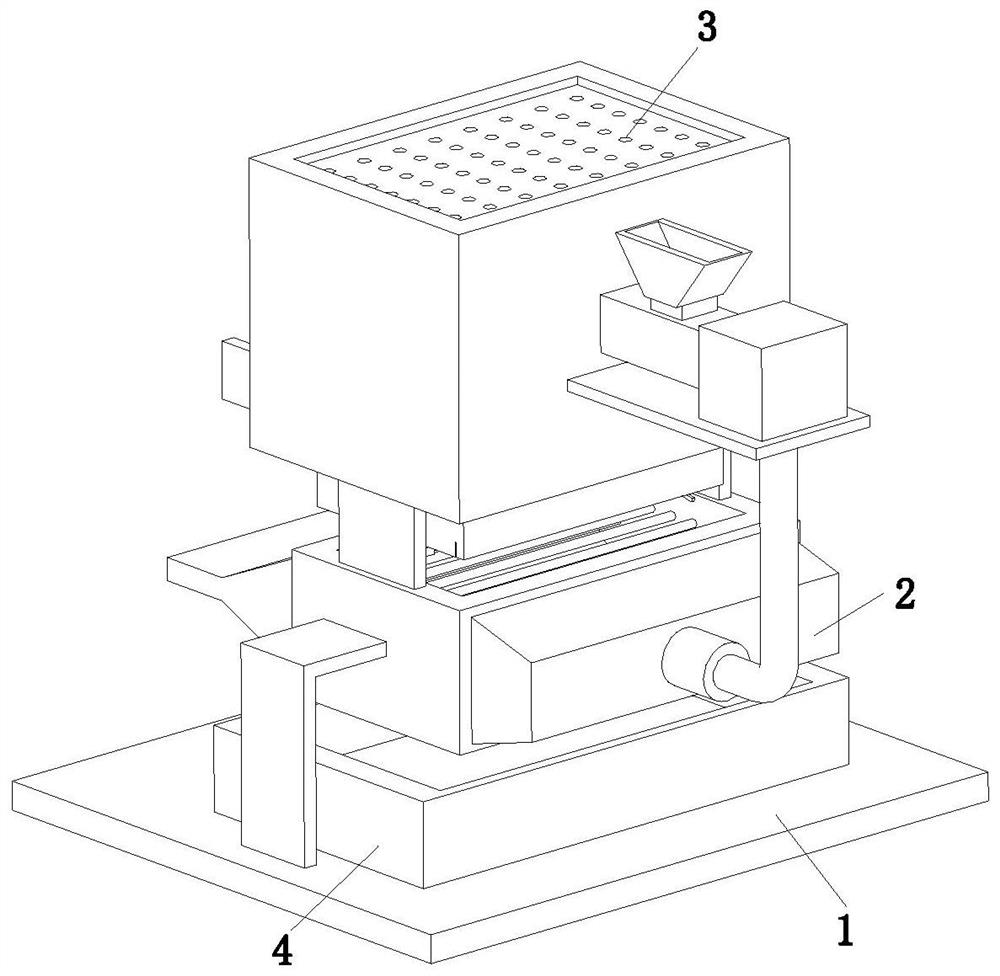

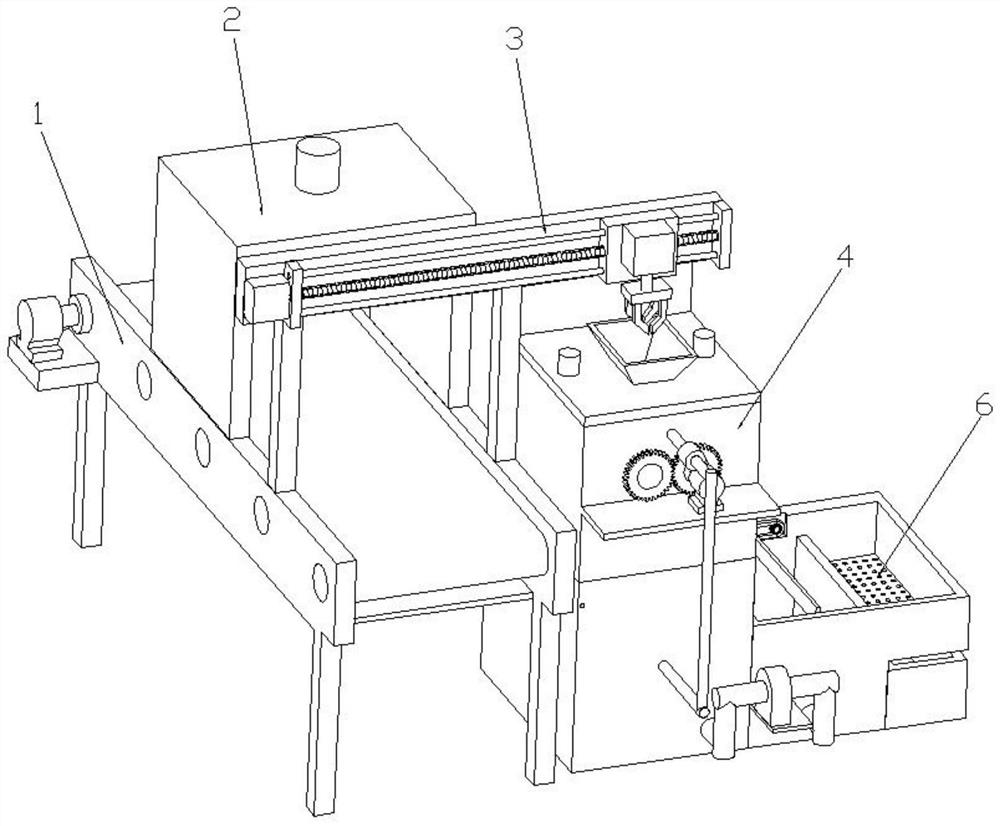

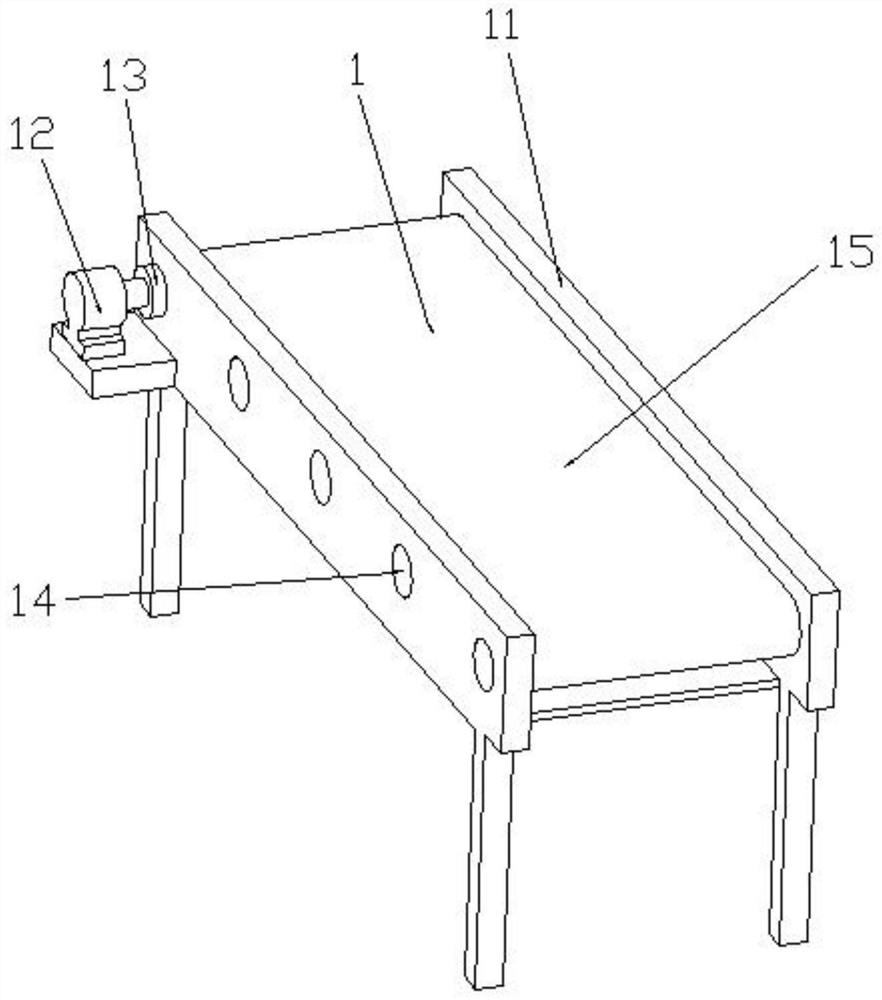

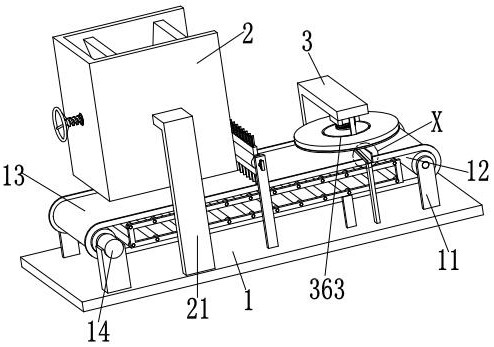

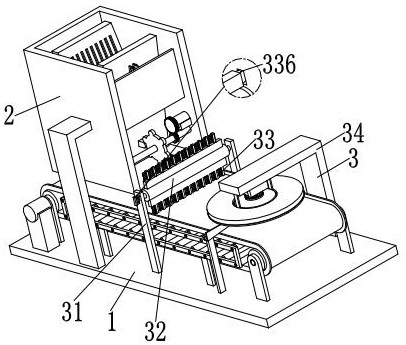

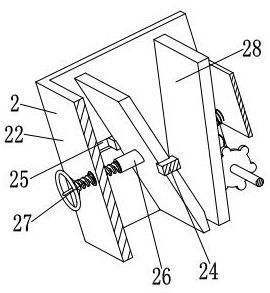

A high-strength film-coated sand core for sand casting, its manufacturing machinery and manufacturing process

ActiveCN111360202BDoes not compromise structural integrityRealize multiple useFoundry mouldsMould handling/dressing devicesProcess engineeringSand casting

The invention relates to a high-strength film-coated sand core for sand casting, a manufacturing machine and a manufacturing process. The core includes a core body, a core bone body, reinforcements, connectors and connecting bolts. A special The manufacturing machine includes a feeding mechanism, a crushing mechanism and a shell, and the feeding mechanism and the crushing mechanism are installed in the shell. The method for making the above-mentioned mold core by using the above-mentioned making machine includes the following steps: coated sand manufacturing, core box manufacturing Core, core trimming and core inspection. The present invention provides a high-strength film-coated sand core for sand casting. The various parts of the mandrel are connected in a detachable manner. After the mandrel is disassembled, the mandrel can be taken out from a narrow space without damage. The structural integrity of the core bone can be realized multiple times.

Owner:台州市通顺铸造有限公司

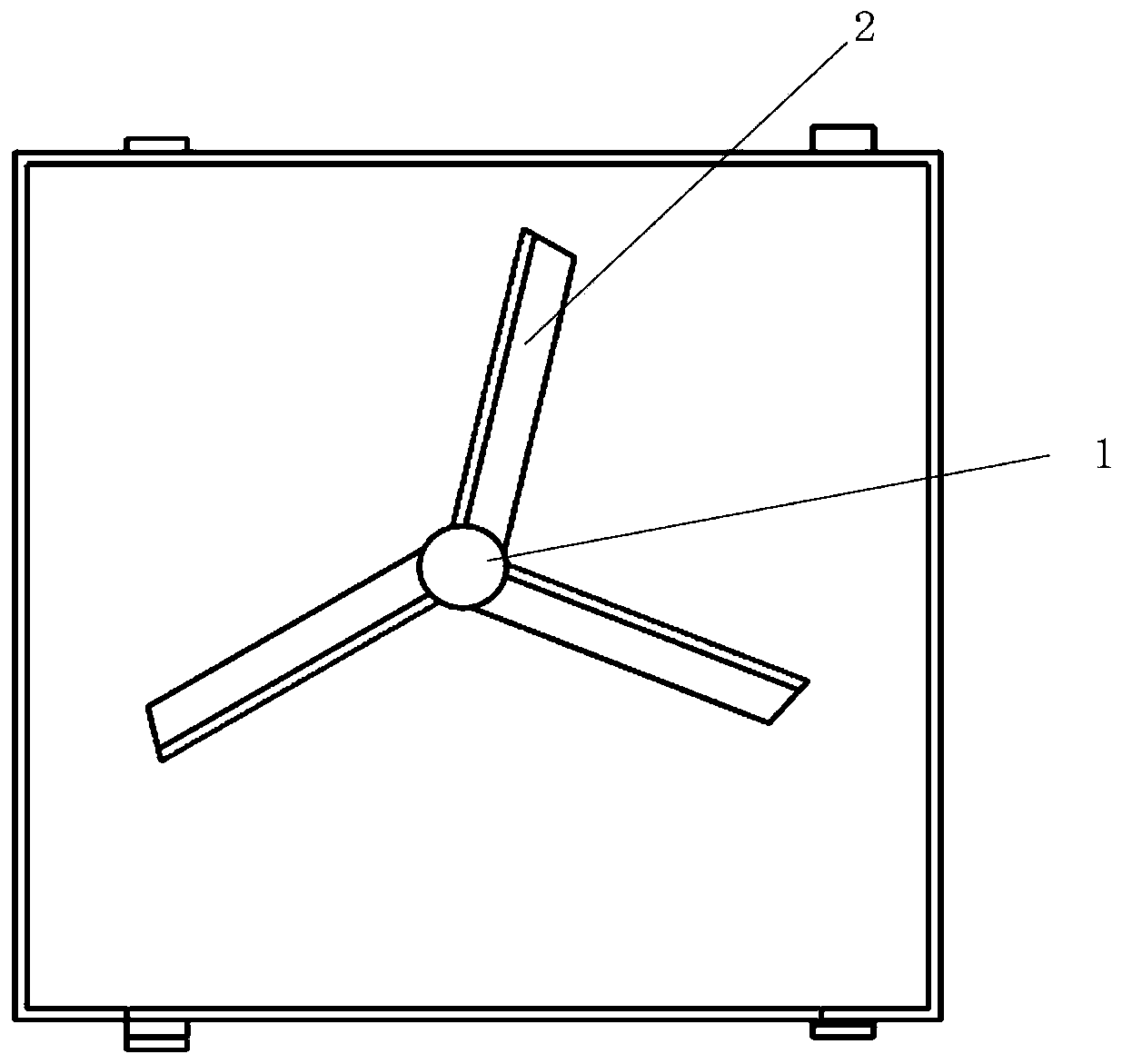

Bottle head rubbing machine for medical waste glass bottles

PendingCN112718792ABroken completelyFully separatedSolid waste disposalElectric machineryManual handling

The invention provides a bottle head rubbing machine for medical waste glass bottles. The bottle head rubbing machine comprises a bracket, a case and a rubbing assembly; the rubbing assembly comprises a rotating shaft rotationally installed in the middle of the case, a sleeve connected to the rotating shaft through a key, a plurality of wing plates evenly and fixedly connected to the sleeve and an arc-shaped sieve plate arranged below the rotating shaft and coaxial with the rotating shaft; the other end of the rotating shaft is in transmission connection with a motor; the motor is installed on the support; the linear edge of the sieve plate is fixedly connected to the inner wall of the case; a gap is formed between the upper surface of the sieve plate and the rotating circumferential surface of the tail end of the wing plate and is smaller than the diameter of the waste bottle head; through grooves which are parallel to the center axis of the rotating shaft and prevent the bottle head from falling off are evenly formed in the sieve plate; and a through cavity is formed between the arc-shaped edge of one side of the sieve plate and the case. The technical effects that the bottle heads are rubbed and crushed more completely; separation is more sufficient; the recycling rate of the bottle heads is increased; environmental sanitation is improved; harm is reduced; and potential safety hazards of manual operation are eliminated are achieved.

Owner:湖北宜昌红源科技有限公司

Fiber plastic section tray and preparation method thereof

PendingCN113861714AAchieve reuseGood mechanical propertiesFibre cleaning/openingFiberWeather resistance

The invention discloses a fiber plastic section tray and a preparation method thereof, and belongs to the technical field of composite materials. According to the fiber plastic section tray provided by the invention, a fiber plastic composite material prepared from waste textile fabrics and waste plastics is taken as a raw material; and compared with an existing wood tray and a common plastic tray (PP or HDPE), the fiber plastic section tray provided by the invention is positioned between a wood support and a plastic support, and the fiber plastic section tray is most obvious in cost performance, large in loading load (static load of 3T and dynamic load of 1.5 T), good in water resistance and weather resistance, anti-falling and anti-damage, long in service life, free of fumigation, convenient for commodity import and export, strong in nail-holding power, easy to cut, disassemble, assemble, locally replace and maintain, and capable of being customized as required.

Owner:上海纤苏新材料科技有限公司

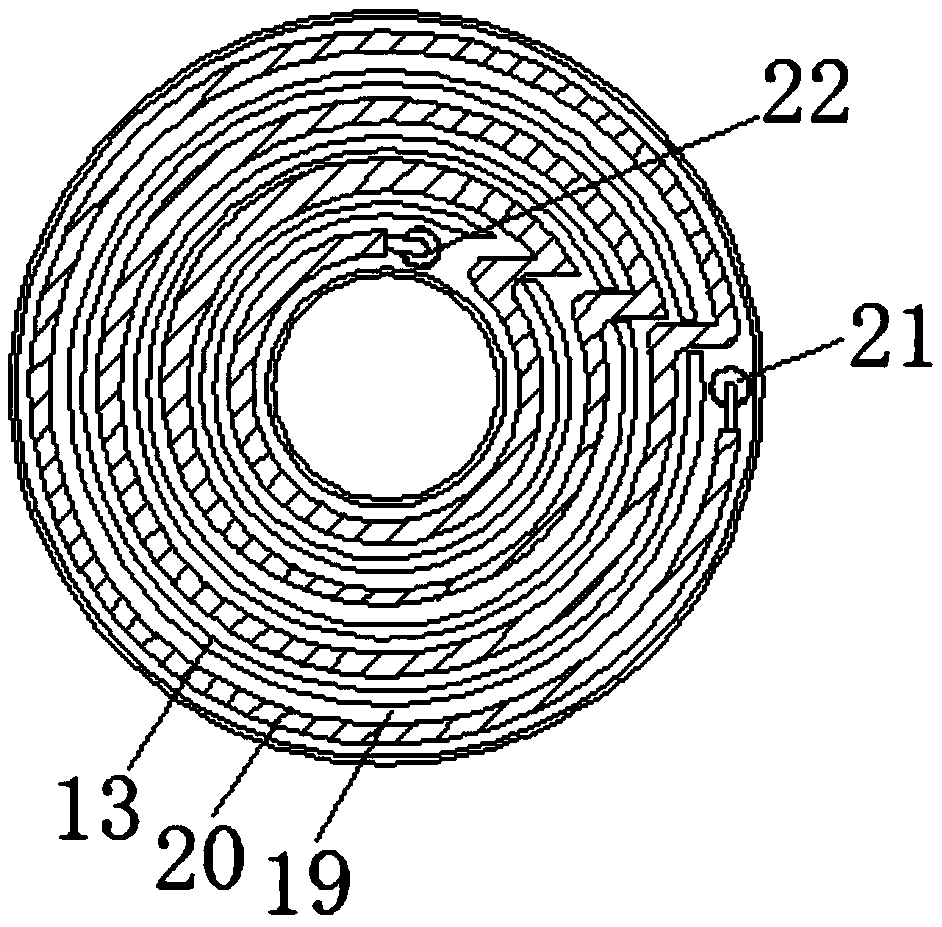

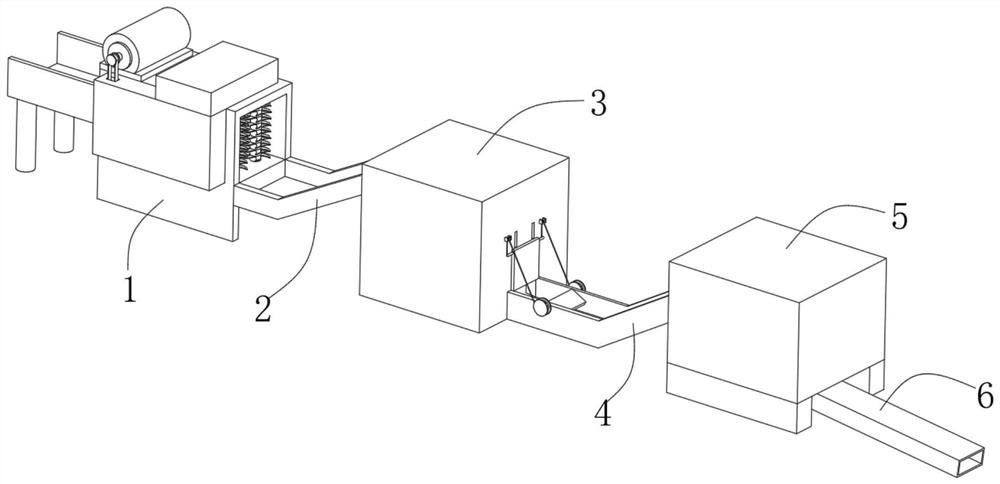

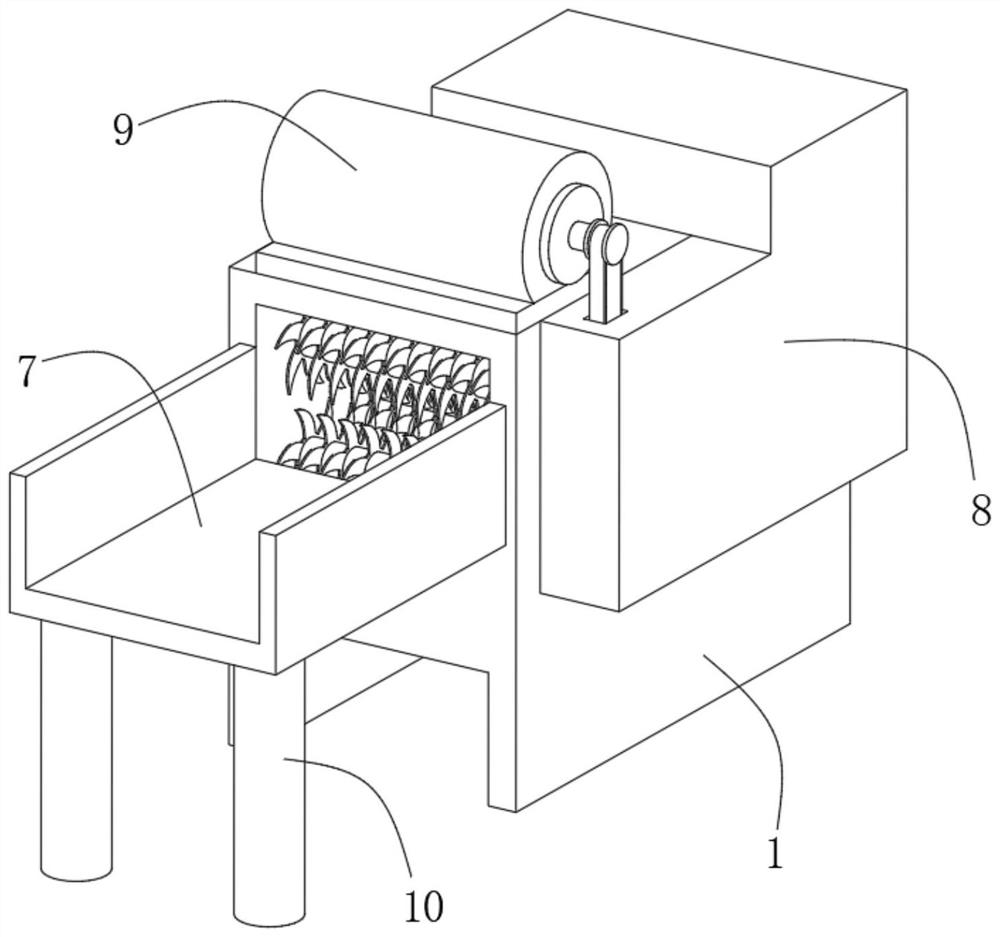

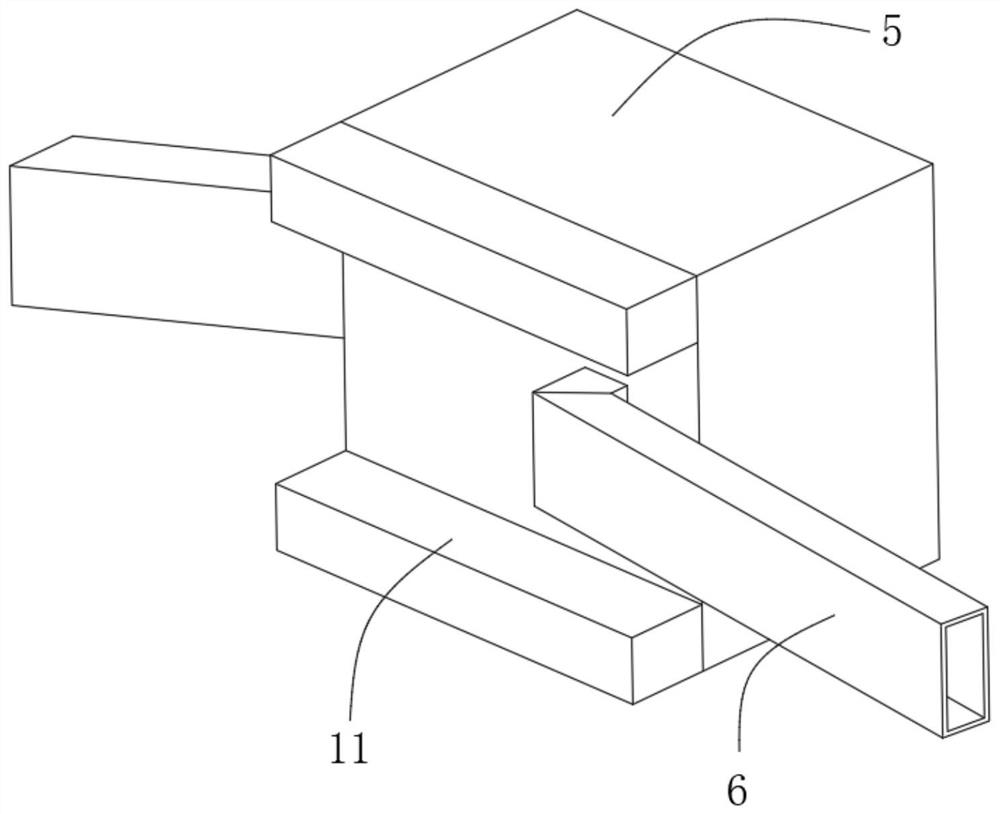

Sand-cast high-strength precoated sand core, manufacturing machine and manufacturing technology

ActiveCN111360202ADoes not compromise structural integrityRealize multiple useFoundry mouldsMould handling/dressing devicesManufacturing technologyCrusher

The invention relates to a sand-cast high-strength precoated sand core, a manufacturing machine and a manufacturing technology. The core comprises a core body, a core bar main body, a reinforcer, a connector and a connection bolt; in the core manufacturing process, the special manufacturing machine needs to be used and comprises a feeding mechanism, a crushing mechanism and a shell body, and the feeding mechanism and the crushing mechanism are installed in the shell body; and the method for manufacturing the core by using the manufacturing machine comprises the following steps of precoated sand manufacturing, core box core manufacturing, core dressing and core inspecting. According to the sand-cast high-strength precoated sand core provided by the invention, parts of the core bar are detachably connected, the core bar can be taken out from a narrow space after being disassembled, the structural integrity of the core bar cannot be broken, and thus, repeated use of the core bar can be achieved.

Owner:台州市通顺铸造有限公司

Carbon nanotube manufacturing automatic processing machine and processing method

PendingCN113019663AAvoid incomplete fragmentationImprove crushing effectGrain treatmentsCarbon nanotubeEngineering

The invention relates to a carbon nanotube manufacturing automatic processing machine and a processing method. The machine comprises a placing plate, a winnowing device, a crushing device and a collecting frame, the winnowing device is installed at the upper end of the placing plate, the crushing device is installed at the upper end of the winnowing device, and the collecting frame is arranged below the winnowing device; and the collecting frame is connected with the placing plate in a sliding fit manner. The machine can solve the problems that when existing equipment crushes and disperses clustered carbon nanotubes, the clustered carbon nanotubes cannot be crushed in a multi-stage manner, incomplete crushing is prone to occurring after the carbon nanotubes are crushed, the carbon nanotube crushing effect is reduced, meanwhile, the carbon nanotubes adhering to the interior of the equipment cannot be separated, separation of the carbon nanotubes is not facilitated, the carbon nanotubes in the equipment cannot be completely removed, the carbon nanotubes are prone to being wasted, and the processing cost is increased.

Owner:程用房

Pretreatment device before production and processing of biofuel

PendingCN114522781AAvoid Fragmentation IncompleteLow costBiofuelsWaste based fuelGear driveAgricultural engineering

The invention discloses a pretreatment device before biofuel production and processing, and relates to the field of biofuel processing. According to the pretreatment device before biofuel production and processing, the front end of a wood crushing bin is fixedly connected with a feeding hopper, the tail end of the wood crushing bin is fixedly connected with a first conveying belt, the end, away from the wood crushing bin, of the first conveying belt is fixedly connected with a storage bin, and the side, away from the first conveying belt, of the storage bin is fixedly connected with a second conveying belt; the end, away from the storage bin, of the second conveying belt is fixedly connected with a wood crushing bin, the lower surface of the wood crushing bin is fixedly connected with a drying pipeline, and the top of the wood crushing bin is connected with a servo motor. According to the pretreatment device before biofuel production and processing, a servo motor drives four groups of transverse crushing rollers to rotate through a first driving assembly, and meanwhile, a fourth gear drives a second transmission assembly through a first bevel gear to drive a longitudinal crushing roller to rotate, so that incomplete wood crushing is avoided, and meanwhile, the wood crushing cost is reduced.

Owner:白 洁

A method for crushing stones used in building or road construction

ActiveCN112774774BPrevent splashGuaranteed to be completely brokenGrain treatmentsHydraulic cylinderArchitectural engineering

Owner:上海闸航路基材料有限公司

A lead-acid battery crushing and sorting device and sorting method

ActiveCN112058373BImprove qualityImprove transmission efficiencyDirt cleaningWaste accumulators reclaimingElectrical batteryStructural engineering

The invention discloses a lead-acid battery crushing and sorting device and a sorting method, including a conveying mechanism, a cleaning mechanism is arranged on the top of the conveying mechanism, and a moving mechanism is installed on one side of the cleaning mechanism and located on the top of the conveying mechanism. A crushing mechanism is arranged on one side of the conveying mechanism and directly below one end of the moving mechanism, and a sorting mechanism is arranged on one side of the crushing mechanism. The crushing mechanism includes a first installation platform, and a crusher is placed on the first installation platform. Shell, the top of the crusher shell is covered with a cover plate, an installation groove is opened in the middle of the top of the cover plate, a feed inlet is fixedly installed in the installation groove, and two second cylinders are fixedly installed on both sides of the top of the cover plate; After adopting the above structure, the lead-acid battery shredding and sorting device can fully shred waste lead-acid batteries, and at the same time, can also conveniently sort crushed materials of different materials.

Owner:太和县大华能源科技有限公司

A kind of RNA extraction method

ActiveCN109609502BEliminate cleaning operationsEasy to operateDNA preparationCell extractionRNA extraction

The invention discloses an RNA extraction method. The RNA extraction method comprises the following specific steps of (1) preserving tissues or cells with an extracting solution A, then adding an extracting solution B to the tissues or cells preserved in the extracting solution A, and performing uniform mixing so as to obtain a mixture; (2) when RNA is extracted from tissues, performing ultrasonicbreaking on the mixture; (3) when RNA is extracted from the cells, directly performing operations in the step (5); (4) reversing the mixture after ultrasonic breaking to achieve a uniform mixing state; (5) adding chloroform to the mixture obtained through extracting the RNA from the cells in the step (3) or the mixture obtained in the step (4), performing centrifugation, and taking upper-layer liquid; (6) adding isopropyl alcohol to the upper-layer liquid, and then performing centrifugation so as to obtain precipitate; (7) adding an ethanol solution to the precipitate, performing uniform mixing, performing centrifugation, and discarding liquid; and (8) finally adding water for dissolving. The method is high in rate, incomplete tissue breaking and interference of endogenous RNA enzymes areavoided, the extraction time is greatly shortened, and the extraction efficiency of the RNA is further improved.

Owner:CHENGDU DAOSHENG BIOTECH CO LTD

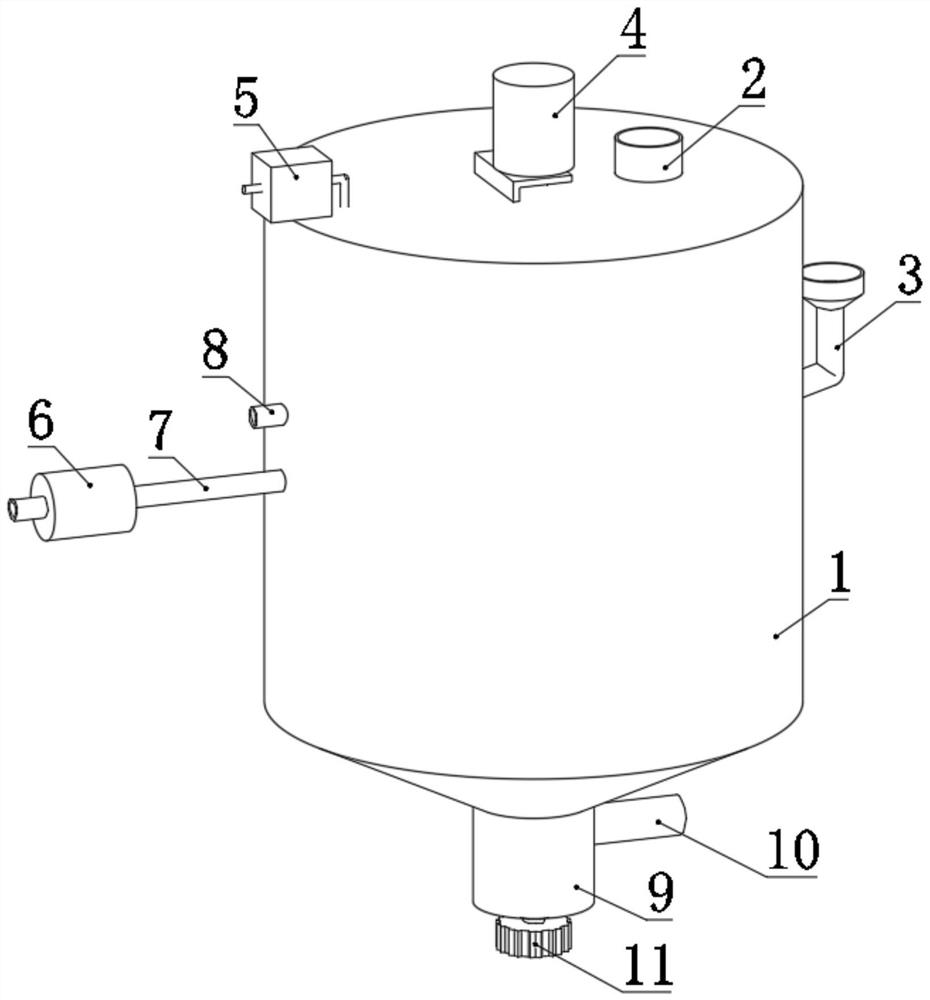

Purification device and purification method for preparing black wolfberry anthocyanin freeze-dried powder

ActiveCN113908944BAdjust feed volumeImprove crushing efficiencyGrain treatmentsPurification methodsElectric machinery

The invention relates to a purification device and a purification method for preparing black wolfberry anthocyanin freeze-dried powder, belonging to the field of anthocyanin purification equipment. It includes a crushing barrel, a motor, a reamer, a control device, two feeding devices, a cover and a filter screen; the inside of the crushing barrel is provided with a motor, and the output shaft of the motor is provided with a reamer; the control device is set on the crushing barrel The upper end and both sides of the control device are provided with a feeding device; the side of the crushing barrel is provided with a discharge channel, the outer end of the discharge channel is threadedly connected with a cover, and a filter screen is fixedly connected inside the discharge channel. The invention can not only adjust the size of the inner space of the crushing barrel according to the amount of crushed materials, improve the crushing efficiency, and avoid the large inner space of the crushing barrel when the raw materials are less, resulting in incomplete crushing; at the same time, the invention can also automatically feed materials, and can The current space size of the crushing barrel adjusts the feeding volume of raw materials.

Owner:北京熊猫健康管理有限公司 +1

A raw material screening and processing equipment for refractory brick production

ActiveCN113399023BQuality improvementAvoid Fragmentation IncompleteMagnetic separationGrain treatmentsFire brickProcess engineering

The invention relates to the technical field of raw material screening, in particular to a raw material screening treatment equipment for refractory brick production, including a base, a crushing device and a screening device. The upper end of the base is provided with a crushing device on the left side, and the upper end of the base is provided with Screening device. The invention can solve the problem that light grass clippings are often neglected when the raw materials for making refractory bricks are sieved, and light grass clippings are soft and difficult to sieve out, and mixed in raw materials often reduce the quality of refractory bricks; It needs to be crushed before screening, and the traditional crushing method cannot control the volume of the crushed soil, resulting in low applicability of crushing equipment. The screening machine designed by the present invention is especially designed to remove the light grass clippings remaining in the crushed raw material soil block, and at the same time avoids the omission problem that is easy to occur in the traditional crushing method, and can control the volume of the crushed soil block to achieve Improve the applicability of crushing equipment.

Owner:新沂新世纪高科耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com