Purification device and purification method for preparing black wolfberry anthocyanin freeze-dried powder

A technology of black wolfberry anthocyanin and purification device, which is applied in grain processing and other directions, can solve the problems affecting the crushing efficiency, the probability of raw materials colliding with each other, and the size of the interior space of the crushing barrel remains unchanged, so as to achieve the effect of improving the crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

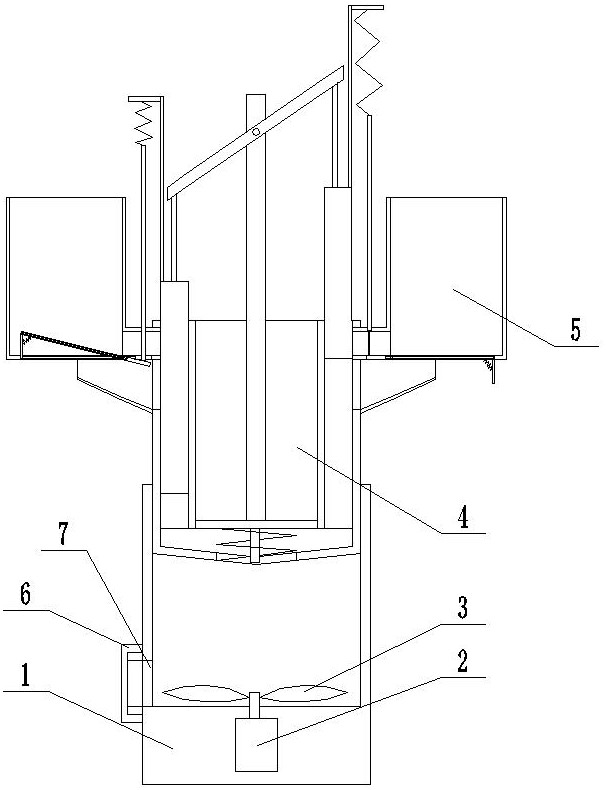

[0017] Specific implementation mode one: as Figure 1-3 As shown, this embodiment describes a purification device for the preparation of black wolfberry anthocyanin freeze-dried powder, including a crushing barrel 1, a motor 2, a reamer 3, a control device 4, two feeding devices 5, a cover 6 and a filter screen 7 ; The inside of the crushing barrel 1 is provided with a motor 2, and the output shaft of the motor 2 is provided with a reamer 3; the control device 4 is arranged at the upper end of the crushing barrel 1, and both sides of the control device 4 are provided with feeding devices 5; The side of the crushing barrel 1 is provided with a discharge channel, the outer end of the discharge channel is threadedly connected with a cover 6, and a filter screen 7 is fixedly connected to the inside of the discharge channel.

specific Embodiment approach 2

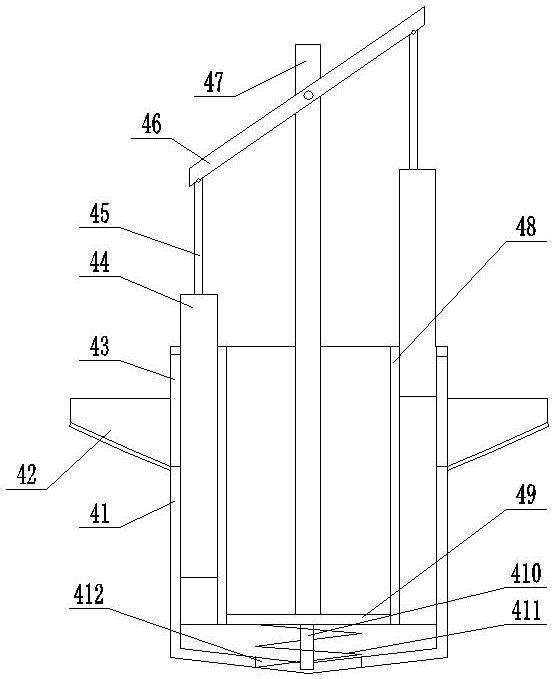

[0018] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of Embodiment 1. The control device 4 includes an outer cylinder 41, a chute 42, two rubber plugs 44, two connecting rods 45, a rotating rod 46, and a support rod 47. , two inner cylinders 48, base plate 49, center rod 410 and spiral plate 411; The side top of described outer cylinder 41 is provided with two openings 43 symmetrically, and the bottom end of outer cylinder 41 is set as taper, and the bottom of outer cylinder 41 The center of the end is provided with a through hole 412, and two chute 42 are fixedly connected to the side of the outer cylinder 41, and the chute 42 is located at the lower end of the opening 43; the two inner cylinders 48 are fixedly connected to the inside of the outer cylinder 41, and the inner cylinder 48 There is a gap between the bottom end and the bottom surface of the outer cylinder 41, and the bottom ends of the sides of the two inner cyli...

specific Embodiment approach 3

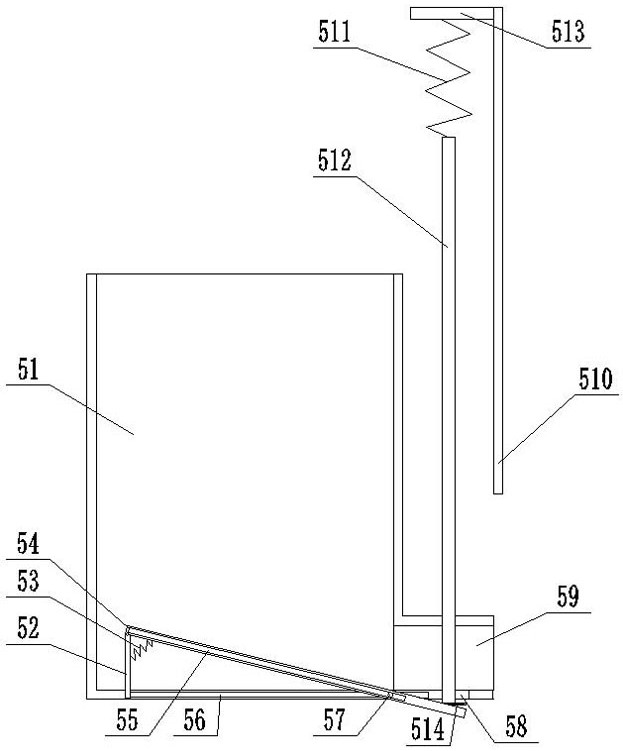

[0019] Specific implementation mode three: as image 3 As shown, this embodiment is a further description of specific embodiment one. Each of the feeding devices 5 includes a storage tank 51, a movable baffle 52, a spring I 53, a movable plate 54, a movable round rod 57, a discharge Port 59, vertical rod 510, spring II 511, baffle plate 512 and horizontal plate 513; the bottom surface of the storage tank 51 is provided with a through groove 58, and the side wall of the through groove 58 is symmetrically provided with a slideway I56, and the slideway I56 runs through The bottom surface of the material storage tube 51; the movable plate 54 is slidingly matched with the through groove 58, the width of the movable plate 54 is equal to the width inside the material storage tube 51, and the side of the movable plate 54 is provided with a slideway II 55 that runs through the movable plate 54 The movable round rod 57 is interference fit with the slideway I56 and the slideway II55, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com