Medicine sampling device for medicine analysis

A sampling device and drug technology, applied in the direction of sampling device, sampling, measuring device, etc., can solve the problems of slow dissolution rate of solid drugs, time-consuming and labor-intensive operation, non-use, etc., so as to facilitate re-use, improve crushing efficiency, and facilitate cleaning and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

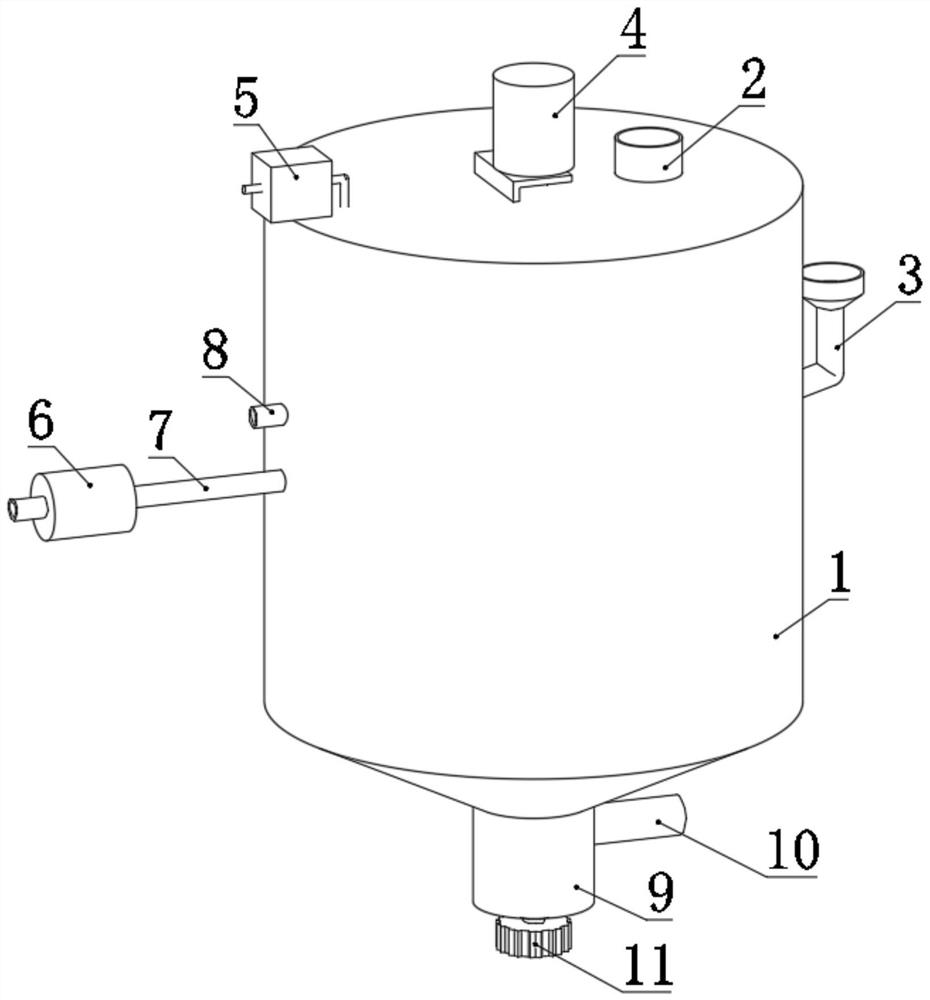

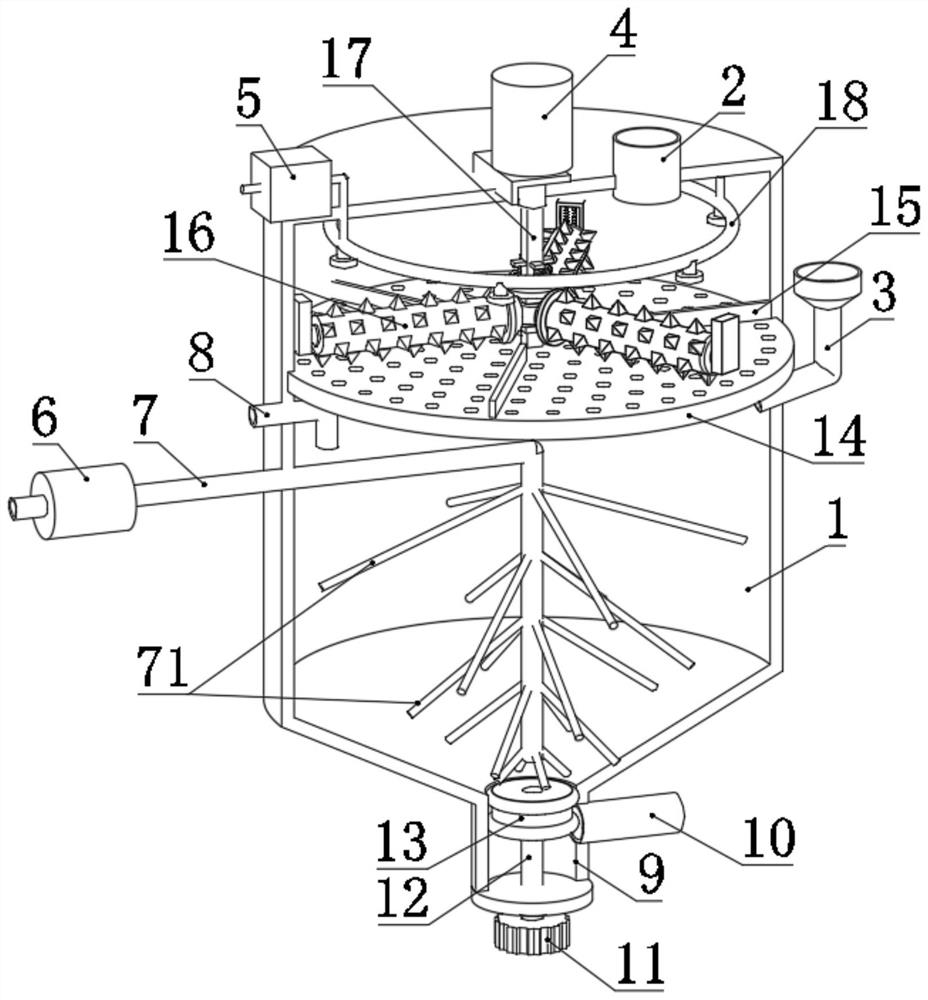

[0046] refer to Figure 1-9 , a drug sampling device for drug analysis, comprising a tank body 1, a delivery tube 2 is installed on the top of the tank body 1, and solid drugs are dropped into the tank body 1 through the delivery tube 2. The bottom of the tank body 1 is bucket-shaped and is equipped with a piston tube 9, a liquid discharge tube 10 is installed on one side of the upper end of the piston tube 9, and a piston mechanism is arranged inside the piston tube 9;

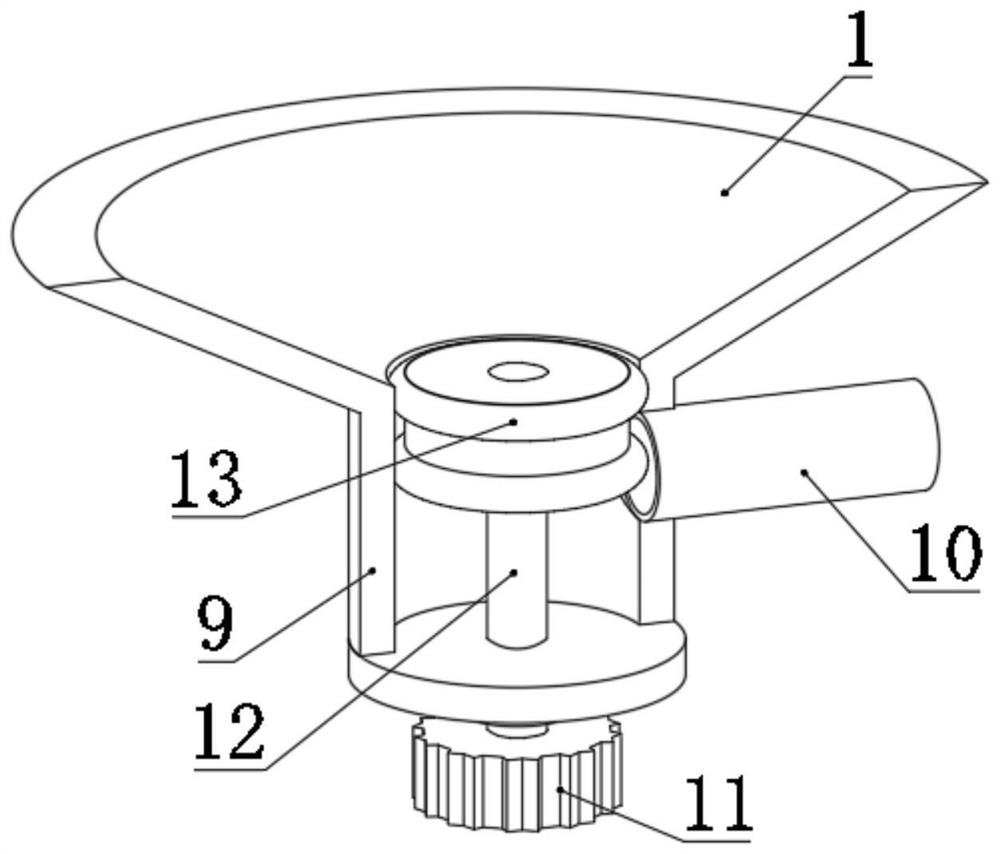

[0047] The piston mechanism includes a piston 13 slidably arranged inside the piston tube 9 , and a rubber sealing ring is fixedly installed on the outside of the piston 13 . The height of the piston 13 is less than the distance between the lower edge of the drain pipe 10 and the inner bottom wall of the piston tube 9, and the vertical thread in the middle of the piston 13 is equipped with a screw rod 12, and the bottom end of the screw rod 12 extends to the bottom of the piston tube 9. The lower side is equip...

Embodiment 2

[0063] refer to Figure 10-12 In this second embodiment, on the basis of the first embodiment above, a heating mechanism 22 is installed on the aeration pipe 7. The heating mechanism 22 includes a heating pipe 221 communicated with the aeration pipe 7, and the heating pipe 221 is fixed on the aeration pipe 7. , and the heating pipe 221 is located outside the tank body 1, and a heating wire 222 is installed in the heating pipe 221.

[0064] After the device is cleaned, the aeration mechanism continues to deliver the airflow into the tank body 1, and cooperates with the heating of the heating wire 222, so that the temperature of the airflow flowing through the heating pipe 221 is increased to form a hot airflow, and the hot airflow enters the inside of the tank body 1. Water stains inside dry quickly. The air flow is finally discharged from the exhaust pipe 8 . Through the rapid drying of the tank body 1, it is convenient for the device to be put into use quickly again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com