Pretreatment device before production and processing of biofuel

A pretreatment device and biofuel technology, which is applied in the fields of biofuel, grain treatment, waste fuel, etc., can solve the problems of incomplete crushing, low production cost, easy clogging of raw materials and crushing equipment, etc., and achieve the effect of reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

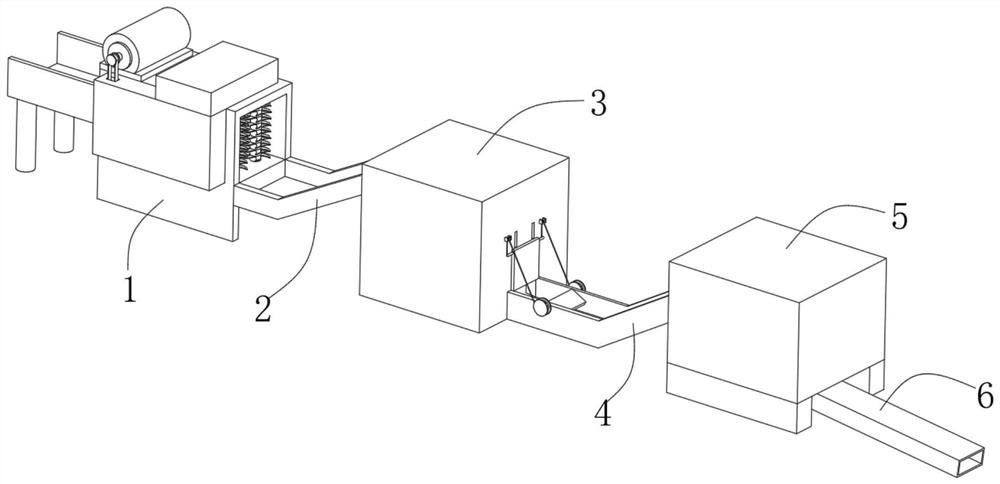

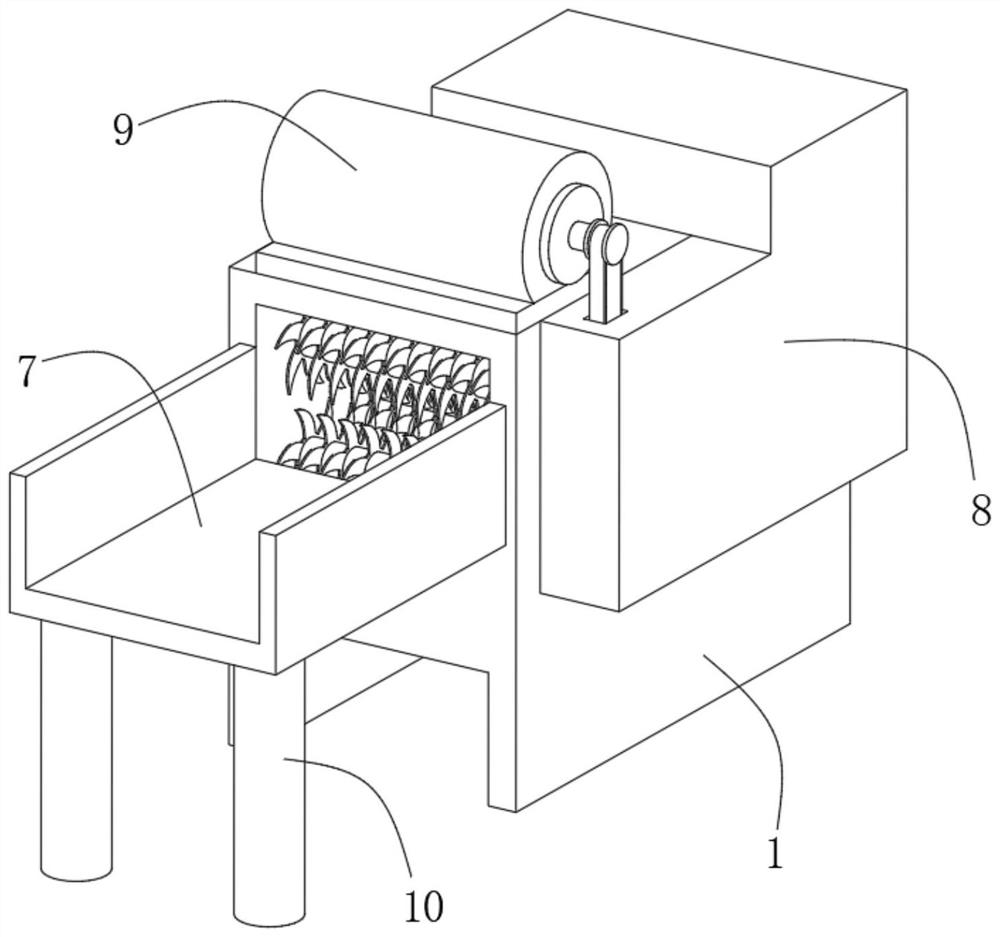

[0030] as Figure 1-7A biofuel production pretreatment apparatus shown, comprising a wood crushing silo 1, the front end of the timber crushing bin 1 is fixedly connected to the feed hopper 7, the end of the timber crushing bin 1 is fixedly connected to the first conveyor belt 2, the first conveyor belt 2 is away from the wood crushing bin 1 is fixedly connected to the storage silo 3, the storage silo 3 is fixed from the side of the first conveyor belt 2 is fixed to the second conveyor belt 4, the second conveyor belt 4 is fixed from the end of the storage silo 3 is fixedly connected to the wood crushing bin 5, The lower surface of the wood crushing bin 5 is fixed connected to the drying pipe 6, the top fixed connection of the wood crushing bin 1 is connected to the servo motor 9, the output end of the servo motor 9 is provided with a first belt 18, the outer surface of the wood crushing bin 1 is fixed connected to the protective shell 8, the interior of the wood crushing bin 1 and...

Embodiment 2

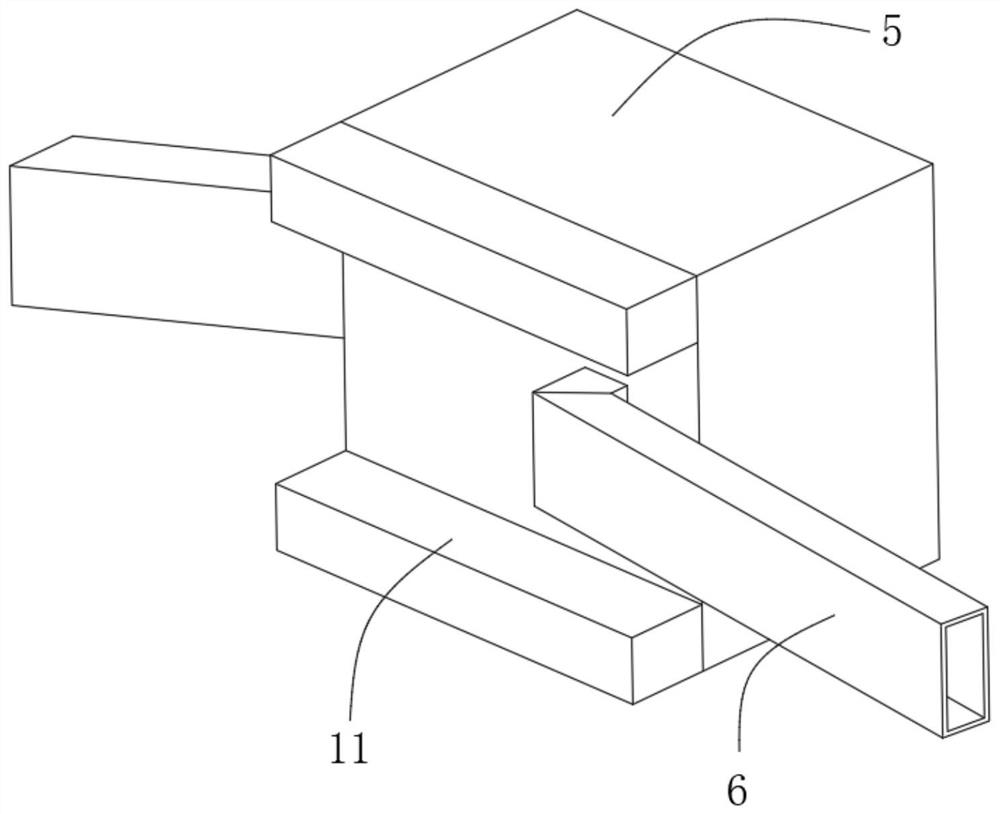

[0034] as Figure 1-7A kind of biofuel production and processing pretreatment apparatus shown, storage silo 3 near the top of the first conveyor belt 2 is opened with an inlet, the inner bottom of the storage silo 3 is provided with a tilting plate 22, the inclined plate 22 is tilted downward from one end of the first conveyor belt 2, the lower surface of the feed hopper 7 is fixedly connected with a support rod 10, the front side of the wood crushing bin 12 is opened with an inlet 12, the lower surface of the wood crushing bin 5 is fixedly connected to the support seat 11, and the outer surface of the storage silo 3 near the second conveyor belt 4 is opened with a chute 24, The outer surface of the discharge baffle 26 is fixed to be connected to the slider 27, the slider 27 slide is connected to the inside of the chute 24, the outer surface of the storage silo 3 and located on the side of the two sets of chutes 24 are fixed connected to the fixed pulley 30, the top of the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com