Bottle head rubbing machine for medical waste glass bottles

A glass bottle and case technology, applied in the direction of solid waste removal, etc., can solve the problems of low recycling rate, insufficient separation, incomplete crushing, etc., and achieve the effect of reducing harm, improving recycling rate, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

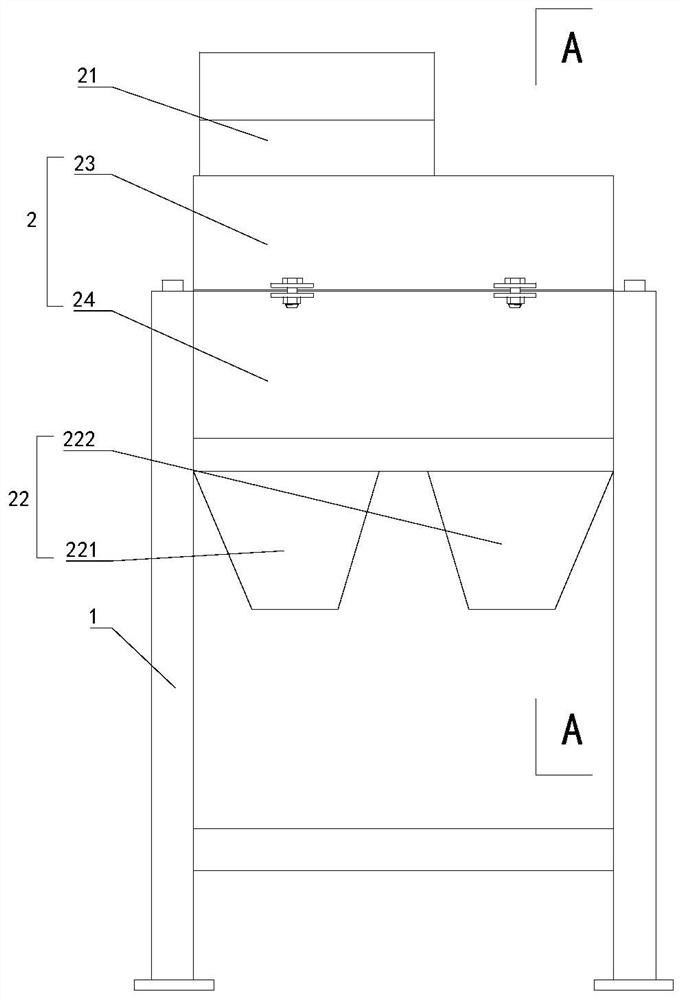

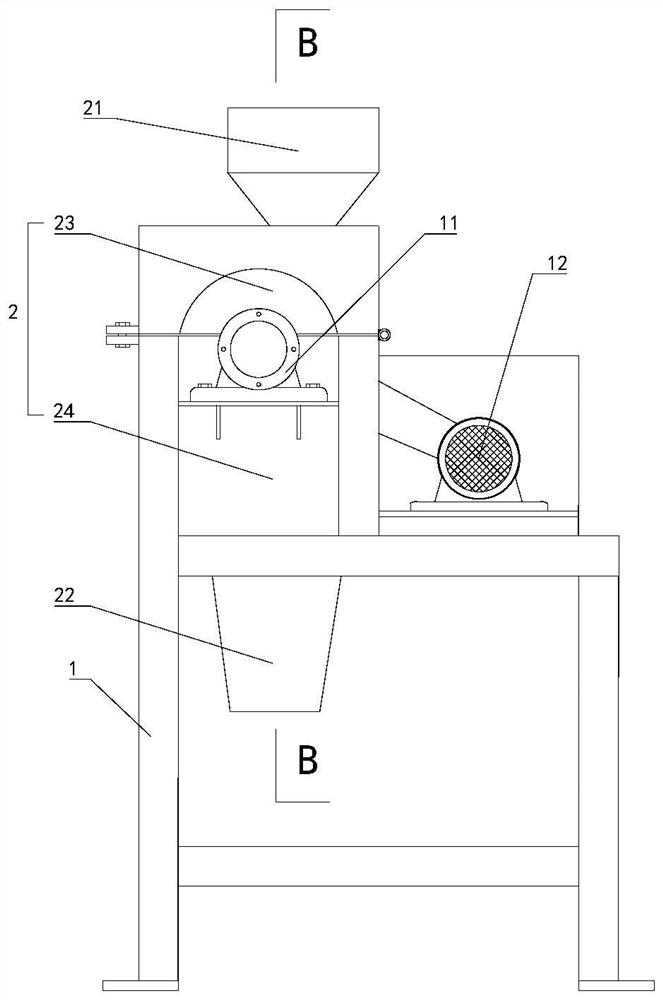

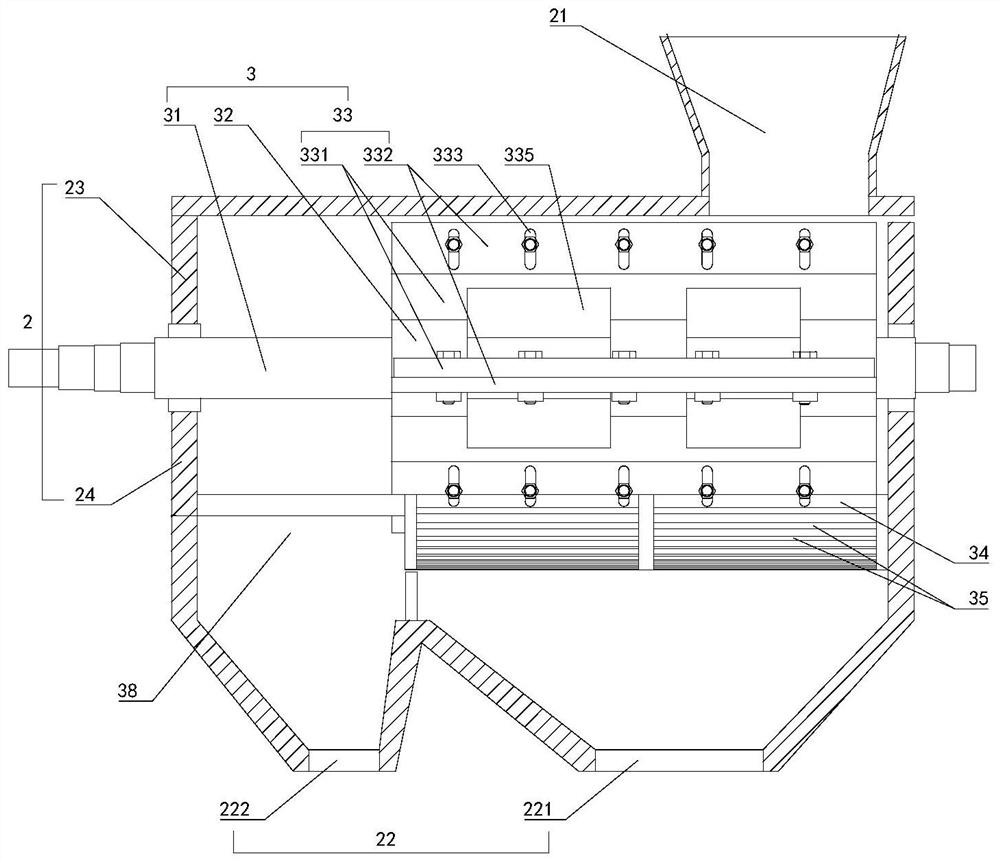

[0013] as attached figure 1 ~ attached Figure 4 As shown, the embodiment of the present invention proposes a bottle head rubbing machine for medical waste glass bottles, including a bracket 1, a chassis 2 fixedly installed on the bracket 1, and a rubbing assembly 3, and the upper part of the chassis 2 is provided with a feeding port 21. The lower part of the cabinet 2 is provided with a discharge port 22. The kneading assembly 3 includes a rotating shaft 31 installed in the middle of the cabinet 2 through bearing rotation, a sleeve 32 keyed to the rotating shaft 31, and evenly and fixedly connected to the sleeve. Several wing plates 33 on 32 and an arc-shaped sieve plate 34 arranged below the rotating shaft 31 and coaxial with the rotating shaft 31, one end of the rotating shaft 31 is rotatably mounted on the bearing housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com