Spiral cleaning machine for small potatoes

A potato cleaning technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of economic loss, low efficiency of manual sorting of small-sized potatoes, etc., and achieve the effect of increasing income, simple structure and sufficient separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

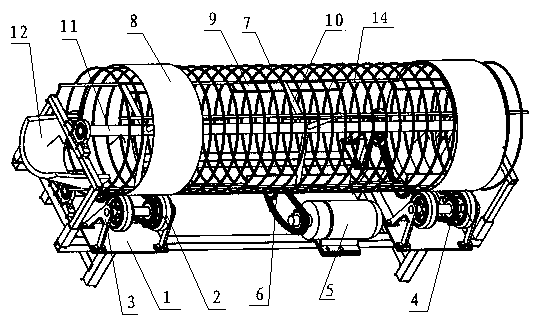

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

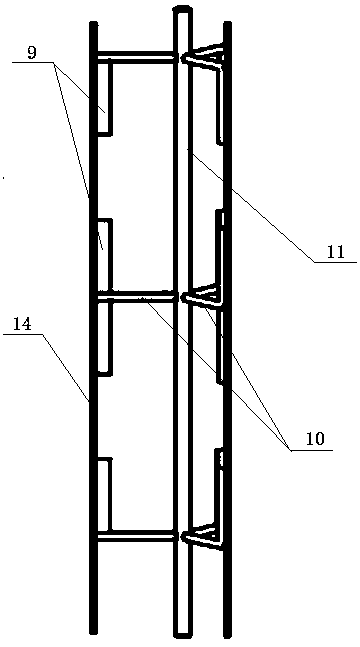

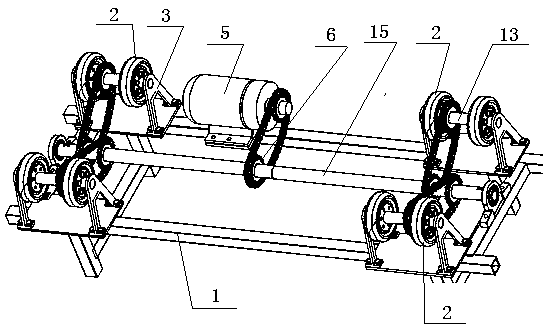

[0019] Such as figure 1 As shown, this small potato spiral cleaning machine comprises a frame 1, a spiral cleaning cage 7, a friction wheel 2, a sleeve 8, a transmission mechanism, an electric motor 5, and an anti-deformation device. frame, the spiral cleaning cage body 7 is located on the frame 1, and the inlet end of the spiral cleaning cage body 7 is provided with a feed funnel 12; the spiral cleaning cage body 7 is a cylindrical cage body formed by a helix, and the helical wire The spacing is 25mm, and the small potatoes with a diameter between 25mm and 35mm among the missed potatoes are harvested; a sleeve 8 is fixed at both ends of the spiral cleaning cage 7, and each sleeve 8 is rolled with its corresponding friction wheel 2 The contact is driven to rotate by the friction wheel 2, and the friction wheel 2 is driven to run by the motor 5 through the transmission mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com