Casting magnetic sheet magnetic powder orientation device and preparation method of wave-absorbing magnetic sheet

A magnetic sheet and magnetic powder technology, which is applied in the preparation of wave-absorbing magnetic sheets, and in the field of cast magnetic sheet magnetic powder orientation devices, can solve the problems of limited magnetic powder effect, large device, and low magnetic field intensity in the orientation magnetic field area, achieving high magnetic field strength, Small magnetic flux leakage and improved uniform orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the wave-absorbing magnetic sheet based on the cast magnetic sheet magnetic powder orientation device comprises the following steps:

[0048] Step S1 , preparing a mixed slurry, coating the mixed slurry on a base film made of non-magnetic material and putting it into a casting machine. The base film can be made of, but not limited to, polymer materials and metal materials, such as PET, stainless steel, etc., preferably a PET film.

[0049] Wherein, when preparing the mixed slurry, polyurethane, flaky sendust magnetic powder and absolute ethanol may be mixed together to form the mixed slurry. Of course, the binder in the mixed slurry is not limited to polyurethane, and can also be liquid rubber, phenolic resin, etc., and the solvent is not limited to absolute ethanol, but can also be ethyl acetate, etc.

[0050] Step S2, the scraper moves along the set direction, so that the mixed slurry forms a casting film 4 on the base film.

[0051] Step S...

Embodiment 1

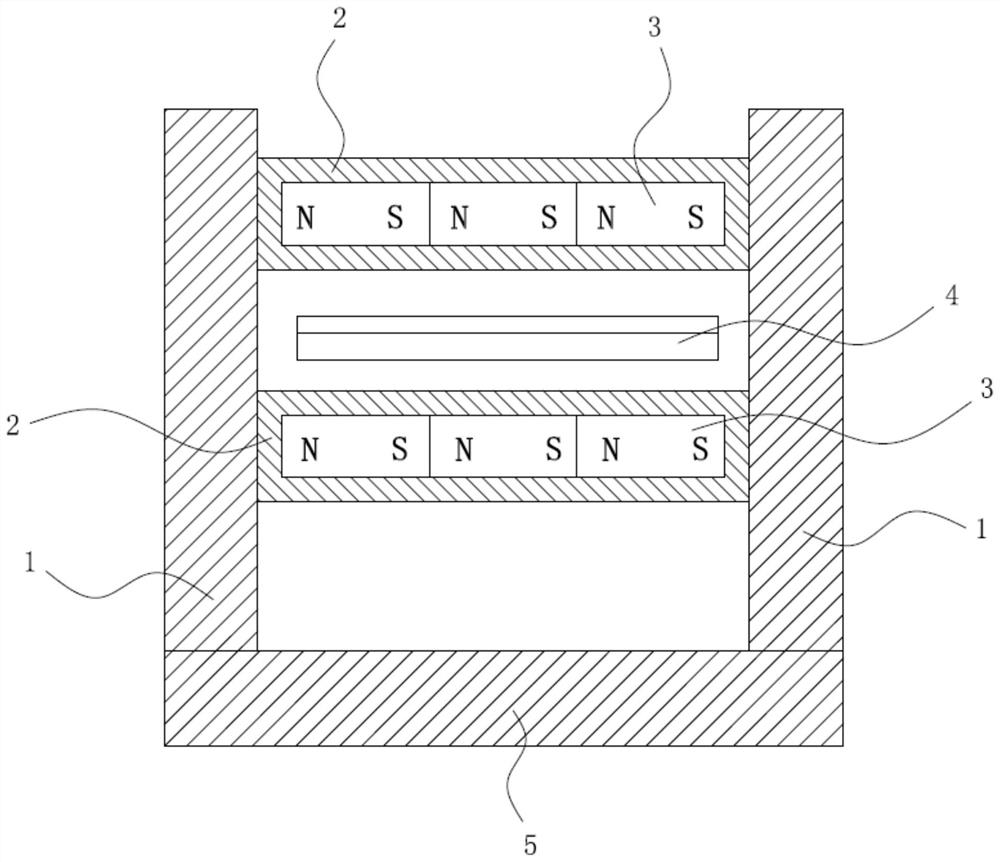

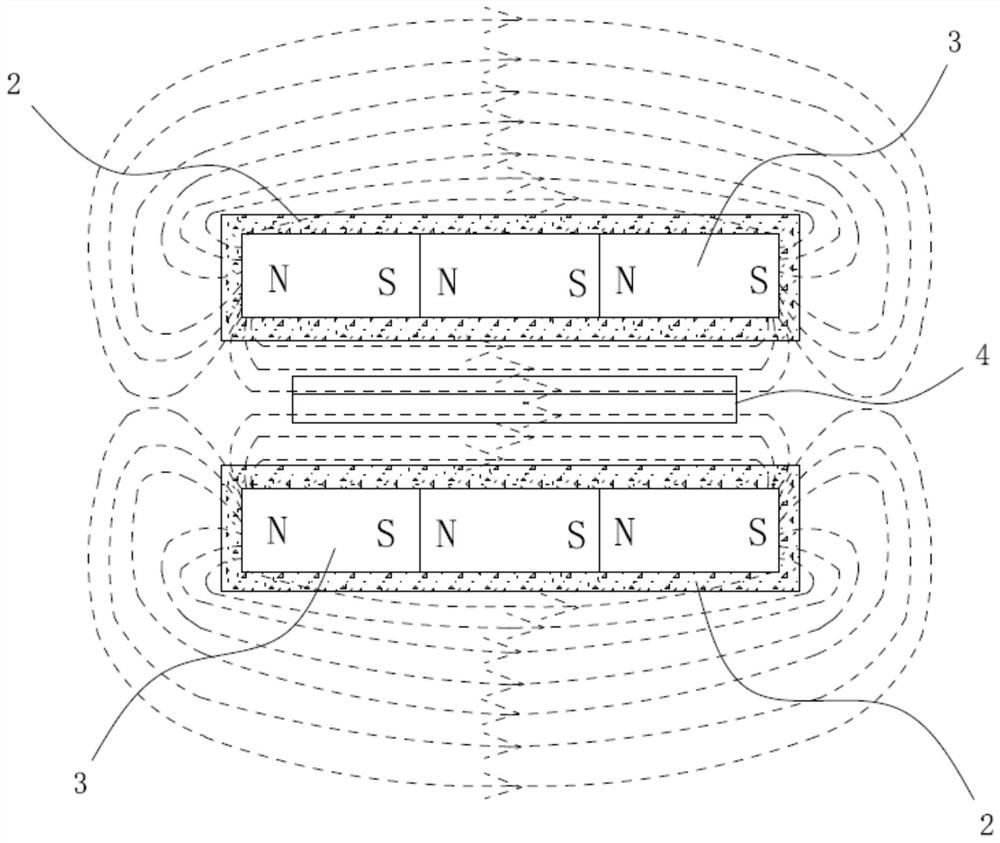

[0056] The distance between the axes of the two permanent magnet modules 3 is 70mm, and each permanent magnet module 3 is composed of six cylindrical magnets with a diameter of 30mm and a length of 100mm; The gap between two adjacent magnets is less than 0.03mm.

[0057] The sleeve 2 is made of stainless steel, the wall thickness of the sleeve 2 is 3.5mm, and the length is 660mm. The permanent magnet module 3 and the sleeve 2 are bonded with epoxy resin; the bracket 1 and the base 5 are made of stainless steel, the sleeve 2 and the bracket 1 are connected by bolts made of non-magnetic materials, and the bracket 1 and base 5 are welded together.

[0058] Gauss meter was used to measure the magnetic field intensity in the orientation magnetic field area, and the magnetic field intensity at 10 different positions were recorded respectively, and the magnetic field intensity in the orientation magnetic field area was 1365Gs-1391Gs.

[0059] The mixed slurry composed of polyuretha...

Embodiment 2

[0063] Used device is basically the same as embodiment one, and difference is: the distance between the axes of two permanent magnet modules 3 is 74mm, and each permanent magnet module 3 is made of six diameters and is 30mm, and length is the cylindrical magnet of 80mm Composition; The material of the cylindrical magnet is sintered NdFeB magnet, the grade is N48.

[0064] The sleeve 2 is made of polytetrafluoroethylene, the wall thickness of the sleeve 2 is 4mm, and the length is 520mm. The pipe sleeve 2 and the bracket 1 are bonded with epoxy resin.

[0065] Gauss meter was used to measure the magnetic field intensity in the orientation magnetic field area, and the magnetic field intensity in 10 different positions were recorded respectively, and the magnetic field intensity in the orientation magnetic field area was 1526Gs-1551Gs. The processing steps are the same as in Example 1, and the obtained wave-absorbing magnetic sheet is tested by an impedance analyzer, and its mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com