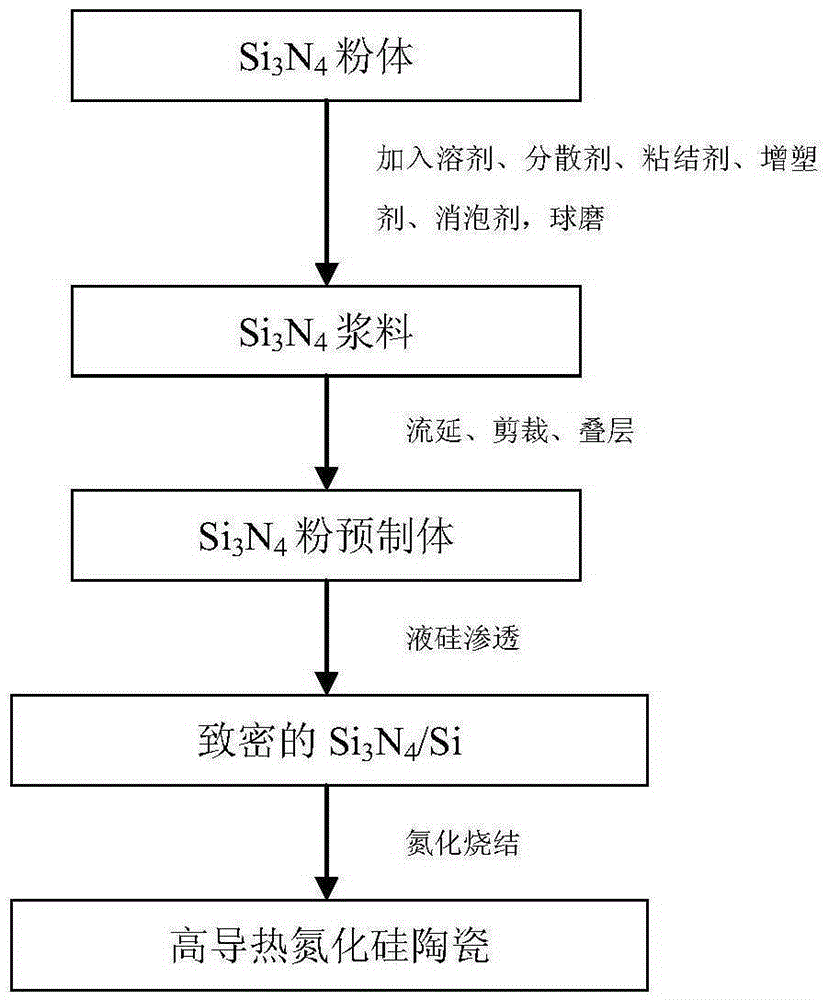

Method for preparing high-thermal-conductivity silicon nitride ceramics

A technology of silicon nitride ceramics with high thermal conductivity, applied in the field of functional ceramics, which can solve the problems of high sintering temperature, introduction of lattice oxygen atoms and equal grain boundaries, achieve low preparation temperature, achieve densification, and reduce the effect of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

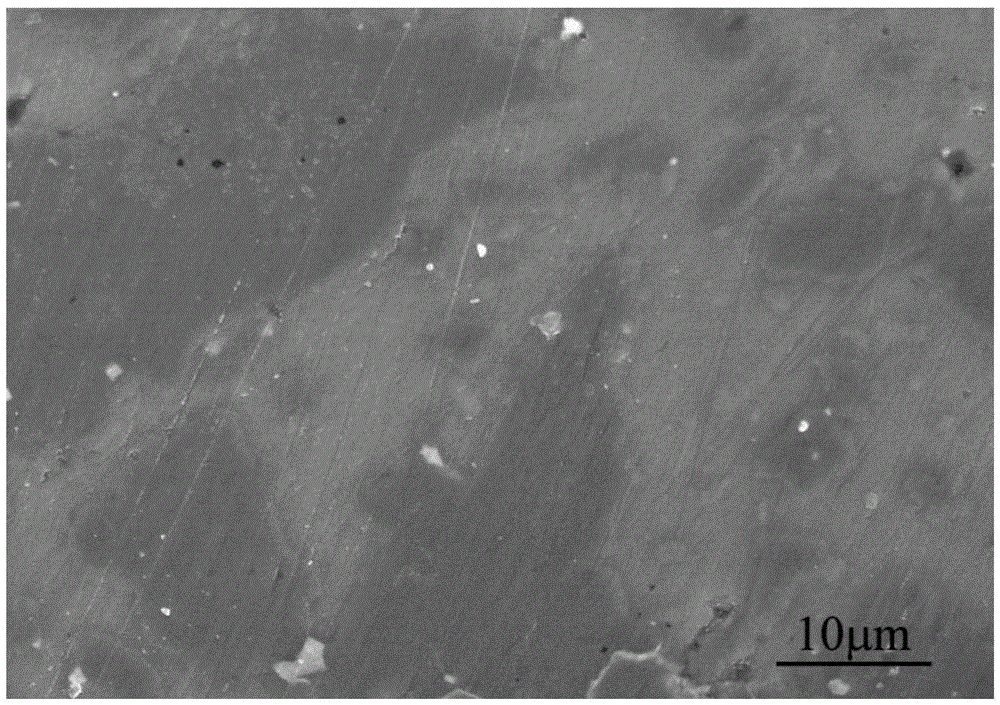

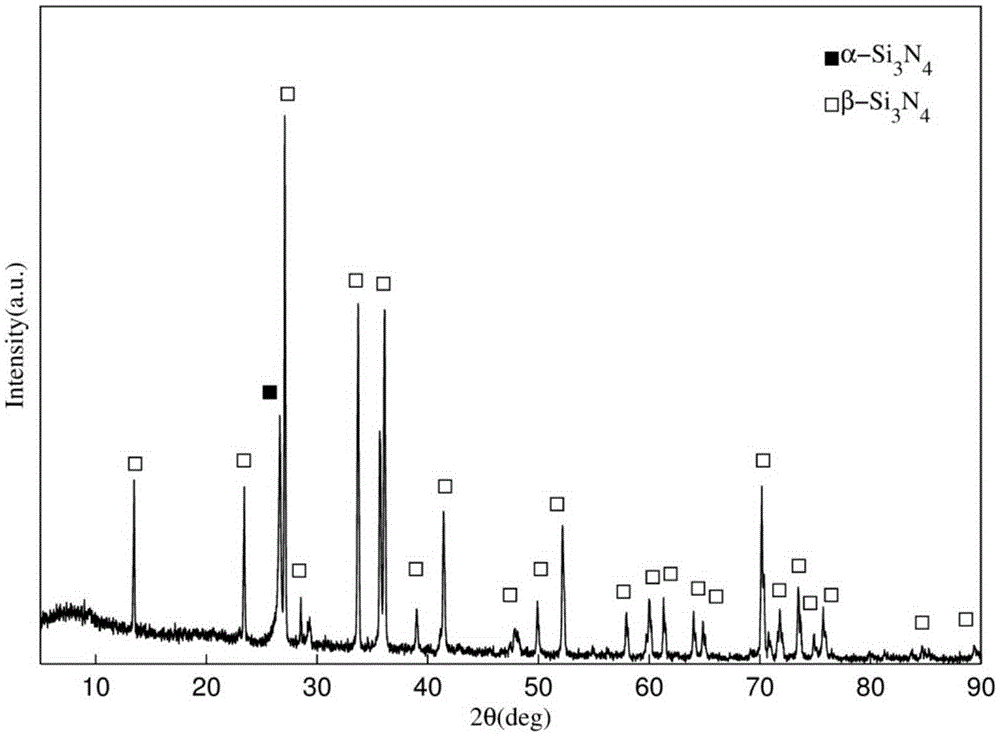

[0028] Example 1: Select β-Si with a particle size of 1.2 μm 3 N 4 Powder, at 1800°C, 0.3MPaN 2 Heat treatment under the atmosphere for 2 hours, and then treat the heat-treated Si with 5% HF acid 3 N 4 The powder was pickled for 6 hours and dried for later use. Weigh 50g of processed Si 3 N 4 Powder, add 50g solvent, the solvent is anhydrous ethanol and methyl ethyl ketone mixed in a volume ratio of 1:1, 4g dispersant triethyl phosphate, put into a nylon ball mill jar, then add silicon nitride balls, on the roller ball mill Ball milled for 12 hours; then add 5g of binder polyvinyl butyral, 5g of plasticizer in the ball mill tank, the plasticizer is glycerol and dioctyl phthalate mixed in volume ratio 1:1 and 4g of disinfectant Foaming agent, defoaming agent is n-butanol and ethylene glycol mixed by volume ratio 1:1; Continue ball milling for 12 hours, obtain Si 3 N 4 slurry. The slurry was cast to obtain a thickness of 0.4mm, Si 3 N 4 A thin layer with a volume frac...

example 2

[0029] Example 2: Select β-Si with a diameter of about 1 μm and an aspect ratio of about 5 3 N 4 Columnar crystal, at 1800°C, 0.3MPaN 2 Heat treatment under the atmosphere for 2 hours, and then treat the heat-treated Si with 5% HF acid 3 N 4 The powder was pickled for 6 hours and dried for later use. Weigh 50g of processed Si 3 N 4Powder, add 50g solvent, the solvent is anhydrous ethanol and methyl ethyl ketone mixed in a volume ratio of 1:1, 4g dispersant triethyl phosphate, put into a nylon ball mill jar, add silicon nitride balls, and ball mill on a roller ball mill 12 hours. Then add 5g binder polyvinyl butyral in the ball mill jar, 5g plasticizer, plasticizer is glycerol and dioctyl phthalate mix and 4g defoamer by volume ratio 1:1, defoamer The foaming agent is n-butanol and ethylene glycol mixed in a volume ratio of 1:1, and ball milling is continued for 12 hours to obtain Si 3 N 4 slurry. The slurry was cast to obtain a thickness of 0.3mm, Si 3 N 4 A thin l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com