Powder metallurgy spring steel composite material and preparation method thereof

A powder metallurgy and composite material technology, applied in the field of powder metallurgy, to achieve the effects of improved wear resistance, good formability, and reduced subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Prepare materials

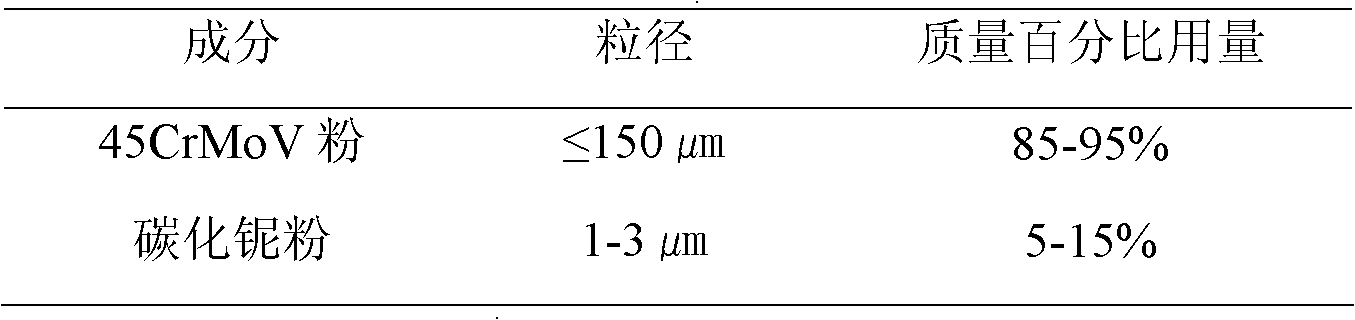

[0024] Prepare powder material according to the following ratio:

[0025]

[0026] Step 2: Mixing and ball milling

[0027] After at least 2 hours of dry mixing on the V-type mixer, high-energy ball milling for 15 hours, the ball milling medium is stainless steel balls with a diameter of 8 mm, the ball-to-material ratio is 10:1, the ball mill speed is 226 rpm, and argon is used as the protective gas. The particle size of NbC particles is 200nm-400nm, and the NbC particles are uniformly dispersed in the 45CrMoV spring steel matrix;

[0028] Step 3: Hot isostatic pressing sintering

[0029] Put the above powder in a stainless steel sheath, and evacuate until the vacuum degree is at least lower than 10 -1 After Pa, it is welded and sealed. After inspection and confirmation that the sheath is completely airtight, it is put into a hot isostatic pressing furnace for sintering. The sintering parameters are: temperature 1180°C, pressure 70MPa, ...

Embodiment 2

[0032] Step 1: Prepare materials

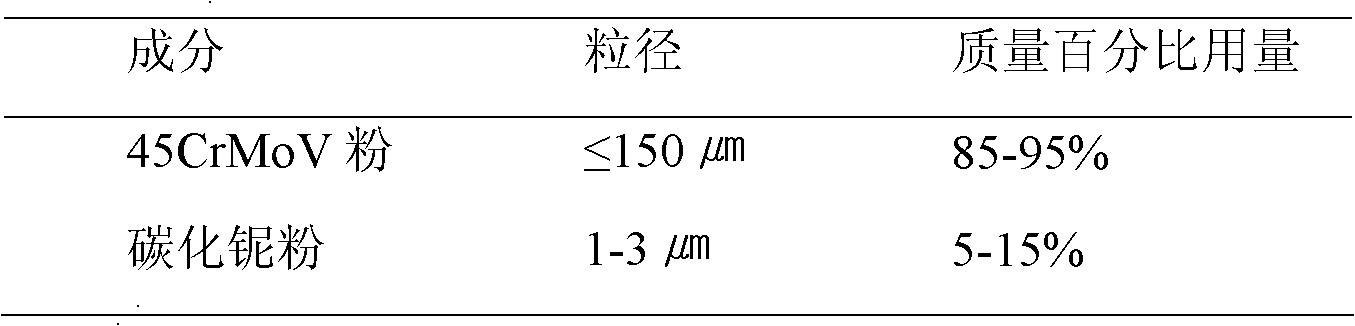

[0033] Prepare powder material according to the following ratio:

[0034]

[0035] Step 2: Mixing and ball milling

[0036] After at least 2 hours of dry mixing on the V-type mixer, high-energy ball milling was carried out for 20 hours. The ball milling medium was stainless steel balls with a diameter of 16 mm. The ball-to-material ratio was 15:1. The particle size of NbC particles is 200nm-400nm, and the NbC particles are uniformly dispersed in the 45CrMoV spring steel matrix;

[0037] Step 3: Hot isostatic pressing sintering

[0038] Put the above powder in a stainless steel sheath, and evacuate until the vacuum degree is at least lower than 10 -1 After Pa, it is welded and sealed. After inspection and confirmation that the sheath is completely airtight, it is put into a hot isostatic pressing furnace for sintering. The sintering parameters are: temperature 1120°C, pressure 100MPa, holding time 2h.

[0039] That is to say, the elasti...

Embodiment 3

[0041] Step 1: Prepare materials

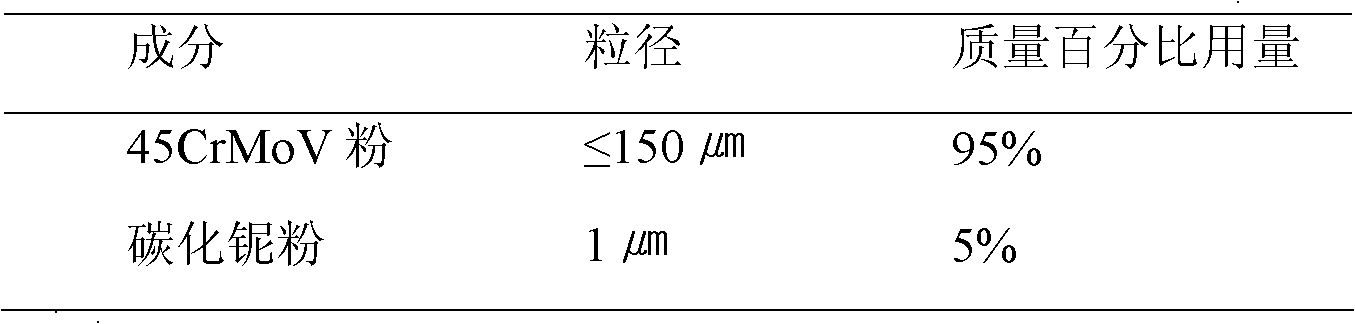

[0042] Prepare powder material according to the following ratio:

[0043]

[0044]

[0045] Step 2: Mixing and ball milling

[0046] After at least 2 hours of dry mixing on the V-type mixer, high-energy ball milling was performed for 10 hours. The ball milling medium was stainless steel balls with a diameter of 12 mm. The particle size of NbC particles is 200nm-400nm, and the NbC particles are uniformly dispersed in the 45CrMoV spring steel matrix;

[0047] Step 3: Hot isostatic pressing sintering

[0048] Put the above powder in a stainless steel sheath, and evacuate until the vacuum degree is at least lower than 10 -1 After Pa, it is welded and sealed. After inspection and confirmation that the sheath is completely airtight, it is put into a hot isostatic pressing furnace for sintering. The sintering parameters are: temperature 1150°C, pressure 80MPa, holding time 2.5h.

[0049] That is to say, the elastic tapered sleeve powder me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com