Micro component liquid forming method conducted under composite action of multiple physical fields

A composite effect and multi-physics technology, applied in the direction of casting mold components, casting molding equipment, casting molds, etc., can solve problems such as unstable mechanical properties and incomplete forming of micro-components, and achieve excellent surface quality, complete forming, and improved The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

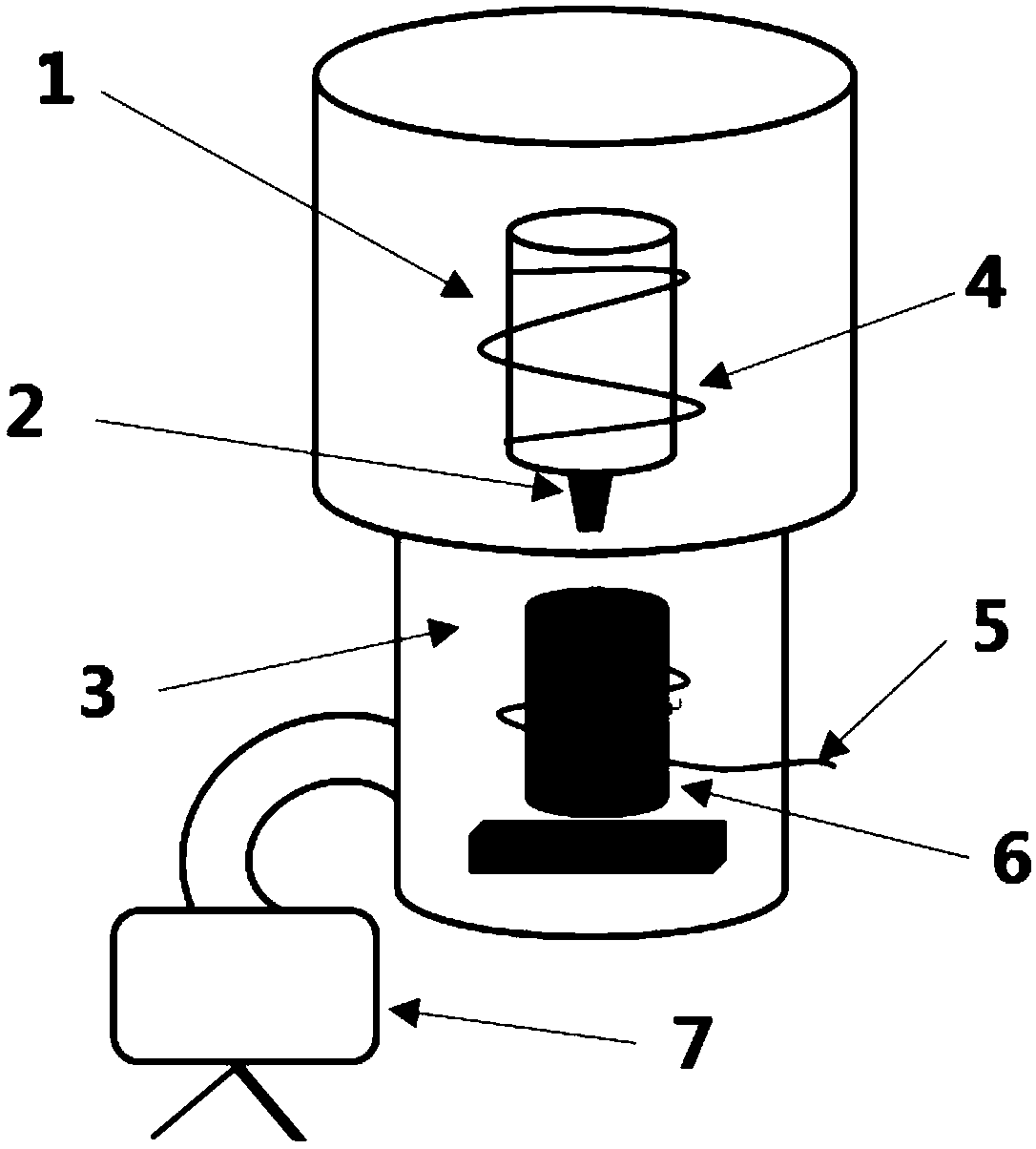

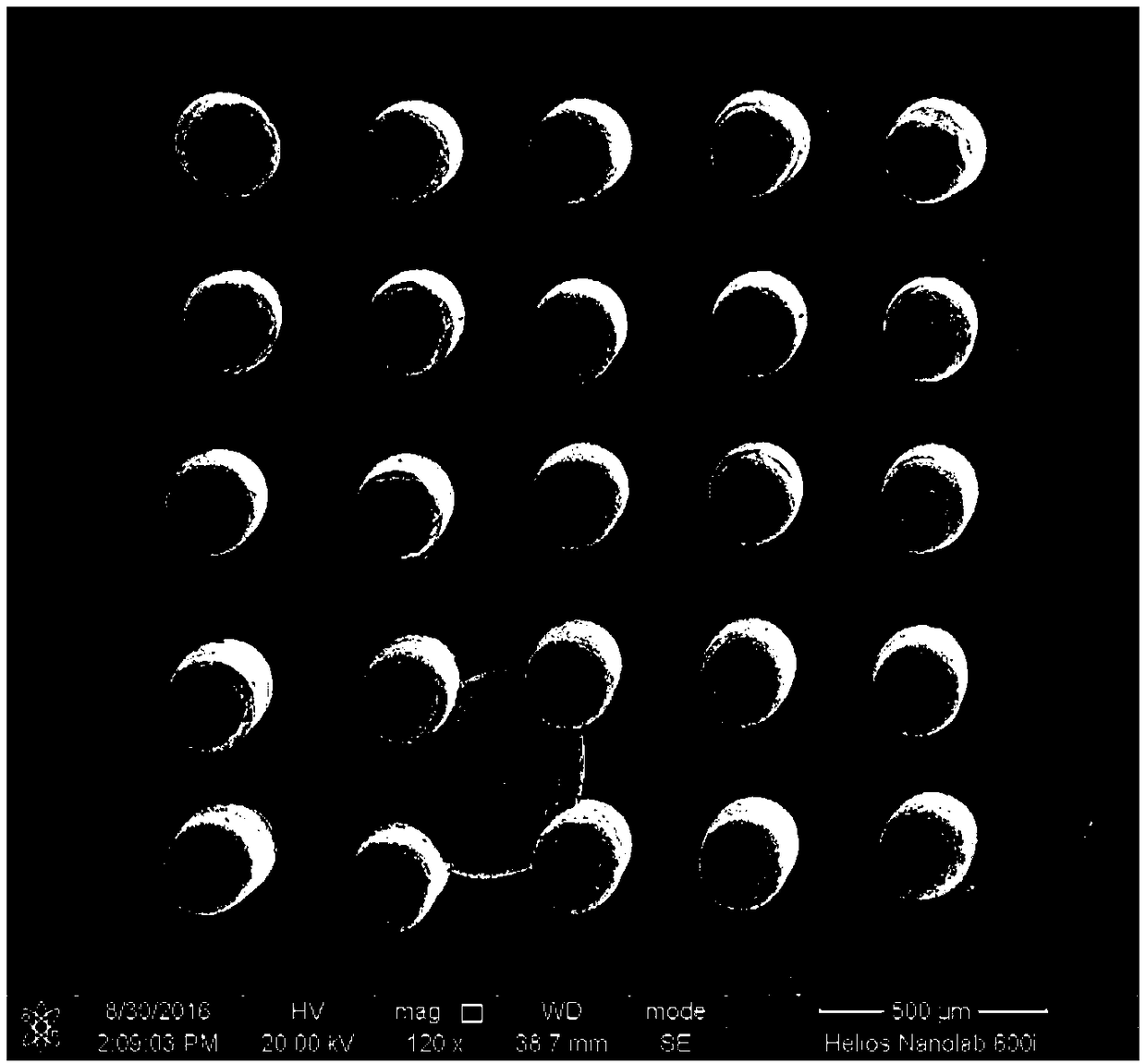

[0021] Specific implementation mode 1: In this implementation mode, a micro-component liquid forming method with multi-physics field composite action is carried out according to the following steps:

[0022] 1. Using additive manufacturing technology to make plastic micromodels, using paraffin to make casting system wax models;

[0023] 2. The plastic micromodel prepared in step 1 is welded with the casting system wax film to obtain the plastic micromodel;

[0024] 3. Mix ultra-fine precision casting gypsum powder, gypsum retarder, defoamer and deionized water, and fully stir to obtain gypsum slurry;

[0025] 4. Use the gypsum slurry prepared in step 3 to embed the plastic micromodel obtained in step 2 to obtain a gypsum cast, then place the gypsum cast in a vacuum environment, solidify and form under the action of ultrasound; then dry naturally, and then put Dewaxing and demoulding are carried out in a resistance furnace with a preheating temperature of 70-350°C, and then co...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mesh number of the ultra-fine precision casting gypsum powder in step 3 is greater than 200 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 3, the gypsum retarder is citric acid, and the defoamer is silicone oil. Others are the same as in the first or second embodiment.

[0031] The plaster mold does not need to add fillers (such as quartz powder, glass fiber, etc.) commonly used in traditional plaster molds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com