Diamond/copper composite material with high heat-conducting property and preparation method thereof

A composite material and diamond technology, which is applied in the field of diamond/copper composite material with high thermal conductivity and its preparation, can solve the problems of high finished product, low bonding strength, single shape, etc., and achieve low energy consumption cost and less follow-up processing , highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

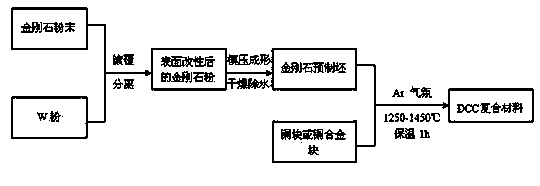

Method used

Image

Examples

Embodiment 2

[0020] Embodiment 2: Preparation of diamond / copper composite material at 1400°C.

[0021] 1) Purify and degrease the surface of diamond particles with an average particle size of 105 μm;

[0022] 2) Salt-bath W plating on the diamond surface: Put the pretreated diamond powder and W powder at a mass ratio of 1:5, add an appropriate amount of alcohol and mix them uniformly on the mixer for 5 hours, place the mixed powder on the bottom of the alumina crucible and Compact, then cover the mixed powder with a layer of mixed salt of NaCl and KCl and compact it, the mass ratio of NaCl to KCl is 1:1, and finally cover the crucible and heat it in a box-type resistance furnace at 1150 ℃ for 120 minutes, with a heating rate of 5 ℃ / min, and finally dissolve the base salt and separate the modified diamond particles. The thickness of the tungsten coating and the tungsten carbide layer on the diamond surface is 3 μm.

[0023] 3) Preparation of diamond preform: add polyvinyl alcohol (PVA) bi...

Embodiment 3

[0024] Embodiment 3: After forming a 1 μm coating, a diamond / copper composite material was prepared at 1300° C.

[0025] 1) Purify and degrease the surface of diamond particles with an average particle size of 105 μm;

[0026] 2) Salt-bath W plating on the diamond surface: Put the pretreated diamond powder and W powder at a mass ratio of 1:5, add an appropriate amount of alcohol and mix them uniformly on the mixer for 5 hours, place the mixed powder on the bottom of the alumina crucible and Compact, then cover the mixed powder with a layer of mixed salt of NaCl and KCl and compact it, the mass ratio of NaCl to KCl is 1:1, and finally cover the crucible and heat it in a box-type resistance furnace at 1150 ℃ for 10 minutes, and the heating rate is 5 ℃ / min, and finally the base salt is dissolved and the modified diamond particles are separated. The thickness of the tungsten coating and the tungsten carbide layer on the diamond surface is 1 μm.

[0027] 3) Preparation of diamond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com