Reciprocating fine blanking compound die

A mold and precision technology, applied in the field of compound molds for blanking process and reciprocating precision compound blanking molds, can solve the problems of reducing the service life of molds, increasing production costs, aggravating cutting edge wear, etc., to improve work efficiency and reduce production. cost, reduce the effect of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

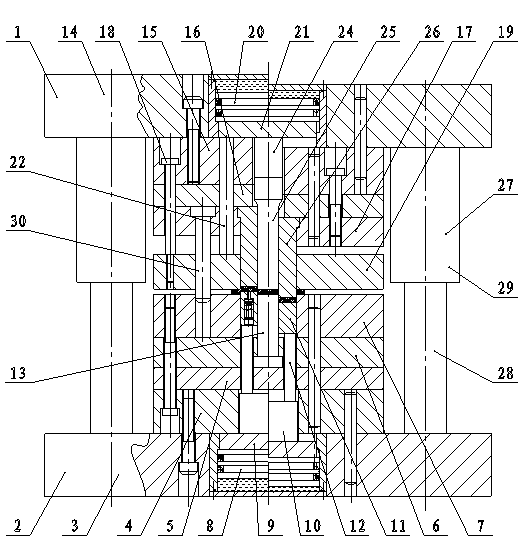

[0016] Such as figure 1 As shown, the reciprocating precision composite blanking die of the present invention includes an upper die 1 and a lower die 2, and the structure of the lower die 2 is: the lower die base 3 is superimposed and fixed with a lower template 4, a lower die base 3 from bottom to top through bolts. The backing plate 5, the lower fixing plate 6 and the lower die 7, the center of the lower mold base 3 and the lower template 4 are all provided with through holes, and the lower oil cylinder 8 is installed in the center hole of the lower mold base 3, and the lower oil cylinder 8 A lower pressure bearing plate 9 is fixed on the piston, a lower pressure block 10 is fixed on the lower pressure bearing plate 9 and the lower pressure block 10 is movably fitted in the center hole of the lower template 4, and the center of the lower die 7 is also provided with a Through holes, the lower convex and concave molds 11 are movably fitted in the center hole of the lower conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com