Burr-free punching mold system

A burr-free, die-free technology, used in perforating tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficulty in meeting requirements, easy to break, increase punching time and cost, and reduce production costs and save subsequent processing. , Improve the effect of product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

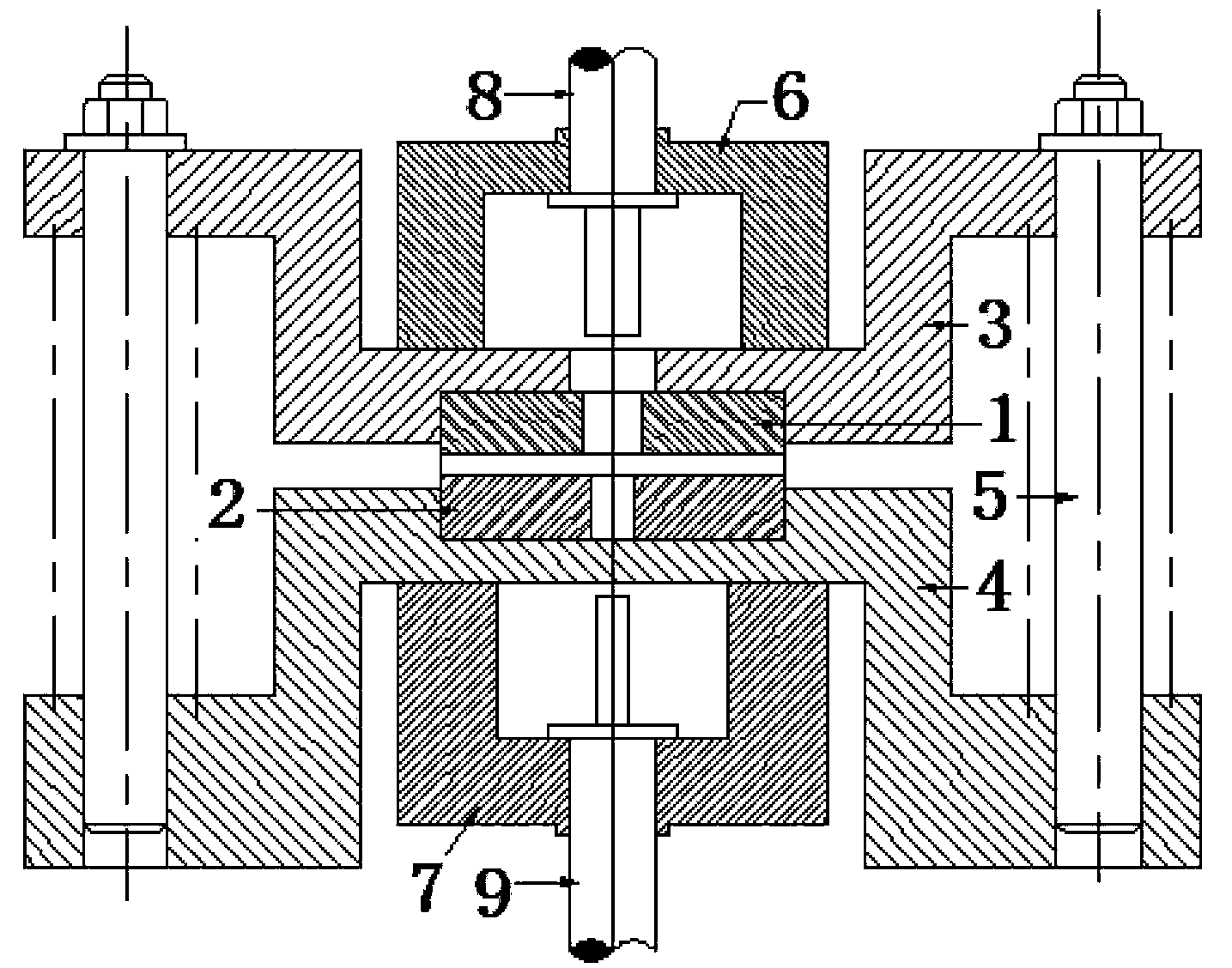

[0017] Such as figure 1 As shown, a burr-free punching die system includes a main punch die, a recoil die, an upper template 3 and a lower template 4, and the main punch die includes a first punch 8 and a first die 2, and the The recoil mold includes a second punch 9 and a second die 1, the first die 8 is fixed on the upper template 3, and the second die 1 is fixed on the lower template 4, when stamping, the The first die 2 and the second die 1 press the stamped part, and after the first punch 8 passes through the second die 1 for the first stamping, the second punch 9 passes through Pass the first die 2 to do the stamping for the second time.

[0018] The upper formwork 3 is connected with the lower formwork 4 through guide pillars 5 . The upper template 3 is provided with a first guide sleeve 6 for guiding the first punch. The lower template 4 is provided with a second guide sleeve 7 for guiding the second punch 9 .

[0019] It works as follows:

[0020] When stamping, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com