Automatic mounting system for mutual inductor magnetic ring shell cotton rings

An automatic installation and transformer technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long time consumption, low work efficiency, and large production volume of the magnetic ring shell of the transformer, so as to reduce production costs and production The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

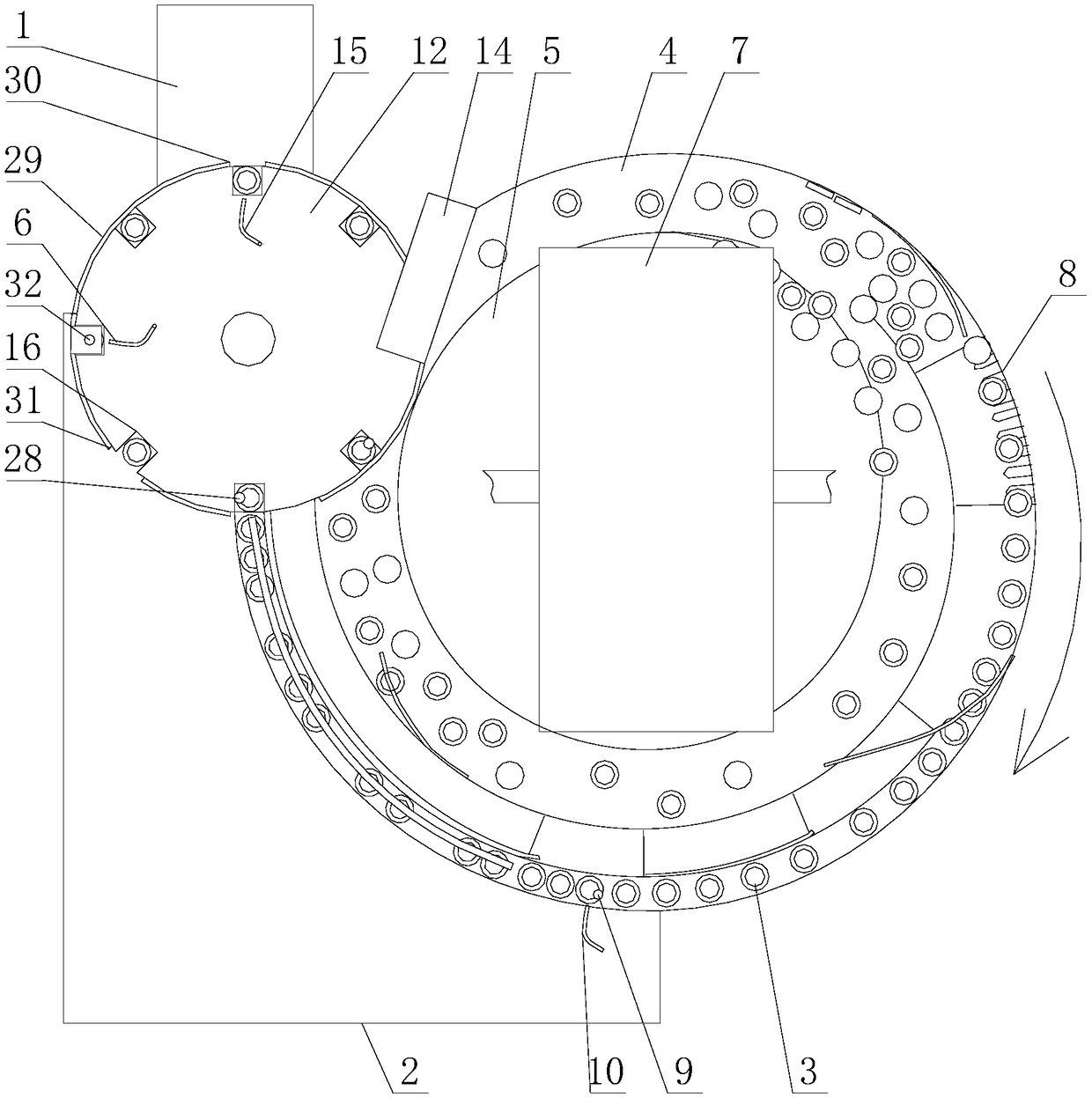

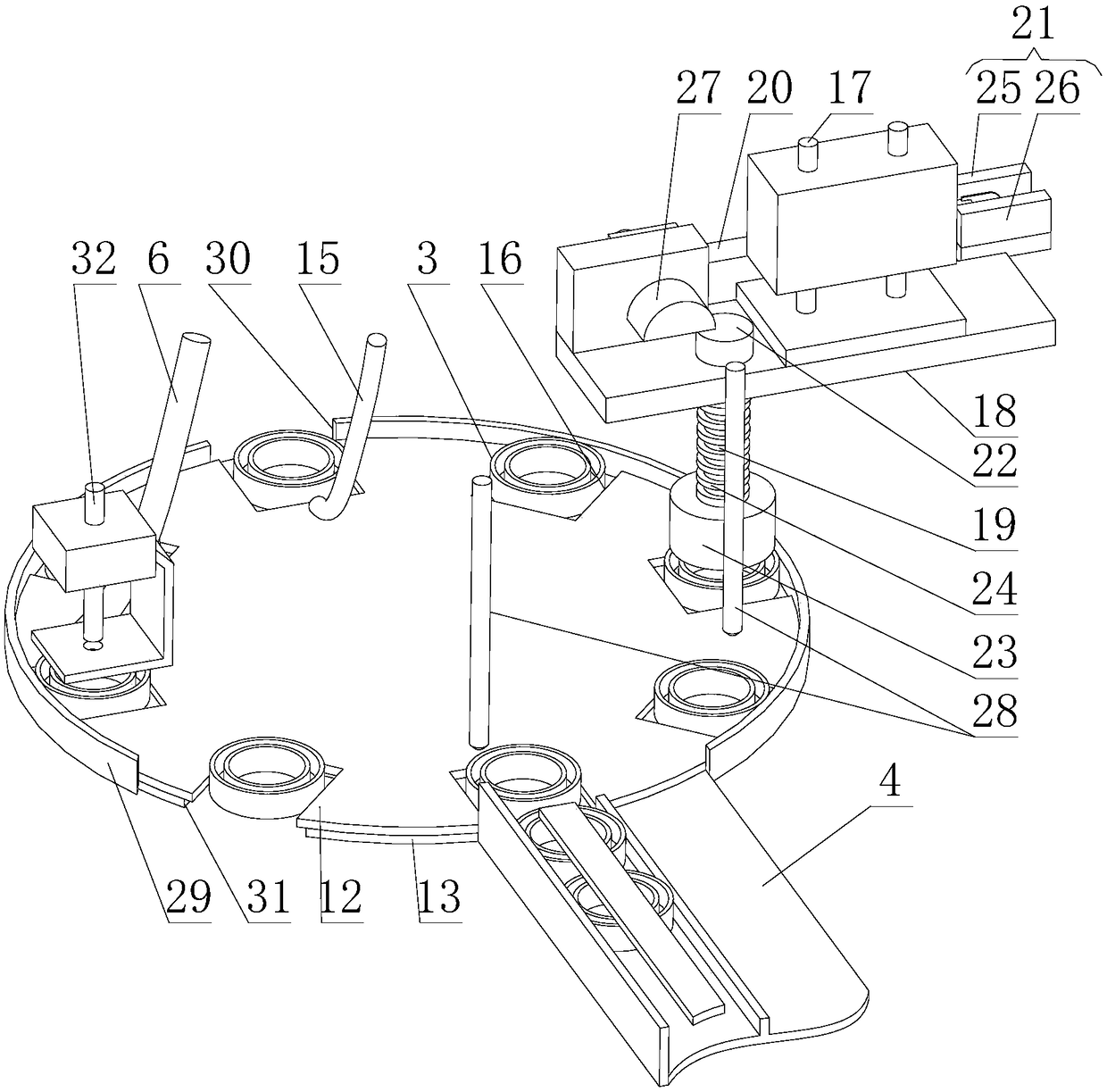

[0018] The automatic installation system for the cotton ring of the transformer magnetic ring shell, the key point is that the system includes the installation roller 7 arranged in sequence along the conveying direction of the transformer magnetic ring shell 3, the vibrating plate 5 with the spiral material guide plate 4 and the spiral material guide plate The screening mechanism connected to the output end of 4, the output end of the screening mechanism is connected with the finished product storage box 1 and the defective product recovery box 2; the output end of the installation drum 7 is located above the input end of the vibrating plate 5 or the two are connected by means of a conveying mechanism; The middle part of the spiral material guide plate 4 is provided with a reverse rejecting section 8 for the transformer magnetic ring shell 3, and is also provided with a shell removal mechanism 10 and a color sensor 9 matched with its control end. The collection end of the color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com