Highway engineering pavement automatic loading and unloading-type drilling core thickness measurement evaluation device and method

An automatic loading and unloading and evaluation device technology, which is applied in the direction of measuring devices, optical devices, measurement, etc., can solve the problems of large thickness error of pavement core samples, influence pavement thickness evaluation, time-consuming and laborious problems, achieve high precision, and facilitate popularization and use , Reduce the effect of human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

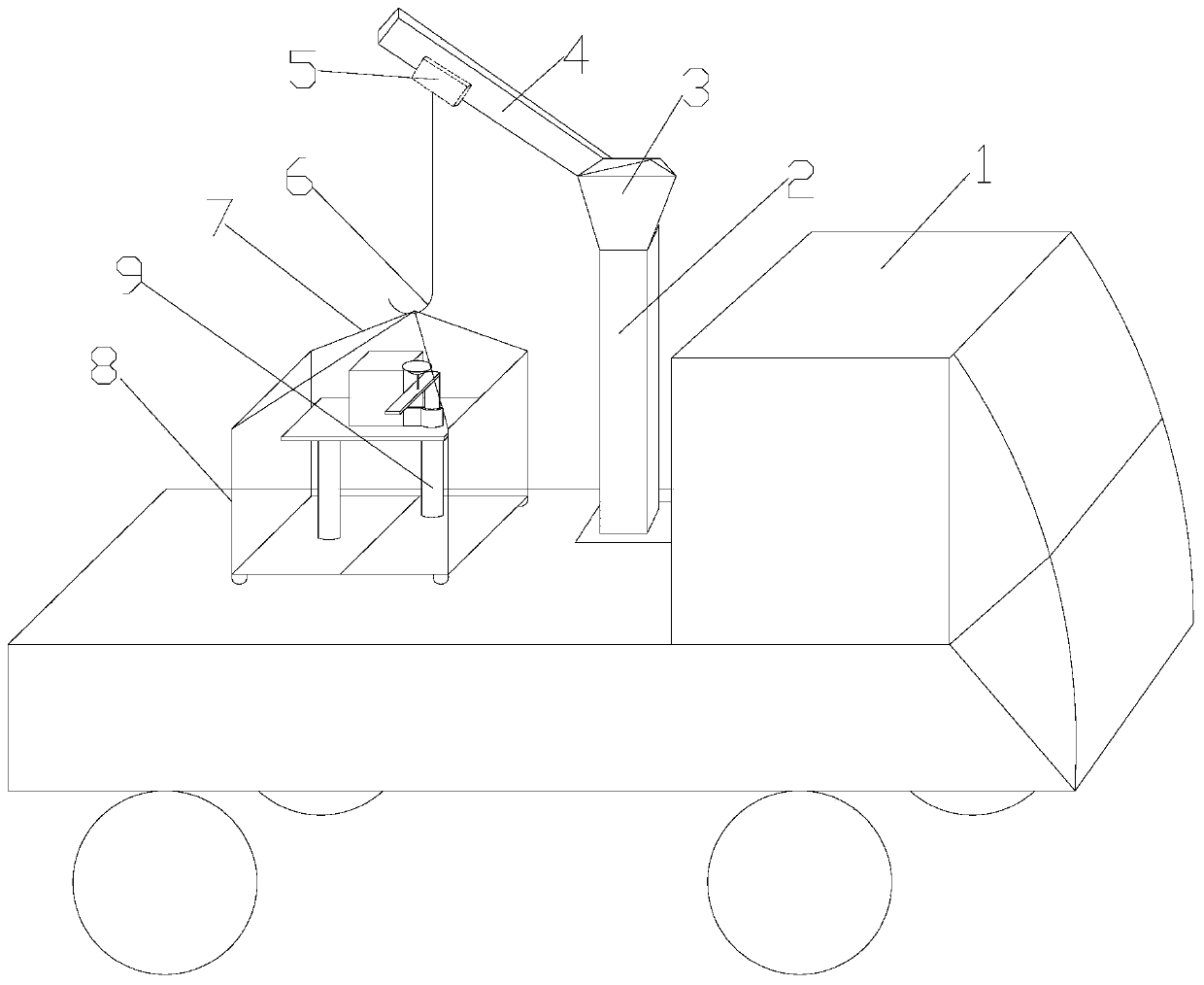

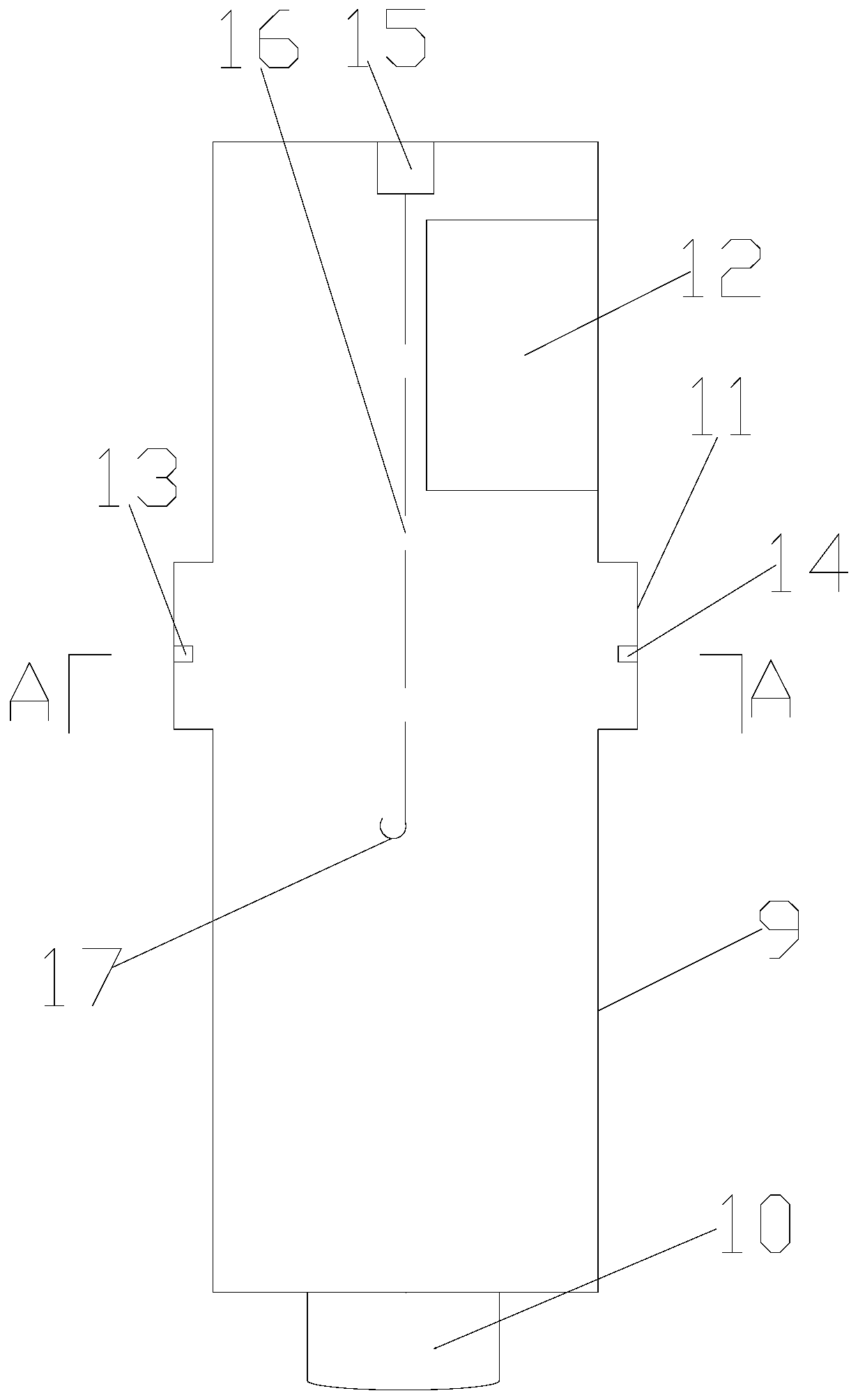

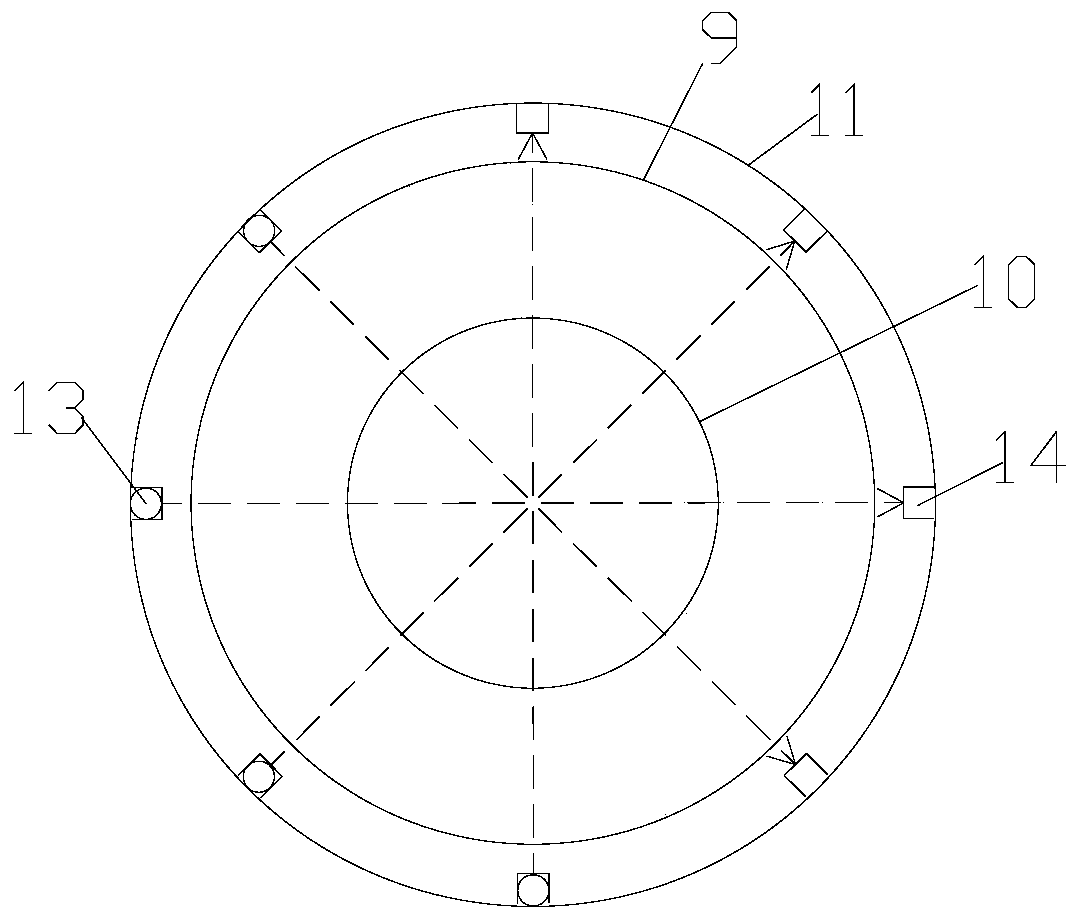

[0044] Such as Figure 1 to Figure 3 As shown, a kind of highway engineering pavement automatic loading and unloading type drill core thickness measurement evaluation device according to the present invention includes a pull ring, a transport vehicle 1 and a cantilever crane installed on the transport vehicle 1 for automatically loading and unloading the drilling core machine 8 machine, the pull ring is installed on the highway engineering pavement sampling point, the frame of the drilling coring machine 8 is provided with a control terminal, and the drill barrel 9 of the drilling coring machine 8 is provided with the drill bit 10 obtained The thickness measurement and evaluation mechanism for the thickness measurement evaluation of the pavement core sample and the window for taking out the pavement core sample obtained by the drill bit 10, the window is sealed by the window plate 12, and the top of the inner wall of the drill tube 9 is equipped with an electric rocking wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com