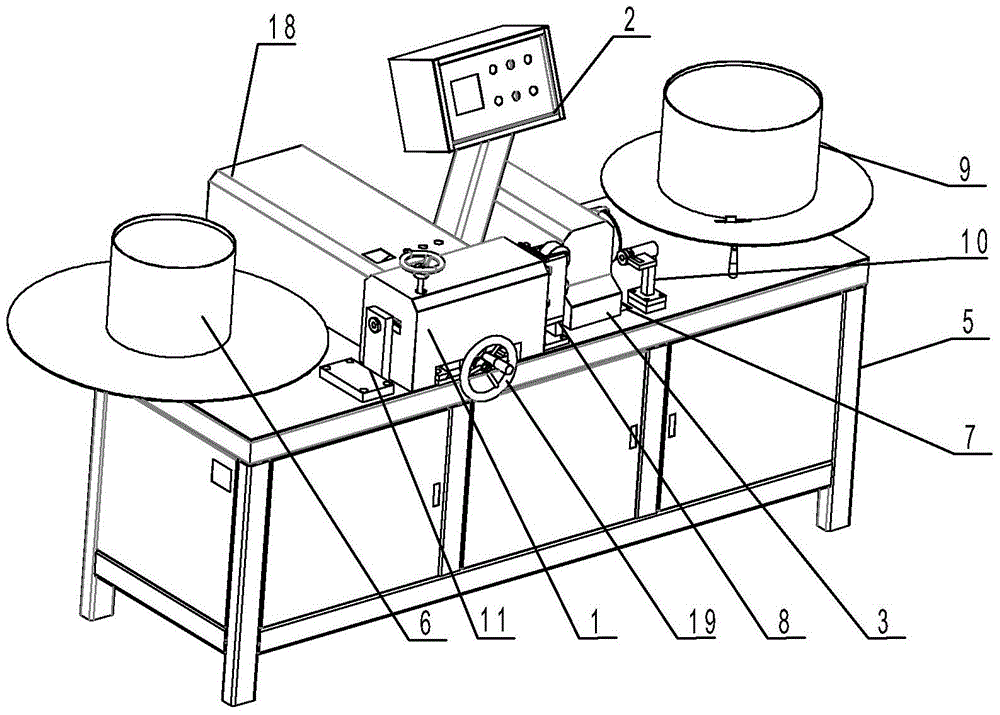

An armored cable automatic meter counting and unloading machine

An armored cable, automatic technology, applied in the field of armored cable automatic meter counting and cutting machine, can solve the problem of automatic stop and cut off of meter counting, and achieve the effect of reducing manual labor, high efficiency, and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

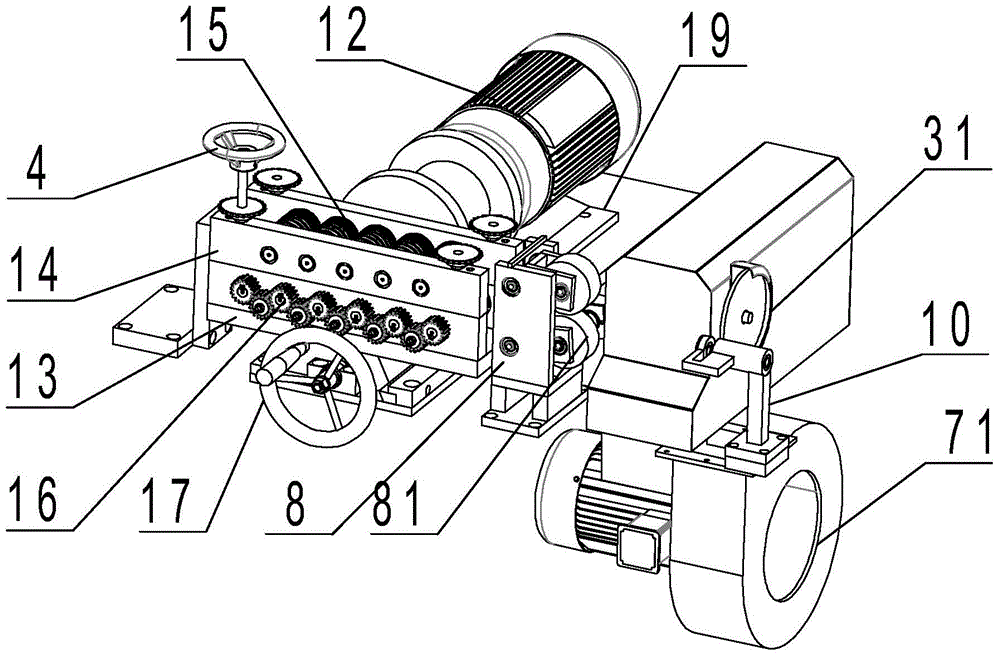

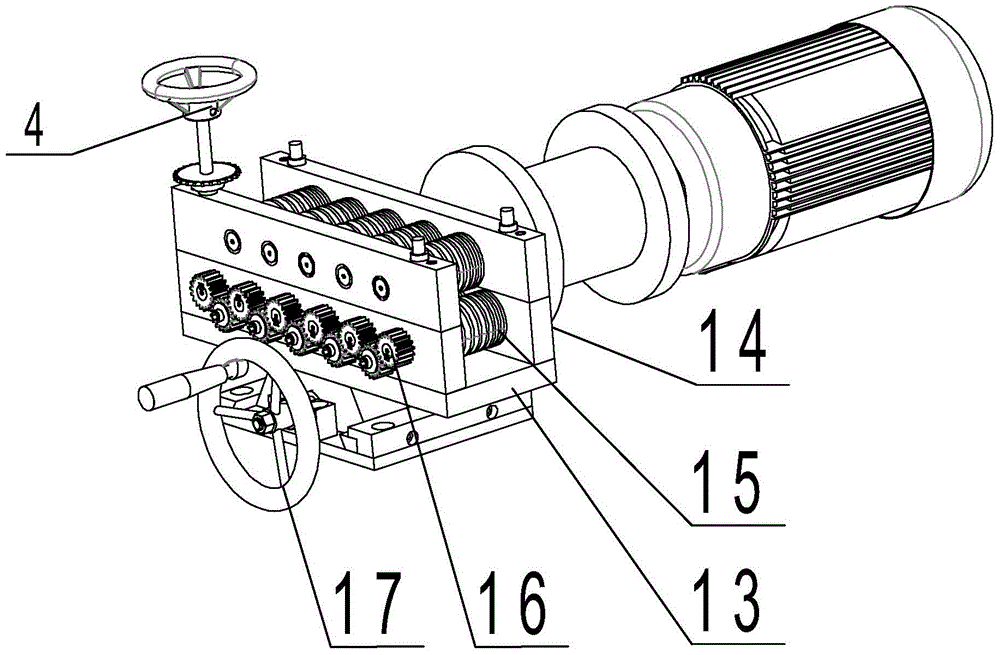

[0018] Embodiment one: during straight material, according to the diameter of armored cable, select corresponding stall, the armored cable that is contained on the driven tray 6 passes through the positioning hole on the guiding mechanism 10 and enters straightening driving device 1, passes through Adjust the hand wheel 17 on the straightening drive device 1 to select the appropriate gear groove, and then adjust the roller 15 through the small hand wheel 4 to perform straightening work, then select the "manual" mode, press the "forward / reverse" button, and straighten The straight machine starts to work. After straightening the armored cable with the "forward / reverse" key, set the quantity and length of the products to be processed in the meter meter device 8 respectively, select the "automatic" mode, select "straight material", The clutch is closed, the brake pads are loosened, and the straightening driving device 1 straightens the armored cable and drives it to move forward. ...

Embodiment 2

[0019] Embodiment two: when coiling material, according to the diameter of armored cable, select corresponding stall, set the quantity and the length of the product to be processed and select " coiling material ", the armored cable that is contained on the driven material tray 6 wears Enter the straightening drive device 1 through the positioning hole on the guide mechanism 10. At this time, the clutch is separated, and the end of the armored cable is manually fixed on the active material tray 9 through the through hole of the guide mechanism 10. During this period, when the end touches the When meter counting wheel 81, meter counting device 8 starts counting meters, turns on " cycle start ", and straightening driving device 1 starts to work, and straightens and drives armored cable to move forward, and simultaneously the reduction motor below active material tray 9 starts, Drive the active material tray 9 to rotate, and evenly wind the armored cable on the active material tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com