Decolorizing method of recrystallized sugar in acesulfame potassium production

A kind of acesulfame potassium and decolorization technology, applied in sugar production, sugar production, food science, etc., can solve the problems of inability to obtain high-quality products, long operation time, discontinuous production, etc., to reduce operational complexity, High utilization rate and effect of reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 3000Kg of heavy condensed sugar and 3000Kg of deionized water to the cooking kettle, turn on the steam and heat the cooking kettle to 90°C;

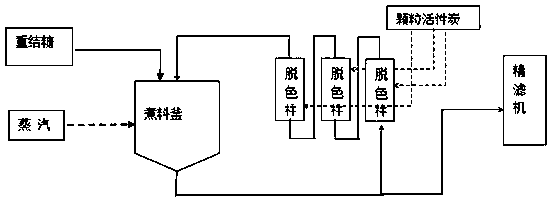

[0022] (2) Add granular activated carbon 500Kg / unit to the decolorization column tower in advance, connect three decolorization columns in series, and turn on the circulation pump to feed the sugar liquid in the cooking kettle to 35M 3 The amount per hour is sent to the decolorization column tower for decolorization, the decolorized sugar liquid is returned to the cooking kettle, and the temperature of the cooking kettle is kept at 90°C; the activated carbon is replaced every 3 tons of decolorized heavy sugar on average, and the replaced activated carbon is heated. It can also process nearly 3 tons of heavy condensed sugar. In summary, it saves half of the activated carbon on average, which greatly saves the cost, increases the utilization rate of activated carbon, and reduces the generation of hazardous waste;

[0023] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com