Soil recycling mechanism of flower transplanting machine

A technology of recycling mechanism and transplanting machine, which is applied in the filling, cultivation, gardening and other directions of flowerpots, can solve the problems of falling on the ground, the soil is easy to fall off, and economic losses, so as to avoid the loss of soil and reduce the The effect of artificial labor and economic loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

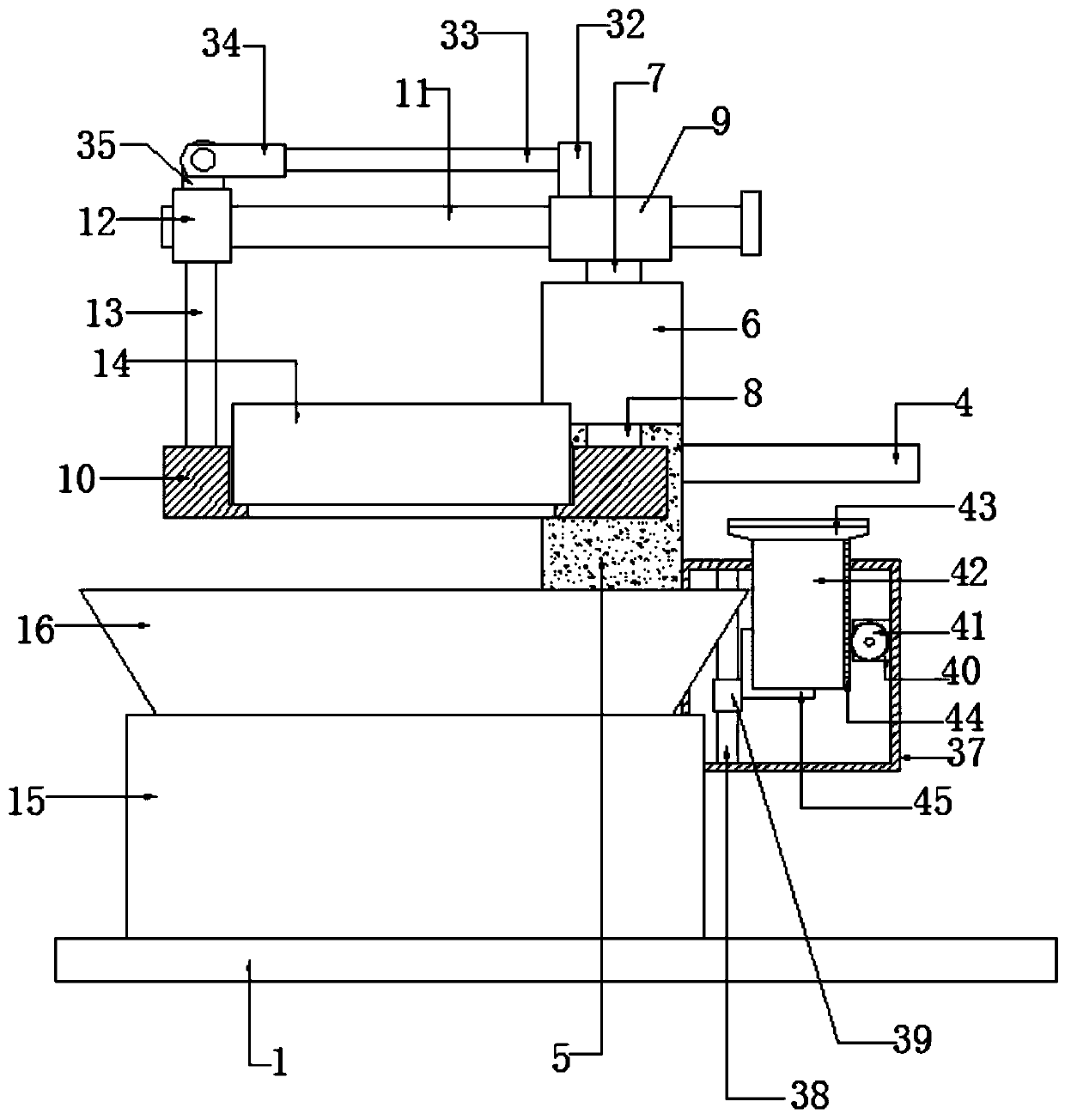

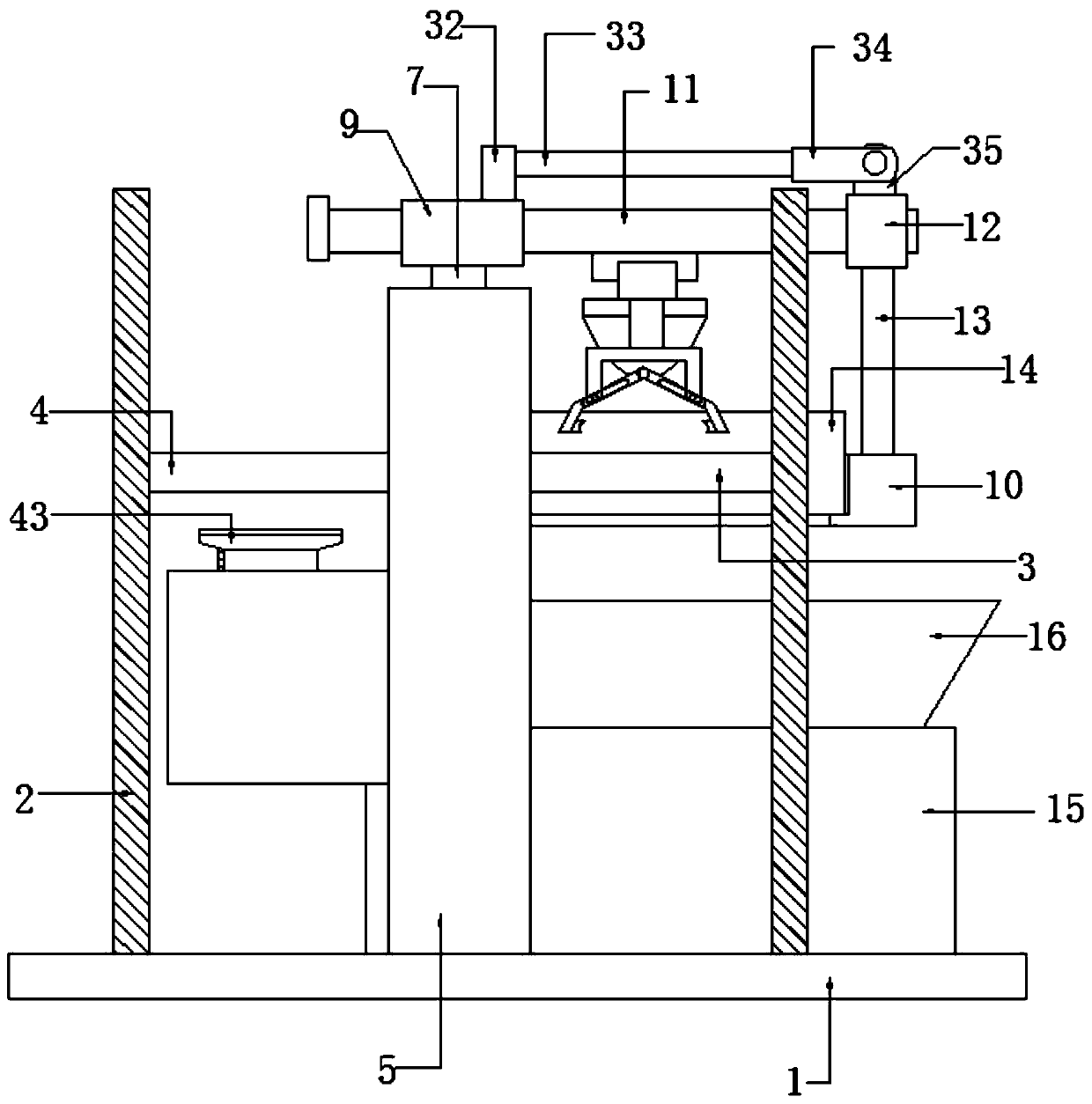

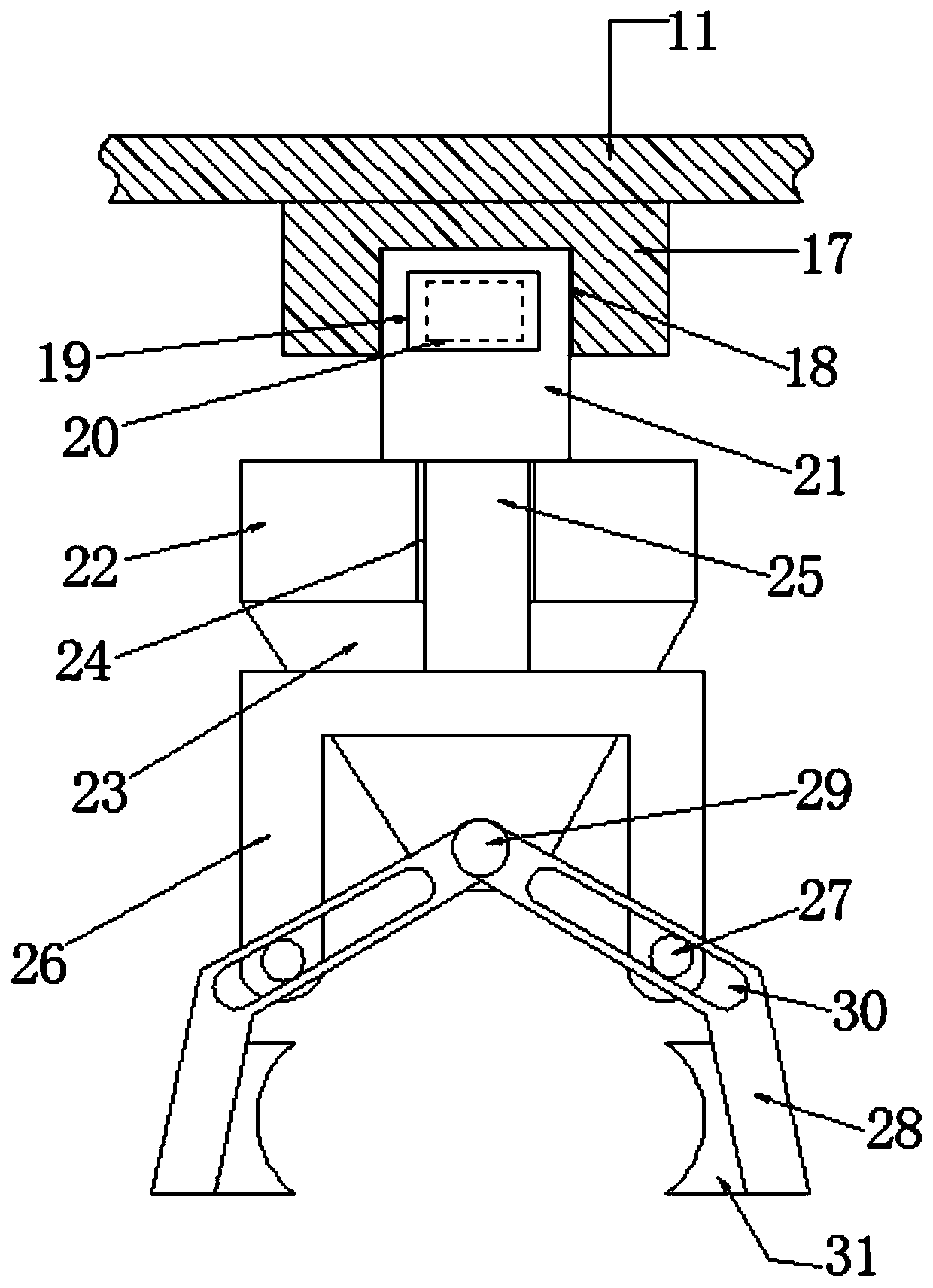

[0031] Embodiment one, such as Figure 1-3 As shown, a soil recovery mechanism of a flower transplanting machine according to an embodiment of the present invention includes a base plate 1, a frame 2 is provided on both sides of the top of the base plate 1, and two parallel frames are arranged between the frame 2. The first conveyor belt 3 and the second conveyor belt 4 are set, a support column 5 is arranged between the first conveyor belt 3 and the second conveyor belt 4, and a bidirectional motor 6 is installed on the top of the support column 5 on the front side. The two ends of bidirectional motor 6 are respectively provided with rotating shaft one 7 and rotating shaft two 8, and the ends of described rotating shaft one 7 and described rotating shaft two 8 are respectively provided with fixed block one 9 and object plate 10, and the ends of described rotating shaft one 9 and The middle part runs through a connecting rod one 11, and the end of the connecting rod one 11 and...

Embodiment 2

[0032] Embodiment two, such as figure 1As shown, the storage board 10 is located below the sides of the first conveyor belt 3 and the second conveyor belt 4 , and the top opening diameter of the material guide funnel 16 is larger than the bottom cross-sectional size of the storage board 10 .

Embodiment 3

[0033] Embodiment three, such as figure 1 As shown, the top of the fixed block one 9 and one end close to the fixed block three 12 are provided with a fixed block two 32, and the fixed block two 32 and the side corresponding to the fixed block three 12 are provided with a connecting rod two 33, the end of the connecting rod 2 33 and away from the fixed block 2 32 is provided with a clamping plate 34, and the end of the clamping plate 34 and away from the connecting rod 2 33 is provided with a clamping plate 1 35, the The top of the fixed block three 12 is provided with clamping plate two 36, and the top of the clamping plate two 36 is connected and fixed with the end of the clamping plate one 35 through a shaft, wherein the connecting rod one 11 is away from the fixed One end of block three 12 is provided with limit block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com